Showing 630 items matching "domestic food"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Safe Cover, Mary Jane Giles (Mrs Harry Giles), Late 19th to Early 20th Century

This food safe cover is one of many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by, Vera and Aurelin Giles. The items are associated with Warrnambool and the Giles Family history. Items donated by the family have come to be known as the “Giles Collection”. Many items in the Lighthouse Keeper’s Cottage were donated by Vera and Aurelin Giles and mostly came from the home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton) who married in 1880 and whose photos are on display in the parlour. Henry was born at Tower Hill in 1858, and was a labourer on the construction of the Warrnambool Breakwater before leaving in 1895 for around seven years to build bridges in NSW. Mary Jane was born in 1860 at Cooramook and she attended Mailor’s Flat State School and where she eventually was to become a student teacher. After which she became a governess at “Injemiara” where her grandfather, Francis Freckleton, had once owned land. Henry and Mary’s family consisted of six, some of the children were born at Mailor’s Flat and later some children at Wangoom. They lived with their parents at Wangoom and Purnim west, and this is where Henry died in 1933 and Mary Jane in 1940.The Giles family collection is of social significance at a local level, because it not only illustrates the level of material support the Warrnambool community gave to Flagstaff Hill during it’s establishment. But the Giles collection also gives us today a snapshot into what domestic life was like in early colonial times prior to Federation.Food safe cover, white with knitted lace on the front and part of the two sides.Nonewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, safe cover, giles collection, henry giles, tower hill, cooramook, mailor’s flat, wangoom, 19th century household goods, textile -

Greensborough Historical Society

Greensborough Historical SocietyDomestic object - Meat Safe, 1920-1950

Used to store meat and other perishables, often with wetted cloth covers to keep contents cool where refrigeration was not available.Grey painted ventilated meat safe with centre shelfmeat safes, food safes -

Greensborough Historical Society

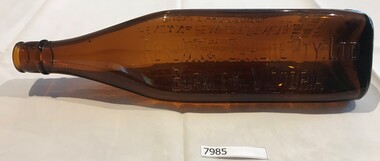

Greensborough Historical SocietyDomestic object - Bottle, AGM (Australian Glass Manufacturers), Methylated Spirits bottle, 1940s

Brown glass, 3-sided methylated spirit bottle. Strong embossing on 2 sides. No cracking or chipping. Crown sealed, circa late 1940s. It was from an era when most common household poisons had their own unique shaped bottle so if the label was removed or illiterate people still knew what the contents were. Brown glass, 3-sided methylated spirit bottle. Strong embossing on 2 sides. Embossed: “Property of Renown and Pearlite Pty Ltd Burney Victoria” “This container must not be used as a food container” methylated spirits, bottles, agm, agm (australian glass manufacturers) -

Greensborough Historical Society

Greensborough Historical SocietyDomestic object - Food mixer, Kan Wondami, 1930s c

... mixers food mixers "Kan wondami R" Hand operated metal kitchen ...Precursor to electric kitchen mixersHand operated metal kitchen food mixer, twin chromed beaters and handle, silver metallic paint with green plastic bowl (non-original)"Kan wondami R"food mixers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyShaker Spices, after 1895

