Showing 746 items

matching machine made

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Spring Balance Scale, George Salter & Co, 1920s

Scales such as the subject item were used to measure commercial quantities, possibly grains and farm produce for quite large amounts of product, also in a domestic situation. Bags of grain or other dry goods would have been hooked up and weighed. Salter has been a name long associated with weights and measures. The firm began life in the late 1760s in the village of Bilston, England when Richard Salter, a spring maker, began making the first spring scales in Britain. He called these scales "pocket steelyards", though they work on a different principle from steelyard balances. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. George later established a manufacturing site in the town of West Bromwich, about 4 miles (7 km) from Bilston. West Bromwich Albion football club was formed from workers at this works site. From here the company produced a wide variety of scales including the UK's first bathroom scales. Other items were added to the range, including irons, mincers, potato chippers, coin-operated machines and the first typewriters made in the UK. The business thrived throughout the 1900s, and by 1950 it employed over 2000 people, still in the same area and owned by the same family.Salter is a British housewares brand developing products that span a wide range of core product categories, including scales, electrical, cookware. It is a market leader in kitchen and bathroom scales and one of the UK’s oldest consumer brands. Established in 1760, Salter has been developing precision products for over 260 years. It was acquired by Manchester-based consumer goods giant Ultimate Products in 2021 after they had previously licensed the brand for cookware and kitchen electrical since 2011.Scale, Salter's improved spring balance, warranted. Brass and iron. Weighs 0 to 25LBS. Long rectangular brass instrument with ring attached to top and hook attached below. Centre of rectangle has long vertical slot with short, horizontal bar that slides down the slot when an object is suspended from the hook, showing its weight on the numbered scale beside the slot.Marked ""SALTER'S IMPROVED SPRING BALANCE" "Number 2". Weighs 0 to 25LBS. flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, salter balance scale, weight measuring scale, weighing dry goods, domestic object, kitchen scale, measure, weigh, measure ingredients, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Spring Balance Scale, George Salter & Co, 1930s

Scales such as the subject item were used in a domestic situation. Salter has been a name long associated with weights and measures especially in the home kitchen. The firm began life in the late 1760s in the village of Bilston, England when Richard Salter, a spring maker, began making the first spring scales in Britain. He called these scales "pocket steelyards", though they work on a different principle from steelyard balances. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. George later established a manufacturing site in the town of West Bromwich, about 4 miles (7 km) from Bilston. West Bromwich Albion football club was formed from workers at this works site. From here the company produced a wide variety of scales including the UK's first bathroom scales. Other items were added to the range, including irons, mincers, potato chippers, coin-operated machines and the first typewriters made in the UK. The business thrived throughout the 1900s, and by 1950 it employed over 2000 people, still in the same area and owned by the same family.Salter is a British housewares brand developing products that span a wide range of core product categories, including scales, electrical, cookware. It is a market leader in kitchen and bathroom scales and one of the UK’s oldest consumer brands. Established in 1760, Salter has been developing precision products for over 260 years. It was acquired by Manchester-based consumer goods giant Ultimate Products in 2021 after they had previously licensed the brand for cookware and kitchen electrical since 2011."Scale Salter's Spring Balance brass cylinder with ring at one end and a hook at the otherSalter trademark stamped on front. Made in England stamped on back. Weighs 0 to 4LBS showing ¼lb increments.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, salter balance scale, weight measuring scale, weighing dry goods, domestic object, kitchen scale -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Voice Recorder, Thomas A. Edison, Edison Laboratory, 1916-1929

