Showing 6740 items matching " cast-iron"

-

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, 1940's

2 Hole Punch Black Cast Iron stawell -

Mont De Lancey

Mont De LanceyBall and Ring Bunion Stretcher

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron ball and ring bunion stretcher.boot stretchers -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

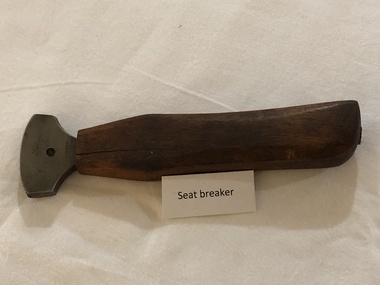

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

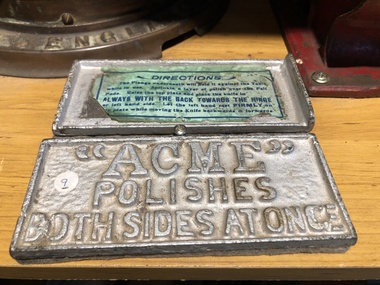

Mont De LanceyKnife Cleaner, Circa 1910

Cast iron static type knife cleaner'"Acme" Polishes Both Sides At Once'knife cleaners -

Mont De Lancey

Mont De LanceyLemon Squeezer, Circa 1910

Enamelled blue, cast iron lemon squeezer.juicers -

Mont De Lancey

Mont De LanceyLemon Squeezer, McMillan & Co, Circa 1912

Cast iron, screw type lemon squeezer'Victor'juicers -

Mont De Lancey

Mont De LanceyLemon Squeezer, McMillan & Co, Circa 1911

Cast iron lemon squeezer, with metal strainer'Success'juicers -

Working Heritage Crown Land Collection

Working Heritage Crown Land CollectionDecorative object - Finial

Cast iron finial spike for a fence post -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Weight, Unknown

None available for this item an early disc weight it's maker date of manufacture is not knownNone availableWeight cast iron disc on-black colourNumber 2 marked on upper surfaceflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight -

Trafalgar Holden Museum

Trafalgar Holden MuseumFunctional object - foot last

Used by cobblers for the repair of footwear ca1910we believe this was retailed by HOLDEN ca 1910Iron cast three shaped shoe lastAJK TITANshoe last, cobblers, civilian, ca1910 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - NATIONAL TRUST

DVD. National Trust. Cast iron collection. -

Warrnambool and District Historical Society Inc.

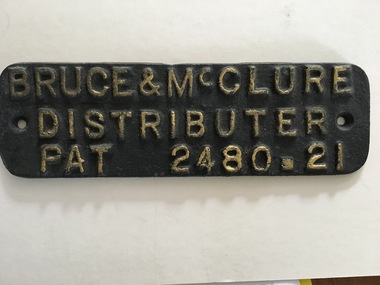

Warrnambool and District Historical Society Inc.Brass Plate, Bruce & McClure Distributer, C early 20th century

Bruce & McClure were manufacturers of windmills and agricultural machinery including motor engines , pumps, tanks,and appliances for supplying and conserving water.Also included was brass,iron and steel foundry works. They won 11 first prizes at the Grand national Show of 1907 and in 1914 designed and manufactured a new water boring machine which could also be used for oil and gold exploration They operated from Lava Street well into the 1940's as well as from the geelong area. This plaque is possibly from one of their machines.A tangible link to one of Warrnambool's manufacturing businesses which was innovative and an essential part of the beginnings of machine use in farms and industry in the district. Cast iron plaque with moulded text which is coloured in gold. rectangular with rounded corners. Back is painted grey.Bruce & McClure Distributer Pat 2480.21warrnambool, bruce & mcclure, bruce & mcclure machinery -

Mont De Lancey

Mont De LanceyIron, Handi Works

Chrome Pumpless Kerosene Iron with green wooden handle."All British Pumpless Iron / Handi Works Brisbane"irons, laundry irons -

Chiltern Athenaeum Trust

Chiltern Athenaeum TrustTeak memorabilia taken from HMS Ship "Iron Duke", Admiral Jellicoe's flag ship, circa 1916