This item was used at a time when there was a limited range of spices available and sought after by domestic and commercial kitchens. The taste buds of the average Australian diner were limited to the basic English style dishes which had been delivered by the early colonial days. Rural areas where slower in experimenting with Asian and European cuisine. The influx of European cuisine from refugees fleeing both World War I and world War II brought a different appreciation of gourmet food. The increase in Asian spices was brought about by Australians becoming more aware of the Asian "scene" through the conflicts of Korean and Vietnam military action. The "standard" type spices such as Cinnamon, nutmeg and similar spices offered by Robert Harper and later other Food and Spices whole sellers and processors where a direct result of a greater influx of migrants from spices rich societies and resulted in a greater range of "Asian" spices This became more visible after demise of the "White Australian Policy" on immigration and the great media revolution of Televised cooking shows from the 1950s on. The sustainability of containers such as this re-useable tin and cardboard spice holder, which could be replenished and not thrown away after it was empty was it a time period well before the "throw away" society had crept into the Valley.This spice container was used mainly in domestic kitchen within the Kiewa Valley. Those European construction workers of the SEC Kiewa Hydro Electricity Scheme had brought their continental cuisine into the valley and that was the beginning of a new era in highlighting different tastes. This rural valley had a greater interaction with people from other nation's cuisines and by association became more infused with a broader range of spices and food preparations.This item (spice shaker) is constructed by using a thick cardboard cylinder with both ends closed by tin plated light steel lids. The bottom lid is not removable however the top lid is removable to allow the contents (Cinnamon Spice) to be refilled. The lid has thirteen small holes which allow the contents to be shaken out. The outer side of the cylinder has been covered (glued on) by a printed black and yellow label detailing contents , weight, and supplier.On the front side of the printed label outside of the label boundary is "To make a shaker of this tin - take the lid off and remove the paper from inside the lid" Within the marked horse shoe shaped boundary is" HARPER'S ground spices star brand" underneath "CINNAMON" underneath this is printed "1 oz. NET WEIGHT" and under this, within its own frame " ROBERT HARPER COMPANY LIMITED (incorporated in Victoria) AUSTRALIA." On the back within its own box is "HARPER'S star brand GROUND SPICES" and underneath "These Pure Spices are packed in the following Varieties". Below this is a list (going down) "CINNAMON CARRAWAYS CAYENNE MIXED CLOVES CASSIA CORIANDER GINGER MACE TURMERIC NUTMEGS PIMENTO"kitchen spices, spice shakers, food preparation -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySlicer Bean, early 1900's

... availability domestic kitchen time savers food processors bean slicers ...This large bean slicer was first manufactured in the late 1800's in England and exported to Australia. Due to the transportation costs it was not used in many Domestic kitchens. This slicer would have been in a kitchen of a higher socio/economic family within the Kiewa Valley. In the 1930's the manufacturer traded this slicer as "domestic labour-saving slicers". This was the beginning of new generation of the kitchen "gadget". The introduction of the Asian "gadget" manufacturer from the late 1950's saw English export diminish by the cheaper Asian products.This item has great significance because it demonstrates that even "remote rural" locations, such as the Kiewa Valley in the early 1900s still were able to optain "state of the art" labour saving "kitchen" appliances. It was these English and European goods that were made "to last" which brought the mind set "British is best" This mindset was only altered by periods of Australian economic down turns and the cheap Asian product availabilityThis bean slicer is made from cast iron with a round body housing three rotating blades screwed into a riveted spinning base plate. The whole body of this slicer is green with a "natural coloured" handle. A "G" clamp is part of the main frame to fasten the slicer onto a table/counter top (when in use). On the side of the handle and along the top plate "SPONG & Co Ltd" and opposite "BEAN SLICER" below this "No 633"domestic kitchen time savers, food processors, bean slicers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyContainer Tin Cylindrical

This item was produced by a Melbourne Tea, Coffee and Cocoa Merchant importers(1898-1960). It was a time when local production of, coffee had yet not begun. Imports from India and the Asian region had dominance in the market place. The blending of coffee with chicory was a cheaper method of providing a flavour enriched drink which was marketed as "containing not less than 55 parts per cent by weight of coffee" The coffee weighed heavier than the chicory. This was a time before strict accurate consumer information/content became mandatory and legally enforceable.This empty container of "Sunbeam" Coffee and Chicory finely ground "instant - just add boiling water" beverage was the start of the "fast" breakfast drink. The use of grinding the coffee beans and percolation to obtain the final drink was at the start of the rural sector's decreasing the time for casual drinking. The once casual countryside psyche was now (mid to late 1900's) becoming more "on the go".This cylindrical container (coffee and chicory) is constructed from pressed cardboard with both ends enclosed by tin(pressed) lid and bottom. The outside wrapping is promotional and descriptive in the colours of purple background and information label areas with purple lettering on a white and silver background. The cylinder is made from 2 mm pressed cardboard.Main label " No.1" underneath "Sunbeam" underneath "COFFEE and CHICORY" UNDERNEATH "Containing Not Less than %% Parts Per Cent By Weight of Coffee" underneath in Hand Writing" Griffiths Bros Limited", below this "TEA ,COFFEE & COCOA MERCHANTS" Below this" Mellbourne, Sydney, Adelaide" and lastly "net 1lb weight". Alternate side "The Following Well Known Economical & Flavoury Teas" underneath this "Packed Specially For The Trade" underneath "SUNBEAM & VICTORY SIGNAL COCOA" and in smaller print "Absolutely Pure, Made in Australia" underneath Equal To The Best Imported"breakfast containers, food storage, instant coffee, speed breakfasts, domestic -

