Showing 695 items matching "warrnambool manufacturing"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lamp, After 1950

The lamp has been manufactured for decorative used, representing lamps of the late 19th and early 20th century used for lighting.The lamp is an example of a 19th century ships lamp. It is currently not associated with a historical event, person or place at this time and is being used to augment Flagstaff's village display.Metal lamp with circular base, 8-sided glass section and conical lid topped by a frilled metal cone and handle made from a strip of metal bent into a 'u' shape and attached so that it can swing back and forth..Cone hinges to side to give access to candle, which is seated in a short ring in the centre of the base. There is a ring of air holes around the circumference of the cone, about half way up the height of it. A shard of glass missing from one of the glass panels and the metal parts are corroded.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lighting, candle lamp, domestic lighting, ship lamp -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pressure Cooker, T & C Clarke and Co Ltd, Late 19th to early 20th century

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to cook food safely without the concern that the metal interior may contain lead or arsenic as earlier cooking utensils had. Pressure cooker, cast iron , pressure vent on top. Removable lid held down by 3 riveted heart shaped clips where they join the base. Metal drop down carry handle.T & C Clarke and Co. on base & size 2 1/2 gallonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pressure cooker, cook ware, cooking pot, clarke and co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, 1900-1920

A colander, sieve or cullender is a kitchen utensil used to strain foods such as pasta or to rinse vegetables. The perforated nature of the bowl allows liquid to drain through while retaining the solids inside it is sometimes also called a pasta strainer or kitchen sieve. Conventionally, colanders are made of a light metal, such as aluminum or thinly rolled stainless or plated steel, colanders are also made of plastic, silicone, ceramic, and enamelware. The word colander comes from the Latin Colum meaning sieve.Early 20th century kitchen item possibly of French manufacture due to the design and shape of the bowl this design appears to have been favoured by the French around 1910 for smaller Colanders. This item gives a snapshot into domestic life around the late 19th and early 20th centuries and the types of kitchen equipment in use.Strainer or colander, metal, with concave base and wood handle, plated metal construction with welded or folded seams. Handle painted black, perforated base.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, strainer, food strainer, seive, food preparation, kitchen ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. Cast Iron Kettle no lidT and C Clark and Co, London. No. 2, 5 pints capacityflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, cooking pot, cook ware, kitchen ware, cast iron kettle, t c clark ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Fred Walker Cresco Foods, 1910

Fred Walker 1884 – 1935 was an Australian businessman and founder of Fred Walker & Co. first in Hong Kong, then in Melbourne as the Fred Walker Company. He also set up Kraft Walker Cheese Co. in partnership with American businessman James L. Kraft in 1926, to market Kraft's patented method of processing cheese in Australia. Fred Walker & Co. is best known for creating Vegemite, a yeast extract-based food spread and Australian cultural icon. Kraft Walker Cheese Co. Is best known for manufacturing a cheese known as Red Coon around 1931, which later became known as Coon cheese. He founded the Fred Walker Company at 54 William Street and later moving to Flinders Street in 1911. This company specialised in canned foods, especially dairy products, exporting them to Asia. It manufactured Red Feather canned foods including butter and cheese from around 1910. He also went on to created Cresco Food Co. for his younger brother, which was the first factory to manufacture "flaked food" or dehydrated food products in Australia.A significant item that catalogues the start of dehydrated food production and sale in Australia was initiated by an Australian businessman and well-known entrepreneur. The history of Fred Walker gives insight into how many food brands in Australia now that we take for granted had his involvement in their early beginnings. Large cylindrical tin with push on lid, painted label on the sides in maroon, black gold and dark fawn colours with text.Palm Flaked Rice manufactured by the Cresco Co. Limited Melbourne Australiaflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, container, food container, kitchen ware, flaked rice, cresco, palm flaked rice, tin, fred walker, dehydrated food -

Flagstaff Hill Maritime Museum and Village

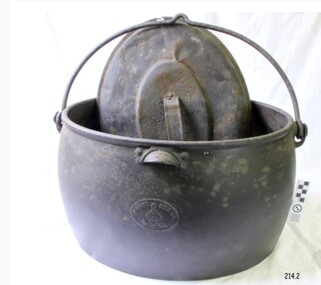

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking Pot, T & C Clarke and Co Ltd, 1840 to 1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The items are significant as they were used as domestic kitchen items to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. This is due to the enamel lining pioneered by TC Clark Pot set; set of three pots. Iron pots, enamelled on the inside with a pouring lip and capacity label on each pot. Pot set a capacity label on each pot. Three pots in set labelled 17 qts and 14 qts on base and flat spot opposite lip - handle for pouring. 12 qts is missing flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pot set, cooking pot, pouring pot, cook ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine & case