HMS Iron Duke was a dreadnought battleship of the Royal Navy, the lead ship of her class, named in honour of Arthur Wellesley, 1st Duke of Wellington. She was built by Portsmouth Dockyard, and her keel laid in January 1912. Launched ten months later, she was commissioned into the Home Fleet in March 1914 as the fleet flagship. She was armed with a main battery of ten 13.5-inch (340 mm) guns and was capable of a top speed of 21.25 knots (39.36 km/h; 24.45 mph). Iron Duke served as the flagship of the Grand Fleet during the First World War, including at the Battle of Jutland. There, she inflicted significant damage on the German battleship SMS König early in the main fleet action. In January 1917, she was relieved as fleet flagship. After the war, Iron Duke operated in the Mediterranean as the flagship of the Mediterranean Fleet. She participated in both the Allied intervention in the Russian Civil War in the Black Sea and the Greco-Turkish War. She also assisted in the evacuation of refugees from Smyrna. In 1926, she was assigned to the Atlantic Fleet, where she served as a training ship.WW1 HMS Iron Duke in the Battle of Jutland 1916. a Piece of wood (teak) taken from the ship HMS Iron Duke Admiral Jellicoe's flag ship, in 1916 (Jutland). Brass plate attached to wood reads as follows: From the Teak of HMS Iron Duke Admiral Jellicoe's Flag Ship Jutland 1916. ww1 the great war 1914-1918, hms iron duke, british navy, battle of jutland -

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1880

Cast iron and wood static knife cleaner. Cast iron base, two circular wooden discs with cork pads between. Brass screw tightener."Our Own"knife cleaners -

Bendigo Historical Society Inc.

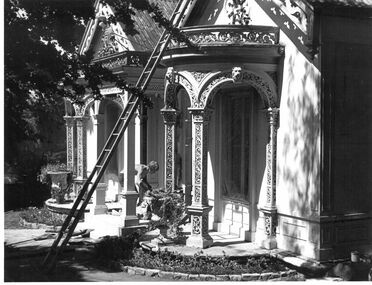

Bendigo Historical Society Inc.Photograph - Lace Iron Work

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and poured into moulds usually med from sand. The alloys needed a minimum of 2% carbon.Black and White photo by A Doney of sandblasting iron lace work on unknown property in Bendigo. Two internal photos of door and arch ways. Larger photo of balustrade with verandah pillars in backgroundA Doney Bendigoalan doney, bendigo, wrought iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCaulking iron

Owner of tools Jim Gillespie Clayton VictoriaCaulking iron medium width single grooved set iron. Mathieson cast steelflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - FLAT IRON

Silvesters Patent number 5 cast iron flat iron. Estate of E. ShermanSilvesters Patentdomestic equipment, laundering, iron, estate of e. sherman -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchPlaque - Naval Association Of Australia Plaque, Naval Association of Australia "Port Adelaide"

Wooden plaque with Cast Circle attached to front.Cast Circle with -Naval Association Of Australia" Crown on top and Anchor with Chain in centre of circle., "Port Adelaide" underneath circle. -

Mont De Lancey

Mont De LanceyFunctional object - Cast Iron Kettle, Unknown

Heavy duty cast iron kettles were used as a domestic item to boil water safely without the concern that the metal may contain lead or arsenic as earlier utensils had. The household depended on constant hot water availability for all cooking, washing and other household chores.A large vintage rusted black cast iron heavy kettle with no lid. It has a flat base and mushroom shaped handle welded onto the pot below the rim of the pot opening. It has a rim to position the teapot lid. The goose neck spout has a shaped pouring end. It was used as a domestic item to boil water safely without the concern that the metal may contain lead or arsenic as earlier utensils had.kitchenware, kettles, kitchen equipment -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, early to mid 1900's

This cast iron kitchen appliance was made in England in the early 1900's and shipped to the "colony" Australia. This was before World War II and the "growing up" of a colony to an independent member of "the British Commonwealth". It was a period when most appliances (be they household) where manufactured in England and shipped to Australian ports. It was not until the late 1960's that the Asian manufacturing giant woke up and started to dominate the market palce.This domestic kitchen appliance is very significant to the Kiewa Valley because it highlights the "made at home" period when food processing was made "in house" due to inability to source food from specialised shops e.g. the butcher or slaughter houses. It was a period before mass food processing factories were established and roads constructed up to the standard for distribution to semi remote regions such as Kiewa Valley was in the beginning of the 1900's.This cast iron (malleable iron) mincer for meat products has a large "funnel" to direct "chunks" of meat to the grinding "wheels". These "star" shaped wheels with "teeth" of three different cutting surfaces (fine, medium and coarse) provide for texture types of the final meat product. The meat is placed into the "loading" funnel and push downwards(gravity feed) through the mincing chamber and out through the front side. There is a long "screw worm" which is rotated by turning the handle. The appliance is table mounted by a vice "G" screw on clamp (hand operated). "BEATRICE No. 3" and "MADE IN ENGLAND", "P 3181"household cast iron appliances, food processors -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Victorian Railways Scales for Weighing up to 25 kg

The Victorian Railways scales were donated by a resident of Wodonga, Victoria, and may have been used in the Wodonga train station. The Wodonga train line and train station opened in November 1873 when the section of the line from Wangaratta to Wodonga was completed. The expansion of Victorian Railways to the northeast of Victoria occurred after the Victorian Government took over the railways in 1867 and the trains serviced large towns such as Seymour, Wangaratta and Wodonga, as well as smaller towns along the way.The Victorian Railways weighing scales has local significance as it was donated by a resident of Wodonga, as well as state significance as an example of the equipment used by the Victorian Railways. Green painted cast iron Victorian Railways scales for weighing up to 25 kg. Rectangular weighing plate above a circular aluminium dial with the weights and 'V.R.' is engraved in black on the front of the scales."V.R." in black on the front of the scales "TO WEIGH / 25 kg. X 250 g." in black on the front of the scales "1714" engraved on a small iron plate screwed onto the front of the base of the scales.victorian railways weighing scales, v.r. weighing scales, railways scales, weighing scales, victorian railways, v.r., vr -

Bendigo Historical Society Inc.

