Showing 526 items matching "use of machinery"

-

Vision Australia

Vision AustraliaDocument - Image, 1934 - 1954 - 50 Years of Talking Book Service, 1984

The Talking Book Library of the Royal Victorian Institute for the Blind is celebrating its 50th anniversary during 1984. This service began in 1934 with 78 rpm records. These were later superceded by 33rpm records which remained in use until 1960. The first cassettes were imported from England and weighed 7 lb. along with the player which weighed 28 lb. These 18 track cassettes usually contained one whole book. In the early 1970's a change was made to smaller cassettes containing 12 hours of recorded material on 6 tracks. The latest system currently being introduced is the Library of Congress 4 Track System utilising cassettes which play for 6 hours and machinery which is adaptable to the conventional 2 track system cassette. The Talking Book Library today provides services to 2500 readers as opposed to only 500 in 1964. The service is free of charge to anyone who is visually handicapped and includes talking books, talking book machines, mail service, servicing of machines at regular intervals and any modifications that may be required. Over 1600 cassettes are handled daily. The library currently holds over 3500 individual titles. Catalogues are available in print, audio and braille format. Once selection is made, borrowers may receive at least 3 books at any one time. Other services include current magazines, foreign language books, newspapers and magazines and regional country newspapers. Many books are recorded at the R.V.I.B. by our volunteer readers while others are bought from similar agencies in Australia and overseas. The department of the R.V.I.B. relies almost entirely on voluntary donations from the public. Other services provided by the Royal Victorian Institute for the Blind Community Resources Section, Aids & Equipment Shop, Tertiary Resource Service, Industrial Department, Retired Personnel Allowance, Children's Services, Social Services, Housing Loans, Vocational Development1 digital image of typewritten pageroyal victorian institute for the blind, talking books -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPoster - Black and white and colour prints, Information Branch Victorian Department of Agriculture, Field Machinery

Collection of photographs pasted on cardboard. (1) Students ? (2) Student on a ride-on grass cutter near Luffmann Ponds labelled, "Photograph by Information Branch Victorian Department of Agriculture Ref. No 1981 (914-43)." (3) Student on ? In Field Station. (4) Students using lawn mower and whipper snipper near Engineering Building. "VCAH" on reverse. (5) Student on ride-on grass cutter on Oak Lawn. Found in Fred Taylor's office, former mechanic. In 2015.students, grass cutter, luffmann ponds, field station, lawn mower, whipper snipper, engineering building, vcah, oak lawn -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesAlbum - 35mm Colour slides, Tree Root Barriers

21 slides labelled "Tree Root Barriers" showing equipment used.tree root barriers, equipment, arboriculture, machinery -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesSlide - 35mm Colour slides, Students Working Outside, 1985-1986

3 slides of a brown patch in lawn Apr 85. 1 of plant climbing against a building Administration Building. 14 of students using equipment and renovating a garden bed Cypress Bed? Jun 86. 2 labelled "PM" Peter May.students, renovation, peter may, equipment, burnley gardens, cypress bed, lawn damage, students working with machinery, students working in engineering -

Tarnagulla History Archive

Tarnagulla History ArchiveTwo sections of Flat Wire Rope used in Tarnagulla mines c.1886

David Gordon Collection. These are an interested relic from the 1880s when the Prince of Wales and Old Poverty Company converted their winding machinery from flat wire rope to round wire rope. The old rope of some hundreds of metres in length was simply dragged clear of the mine and discarded in the surrounding bushland. This style of rope succeeded the old Indian hemp flat rope, and was in turn superseded by the round wire rope. These segments are most instructive and quite rare relics. The smaller segment measures approximately 40 x 10cm. The longer segment measures approximately 96 by 10cm -