Kiewa Valley Historical Society

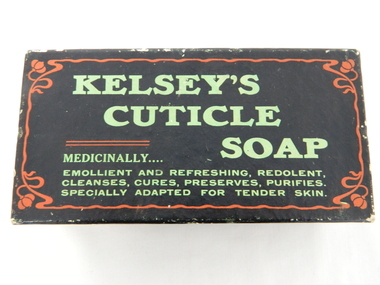

Kiewa Valley Historical SocietyBox Cuticle Soap, mid to late 1900's

The mid 1900's provided the start of "the body beautiful" revolution. The cosmetic industry, with the help of quasi scientific selling advertising slant targeted those "customers" that needed the "extra care" factor that only their product could offer. At this period in time their advertising power was based on in store, radio and newspaper media channels with saturation levels relatively low. In the later years of the 1900's saturation levels and a wider range of products and increased competition further increased the product saturation levels available to the buying residents. With the introduction of television the advertisements become more elaborate and "catchy" words, phrases and comedy type situations helped boost the advertising "pitch" and subliminal undertones to effective levels required for a highly competitive health related market place. 'sellingThis subliminally,"medically" endorsed product was one of many during the great "spin" revolution of product marketing and selling. This item is significant in that it demonstrates that greater infusion of product awareness throughout rural areas was highly successful through a greater variety of advertising media. It also demonstrates that in a highly competitive marketplace there are no physical boundaries that impinge upon the distribution of products and services. The rural sector is a highly lucrative region for any product that helps protect the body from all the "nasty's" that become more noticeable in a rural environment. This rectangular box which had contained cuticle soap is constructed from cardboard and reinforced by a black nylon impregnated sheeting. This impregnation was required to keep the box from soaking up any water from the user's hands. The top section of the box(lid) has and in large print "KELSEY'S" top line followed by "CUTICLE" off to the right and underneath and to the right "SOAP". Below this and in smaller print is "MEDICINALLY..." below this and in smaller print "EMOLLIENT AND REFRESHING, REDOLENT, CLEANSES, CURES, PRESERVES, PURIFIES." and last line underneath "SPECIALLY ADAPTED FOR TENDER SKIN" On each of the sides of the top lid are, side 1 "INVALUABLE FOR THE NURSERY." underneath in smaller print "JOHN M. KELSEY CO." to the left of this and on a green backed highlighter "No. 1744 - Guaranteed under Pure Food Act, 1908, N.S.W. by John M. Kelsey Co. - No. 1744. Melbourne, Victoria." On the right side and in large print "KELSEY'S CUTICLE SOAP" on the next side and also a similar sign on the opposite side "SPECIALLY ADAPTED FOR TENDER SKIN." below this "JOHN M. KELSEY CO." "Registered" and on the other long side in large print "SPECIALLY ADAPTED FOR TENDER SKIN" underneath in smaller print JOHN M. KELSEY CO. Registered"specialised soap, toilet requisites, nursery health., bathroom, domestic -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Biscuit/Tea, Early to mid 1900s

This biscuit/tea caddy was probably targeting the "theatre going" family or those who liked looking at the colourful shakespearian scenes. This item however demonstrates that the rural (Kiewa Valley) appreciation of classic English plays was, in this time period (early 1900's), just as strong as in the larger towns and cities. This item also presents the period in which the "olde" Elizabethian phrases and words were taught in regional high schools. Although this speech pattern and phraseology was of a specific time period and going out of fashion when Australia was first settled it was an inherited form of communication(higher social/economical level). In the context of the rural Australia "scene" and in this time frame of the elite "boarding school" generation this item was a visual reinforcement of the education level and position of the family who owned this tin.This item is highly significant because it not only presents the social aspects of early life in the Kiewa Valley but also the variety of educational levels and economical variations of the rural population within the Kiewa Valley. The egalitarian perception of the inhabitants of the Kiewa Valley was still at the infancy of early Australian social interactions. This biscuit /tea container was however a leveling of the socio-economic playing field of the time.This biscuit or tea tin, has besides having an outer lid (hinged), it also has an internal lid(with a circular finger grip). Although the shape is rectangular it has a slight concave bulge at each side of the centre of each of its main frame. It is made of pressed light steel and has a raised floor. The corners are bevelled and the outer lid has a bevelled slope ridge in parallel to the extremities of the main tin frame. There are painted scenes from the following Shakespearian plays on each side of the tin; "As you like it", "Hamlet" and on each of the bevelled corners are the portraits of Shakespeare(in the middle), the caricature mask faces of "the theatre" above and on the bottom section the "Director's chair"food storage, kitchen table container, domestic educational storage, shakespeare illustrations -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBowl Enamel, unknown, circa mid to late 1900's