... is mounted inside the machine. A round device called a ‘reproducer ...This Edison Ediphone voice recording electronic business machine is manufactured to suit a small office and is light enough to carry between work and home for use outside normal business hours. It is a dictation machine, also called by the competitor’s brand name ‘Dictaphone’, and is used for recording spoken words that would later be transcribed and typewritten. A wax cylinder would be installed onto the machine’s drum and the Reproducer on the machine would be lowered onto the cylinder. The user would speak a message into a microphone and the reproducer would then convert the sounds to scribed marks on the cylinder. Later, the cylinder could be played and the Reproducer would enable the sound to be amplified through an attached speaker. This machine is currently without its power cord, microphone and speaker horn. Thomas A. Edison extended the technology of the telegraph to his phonograph machine, invented in the late 19th century. It could record and play back sounds of music and voice on a manually operated mechanical machine that used wax cylinders to store the sound. He envisaged the way this technology could be an asset in the office, and he was right! However, most of his phonograph machines were used for entertainment, some for playing lessons, and some for-teaching languages. In 1916 Edison introduced the Ediphone, which grew in popularity after the First World War and into the late 1920s until flat round records replaced the wax cylinders. This Edison Ediphone is significant for improving the way business administration was carried out in the early 20th century, freeing up precious time for professionals and administrative personnel. It was the forerunner of audio tapes and digital technology. The Ediphone enabled letters to be dictated when the time and place suited and reduced the time professionals needed to spend with their secretaries. Secretaries were able to type the letters as they played the recording and they could replay the message if necessary.Voice recorder; a dictation machine; desktop model Edison Ediphone. The electronic machine is in a medal case with remnants of the original grey colour. It has a rectangular base with an A4-sized footprint and a domed hood that retracts halfway into the back of the base. The corners of the base have metal reinforcing, and a short metal bar is on the front centre edge of the lid and the base. A long metal drum is mounted inside the machine. A round device called a ‘reproducer’ is mounted above the drum. There is a folding handle on the left front of the machine and an angled stand with paper guides in front of the drum. A rear cover has the maker’s name stamped on it. An electrical socket with eight pins is recessed beside the cover. Made by Edison.In white letters; “EDISON”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, edison, ediphone, dictating machine, office equipment, voice recorder, usa, dictation, communication, office machine, dictaphone, speaking phonograph, thomas edison, ediphone voicewriter, voice writer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottles, Caldwell’s Ink Factory, Early 20th century

This crate of bottles may have come from a wholesaler, business, stationer or school. The design of the bottles is sometimes called a ‘cottage’ or ‘boat’ shape. Each of the 70 Caldwell’s handmade glass ink bottles was mouth-blown into a two-piece mould, a method often used in the mid-to-late 19th century. The glass blower burst the bottle off the end of his blowpipe with a tool, leaving an uneven mouth and sharp edge on the bottle, which was usually filed. The bottle was then filled with ink and sealed with a cork. More expensive bottles would have a lip added, which was more time-consuming and costly to produce. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. The nis only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This large collection of similar ink bottles is of particular significance as the bottles have come from the same source, most have their original corks and some retain their original labels, which is rare. The method of manufacture of these bottles is also representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottles and their contents are of state significance for being produced by an early Melbourne industry and exported overseas. This case of ink bottles is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottles in a wooden crate; 70 rectangular, hand-blown clear glass ink bottles. They have side seams, uneven thickness, especially at the bases, and rough, burst-off mouths. The shoulders on the long sides have horizontal grooves used for pen rests. The bottles vary; some have labels, some contain remnants of blue-black ink, and many have their original corks. The glass has bubbles and imperfections. The remnants of printed labels are on white paper with a swirly border and black text. The bottles contained Caldwell’s blend of blue black ‘Flo-Eesi’ ink.Printed on label; “CALDWELL FLO-EESI BLUE BLACK INK” “ - - - - “ Printed script signature “F.R. Caldwell”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, flo-eesi, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, two-part mould, sheer-lip bottle, burst-lip, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - HORWOOD COLLECTION: DEBORAH EXTENDED, c1978

Horwood Collection. Machinery at Deborah Extended small boy standing at rear of machine. Markings: Deborah Ext. I think. 9 SEP 78 M1 Made in AustraliaKodakmine, gold, deborah extended, horwood collection. machinery at deborah extended small boy standing rear machine -

Bendigo Historical Society Inc.

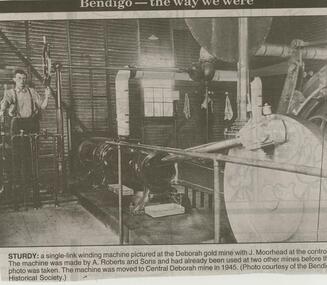

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: STURDY

Bendigo Advertiser ''The way we were'' from 2000. A single-link machine pictured at the Deborah gold mine with J. Moorhead at the controls. The machinery was made by A. Roberts and Sons and had already been used at two other mines before this photo was taken. The machine was moved to Central Deborah mine 1945. (Photo courtesy of the Bendigo Historical Society). The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - BABY CLOTHES COLLECTION: BABY MITTENS, Early 1940's