Melton City Libraries

Melton City LibrariesPhotograph, Edna Barrie, 1920, 1924, 1933 and 1940

SUMMARY - Edna (Myers) Barrie, 1918 – 2018, Profile Early Life Edna was born at Melton and delivered by Hannah Watts. Her mother Martha walked in the dark at night with her basket under her arm to the bridge over the Toolern Creek Bridge and into Sherwin Street to the corner of Yuille Street to Hannah’s house Lynch Cottage. Martha’s husband was away shearing and eventually heard the news of the birth of their blue eyed third child and second daughter. She was born into a family that was surrounded by music; her father played the “squeeze box” and mother the mouth organ. From an early age the family were aware of the great composers, a framed picture of Beethoven, Chopin, Schubert and Wagner hung above the door to the lounge room of their 4 roomed cottage, the room where the piano stood. Her life on stage started as a singer aged 6 years at the Melton Mechanics Institute Hall. Edna was born with a natural ear for music learning piano and singing from her older sister Marjorie who became an accomplished pianist and soloist and renowned music teacher in Melton and district. In the 1920s and 1930s concerts at the Melton Mechanics Institute were regular events were the local talent was fostered. The Myers children, like other children of Melton and Rockbank, studied singing, piano and elocution, sat examinations, entered in competitions in South Street Ballarat, Footscray and Melbourne. In 1929 a Sacred Concert was broadcast by 3AR from the Hall as part of the Back to Melton Celebrations. Marjorie Myers performed two of the items on the piano. Edna attended Melton State School 430 from 1924 – 1933. Her father Fred had also attended the same school. In 1924 the School staged Cinderella at the Melton Mechanics Institute Hall with a cast of 33 students. After completing her education a Melton she boarded in South Melbourne and attending Melbourne Girls High School (MacRobertson Girls High School), a school which recognized her musical attributes. She travelled home on the train on the weekends, sometimes getting off at Rockbank to save a few pennies in fares. Working life The early 1930s the Depression was a difficult time for a young woman to find work. Jobs were often menial and given to the youngest and therefore cheapest applicant. She worked as sales assistant at Polonskis and Myer in the city, and Irvines Modes in Footscray. Working to 1pm on Saturday, and when held up by a customer meant missing the train home. While at Myer Department store she lived at home and rode her bike to the Melton railway station. On one occasion she had a nasty fall when a part of her bicycle came loose causing the bike to crash rendering her concussed and injuring her nose. During the 1930s she was given a camera “a little snap” by Mrs Kelly her landlady. This began her interest in photography documenting family life at their “Burnbank” home. Musically, while at Myers she participated in annual performances held at The Kings Hall and the Myer Mural Hall. Working in the basement at Myers she was often embarrassed when her name was called, customers assuming she belonged to the Myer Family. Ken Myer worked in the basement at the same time handling the ‘Wheeler’, a wicker basket used for moving goods around the store. The family philosophy was for the children to start at the bottom and work their way up. Social life Social life in her teenage years was connected also with Scots Presbyterian Church. She attended Sunday School classes and received book prizes for attendance. She loved to read and welcomed the times when she received new book. She took part in the Sunday School Anniversaries and was presented with a Bible from the Superintendent, Henry Robinson for her assistance with the music. Marriage and War years In 1941 Edna married Ernest “Bonnie” Barrie. War in the Pacific was soon to break out. While in Sydney on their honeymoon they met up with Jim Barrie who was on his way to Canada via Hawaii just missing Pearl Harbour by two days. Jim became a Spitfire Pilot and joined the RAF and was based in England. He returned to Australia later in RAAF to fight the Japanese off the coast of New Guinea. The three eldest Barrie brothers were farmers and food producers and were thus except from military service. Edna and Bon were members of the VAOC- Volunteer Air Observers Corp entailing being rostered on duty as plane spotters. The women took shifts during the day and the men at night which involved staying overnight in the Shire Offices. Later the spotting tower was built in the plantation opposite the Post Office. Edna and Bon carried on with this from their