Showing 428 items

matching shaping tool

-

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

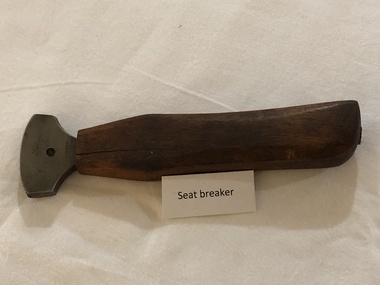

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

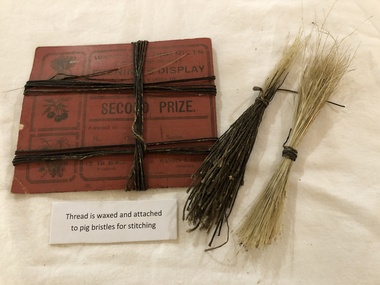

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Trafalgar Holden Museum

Trafalgar Holden MuseumFunctional object - Leather belt mount tool pouch

... Brown leather tool pouch rectangular in shape sewn... Designed to carry a specific tool on belt manufactured and sold ...Designed to carry a specific tool on beltmanufactured and sold by Holden and FrostBrown leather tool pouch rectangular in shape sewn with studs strengtheningleather, tool, holder -

Kilmore Historical Society

Kilmore Historical SocietyTool - Shoe stretcher, Metal shoe stretcher

Metal toe shape with 6 holes in top, cut out at point of toe.Toe and heel joined by adjustable metal rods. Metal heel extender with holes on sides to put metal rod into so as to adjust length.Sky-line Made in England stamped under heel extender -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillTool - Pattern, wooden

It is unknown what this item was a pattern for.One flat piece of rectangular wood with a hole on the top - center and two nails, one at the top left corner, one at the bottom - RH corner. A second piece of wood is attached on top of the first; it is smaller in width and split exactly in two. There is a design cut out of second piece in shape of a pear. Bulbous part of design is centered around a hole in the first piece of wood. Three nails protrude from the second piece of wood. Three nails in the second piece of wood are located; one in each section of the more bulbous end of cut-out, & third on one section of the smaller end of cut-out. Hole on bottom of wood does not go all of the way through. -

Mont De Lancey

Mont De LanceyTool - Chain Pipe Wrench, J.H Williams and Co, Late 19th century

A tool used in the early 20th Century.A two piece metal wrench with an adjustable chain that is used to tighten around metal objects. It has a double triangular pointed grooved jaw grip, a handle and chain attached. They provide safe, reliable and powerful torque. The dual reversible jaws allow ratchet action in both directions without removing the chain wrench from the pipe.Stamped on the handle - Drop forged from bar steel by J.H. Williams & Co, Brooklyn, NY. On a grip jaw at the top is stamped - No 1, 'W' in a triangle shape, Patented Oct.4 '81, Dec.13 '81, Mar. 14 '82, Sep.25 '83, Feb.14 '88 and Brook Chain Wrench at the bottom.tools, equipment, hand tools, wrenches, steel -

Mont De Lancey

Mont De LanceyTool - Shingle Splitter, Wolpin Wedge Mills, Unknown

Used in the late 19th century.A steel bladed wooden curved handled Shingle Splitter sometimes called a Paling Knife used for splitting or cleaving timber. It has two crossed hammer shape symbols stamped at the beginning and end of the inscription - Wolpin Wedge Mills. It was used in the late 19th century.Wolpin Wedge Millssteel, wood, froes, cleaving axes, axes, cutting tools, hand axes, woodworking tools -

Mont De Lancey

Mont De LanceyTool - Carpenter's Adze, Unknown

Used in the 19th century.A curved wooden handled adze with a forged steel head which has a wide cutting blade and a small 5cm steel knob on top. It was used by woodworkers for cutting and trimming rough wooden planks and shaping ans smoothing wooden surfaces in the late 19th century.woodworking tools, wood, steel, froes, cleaving axes, axes, cutting tools, hand axes, adzes -

Mont De Lancey

Mont De LanceyTool - Broadaxe Head, Unknown

Used in the 19th century.A forged steel broadaxe head without a handle - it has a hole for the handle. It can be known also as a trimming axe blade or a long bearded axe because of its beard shape. It was commonly used in manufacture of square timbers for wooden shipbuilding, log building, timber framing and railroad ties. It was used in the 19th century.woodworking tools, steel, froes, cleaving axes, axes, cutting tools, hand axes, broadaxes, felling axes, hewing axes, axe heads, tool components -

Mont De Lancey

Mont De LanceyTool - Adze, Unknown

Used in the 19th century.A long bladed forged steel adze head. It was used by woodworkers for cutting and trimming rough wooden planks and shaping and smoothing wooden surfaces in the late 19th century.woodworking tools, steel, froes, cleaving axes, axes, cutting tools, hand axes, adzes -

Mont De Lancey

Mont De LanceyTool - Broad Axe, PLUMB USA, Unknown

Used in the 19th century by Bill Homefield.A forged steel headed broad axe with a handmade turned wooden handle for a left handed person's use. It was used to trim or square up posts or logs and shape timber in the 19th century.PLUMB USA is stamped on the head.axes, cutting tools, hand axes, froes, woodworking tools, cleaving tools -

Mont De Lancey

Mont De LanceyTool - Adze, Unknown

Used in the 19th century.A wide bladed forged steel adze with a smooth curved wooden handle. It was used by woodworkers for cutting and trimming rough wooden planks and shaping and smoothing wooden surfaces in the 19th century.woodworking tools, steel, froes, cleaving axes, axes, cutting tools, hand axes, adzes, wood -