Sewing machine and case. Hand operated portable sewing machine, PFAFF brand. Wood inlaid design. Black machine body has gold floral decorations."PFAFF"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sewing machine, hand operated sewing machine, clothing, clothing manufacture, tailor, industry, garment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Music stand, Early 19th Century before 1860

Thomas Sheraton (1751-1806) appears to have been the first to record the written term “Canterbury” music or magazine stand. In his Cabinet Dictionary of 1803 he refers to “a small music stand” with divisions for holding loose sheet or bound volumes of music. The music stand designed to hold sheet music came into fashion in the late 18th Century in England and was often crafted from mahogany, rosewood or walnut. They were seen as status symbols since music was practiced exclusively by the upper classes of society. In a period when printed music was more widely available and disseminated due to more affordable printing techniques, modern sheet music was very popular and therefore storage for such favoured tunes became a luxury and an opportunity for innovative design by cabinet makers. The Classical period of music, from about 1750 to 1820 and the Romantic Period from around 1815-1910 was the golden age of classical music. And it was at this time that The Canterbury often accompanied the piano in the parlour with styles ranging from Georgian simplicity to Victorian exuberance. Social activities of colonial Victoria would have included evening gatherings of family and friends around the piano to enjoy performances or sing along together with from old and up-to-date music sheets. The Canterbury would also be an elegant and practical place to also store newspapers, magazines, posters and drawings from overseas. The news from ‘home’ would be enjoyed by all. THE INSCRIPTION “Jack Morse” Morse. In 2010 Mr Jack Morse was recognised as one of the “people who have contributed to the long term development of Flagstaff Hill Maritime Village”. He was a member of the Flagstaff hill Planning board and a Current Life Member and had been awarded a Certificate of Service and the provision of an Annual Family Membership for life by Flagstaff Hill. The Morse’s family business, Morse’s Engineering, closed in 2010. It was considered “One of Warrnambool’s longest operating businesses with roots dating to 1883 with the design and manufacture of coaches and buggies, progressing to automotive repairs and later specialising in under-vehicle work” The Canterbury appears to have been handmade prior to 1860 as the dovetails are handmade and there are no saw marks on the drawer sides or back as well the sides. Also the back has small nicks indicating a hand plane or drawer knife was used rather than a saw blade to size the material. Additional indications are that the spindles are slightly different in size meaning they were handmade individually not mass produced. From these indicators the writer believes that the item was made before 1860 as machinery was only used after this date to produce furniture. As yet no individual maker can be attributed to this item, however it is a significant piece historically and is quite valuable if a known maker can be associated with the Canterbury. The item highlights a time in our social history when music played an everyday part in people’s lives as the only entertainment families could enjoy together in their own homes. A Canterbury music stand, having three compartments consisting of twenty turned spindles supporting the slat dividers. A drawer, with two turned wooden handles, is fitted below. The music stand has turnip style turned feet. The drawer front and carcass of the stand are veneered rosewood over a mahogany carcass. The underlined words "Jack Morse" are handwritten underneath the drawer bottom.Hand written inscription on underneath the drawer bottom "Jack Morse".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canterbury, music rack, magazine rack, music stand, magazine stand, 19th century furniture, occasional furniture, frederick cornwallis, jack morse, morse’s undercar, music, thomas sheraton, regency furniture, music canterbury -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