home in Ferris Rd when the threat of invasion had ceased Community life Community life in Melton revolved around fund raising events for the Melton Mechanics Institute for the War effort and keeping up with maintenance for the Hall. In 1944 the Minister for Health gave approval for the Shire of Melton to open and Infant Welfare Centre inviting Edna to form part of the Committee with seven other women. In 1948 she was President of Melton Branch of the Victorian Health Centres Association. She volunteered this use of her car driving the person in charge, Sister Smith to visit mothers and their babies. In 1963, along with Betty Jones and Isabel Snell, Edna was instrumental in forming the 1st Melton Cub Pack and later supported the formation of the 1st Melton Scouts. During 1963 – 1968 she completed the Australian Boy Scout Association Cub Pack Preliminary Training and achieved her Wood Badge. Country Women’s Association In 1944-1996 she was a member of the Melton Branch Country Women’s Association (CWA), Melton Branch, Secretary of the Branch in 1945 – 1946 and Branch International Secretary 1970-1971. She worked with choir, music and drama interest groups within the branch attaining both first and second place in 1959, second place in 1952 Exhibition and second in Music in 1960 in the state. She was involved in their handicraft craft events, fund raising and musical events and singing competitions. During the 1950s she trained Trios and Quartets in part singing for the CWA competitions in Ballarat and Melbourne. It was at this time that she developed her skill as a conductor and trainer of choirs. She later auditioned for the Victorian Choir for alto parts believing she would stand a better chance of being chosen, because of her ability to sing in natural harmony. In 1962 she participated in the Tenth Australian Country Women of the World (ACWW) Triennial Conference “Australia Presents: CWA Massed Choir” in the Melbourne Town Hall. This event was recorded by Super Sound Spotlight on 45 extended play vinyl record. The songs were Australian music and words, for example The Silver Stars are in the Sky, The Graceful Swaying Wattle and Kookaburra. Edna continued with her interest in the Victorian Choir regularly meeting at the CWA Headquarters in Toorak for rehearsals. In 1974 she took part in the Australian Choir at the fourteenth Triennial conference of the ACWW Interfaith Service held at the Perth Concert Hall on the 13th of October. Arts and Culture Edna was also in the Choir of 3KZ Carols by Candlelight at the Myer Music Bowl in 1963 and 1964. Melton Choral Society. Edna was Director and Conductor in the 1970s performing at many community events such as Carols by Candle Light, Church Services, Easter and Palm Sunday services, Mothers Union and the 1976 Community Services Week Combined Church Service. The October – November 1978 Program covered the following: songs from the Musicals, Choral and Solo with Narratives, Guest Instrumental Item, Recitation Negro Spirituals and Australian Songs. Her involvement with church choirs included the Scots Presbyterian Church Choir Easter and Christmas performances and the 1967 Centenary Service. In 1980s the Melton Uniting Church Sacred Music Performances included The Crucifixion by Stainer, The Olivet to Calvary and other church Hymns. Edna was Musical Director of the Melton Amateur Theatrical Society and worked on performances in collaboration with Mabel Rogers on script and musical interpretation. Melton and District Historical Society Annual Art and Craft Show. First held in Melton Mechanics Institute Hall in 1973, it later took place in the in the Melton Community Hall. The Art Show was also run in conjunction with other community organizations such as Rotary and Girl Guides. Community history and research Melton streetscape and society Over 20 years commencing in the 1970s, Edna undertook extensive photographing of the changing streetscape of Melton’s High Street. She anticipated the impact of change on the community during the time of Melton’s rapid transition from a small farming district to a large urban community and this led to her extensively document and photograph many of the structures and landscape features of the township that have since been lost. She also meticulously recorded much of the contemporary life of the town and has left a significant legacy of archival material. Melton State School 100 Years Celebration, October 1970 Co-author with Mabel Rogers “The First 100 Years, 1870 – 1970” Assembled a collection of School Class Photograph and identified and compiled lists of names for future school history. She also assembled a photographic display for the 125th anniversary in 1995. Melton and District Historical Society (M&DHS) Foundation Member, 1968 Held President and Secretary positions from its inception Research associated with the classification of Heritage buildings Christ Church Classification C Scots’ Presbyterian Church Classification D Set up the storage and Catalogue system in the Office at the Willows Organised society visits to Heritage sites in and beyond the Shire of Melton, including Stathtulloh, Eynesbury, Deanside, ToolernVale sites including Merrywood (now demolished) Staughton Vale, Chirnside, Point Cook, Shwerkolts Cottage. 