Mont De Lancey

Mont De LanceyTool - Adze, Unknown

Used in the 19th century.A wide bladed forged steel Cooper's Adze head with a curved blade. There is no handle. At the opposite end there is a hammer shaped head. It was used by woodworkers for cutting and trimming rough wooden planks and shaping and smoothing wooden surfaces in the 19th century.woodworking tools, steel, froes, cleaving axes, axes, cutting tools, hand axes, adzes -

Mont De Lancey

Mont De LanceyTool - Scarifier, Unknown

A small combined hoe and rake metal headed hand scarifier or cultivator tool with a wooden handle. It has a pointed hoe shape at one end and at the opposite two hooked spikes. It could be used in small areas such as a garden.agricultural tools, tools, rakes, scarifiers, gardening tools, hand tools, hoes -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryBox, tool

Used to store tools and other assorted items associated with Maldon State Battery..1 storage box with compartments and lid, painted green, made from wood, leather and are chains attatched from box to lid, trapeze shape, .3 grooves on top of box parallel to wooden supports on lid, latch, nails and bolts attatching wood and inner compartments, leather straps on innner lid and inside main compartment for holding tools, main compartment contains torn newspapers, severed cloths, pieces of rock, pipe peices made of metal and plastic, assortment of metal pieces, paint lids, green bucket with grease, food packaging, tap/valve, metal mesh, leather and plastic pieces, 2 keys/padlocks, nails, nuts, assortment of tools, wooden pieces, wooden handle for screwdriver, broken chair, chalk, pieces of ceramic (Bendigo pottery) , pocket handle with inscription, bottle lids, plastic container, rope/belt for machines, piece of belt, broken canvas strap, peices of broken dark brown glazed textured pottery, large circular threaded joins, large elboiw threaded elbow joins .2 upper left compartment containing brush head, sandpaper and assorted rusty metal objects .3 upper middle compartment containing rusty weighing hook, rusty bolt and scrap metal .4 upper right compartment containing broken tan pottery, rusty threaded T join, unknown green paper with inscription .5 lower left compartment containing white cotton waste, assorted circular rusty metal objects, assorted rusty nails and washers, orange lid with insciption, nut and bolt .6 lower left middle compartment containing unknown assorted metal objects, peice of broken clamp and felt .7 lower right middle compartment containing large rusty nuts and unknown rusty metal objects .8 lower right compartment containing assorted threaded rusty circular metal objects, rusty nut and bolt, metal pump part, rusty mobil oil tin 20litres, old newspaper scraps, -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Ceramic pie Funnel, Thomas M. Nutbrown, c1930

A ceramic pie funnel was a hollow ceramic tool that bakers and home cooks placed in the centre of pies to prevent the contents bubbling over. The hollow core allowed steam to escape during baking leaving the pie crust as light and flaky inside as on the surface. They came in a variety of shapes and sizes. This pie funnel was produced by Thomas M Nutbrown who started manufacturing kitchenware in 1927 from his factory on Walker Street, Blackpool. He registered the company in 1932 and over the following years his company was exporting goods all over the world. His company pioneered many unseen kitchen gadgets and utensils onto the market and had many products patented. The company closed in 1988.This item was typical of kitchenware used widely in the early twentieth century when a broader range of food items were home cooked.A ceramic pie funnel in the shape of an elephant. This is marked “NUTBROWN PIE FUNNEL Made in England” and was made by a company called Thomas M. Nutbrown Ltd of Blackpool. It also has a registered design number which is a little indistinct but is probably No 860928. It dates from the 1930’s and is in very good condition.On side of elephant in black ink "NUTBROWN/ PIE FUNNEL/ Made in England/ Reg. No 860928"domestic appliances, pie funnel, kitchenware early 20th century -

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumTool - Butter Pats

These wooden butter pats were used to shape butter into bricks; making butter ready for sale and use. The excess moisture would be squeezed out of the butter; which was then transferred to a wooden board. The butter maker would hold one of these pats in each hand and work the butter into shape. These wooden pats are thin; light and easy to hold. The inside face is serrated to grip the butter and squeeze out any further water. It was also used to make patterns on the finished butter.Wooden butter pats with handle. One side is rubbed, the other smoothbutter pats, butter making -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 pairs of handmade, adult brown leather boots, with decorative stitching, eyelets and stitched with waxed thread. Soles covered with hob nails in a decorative pattern. 1 handmade child's brown leather boot, with decorative stitching, metal eyelets, heel has patterned nails.bootlaces, boots -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Mont De Lancey

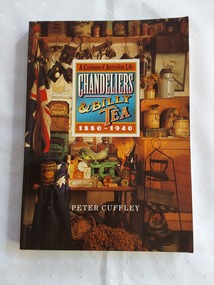

Mont De LanceyBook, Peter Cuffley, Chandeliers and Billy Tea: a Catalogue of Australian Life 1880 - 1940, 1984 (1995 reprint)

A comprehensive historical catalogue of the life and times between 1880 and 1940 in Australia of household items, the people, favourite pastimes, life outdoors, travel and adventure, packaging, down on the farm, tools of trade and much more.A comprehensive catalogue book: Chandeliers and Billy Tea 1880 - 1940. The front cover has brown tonings and shows a full page photograph of many kitchen and household objects from the past. The title is written in different elaborate lettering inside a square shape towards the top of the cover. The author's name, Peter Cuffley, is printed in white lettering at the bottom. Inside is a Contents page with Catalogue references, a Selected Bibliography, Acknowledgements and an Introduction. There are hundreds of black and white drawings and photographs of household items and general life of the times.non-fictionA comprehensive historical catalogue of the life and times between 1880 and 1940 in Australia of household items, the people, favourite pastimes, life outdoors, travel and adventure, packaging, down on the farm, tools of trade and much more.social history, australian history, family history, history