In 1902, William E Sessions and other family members purchased a controlling interest in the E.N. Welch Company, a clock manufacturer located in Forestville, Connecticut. Sessions' father owned a foundry located in the town of Bristol, Connecticut that produced cases for E.N Welch Co. On January 9, 1903, the company was reorganized and registered as The “Sessions Clock Company”. Within a few years the Sessions Clock Company was producing clock movements, cases, dials, artwork and castings for their line of mechanical clocks. Between 1903 and 1933 Sessions produced 52 models of mechanical clocks, ranging from Advertisers, large and small clocks with logos of various businesses, to wall, or regulator clocks, and shelf or mantel clocks, designed for the home. Many of the Session clocks from this period are prized by collectors. In 1930, the company expanded to produce electric clocks and timers for radios, while continuing to produce traditional brass mechanical movements. Beginning at the end of World War II Sessions W Model (electric) was widely used by various casting companies for their clocks. The dial of the W Model read Movement by Sessions. In the early 1950s Sessions begin to produce timers for television. In 1956, Sessions was absorbed by a company interested mainly in their timing devices. In 1959, William K. Sessions, grandson of William E. Sessions left the Sessions Clock Company and formed the New England Clock Company. In 1960, one of the Sessions Clock buildings was sold to the Bristol Instrument Gears Company. Kept as the Sessions Company, the new owners ran the operation until 1969 when changes in the market forced the Sessions Company into liquidation. In 1970, the remaining buildings were sold to Dabko Industries, a machine parts manufacturer.The item marks a time when clock production in America was at it’s peak producing clocks for sale in many countries, they were keenly priced, mass produced and available to all. The company had a relatively short life span life regards clock manufacture later diversifying into electric timer mechanisms. Yet it was perhaps inevitable with the advent of electricity along with stiff competition from other clock manufactures that would ultimately herald the end in 1935 of the Sessions company's ability to continue manufacturing mechanical clocks. Clock mantle type face set in a painted black case designed to represent a Greek building with gold decorative pillars. Free standing with decorative feet. No markings or inscriptions on clock case or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sessions, mantel clock, clock, clock industries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Balance Scale, Rebure Germany, 1930s

A mass produced utilitarian item made for domestic use, there is no history or manufacturing provenance currently available.The subject item at this time cannot be associated with an historical event or person It is believed the item was manufactured in Germany pre World War ll, in the 1930s, as other examples from the period are on a number of internet sale & auction sites. This item is regarded as a collectors piece however information and company history regards the manufacturer "Rebure" has not yet been established. Balance spring scale elongated brass graduation scale to 100 Lbs hook at one end and a ring the otherRebure Pocket Balance. Made in Germany measures from 0 to 100LBSflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spring balance scale, rebure scale company, rebure germany, domestic item, kitchen weighing scale -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Dish

The development of bronze and iron metalworking skills allowed for cookware made from metal to be manufactured, although adoption of the new cookware was slow due to the much higher cost. After the development of metal cookware there was little new development in cookware, with the standard medieval kitchen utilising a cauldron and a shallow earthenware pan for most cooking tasks, with a spit employed for roasting. By the 17th century, it was common for a Western kitchen to contain a number of skillets, baking pans, a kettle and several pots, along with a variety of pot hooks and trivets. Brass or copper vessels were common in Asia and Europe, whilst iron pots were common in the American colonies. Improvements in metallurgy during the 19th and 20th centuries allowed for pots and pans from metals such as steel, stainless steel and aluminium to be economically produced. https://en.wikipedia.org/wiki/Cookware_and_bakewareThis item is significant as an example of an item in common use in the kitchen in the second half of the 19th Century, and thereafter.Metal oval cake/pie dish. Significant rust all over..None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cookware, bakeware, kitchenware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, Circa 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early rural and industrial manufacturing became established in Australia.Rectangular butter churn, a footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Lettering in black on a transfer "CHERRY & SONS PTY LTD. GISBORNE VICTORIA". Model 00warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, butter churn, gisborne, edward cherry, george cherry, thomas cherry, ann appleby, dairy equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Eight day movement wall clock with Roman numerals, octagonal shaped rosewood veneered casing, hinged face with locking clip. Wound from front. Face has adjustment for Fast-to-Slow.Part paper label on back of case can just make out "Jerome" and "ight and One" probable meaning is "Eight and One Day" describing the movements operational time between winding the mechanism.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock maker, jerome & co, new haven, chauncey jerome, canaan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSign - Hudson's Soap Enamel Advertising Sign, Patent Enamel Co Ltd, c. late 19th century- early 20th century

Hudson's Soap Powder, was the first satisfactory and commercially successful soap powder and was made in Liverpool by Robert Spear Hudson. He was also an innovator in using advertising, commissioning striking images from professional artists and paid for publicity , something which few other businesses did, and as such Hudson's soap became a household name. Horse, steam and electric tramcars, print periodicals and chemist shops carried his advertisements. This sign was manufactured by Patent Enamel Co Ltd was a company built in 1889 at Selly Oak, Borough of Birmingham, West Midlands, England, United Kingdom. The business was the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides. It is believed that the factory was decommissioned and demolished in the 1960's.the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides.The factory was decommissioned and demolished in the 1960s.The signage demonstrates the increasing demand for domestic soap products and new forms of advertising. The soap business was apart of the flourishing export trade between Australia and Britain during the height of the British Empire.Enamel advertising sign for Hudson's soapflagstaff hill, warrnambool, maritime museum, hudson's soap, advertising signage, patent enamel co ltd, selly oak, borough of birmingham, robert spear hudson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Paper, circa 1908