1970 – 1983 Melton and District Historical Society Letterhead. Staughton Memorial Light from early newspaper cutting in its location before restoration to present location. Sketch by Wendy Barrie. Designing and printing pamphlets, stationery, and other sale items with Willows title. M&DHS street naming research for new housing developments (1970 – 2000). Collaborated with Mary Tolhurst to research the names of early landowners and pioneer families connected to the first settlers. Researched Aboriginal names for inclusion on lists submitted to developers. An early example is the naming of Kuranjang and the street names associated with the McPherson family. Plains of Promise (Shire of Melton history) by Joan Starr (1985). Edna assisted with Historical Society materials and contributed her own research and photographs. Contacted and organised for Hubert Opperman to launch the book. (She was also present at his last bike ride at Rochester in 1995.) Western Metropolitan Groups of Historical Societies. Member attending meetings and representing Melton, also hosted the Group at Melton The Willows Member of the Committee of Management for the restoration of the “Willows” house the establishment of The Willows Park 1982 March - Official Opening of the Willows Park- Preparation and planning for the event. Involved in the collecting of items in the furnishing of the display rooms in the Willows house. Donated items and furniture from the Myers and Daley family houses. (19th century) Machinery Shed Establishment. Involved with Jeff Robinson in the construction and collection of machinery display Other significant sites Championed and participated in the restoration and preservation significant sites in Melton, including: restoration of the Staughton Memorial Light and its return to its present site restoration of the Pykes Grave (using EW Barrie earthmoving equipment) restoration and reconstruction of Dunvegan restoration and reconstruction of Macs Cottage, the management and Caretakers residence Melton State School War Memorial Gates removed from Unitt Street entrance and relocated to the Willows Park Donated the Barrie family single furrow plough which was standing at the Court House Plaza. It removed and to Council Depot and later missing. The plaque was taken to the Willows. Jimmy Melrose (aviator) cairn restoration at crash site in Melton South Donald Mackintosh (Olympic gold medallist marksman) grave site at the Melton Cemetery (Historical items held by the Myers family collection.) Houdini first flight at Diggers Rest. Edna’s father was shearing at Diggers Rest at the time and witnessed the flight. She attended the 90 year anniversary of the event at the site in 2000. Radio and electronics Edna’s husband Bon interest in wireless communication dates in the 1920s with the building of a crystal set in the early days of public broadcasting. At the Back to Melton Celebrations in 1929, 3AR broadcast a concert from the Melton Mechanics Institute on the 20th February at 8pm featuring Footscray City Band, James Hill baritone, Vera Carew Soprano, James Foran Tenor, Marjorie Myers Piano, and James Williamson Entertainer. Accompanists: Miss Agnes Ross and Mrs James Hill. The Myers children had recordings of their piano playing made onto the aluminium records, Martha Myers’ voice can be heard introducing an item. These were made in a studio in Melbourne. Marjorie was given a upright Gramophone by Donald Mackintosh in recognition of her talent and her contribution to the cultural life of Melton. The family were then able to listen to 78rpm recordings of the famous classical recordings. The turntable was hand wound metal stylus needles had to be regularly replaced. The aluminium disk needed a bamboo needle to prevent damage to the surface. Before electricity was introduced to Melton in 1939 the Mechanics Hall relied on generators to produce electricity. Bon Barrie, being mechanically minded, built a public address system for be used a community functions at the Hall and Recreational Park. By 1939 this was up and running and used for over three decades. A large Collection of 