This "mixing" bowl was used in a period before electric food processors and mixers were readily available(1940's). Basic food ingrediences requiring mixing such as cakes scones and bread had to be hand blended.This mixing bowl is very significant to the Kiewa Valley andrural regions because it details not only what kitchens, be they commercial, domestic or rural camp, required to be stocked with but also a period in time when electrical goods such as blenders were not on in production and electricity was not available.This bowl is made from steel and has a green enamel covering. The rim of the bowl has a black border to highlight its edge.nilmixing bowl, kitchen -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, early to mid 1900's

This cast iron kitchen appliance was made in England in the early 1900's and shipped to the "colony" Australia. This was before World War II and the "growing up" of a colony to an independent member of "the British Commonwealth". It was a period when most appliances (be they household) where manufactured in England and shipped to Australian ports. It was not until the late 1960's that the Asian manufacturing giant woke up and started to dominate the market palce.This domestic kitchen appliance is very significant to the Kiewa Valley because it highlights the "made at home" period when food processing was made "in house" due to inability to source food from specialised shops e.g. the butcher or slaughter houses. It was a period before mass food processing factories were established and roads constructed up to the standard for distribution to semi remote regions such as Kiewa Valley was in the beginning of the 1900's.This cast iron (malleable iron) mincer for meat products has a large "funnel" to direct "chunks" of meat to the grinding "wheels". These "star" shaped wheels with "teeth" of three different cutting surfaces (fine, medium and coarse) provide for texture types of the final meat product. The meat is placed into the "loading" funnel and push downwards(gravity feed) through the mincing chamber and out through the front side. There is a long "screw worm" which is rotated by turning the handle. The appliance is table mounted by a vice "G" screw on clamp (hand operated). "BEATRICE No. 3" and "MADE IN ENGLAND", "P 3181"household cast iron appliances, food processors -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBiscuit Forcers, c1906

Ada Higginson owned the biscuit forcers.Historical: Ada Higginson and her family are pioneers of the Kiewa Valley.Large: Solid cylinder wooden roller with 1 end a wooden knob glued on and other end flat. The metal hollow cylinder fits over the wooden cylinder and has a screw cap with a hole and rim at the flat end. (This enables the disc to fit in while the food is forced through by the wooden cylinder.) There are 6 decorator, metal discs each with a different hollow pattern in the middle. This plunger has a pointy nozzle that can be attached by screwing on. Small: the same but with 7 decorator discs. Both metal cylinders have a cap at the flat end with 2 clips to hold it on, but move when you screw the cap off.The small one has a handle that is part of the cylinder but its knob looks as though it has fallen off. Old Cigar Box: 13 Discs inside and a folded yellow paper with recipes - Gingernuts & Sagasco Biscuits, in brown print.Simpson's / "Pirie", "Universal" & "Enterprise" / Biscuit Forcers domestic, cooking, biscuits, decorating, baking, icing, ada higginson -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFood Cover

... domestic storage handmade item Metal pale yellow enamel food cover ...Food covers were used to cover food from insects.Metal pale yellow enamel food cover with black handle on top. Oval shape is slightly higher in the middle. The edges are a metal 'netting'. The top has a join line. The edge has a join line at each end. The base is curved with a metal piece around the edge to make it smooth (for safety).food, kitchen, domestic, storage, handmade item -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Invalid Cup, Ceramic Invalid Cup, Circa early 20th century

Invalid feeding cups were common in Victorian and early 20th century. They were ideal for patients and the infirm to be able to drink food, soups and broths while propped up slightly in bedCommon item which could be purchased at the chemist and was well suited to its purpose.Small white china cup with spout and partially covered top.Made in England stamp on base.cup, ceramic -

