Showing 574 items matching "small tools"

-

Mont De Lancey

Mont De LanceyPeg Tool

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

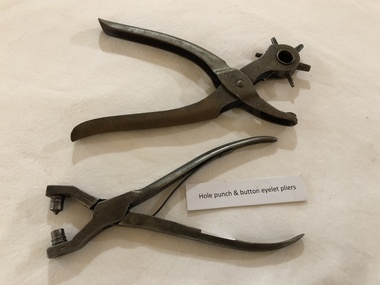

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

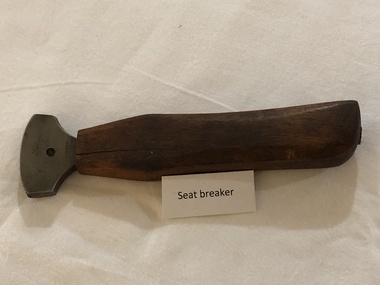

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

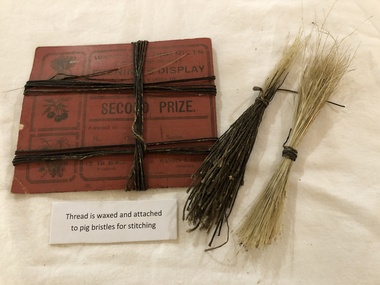

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Mont De Lancey

Mont De LanceyGrease Gun, Tecalemit

Brass Grease Gun with removable filling nozzle.Tecalemit. Made in England. 2 small circular patterns.tools -

Bacchus Marsh & District Historical Society

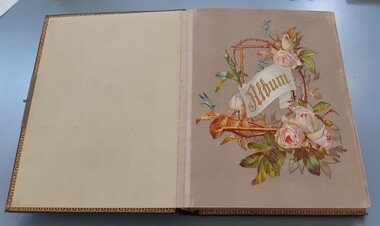

Bacchus Marsh & District Historical SocietyAlbum, Jeremeas Family Album of Photographs of Bacchus Marsh and District in 1883 by Stevenson and McNicoll

In late 1883 the Melbourne based photographers Stevenson and McNicoll visited the Bacchus Marsh township and nearby districts. They are known to have been visiting the town in September 1883 and by November 1883 they were reported to have moved on to Myrniong and Ballan. During their visit they took numerous photographs. The images produced comprise scenes of shops and businesses in Bacchus Marsh, public buildings like the Court House and Bacchus Marsh Primary School, houses and their owners and several broader views of streets. The photos were then offered for sale. Photography businesses also sold albums for purchasers to display their photos.A unique and comprehensive set of images of people and places in the Bacchus Marsh town and district at a particular period in time, September-November 1883. This album of "carte de visites" photographs presents a rare compilation of the work of the Stevenson and McNicoll photography business. This team of photographers are known to have made several visits to towns and districts in the rural areas of Victoria and southern New South Wales in the 1880s and this album represents a very rare example of their non-portrait photography. The album is an example of the Victorian middle-class fashion to display family photographs for themselves and their visitors. These albums were often very expensive and in themselves evidence of the affluence of the family. They were made possible by the popularisation of photography as a social medium and were a forerunner of the coffee-table book. Medium sized leather-bound album, brown, front cover engraved with gold tooling in a starburst pattern. Pages are gold-lined. The inside front and end covers are in pale blue silk embossed with a gold floral pattern. The metal locking clasp is broken. The front page has a floral wreath of roses and forget-me-nots and a dragon-fly. The word "Album" is in the centre of the wreath, printed in gold in Gothic print. There are nine pages with pockets for four 65mm x 105mm sized "carte de visites" style photographs. Several feature pages have a single pocket for a larger photograph, or double pockets, possibly designed for family portraits. These portrait pages are also decorated with floral wreaths and insects, reflecting the theme of the frontispiece page. The smaller photos in the album were taken by the Melbourne photographers Stevenson and McNicoll, There are 48 of these smaller images. The images were created around September 1883 when photographers for Stevenson and McNicoll are known to have visited Bacchus Marsh and district. The images comprise scenes of shops and businesses in Bacchus Marsh, public buildings like the Court House and Bacchus Marsh Primary School, houses with their owners and several broader views of streets. References to various photos being created and being available for sale are mentioned in the Bacchus Marsh Express newspaper during September to November 1883. Each smaller photo has printed on the verso: Light & Truth. Copies of this Portrait can be had at any time by sending the Name and Post Office Money Order or Stamps for the amount of order to Stevenson & McNicoll, late Benson & McNicoll, Photographers. 108 Elizabeth Street, Melbourne.bacchus marsh vic. history, streetscapes, shops bacchus marsh vic., roads and streets bacchus marsh vic., stevenson and mcnicoll photographers, stevenson and mcnicoll 1883 photographs of bacchus marsh and district -