78rpm records provided music for dances, marching, parades and any public event needing music and microphones. The early system was portable and worked on batteries. CFA Radio Communication In the 1950s with the introduction two-way HF and later VHF very high frequency radio sets. Melton Rural Fire Brigade was part of the Bacchus Marsh Group. Radio sets where located in the Melton Fire Truck, and in the house of the Barrie family at Ferris Road. This was an ideal location to observe a 360 degree view in all directions when smoke appeared on the horizon. An antenna was erected beside the house. The set OX 7 was located in the kitchen and monitored 24 hours by the family. When an electrical fire occurred at the junction of the electricity to the house there was time to radio the fire station and summons the men working in the paddocks, thus saving the house from possible destruction. With the introduction of UHF – ultra high frequency Vinten Radios the signal was clearer and static and interference lessened and radio traffic became easier to read, and reduced noise levels in the household. VL3 LY Radio Base became the Group Headquarters was established in 1967. By 1970 the Brigades were: Melton, Rockbank, Sydenham, Toolern Vale, Diggers Rest, Truganina, and Werribee. In 1974 when the family moved to First Avenue, another antenna and a small building were erected adjacent to the residence and used to house the equipment, maps. Radio traffic consisted of regular schedule times and communication with adjoining groups of brigades such as Bacchus Marsh, Mt Macedon and Little River Groups. Many of the brigade and group base radios were situated in private residences and operated primarily by fire fighters wives who held the position of Communications Officer, either registered as a brigade member or informally. Edna was never registered as an operational brigade member but operated informally as an assistant to her husband Bon. She was however a member of the Melton Fire Brigade Ladies Auxiliary from its inception in 1968, a non-operational position. Edna kept up to date with radio procedure following the 1967 handbook; preparing maps, plotting compass points and taking notes on weather forecasts from the SA Border and Western District. Daily notes were taken in anticipation of fire warnings. These log books and daily radio traffic were incidental to the regular radio schedules. Emergency turnouts noted, burning off times and predicted location of smoke. In the summer fire season all TBF (total fire ban days were recorded.) In times of emergency the Barrie family assisted Bon the base radio operator to plot the position and location of fire trucks and to help clarify garbled radio traffic, keep notes and make telephone calls. These log books are held in the EE and EW Family Archive. Melton Uniting Church Edna founded the Church Opportunity with Maisie Robinson in 1975 in the Melton South Methodist Church building. Methodist and Presbyterian Churches of Melton had combined severing their long held connection with Bacchus Marsh. A Manse had been recently built for the Melton Minister. At a Parish Committee meeting at the Melton South Church it was suggested to use the building as an Opportunity Shop. It opened in July 1975, and it raised $1,600 contribution to the church budget in 1976. In 1977 The Uniting Church in Australia was formed and the Melton South Uniting Church Opportunity shop continued to go from strength to strength expanding the buildings providing the welfare needs of the community. Archive Set up by Edna Catalogued items dating from 1857 Minute Book and set ongoing system and storage of items of heritage. Melton Un Awards and recognition of service to the Melton community Rotary Award for Community Service, 1980 Victoria 150th Anniversary Celebrations contributions, 1985 Life Membership of the Melton and District Historical Society (M&DHS), 1989 Extra-Ordinary Contribution for years of service to M&DHS, 1992 Long Service for Exceptional Service MD&HS, 1993 Royal Historical Society of Victoria Award of Merit, 1997 Shire of Melton Certificate of Appreciation for continued support and dedication as a member of MD&HS to the preservation of Melton’s History, 1998 Centenary of Federation Peoplescape (Canberra) Melton Shire nomination, 2001 Uniting Church Melton Life Membership of the Opportunity Shop Uniting Church in Australia Commission for Mission for 30 years of hard work and dedications to the Uniting Church, 2007 Uniting Church Adult Fellowship Certificate appreciation in recognition of valuable support through the “Sammy” Stamp Fund Neighbourhood Watch 5 year award Photographs of Edna at different ageslocal identities -