Orbost & District Historical Society

Orbost & District Historical Societyfood cover, late 19th - early 20th century

... food-storage domestic kitchen... insects. This food cover is a simple shape and would be a domestic ...Food covers were used to cover food and protect it from insects. This food cover is a simple shape and would be a domestic utensil.This food cover is an example of a simple kitchen item used in the late 19th-mid 20th century.Small black metal meat cover with small handle.food-storage domestic kitchen -

Orbost & District Historical Society

Orbost & District Historical SocietyBread maker, Landers Frary and Clark, Early 20th century

... bread domestic-appliance bread-maker food-technology bakery... at bread-making. bread domestic-appliance bread-maker food ...Bread machines were made for quite a long time from the 1890's on. They came in different heights and capacities. The advertisements at the time stated that making bread with their machine was superior to hand kneading, This item is good example of a domestic appliance used when most foods were home-made. Access to commercial bread was limited in rural areas and housewives became skilled at bread-making.Metal bucket with lid. Lid has hole in centre through which a handle for turning the dough hook comes. Grey rusty coloured.Put in all liquids first, then flour, turn 3 minutes, raise in pail. After raising, turn until dough forms a ball. Take off cross piece, lift out dough with kneader.bread domestic-appliance bread-maker food-technology bakery -

Orbost & District Historical Society

Orbost & District Historical Societyraisin stoner, late 19th century

This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesA cast iron raisin stoner with a clamp. It has a wooden handle on a turning arm.On arm-PAT.APP. Aug 20.95 Oct 5-97 On one side- WET THE RAISINS On other side-ENTERPRISE M.F.C. PHILADELPHIA. P.A. U.S.A. On chute- No. 38raisin-stoner food-preparation -

Orbost & District Historical Society

Orbost & District Historical Societyglass rolling pin, 1930's

Starting in the 18th century, glassworks in English port towns like Bristol, London, Sunderland, and Newcastle began producing hollow glass rolling pins. They were originally produced for sailors to give to loved ones, particularly young women they were hoping to woo for marriage. Plain, clear glass rolling pins became a common kitchen item in the first half of the 20th century as they were seen to be more easily cleaned that wooden ones.This item is an example of a once commonly used kitchen item.A moulded clear glass cylinder rolling pin with glass handles at each end. It is hollow and can be filled with cold or warm water to better roll a preferred food. There is no stopper at one end. It is marked with M at one end (probably indicating size).one one end - Mdomestic kitchen glass rolling-pin, -

Orbost & District Historical Society

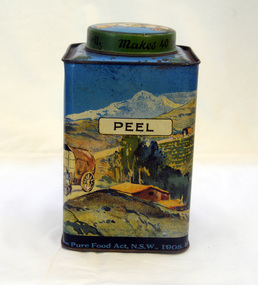

Orbost & District Historical Societytea caddy, First half 20th century

This container is part of a collection of retail packaging, domestic goods, tinplate, made for Bushells, Australia, 1908-1940 In the mid-nineteenth century custom branded tins developed as a tasteful form of advertising. They were often cheap and decorative and found their way into households as gifts, often being kept as ornaments and storage boxes.They have survived well in many homes. This tea caddy is an example of an Australian branded item used in local households. Rectangular metal storage tin printed with scenery of a tea plantation, hills, women carrying baskets and carts. At the top of the front face is the word 'PEEL'. A small cylindrical lid fits on a short neck on the top. Printed around the lid and base is information about Bushells.lid: "Bushells makes 40 more cups to the pound. On bottom: "Net 1lb wt; No.144 - guaranteed under the Pure Food Act; NSW; 1908 by Bushells , Ltd, No.144" -