Machine knitted and stitched baby mittens. Salmon pink wool. Knitted woollen ties at wrist.This collection of knitted and sewn garments were made in the early 1940s and were intended for a baby that was stillborn.costume, children's, baby mittens -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - BABY CLOTHES COLLECTION: BABY PANTS

Machine knitted woollen short baby pants. Cream coloured. Hemmed at waist and legs. Fine lacy pattern all over. Side opening. RHS fastened with one button.This collection of knitted and sewn garments were made in the early 1940s and were intended for a baby that was stillborn.costume, children's, baby pants -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - RANDALL COLLECTION: EMU SEWING MACHINE MANUFACTURING CO P/L

Document, Emu Sewing Machine Manufacturing Co P/L , Bendigo, Australia.Combining Beauty and Utility, made by Expert Australian Workmen from the Finest Australian Materials.document, names of bendigo pioneers, emu sewing machine co -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - AILEEN AND JOHN ELLISON COLLECTION: CRIMPLENE DRESS BY GINA OF MELBOURNE:PART OF ENSEMBLE WITH 11400.521, 1950s

Cream coloured knee length dress of crimplene fabric. Fabric has all over pattern of horizontal rows of looped knot pattern. Fabric also has silver thread woven into fabric. Dress has a high round neckline both front and back. Dress is A line, with front having side darts at bust line and two 30cm darts – vertical on either side of centre front from bust line to hip line. At lower end of each dart is a false pocket flap (11cm x 5cm). Back opening from centre neckline has 54cm nylon zipper with hook and loop at neckline. Back has two vertical darts on either side of centre back. Dress has short set-in cap sleeves. Part of ensemble with 11400.521.Top inside back below neckline: Fashioned by Gina of Melbourne Registered TMS Crimplene. Made from terylene polyester fibre. Wash by hand or machine in warm water. Rinse thoroughly. Gently squeeze out surplus water. Drip dry.costume, female daywear, dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - AILEEN AND JOHN ELLISON COLLECTION: CRIMPLENE COAT BY GINA OF MELBOURNE: PART OF ENSEMBLE WITH 11400.520, 1950s

A Line cream coloured knee length coat of crimplene fabric. Fabric has all over pattern of horizontal rows of looped knot pattern. Fabric also has silver thread woven into fabric. High round neck with stand-up collar - 4.3cm. Two press studs at top below collar, plus one hook and loop to close the collar. Full length front opening with 4.5cm band. Five 2cm fabric covered buttons – evenly spaced from neckline to below hip line. Front has two side darts at bust line. Two false pocket flaps (14cm x 5cm) set at 45° angle to side seams at hem line. Long straight set in sleeves slightly tapered to the wrist. Part of ensemble with 11400.520.Top inside back below neckline: Fashioned by Gina of Melbourne Registered TMS Crimplene. Made from terylene polyester fibre. Wash by hand or machine in warm water. Rinse thoroughly. Gently squeeze out surplus water. Drip dry.costume, female daywear, coat -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - AILEEN AND JOHN ELLISON COLLECTION: MID LIGHT BLUE SLEEVELESS DRESS BY ZANKO:PART OF ENSEMBLE WITH 11400.523, 1950s

Sleeveless mid blue below the knee length dress of rayon fabric. Shallow scooped front neckline. Wide shoulders extend over top of arm. Front of bodice in two parts. Top yoke is attached to 12cm midriff section. Midriff section has wide section with two side sections. Front yoke section is attached to midriff section with two small pleats under bust on either side of centre. Across the centre seam of yoke and midriff is a decorative strip of light blue lace of open floral pattern. The back of the bodice is of two pieces with centre seam attached at the waist with vertical darts on either side of centre. Back opening with 50cm metal zipper beginning 9.5cm below the rounded back neckline. Skirt is made of two pieces joined at front and back centre. Front centre panel 16cm with centre seam. From side of centre panel, the skirt is box pleated (4cm). Six box pleats on either side attached to waist of bodice. Pleats continue to back centre seam. Decorative piping attached around waistline. Machine stitched. Unlined. Faced at neck and sleeves with same fabric. Part of ensemble with 11400.523.Created by ZANKO of Melbournecostume, female daywear, dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - AILEEN AND JOHN ELLISON COLLECTION: ROYAL BLUE COAT BY ZANKO: PART OF ENSEMBLE WITH 11400.524, 1950s