This roll or reel of paper was part of a consignment carried as cargo of the Falls of Halladale. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. The roll of paper is an example of cargo brought to Australia in the early 20th century. It is also significant for its association with the Falls of Halladale shipwreck, which is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Roll of paper. Paper was part of a large consignment of paper listed as part of the cargo manifesto. It was recovered from the wreck of the ship Falls of Halladale. A section of the paper has been cut away after it was recovered.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, falls of halladale, shipwreck peterborough, 1908 shipwreck, great clipper ships, russell & co., paper, reel, roll, paper reel, paper roll, cargo, consignment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Paper, circa 1908

These sheets of paper were from a roll or reel of paper that was part of a consignment carried as cargo of the Falls of Halladale. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four-masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. The roll of paper from which the sheets were cut is an example of cargo brought to Australia in the early 20th century. It is also significant for its association with the Falls of Halladale shipwreck, which is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Wad of paper sheets that was cut from a roll of paper. Three sides of the sheets are straight and the other side is rough due to exposure to sea water for many years. The roll was part of a large consignment of paper listed on the cargo manifesto of the wreck of the ship Falls of Halladale. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, falls of halladale, shipwreck peterborough, 1908 shipwreck, great clipper ships, russell & co., paper, paper reel, paper roll, cargo, consignment, paper sheets, wad of paper -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Caldwell’s Ink Factory, Late 19th to early 20th centuries

This design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a three-piece mould, a method often used in the late 19th and early 20th centuries, with the maker's name engraved into the mould section for the base. The glass blower would cut the bottle off the end of his blowpipe with a tool and join a mouth onto the top, rolling the lip. The bottle was then filled with ink and sealed with a cork. This method of manufacture was more time-consuming and costly to produce than those made in a simple two-piece mould and 'cracked' off the blowpipe. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. This particular bottle is unusual as it has four sloping indents at the corners of the shoulder, most likely for resting a pen with its nib upwards and the handle resting on a flat surface. Most of the bottles made during this era had horizontal pen rests that were indented into both of the long sides of the shoulder. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. This only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This hand-blown bottle is significant for being the only bottle in our collection with the unusual sloping pen rests on its shoulder. It is also significant for being made in a less common three-piece mould. The method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle is of state significance for being produced by an early Melbourne industry and exported overseas. This ink bottle is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottle; rectangular base, hand-blown clear glass bottle with its own cork. The bottle has side seams from the base to the mouth, an indented base and an applied lip. The corners of the shoulder sides have unusual diagonal grooves that slope down and outwards that may have been used as pen rests. Inside the bottle are remnants of dried blue-black ink. The glass has imperfections and some ripples on the surface. The bottle has an attached oval black label label with gold-brown printed text and border. The base has an embossed inscription. The bottles once contained Caldwell’s blend of blue black ink.Printed on label; “CALDWELL's BLUE BLACK INK” Embossed on the base "CALDWELLS"flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture, three part mould, cauldwells, cauldwell's -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBadge - BMA Ladies Badge, Stokes, 1935

The badge was issued by the British Medical Association 'BMA'. It is known as the Female Relative's Bade or Ladies' Badge. It was manufactured in Melbourne in 1935 by Stokes of Melbourne. The BMA badge is one of a set of badges collected by Dr W R Angus from the organisations in which he was involved. They are now part of Flagstaff Hill’s comprehensive W.R. Angus Collection, donated by the family of Dr W R Angus, surgeon and oculist. The W.R. Angus Collection: - The W.R. Angus Collection includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. It includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. During World War II He served as a Military Doctor in the Australian Defence Forces. Dr Angus and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the responsibility of part-time Port Medical Officer and was the last person appointed to that position. Both Dr Angus and his wife were very involved in the local community, including the planning stages of the new Flagstaff Hill and the layout of the gardens there. Dr Angus passed away in March 1970.This badge is significant for connecting Doctor Angus with organisations that support men and women who performed military service for Australia. The badge was specifically for a female relative of the person who did service, showing compassion for women. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The Collection includes historical medical objects that date back to the late 1800's.This BMA badge is an overall rectangular shape made in a silver metal. It has a raised oval section in the centre. The badge has embossed text and a basket weave background pattern within the metal. It is a Ladies Badge, made for the women connected to members of the British Medical Association. It was made in Melbourne in 1935. This badge is part of a set of badges collected by Dr W R Angus. the set represents organisations that he was involved in, and is part of the W.R. Angus Collection.Front embossed; “BMA” “LADIES” “BADGE. Back embossed; “MELBOURNE / 1935 “ “STOKES MELB”flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, w.r. angus, badge, bma, british medical association, ladies’ badge, female relative's badge, military service, stokes, melbourne, w.r. angus collection -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