Orbost & District Historical Society

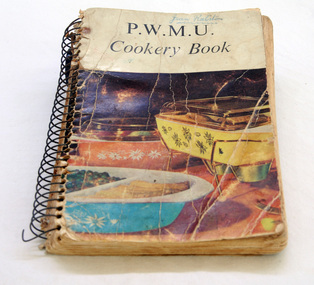

Orbost & District Historical Societybook, P.W.M.U Cookery Book, 1962

This copy was used by Jean Ralston (nee Cameron) of Orbost. She was married to Jack Ralston. John Gavin Ralston was born 26 July 1914 at Eden, N.S.W. and came to Orbost in the early 1920's, with his parents and siblings. They lived at the corner of Tennyson and Salisbury Streets. Jack was educated at Orbost Higher Elementary School before being apprenticed to William Ross at the Snowy River Mail as a lino-type operator. He married Jean Cameron. After WW11 when he served overseas in the islands) He resumed his trade at the Snowy River Mail until 1949 when began J.G.& J.M. Ralston, Seed & Produce Merchants. Jack Ralston was very involved in the Orbost sporting community, the Presbyterian Church and the Orbost Municipal Band. He also served in the Orbost sub-branch of the R.S.L. He died on April 15 1967. (ref. Margaret Smith O.D.H.S. Newsletter) This item reflects community affiliation with the Presbyterian Church as well as being a popular domestic reference item for many households. A cardboard covered spiral bound recipe book with a colourful cover - photographs of prepared food. Above the photos is the title, "P.W.M.U. Cookery Book" in black print.front cover: Jean Ralston handwritten in blue pen Inside back several recipes have been handwritten.cookery recipes book-cookery p.w.m.u. -

Orbost & District Historical Society

Orbost & District Historical SocietyCoolgardie safe, first half 20th century

... food-storage coolgardie-safe domestic... available for domestic use. food-storage coolgardie-safe domestic ...Without refrigeration, storage of meat was difficult. Flies were a problem, and it was important to keep meat cool and out of the way of pests. One way of doing this was to use a meat safe: a kind of cupboard designed to store meat and keep it fresh enough to eat. Meat safes are ventilated. They were sometimes made with sides of wire mesh or perforated metal, so that air could circulate around the meat while keeping flies and other animals out.The Coolgardie safe was invented in the late 1890s by Arthur Patrick McCormick, who used the same principle as explorers and travelers in the Outback used to cool their canvas water bags Originally they were handmade using materials to hand. In the early 20th century, Coolgardie Safes were manufactured commercially across Australia, and found their way into homes in both rural and urban areas. These safes incorporated shelving and a door, had metal or wooden frames and Hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (refs ABC-Home; Museum Victoria)The Coolgardie safe was an Australian invention used especially in country areas from the 1890s until the mid 20th century. It began to be replaced by ice chests from the turn of the twentieth century in cities and country towns which had ice works. This item is an example of a domestic appliance commonly used before electricity was widely available for domestic use.A cube-shaped metal Coolgardie safe painted blue. It has a triangular hook on the top for hanging or lifting. There are small feet at bottom . The sides are perforated in a Above the door; Inside a rhomboid shape "WILLOW"food-storage coolgardie-safe domestic -

Orbost & District Historical Society

Orbost & District Historical Societymincer, 1890's

This item was used by Helena Warren (nee McKeown), a well known photographer and local press correspondent. She lived at Newmerella. The meat mincer was a particularly popular kitchen gadget. By means of the mincer left overs and off cuts could be transformed into shepherd's pie or mince steak. Gadgets like this Universal food chopper are typical of domestic inventions designed to reinforce the principles of thrift and labour-saving. Many of these gadgets were imported from the United States. A cast iron metal hand mincer with a long metal body with an opening at one end, inside which is a circular spiral blade and a screw clamp attachment at the other end. On one side of the mincer is a curved metal handle held in place by a metal nut and a wooden bulb shaped knob at the end. There is a metal circular webbed blade held in place by a metal nut and bolt."Universal No. 2 brand; L.F. & C., New Britain, Conn., U.S.A."mincer chopper food-preparation -

Cheese World Museum

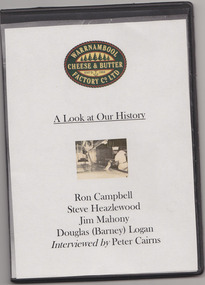

Cheese World MuseumDVD, A Look at our History -Vol.2, 2005

Series of interviews with former employees of Kraft (Allansford) and directors of Warrnambool Cheese and Butter Factory discussing their time and experiences as employees and directors of the factories. Warrnambool Cheese and Butter Company Ltd was established in 1888 and in 1935 developed a relationship with Kraft Foods Australia whereby Kraft leased premises from WCB. The two companies shared the milk collected to make their core products of cheese (Kraft) and butter and milk for domestic use (WCB). This arrangement continued until 1997.Gold DVD in plastic case, B&W cover with colour WCB logo.A Look at our History: Ron Campbell, Steve Heazlewood, Jim Mahony, DJ (Barney) Loganallansford, heazlewood, steve, campbell, ron, mahony, jim, logan, dj (barney), wcb, warrnambool cheese and butter factory company ltd, kraft foods ltd, dairy industry, dairy processors, factories, local history, cairns, peter, cheese manufacture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Landers, Frary & Clark , 1897-2000