Melton City Libraries

Melton City LibrariesPhotograph, Peter Barrie, 1963, Unknown

Peter Ernest born Nov 7th 1945. Peter and his brother Robert continued operating the farm on Ferris Road. Peter remembers the horses being used. Robert and Peter worked with their father uncles and cousins until the decline of farming and the impending division of the properties and the encroaching urban development made farming no longer viable. The remaining connection of the Barrie family with property known as Darlingsford finally ceased in 1982. Peter continues to combine a small farm with his earth moving business, known as Melton Plant Hire (MPH) . Peter’s wife Jennie and daughters Deborah and Coralie administer the MPH (Melton Plant Hire) Office, and assist with operation the machinery. Photographs of Peter Barrie from different eraslocal identities, agriculture -

Mont De Lancey

Mont De LanceyTool - Plough Spanner, Unknown

It was made late 19th Century.A long large steel curved handled single headed plough spanner made by a blacksmith. It was used to tighten or loosen large nuts on a plough or other machinery.spanners, wrenches, tools, farm equipment, steel -

Mont De Lancey

Mont De LanceyTool - Plough Spanner, Unknown

... large nuts on a plough or other machinery. It was used... double headed plough spanner made by a blacksmith. It was used ...It was made late 19th Century.A medium sized steel curved handled double headed plough spanner made by a blacksmith. It was used to tighten or loosen large nuts on a plough or other machinery. It was used in the late 19th century.spanners, wrenches, tools, farm equipment, steel -

Mont De Lancey

Mont De LanceyTool - Plough Spanner, Unknown

It was made late 19th Century at the Golden city co. in Bendigo Victoria. It was supplied with Golden City's One Way Disc Cultivator.A steel curved handled double headed plough spanner made by Golden City Co. in Bendigo. It was used to tighten or loosen large nuts on a plough or other machinery in the late 19th Century. spanners, wrenches, tools, farm equipment, steel -

Mont De Lancey

Mont De LanceyTool - Plough Spanner, Unknown

It was made early 20th Century.A steel straight handled plough spanner with one curved head and at the opposite end three decorative different sized and spaced heads. It was used to tighten or loosen large nuts on a plough or other machinery in the early 20th Century. spanners, wrenches, tools, farm equipment, steel -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreCider Press, 1880s

A 'BUCKEYE" grape and cider press, manufactured by P.P. Mast & Co. of Springfield, Ohio, USA and distributed by P. Rohs, Sandhurst (Bendigo). The PP Mast Company was established in 1854. Their Buckeye drills, seeders and other implements played an important role in the development of American farm machinery, being sold in every American state, Europe and Australia. This press was used by the Gaasch family of Harcourt over several generations from 1898 to crush grapes for wine and vinegar making, subsequently to crush apples and then press the pulp to make apple vinegar and cider. The crushing was accompanied by lusty singing of songs and hymns such as 'Ein Feste Burg ist unter Gott'. The press was designed to be hand-operated but was later used by Harcourt Coolstores to press apples. It was then belt-driven by an electric motor. The press was restored (timber cleaned and varnished, metal shoes on base of wooden uprights, which had rotted ) by Mr. Howard Carr, 2001-An early application of mechanics to the crushing of grapes. Hand-driven, geared drive metal crushing parts, with metal flywheel, wooden feed hopper in vertical arrangement, wooden frame, tray and vat, with metal pressing screw installed in heavy metal yoke at front. Metal crushing section carries cast-in maker's name and patent details'BUCKEYE" manufactured by P.P. Mast & Co. of Springfield, Ohio, USA distributed by P. Rohs, Sandhurst (Bendigo). -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Cream Separator

... and dairying machinery used throughout rural areas of Australia ...A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. ALFA-LAVAL SEPARATORS The principal works and head office of Aktiebolaget Separator was established by Gustaf de Laval in Stockholm. The first Laval milk separator was patented in1884. In Australia three old established firms commenced pioneering the Alfa Laval cream separators in about 1885. These were A. W. Sandford & Co. Ltd., in Adelaide, J. Bartram & Son, of Melbourne, who have ever since been the Victorian agents of Aktiebolaget Separator. In New South Wales and Queensland, the pioneering firm was Waugh & Josephson Ltd. J. Bartram & Son, the distributor of the separator in this collection, established their business in Melbourne in 1881. In 1892 Bartram & Son estimated that 1,130 of these machines were operating throughout Victoria. This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is made from cast iron. The cover and vat are made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A name plate featuring the Victorian distributor, J Bartram & Son of Melbourne and a plate outlining patent information are attached to the base by screws.Around edge of wheel "Aktiebolaget Separator Stockholm/ 2236"dairying industry, dairy machinery, milk separators -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Cream Stirrers