Royal blue rayon long sleeved coat to wear with 11400.524. Fully lined with blue rayon lining, ¾ length set in sleeves with 10cm fold back (fully lined) cuffs. Front opening with no fastening or crossover. Fold back shawl collar. Front darts running from centre shoulder – 24cm vertically Internal pocket of lining fabric. Pockets on either side at hip level. Angled 15 degrees away from side seam with a band along opening edge – 16 cm. Back made from one piece. A line shape. Slightly flared at hem. Machine stitched. Part of ensemble with 11400.524.Created by ZANKO of Melbournecostume, female daywear, coat -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - FAY BRYANT COLLECTION: SUTEX MEN’S WOOLLEN CARDIGAN, 1970s

Pure wool, navy blue men’s cardigan. Five navy blue buttons. One bound pocket on each side front. A 10.5cm wide band of woven pattern on each side front. Fine knit of heavy density. Set in sleeves with a 2cms wide fine knit cuff. Machine stitched button holes. Overlocked seams.Sutex ® Quality Knitwear. Made in Australia. Size 18 to fit 100cm. PURE WOOLcostume, male, cardigan -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - INFANT BOY'S DRESS, 1883- 1885

White child's dress of heavy cotton lace. Sleeveless bodice with arm holes edged with 3cm ungathered broderie type lace. High round neckline with 5cm lace flat collar. Back opening to waist with 5 x 1cm white buttons. LHS is seamed with buttons attached. RHS edge has button holes pushed through edge of lace. 5mm cotton tape is threaded through seam at neck line to form ties at the back. Skirt is made up of two layers of fabric gathered onto the bodice. Underneath layer is 25 cm deep - 12 cm plain fabric from waist with 13 cm edge of broderie type lace with scalloped edges. Top layer of 13cm of broderie type lace with scalloped edges. Unlined. Machine stitched. Skirt pieces are single pieces of lace fabric with seam at centre back.costume, children's, infant boy's dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - INFANT BOY'S DRESS, 1883 - 1885

Heavy white cotton lace dress. High round neckline with cotton drawstring ties. 6cm lace collar with scalloped edged. 7cm cap lace sleeves with fine scalloped edges. Casing at the waist with cotton ties to back. Back opening from neck line to 9cm below waist. Cotton tie at neckline at back. Two x 1cm white buttons spaced at 6cm and 12cm below neck. Hemmed edges of lace form the edges of the back opening. Two machine stitched button holes on RHS with 4.5cm layer of lace covering the button holes. LHS of opening is plain. Lace skirt made of single piece of lace fabric gathered at the waist. Seam at centre back. Skirt 31 cm. Scalloped edges dipping to V shapes. 5mm cotton ties at waist and neck go through metal ties. Machine stitched.costume, children's, infant boy's dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - HELEN MUSK COLLECTION: BLUE SILK DRESS. PART OF A TWO PIECE ENSEMBLE

Floor length dress of royal blue silk fabric with a metallic thread forming a tinsel like pattern. There is a V neck at front with a high round neck at the back. The bodice front is made from two pieces with a centre seam. The bodice is attached to midriff panel of royal blue satin. At the front the bodice is gathered slightly onto the panel with a V shape at t centre front of the panel. At the hip line centre front the midriff panel narrows and then widens and the panel extends to the hem. The centre panel is divided and has a godet insert in the centre. Fifteen decorative fabric covered buttons with roulette loops are attached at centre of midriff panel. The back of the bodice is one piece is gathered slightly into a high waisted skirt made up of four gored pieces. The side opening (21 cm) at the waist on the LHS has three metal hooks with cotton loops and two press studs. The long sleeves are set in with lily point finish at the wrist. The underside of the sleeve at the wrist has ten decorative fabric covered buttons with roulette loops. Machine and hand stitched.costume, female daywear, blue silk dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - HELEN MUSK COLLECTION: WEDDING BODICE AND SKIRT