... of modern manufacture. flagstaff hill warrnambool flagstaff-hill ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture.Compass saw with wooden handle and metal blade. Small teeth. flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

... of modern manufacture. flagstaff hill warrnambool flagstaff-hill ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw with wooden handle broken and metal blade. Small teeth.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Porcelain Insulators, Mid-twentieth century

White Porcelain “Made in Occupied Japan” electrical insulators. Insulators can be dated from September 1945 to April 1952 during the allied occupation of post WWII Japan. Pin insulators were manufactured specifically for Australian export. Pin insulators are made of non-conductive porcelain and were used to create a barrier between outer wrapped suspended wiring and threaded wood or metal dowel. Pin insulators such these have been found on utility poles around Australia.Porcelain insulators stamped with “Made in Occupied Japan” are often viewed with much interest by collectors given their connection to WWII and short seven year manufacturing time span. Pin insulators such as these are an example of Australia’s continued electronic development which began in the late 19th century. Collection of seven white porcelain insulators made in Occupied Japan. Insulators are cylindrical in shape, with indentation at top. The indentation creates a flat mushroom top head. Insulators display a manufacturer stamp at the bottom of the cylinder. Insulators are single walled and hollow inside with threading at the enclosed top end. flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, insulators, porcelain, electrical insulators, occupied japan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Glass Lens, 1886-1908

This glass lens was recovered from the wreck of the Falls of Halladale. Its purpose is unknown but could have been a clock face cover, a lamp or torch lens or even the lens from underwater equipment. The FALLS of HALLADALE 1886 - 1908- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roof tiles, barbed wire, stoves, oil, benzene, and many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. This glass lens is significant for its association with the wreck of the sailing ship the Falls of Halladale. The Falls of Halladale shipwreck is listed on the Victorian Heritage (No. S255). She was one of the last ships to sail the Trade Routes from Europe and the Americas. Also of significance is that the vessel was one of the first ships to have fore and aft lifting bridges as a significant safety feature still in use on modern vessels today. The subject model is an example of an International Cargo Ship used during the 19th and early 20th centuries to transport goods around the world and represents aspects of Victoria’s shipping industry. Glass lens; transparent glass rectangle with bevelled edges. It was recovered from the wreck of the Falls of Halladale. flagstaff hill, warrnambool, flagstaff hill maritime museum and village, shipwreck coast, great ocean road, shipwreck artefact, falls of halladale, glass lens, rectangular lens, glass cover -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Glass Lens, 1886-1908

This glass lens was recovered from the wreck of the Falls of Halladale. Its purpose is unknown but could have been a lamp or torch lens or even the lens from underwater equipment. The FALLS of HALLADALE 1886 - 1908- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roof tiles, barbed wire, stoves, oil, benzene, and many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. This glass lens is significant for its association with the wreck of the sailing ship the Falls of Halladale. The Falls of Halladale shipwreck is listed on the Victorian Heritage (No. S255). She was one of the last ships to sail the Trade Routes from Europe and the Americas. Also of significance is that the vessel was one of the first ships to have fore and aft lifting bridges as a significant safety feature still in use on modern vessels today. The subject model is an example of an International Cargo Ship used during the 19th and early 20th centuries to transport goods around the world and represents aspects of Victoria’s shipping industry. Glass lens; transparent glass dome with flat base. Glass has bubbles and several concentric lines on the surface. There are light coloured encrustations on the surface. It was recovered from the wreck of the Falls of Halladale. flagstaff hill, warrnambool, flagstaff hill maritime museum and village, shipwreck coast, great ocean road, shipwreck artefact, falls of halladale, glass lens, glass cover, glass dome -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Spoons, Prior to 1878