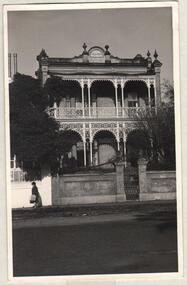

Bendigo Historical Society Inc.Photograph - "Illira" Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore was melted in a blast furnace, mixed with alloys and then poured into molds usually made of sand. The alloys needed a minimum of 2% carbon. Three black and white photographs by Alan Doney of the residence 'Illira' at 57 Forest St, Bendigo. The first photo shows the front of the residence. The other two photos show detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron, illira bendigo -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - Gates, Victoria Park, 1988

The Kew Asylum Entrance Gateway and an adjacent gate lodge were built at the Princess Street entrance in 1873.1 The imposing sandstone pillars and cast-iron gates impressed upon visitors the therapeutic and civilising vision of the asylum. The entrance opened onto a tree-lined drive (now known as Main Drive) which culminated in an elliptical carriageway in front of the main building. (Heritage Council of Victoria)Colour photographic positive of the former Kew Asylum Gates which were relocated in 1942 to Victoria Park in High Street, Kew. The gates were listed by Heritage Victoria in 2020. The citation reads: "The Former Kew Asylum Entrance Gateway consists of two 4.5 metre sandstone gate piers on bluestone bases on either side of a 5.5 metre vehicle entrance set back from the High Street pavement. The 1870s gate piers are of Barrabool sandstone and repairs during 2015-16 were undertaken with sandstone from English Town, Tasmania. The gate piers are highly decorative and feature oculi, triglyphs, dentils, corbeling and other ornamental work. Each gate pier incorporates a pedestrian archway with a cast-iron pedestrian swing gate. Two curved sections of cast-iron palisade fencing on rusticated bluestone blocks extend from the outer edges of the piers to a set of shorter sandstone pillars on the High Street pavement. Straight sections of cast-iron fence extend 4.5 metres ending at two bluestone pillars. Garden beds have been created within the curved sections of fencing, bordered by concreted bluestone and planted with shrubs." (Heritage Council of Victoria)gates -- kew asylum, gates -- victoria park -- kew (vic.) -

Orbost & District Historical Society

Orbost & District Historical Societybilliard table iron

This item was used at The Men's Club Orbost in Livingstone Street, Orbost.This item is representative of the leisure activities of people during the nineteenth century and early 20th century. The Orbost Men's Club no longer exists. It is also significant as being associated with the history of Australia's leading manufacturer of billiard tables, Alcock of Melbourne who were established in 1854 and are still in business today.Billiard table iron; a heavy iron of cast metal. This has a large, rectangular face with attached, cast metal handle. This was used for pressing the cloth of a billiards table. Engraved/embossed on handle is ALCOCK THOMSON & TAYLOR PTY LTDrecreation billiards billiards-table-iron men's-club-orbost -

Kiewa Valley Historical Society

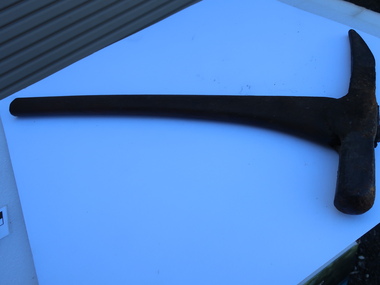

Kiewa Valley Historical SocietyMiners Pick - short

Formerly KV 071. It was used to break up rock and ore, making it easier to extract valuable minerals. The pointed end of the pick axe was used to chip away rock, while the flat end was used to strike the rock for breaking it apart. This one has a short handle. Miners picks were commonly used in the the 19th and early 20th centuries for extracting gold from underground mine tunnels.Used in the Kiewa Valley where prospecting for gold occurred.Formerly KV 071. Cast iron symmetrical pick tool on cast iron with a wooden handle. It has a pointed end and a flat end. It is 12 inches long.gold mining, miners' pick axe, hand tool -

Mont De Lancey

Mont De LanceyKnife Cleaner, Circa 1929

Cast iron and wood encased, hand-cranked, static type knife cleaner. Wooden box shape with cast iron and wood handle and 'buffer' enclosed within.knife cleaners