Ivory coloured waist length silk wedding bodice with front opening. Silk fabric has alternating striped pattern of chequerboard pattern, running stitch pattern and diagonal woven pattern. The bodice is made of two layers of the silk fabric with cotton fabric lining. The front inner layer has two darts from the waistline. The back inner layer has a centre seam and three darts from the waist on either side. The outer layer on both front and back has three knife pleats falling from the shoulders creating a gathered effect. These side panels of pleated fabric create a deep V neckline by crossing over 5cm above the waist. The V shape neckline is filled with an insert of cream and dark green lace with a floral pattern. The lace insert extends to the throat to form a high round neckline. The neckline is edged with cream coloured woven cotton braid. The side edges of the outer layers are trimmed with cream lace with a floral pattern and 5cm zig zag peaked edges that extends from centre waist at the front, over the shoulders and to the crossover section at centre back where there is a decorative silk fabric flower stitched at the crossover point just above the waist. The front opening is fastened with fourteen hooks and eyes plus another hook and eye offset 5 cm above the waist at the crossover point. Set in long sleeves are in two sections. An inner layer of silk fabric widens to the elbow where two five cm frills of gathered tulle are attached. Each frill is edged with a row of silk stitching. Attached below the frills are two 7 cm strips of lace stitched together to form the lower part of the sleeve. The edge of the lace forms the hem at the wrist. Each sleeve has a 5 cm hemmed V shaped split from the hem at the wrist. The outer layer of the sleeve is bell shaped falling from the shoulder to the elbow. This section of the sleeve is edged with cream lace with a floral pattern and 5cm zig zag peaked edges that are stitched to the fabric of the sleeve. Ivory coloured full-length wedding skirt with train. The skirt is made in two layers. The under layer is made from cotton from the waist with a wide border of silk fabric - 18 cm wide at centre front, widening to 37 cm at the side seams. The back of this skirt extends to a train and the border widens to 48 cm. The border section is lined with cotton fabric. At the centre back, the border has two godet inserts to create fullness in the train. The outer layer of the skirt is of ivory silk fabric with alternating vertical stripes of a chequerboard pattern, a running stitch pattern and a diagonal woven pattern. The lower edge of the skirt is edged with an 18 cm border of lace patterned with embroidered circles. The edge of the lace forms a zig zag pattern of elongated V shaped peaks (7 cm). The front of the skirt dips to a V shape at centre front with the point of the V reaching the hemline. The back of the skirt dips below the front hemline in a U shape over the train. The waist band is made of cotton tape. The centre front of the waistband has an embroidered pattern in silk thread. The centre back opening is fastened with seven metal hooks with six cotton loops plus one metal eye on the waistband. There are two cotton tape hanging loops on either side of the inner waistband. Hand and machine stitched.costume, female ceremonial, wedding bodice -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Postcard - BASIL WATSON COLLECTION: AVRO PLANE

Postcard: black and white card - two sections. On top aeroplane, 'Patented 1906, the first free aeroplane to leave the ground in Britain' On bottom of card, photo of three tiered wing aeroplane. Written on bottom' Avro' plane flying with only 14 h.p. On back of card: The 'Avro'plane. The first aeroplane illustrated was the first free heavier-than-air machine to leave the the ground. Before this however, very interesting flights were made when towed by a motor car at Brooklands Track. The other photo shows a flight with 14 horse power, but previous to this some hundreds of flights were made with only a nine horse power engine. A record which has not yet been beaten or equalled. Mr. A.V. Roe is now making monoplanes, biplanes and triplanes &c. For full particulars please write to A.V. Roe & Co., Brownsfield Mills, Manchester.aviation, civilian, avro biplane, basil watson, biplane, aeroplane -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Machine - CHECKWRITER: PROTECTOGRAPH

A Mechanical Cheque Writing Machine. A Brand label on the machine includes 'The PROTECTORGRAPH CHECKWRITER' manufactured by TODD PROTECTROGRAPH Co. , Rochester , N.Y., USA. There is a RED Number included with the figures 657908.. It is approximately 45cm long and 12 cm high made of cast metal? It has a handle that rotates a set of rollers to apply ink to 'checks' as they progress through the machine In a cardboard Box with the words 'Les Gillies Collection' written on itTODD PROTECTORGRAPH Co. Rochester. NY, USAcommerce, office equipment -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Model, USS ASHEVILLE (PGM-84)

The long ship has one third of its length made of controlling room in the middle. It has on autocannon at the front and a machine gun station at the back and text '84' on side.84 USS ASHEVILLE (PGM-84) VIETNAM 1967/72model boat, uss asheville -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyEquipment - Comptometer, J E Earl Pty Ltd, Bay Street, Port Melbourne, 1950s

This machine was given to Betty GODDARD, clerk in the office of Earl's, when the office technology was updated. She had used it herself but it was also a favourite of James Earl the younger, who did his calculations on it. Betty donated it to the Society in 1996. This was the only machine Jim EARL would use; converted by Burroughs in1966Comptometer, beige, used in the office at J.E. Earl's timber yard and ironmongers, Bay Street 1950s - 1970s. A comptometer was an early calculator.'Peacock Bros. Pty Ltd Sole Agents Business Systems':'Comptometer':Guaranteed made in Great Britainbusiness and traders - timber, james edward earl, beatrice (betty) goddard, j e earl pty ltd -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Neville-Barnes obstetric forceps used by Dr Lorna Lloyd-Green