Mont De Lancey

Mont De LanceyTool - Blacksmith Tongs, Unknown

... tools Furnace tongs Tools A pair of small vintage handmade ...A pair of small vintage handmade blacksmith tongs with two handles called reins, which are riveted together to form a hinge joint for the flat edged tongs. The blacksmith opens and closes the tongs using the handles. They are made of flat mild steel. They were used for holding steel in position and turning it over during forging operations.blacksmithing tools, forging tools, metalworking tools, furnace tongs, tools -

Mont De Lancey

Mont De LanceyDomestic object - Mincer, Loveload, Unknown

A meat grinder or mincer was used for mincing or fine chopping of raw or cooked meat, fish, vegetables or similar food. It replaced tools like a mincing knife.A small vintage cast iron mincer with a wooden handle attached to the long cast iron handle. It can be screwed to a table or bench, secured tightly by a two pronged claws. It has a white enamel coated funnel at the top for the meat to be pushed into the mechanism which when the handle is turned operates the inner mechanism which forces the minced meat out through a side opening. The cast iron handle is curved.'Loveload London 1'domestic objects, kitchen equipment, cooking equipment, meat grinders, meat mincers -

Mont De Lancey

Mont De LanceyDomestic object - French Fry Cutter, Nutbrown Products

Since 1932 Nutbrown has been producing crafted kitchen products which were a staple in British homes. Nutbrown continues to be in production today.A vintage manual metal and plastic Chipper and French Fry Cutter with two blue turned wooden handles each side which are attached to folding crossed metal supports joined to a square frame. The frame has 36 small squares with sharp blades on the edges to cut the potatoes A yellow coloured plastic support with raised squares under the cutter holds the potato in place. This is screwed to the metal base. There are pieces of cardboard from the original packaging explaining the use.Underneath the yellow support is stamped: ' A Nutbrown Product Patented Made in England Registered design'.domestic objects, kitchen appliances, kitchen tools, vegetable cutters -

Trafalgar Holden Museum

Trafalgar Holden MuseumTool - Steel stitching shears

Scissors used for embroidery and removing small stitchesAs used and sold by Holden and Frost Ca1900Small steel embroidery and cutting scissorsscissors, embroidery -

Kilmore Historical Society

Kilmore Historical SocietyTool - Divided shoe last, Wooden shoe last, April2002

Pale coloured vanished wooden shoe last with metal hinge at the heel end. Hollowed inside with nail at the toe to join both sides. Large hole through both sides below the arch. 5 smaller holes on both sides from toe to instep9 stamped on left side 10 stamped on right side between arch and toe -

Kilmore Historical Society

Kilmore Historical SocietyTool - Wooden shoe last extensions, Pair of wooden shoe last extensions

Pale wooden shoe last extensions with metal rings attached at the top. small locating holes on both sides of each. Locating grooves on each.L and R stamped on side. 10/3 written in lead pencil on inside -

Kilmore Historical Society

Kilmore Historical SocietyTool - Shoe Last, Cast iron shoe last

Pointed toe, instep slide, instep groove on foot space, general dust and grime.6/DD on toe2 cast hole on out foot, 2 cast holes on sole, various small cast faults -

Kilmore Historical Society

Kilmore Historical SocietyTool - Shoe last, Cast iron shoe last, UK

Small foot shoe last with instep slide and groove in foot space. piece missing in cast in instep slide in foot space. 2cast holes on sole. dirty and dusty12 cast on toe -

Parks Victoria - Andersons Mill

Parks Victoria - Andersons MillTool - Pattern, wooden

It is unknown what this item was a pattern for.One flat piece of rectangular wood with a hole on the top - center and two nails, one at the top left corner, one at the bottom - RH corner. A second piece of wood is attached on top of the first; it is smaller in width and split exactly in two. There is a design cut out of second piece in shape of a pear. Bulbous part of design is centered around a hole in the first piece of wood. Three nails protrude from the second piece of wood. Three nails in the second piece of wood are located; one in each section of the more bulbous end of cut-out, & third on one section of the smaller end of cut-out. Hole on bottom of wood does not go all of the way through.