... attachment. Domestic object Food Mincer Landers, Frary & Clark ...Landers, Frary & Clark were a housewares company based in New Britain, Connecticut. It operated from 1865 until its assets were sold to the General Electric company in 1965. They manufactured a wide variety of products over the years, including stainless steel bull-nose rings and electric ranges, kitchen scales and vacuum bottles, window hardware and ice skates, mouse traps and percolators, can openers, corkscrews, cutlery, straight razors, aluminium cookware, and thousands of other products. Many of these items were marketed under the brand Universal. Some of the non-electric kitchenware assets were acquired from G.E. in 1984 by Universal Housewares, Inc./Universal Trading, Inc., who still market "Universal" meat grinders and coffee mills.An early domestic item its function was for use in the home kitchen that's the original patented design from 1897 is still being produced today under its brand name of Universal by Universal Trading Inc USA.Food mincer cast iron with wooden handle & thumbscrew for bench attachment.Marked "No. 2 Universal".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, mincer, food mincer, universal brand, kitchen appliance, food grinder, lander frary & clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pot Set

This set of pots represents the type of pot or saucepan used on an open range wood fired stove. The pots are heavy and thick, and have a solid lid suitable for slow cooking.This pot set is currently not associated with a historical event, person or place at this time and is being used to augment Flagstaff's village display.Pots; two cast iron pots with lids. Wooden handles on pots have ring on end for hanging. Pots have inscriptions. The large post has the capacity of 3 quart (3 quarts or 2.84 litres) and the small pot holds a capacity of 2qt (2 quart or 1.89 litres). Stamped on large pot "Made in Taiwan" "3qt" Stamped on small pot "Taiwan" and "Sauce Pan 2qt"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pot, saucepan, sauce pan, cooking pots, cook ware, food, slow cooking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, 1890-1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s.Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Brown salt glaze stoneware bottle None (possibly made by Royal Doulton UK)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, flagstaff hill maritime village, great ocean road, bottle, stoneware bottle, storage, kitchen ware, salt glazed, stoneware, shipwreck coast -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1900 - 1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s.Item's significance and origin of manufacture is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past. Stoneware jug badly cracked and repaired with handle and short neckNoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, earthenware jug, kitchen storage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1920-1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthenwares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s. Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Brown Stoneware jug with short neckThe number "1" under neck flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, salt glaze -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGlue Pot, T & C Clark, Late 19th Century

T. & C. Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enameled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councillor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enameled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enameled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enameled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.An item that was made by a British foundry that was a pioneer and innervated many new processes in the manufacture of enamel ware, producing many items for every day use.Glue pot with inner pot, metal, corroded, both pots have handles."T & C CLARK & Co Ltd, ENGLAND, 55279 RD" and "FIRST QUALITY No. 4/0"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t& c clarke, cast iron, foundry, sanitary ware, ironware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Enterprise Manufacturing Company, circa 1911

... by Silex Co. A mass produced early domestic item made for home food ...This particular food mincer was manufactured by Enterprise Manufacturing Company. Located in Philadelphia, this company specialized in making hardware products. The company was especially known for its cherry pitters, apple peelers, and coffee mills. The company was founded in 1864 and was located on the corner of Dauphin, 3rd, and American Streets. Enterprise Manufacturing Co. remained in business until 1956 when it was bought by Silex Co.A mass produced early domestic item made for home food preparation this item's first patent design was approved in 1897. Manufactured by a well known company in the USA the "Enterprise Manufacturing Company” up until 1956. They specialised in making kitchen appliances of various types for domestic use and for export. Food mincers of the subject items design are still being produced today under the brand name of "Universal" made by Universal Trading Inc USA.Food mincer, metal, clamp on bench style, with rotating wooden handle. Inscriptions stamped on metal.Marked "Enterprise tinned Meat Chopper" "No. 10" "Enterprise MF'G Co. PHILA. USA" "PAT. JAN.30.83" flagstaff hill, warrnambool, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mincer, food mincer, meat mincer, food preparation, kitchen utensil, domestic object, enterprise manufacturing company, kitchen appliance