These stirring rods with long handles and base referred to as a dasher were common in the dairy industry. They were made to agitate milk or cream in milk cans and were used on dairy farms and in old creameries. They helped to cool the milk and stop it from separating. They were used on the properties of the Conway and Lemke families in Wodonga.These items are significant as they are representative of tools used in the early dairy industry and were owned by families in Wodonga.Milk / cream stirrers made from steel with a circular blade attached to enable milk to flow through.dairy industry wodonga, dairy tools, dairy machinery -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hand operated seed broadcaster

... is representative of agricultural machinery used on a local, national ...Seed broadcaster were used to distribute seed across a small area or to fill in patches where seeding has been missed. This method does not ensure a uniform distribution of seeds unless the person using the machine walks at a very measured pace. It also requires a lot of time and manual labour if used in larger areas. It was most used for planting cover crops, grains, grasses and similar plants that do not need to be in neat rows. The hand-crank broadcast seed spreader was invented in 1868 by Samuel S. Speicher (aka. Spyker) in Indiana, USA. By 1955 new developments included the invention of a seed broadcaster on wheels and these smaller spreaders started to disappear.This item is representative of agricultural machinery used on a local, national and international level in the late 19th and early 20th century.A metal hand seed broadcaster. A hopper at the top was the receptacle for seed. The wheel with a handle on the side when turned drives the cogs attached to an axle. This action rotates the attached spindle with blades to propel seed out the front of the broadcaster. The broadcaster would have had a shoulder strap and a bag of seed would have been added to the hopper and secured with twine through the holes around the top.agricultural tools, farm machinery -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Lister Cream Separator, R.A. Lister & Co. Ltd, c1910

... of domestic and dairying machinery used throughout rural areas ...A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk with a hand operated machine for domestic use. The milk was poured into the bowl on the top and the handle had to then be turned fast enough to get the separator up to speed adequate to separate the cream and the milk. The milk would come out of one spigot and the cream out of the other. In general practice some of the skimmed milk was consumed by the family, while the rest may have been used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. In many cases excess could be bartered or swapped with neighbours for other items of produce. LISTER - A prominent make of separator which became very popular with the dairy farmer, was the "Lister" separator. The early separators sold by R. A. Lister in the 1880's, were made by "Koefoed & Hauberg", Copenhagen. Denmark, called the "Alexandria". Ashton Lister became the sole agent for Koefoed & Hauberg made separators in England and all the English Colonies, throughout the world. Being an enterprising salesman, Ashton, sent his son Edward on a three-year sales tour of Australia & New Zealand in 1890, (hence the strong presence of Lister in Australia.) Initially, the separator was totally manufactured in Denmark and assembled in Dursley, England. By 1892 Lister were making parts at their Victorian Iron Works, and around about the early 1900's, Lister began manufacturing separators in their own right, severing ties with Koefoed & Hauberg. The Lister firm is still going today, under the name of Lister Petter, England, but do not manufacture separators, as the manufacture of farm / domestic separators ceased in the early 1960's.This item is significant as it is representative of domestic and dairying machinery used throughout rural areas of Australia in the early to mid 20th century.The separator is made in 3 sections. The base is metal plated with blue enamel. The vat is made from silver painted tin. There are 2 outlet spouts. The detachable handle, made from cast iron and wood, is held in place by a screw. A metal plate featuring the manufacturer information is attached to the side of the handle. Model CR 15 hand operated table version.On metal plate attached to handle" Lister/ MADE BY R. A. LISTER & Co.LTD. / AT DURSLEY ENGLAND / VICTORIAN AGENTS / GIPPSLAND & NORTHERN CO-OP/ CO. LTD. / MELBOURNE C.1"dairying industry, dairy machinery, milk separators, lister separators -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Fred Rochow Railways Collection - Shunting at Shelley Station, 1961