Neville Barnes Obstetric Forceps have a cephalic and pelvic curve and are used for delivery of babies presenting as occipitoanterior. The left blade being put on first followed by the right blade – the baby is then pulled down until the occiput is under the symphysis, then pulled around. (RACGP)Neville-Barnes forceps with traction attachment and pouch. The forceps are nickle plated, and consist of two blades and an attachable axis traction handle. Pouch is made of denim and has a full length pocket insert. The edges of the pouch are bound with a narrow satin binding and machine sewn. The pouch is fastened with a press stud.obstetric delivery -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, Circa 1971

The Vogt LO150 is a sailplane first produced in 1954. Designed in Germany by Alfred Vogt, the LO150 is of wood construction. It has a two piece wing of 15 metre (49 feet) span and a fuselage of monocoque design. The first of the type to be imported into Australia arrived in late 1955. In January 1956 this aircraft type was used to create a world speed record of just under 75 km/h for speed around a 300 km triangle and went on to win the Australian National Gliding Championships. The Museum’s LO150 (VH-GUC) – serial number EB71 was imported from Germany in 1971 by the late Frank Erdmann and an ownership syndicate formed. Following Erdmann it has had a number of owners. Much of its usage was at Bacchus Marsh and Horsham with excusions elsewhere for competition. This Vogt LO150 was last flown on 3 January 1988. Overall, since arriving in Australia, it has flown 315 hours from 273 launches, which is a commendable average performance of over an hour per flight. VH-GUC was donated to the Museum by Warren Mayfield in 2002. Substantial glue deterioration was discovered in one wing and, as a result, a decision has been made not to restore the glider to an airworthy condition. In due course the glider will be repainted and further prepared for display. This exhibit is an example of the Vogt LO150 semi-aerobatic competition sailplane.Single seat competition sailplane of wood construction.Builder's serial number EB71australian gliding, glider, sailplane, vogt, lo-150, erdmann, mayfield, geelong gliding club -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1963

The Skylark 4, the final in the Slingsby Skylark series, dates from 1961. The design heralded a trend towards the use of plastics in the construction of gliders. Slingsby incorporated GRP (glass reinforced plastic) panels to achieve a streamlined fuselage nose and cockpit area while retaining the more traditional wood techniques for the rest of the aircraft. Another notable feature was the smooth wing surface that was obtained using a Gaboon ply skin across the ribs. Best glide performance of 1:33 was found to be comparable with the early full GRP glider designs. The Museum’s example (VH-GTB – C/N 1382) was built in 1963 and originally owned by Chuck Bentson of the UK. It was brought to Australia in 1967 by Jeremy Picket-Heaps and flown at various places including Benalla, Cooma and Gundaroo. In 1970 the glider was transferred to the New England Soaring Club. Many flights were made from Armidale and Bellata in Northern New South Wales. On one occasion, the glider was kept aloft for 8 hours 45 minutes and on another the pilot took it around a 500 kilometre triangle in nearly 8 hours. In 1980 it was sold to Ralph (“Feathers”) Crompton and was flown extensively in South Australia until 1988. The final owner before the glider was given to the Museum in 2004 was Ross Dutton of Melbourne. The last recorded flight occurred in 1992. The glider at that point had logged over 2000 hours flying time from about 2000 launches. The airframe is currently being restored to flying condition. Technically this aircraft represents the state of the art at the stage that sailplane design was changing from traditional wood construction to composites (GRP) The Slingsby Skylark 4 is high wing single seat sailplane of mainly wooden construction with plywood and fabric covering. However, the cockpit and forward part of the fuselage consists of glass reinforced plastic which was innovative at the time that the type was designed. The cockpit provides for a semi reclining position for the pilot protected with a full Perspex canopy. The wings are made up of a centre section with constant chord and tapered wing tips. The aircraft has a conventional arrangement for the tail stabiliser / control surfaces. The sailplane bears construction number 1382 and is registered in Australia as VH-GTBaustralian gliding, glider, sailplane, skylark, slingsby, bentson, picket-heaps, crompton, new england soaring club, dutton