The Fred Rochow Railways Collection incorporates photos related to the operation of the Wodonga Railway Station including different types of trains and railways staff C. 1930 – 1990. It was donated to the Wodonga Historical Society by Fred Rochow, a railwayman who spent many years based in Wodonga. He joined the Victorian Railways on 17th June l947 and retired in 1988. For some time, he was a member of the Australian Federated Union of Locomotive Enginemen and served a term as a member of the Trades Hall Council. He had an extensive knowledge of the struggles that took place to achieve better conditions for railway workers. Fred worked for many years as a fireman and then worked his way up the ranks to driver, experiencing many changes from the days of steam locomotives through to diesel trains, locomotives and even the modern XPT train. He worked throughout Victoria at different stages of his career, with his final working years focused on the northeast of Victoria and the Albury to Melbourne line. After his retirement, Fred continued to share his love of steam miniature trains with the community. Shelley Railway Station - Shelley was once Victoria's highest railway station, located 781 metres above sea level. The Shelley Railway Station was opened in 1916 and closed in 1979. The railway was used early in its life to transport farmer’s livestock from the Upper Murray to Wodonga. From the 1950s the railway was used heavily to transport equipment and machinery from Wodonga to the Upper Murray to help build the Snowy Mountains Hydro Electric Scheme. The Snowy Hydro Scheme was completed in 1974 and after several years of low level use, the railway was closed. Some remnants of the Shelley Station passenger platform can still be seen today, along with some information boards. The Shelley Railway Station now forms part of the High Country Rail Trail.This collection has local and statewide significance as it captures images of trains, locomotives and personnel who operated the railway services in Wodonga and throughout Northeast Victoria. The railways played a critical role in opening up Victoria and connecting Australia for trade, business, social communication and transport.Left to Right: Fireman Bert Cadman, Driver Wally Riley, Guard Hugh Fraser. Locomotive S300 - the ‘Matthew Flinders’ The S class diesel locomotives were built by Clyde Engineering in 1957 for the Victorian Railways. Designed as premier express passenger diesels, they assumed the ‘S class’ title from a fleet of steam locomotives. They were also given names of famous Australians. The S300 took the name ‘Matthew Flinders’. In 1962, S300 was converted from the Victorian broad gauge of 5’3” to the New South Wales gauge of 4’8.5”, in order to operate the new Southern Aurora between Sydney & Melbourne. As the locomotive grew older it was removed from these duties and was sold to Chicago Freight Car Leasing Australia (CFCLA) in 2004. It is now owned by a private owner and is on loan to the Canberra Railway Museum.railways wodonga, fred rochow, wodonga railwaymen, s class locomotive -

Wodonga & District Historical Society Inc

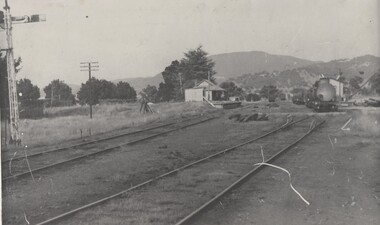

Wodonga & District Historical Society IncPhotograph - Fred Rochow Railways Collection - Cudgewa - As most railwaymen knew it, C. 1950s - 1960s

The Fred Rochow Railways Collection incorporates photos related to the operation of the Wodonga Railway Station including different types of trains and railways staff C. 1930 – 1990. It was donated to the Wodonga Historical Society by Fred Rochow, a railwayman who spent many years based in Wodonga. He joined the Victorian Railways on 17th June l947 and retired in 1988. For some time, he was a member of the Australian Federated Union of Locomotive Enginemen and served a term as a member of the Trades Hall Council. He had an extensive knowledge of the struggles that took place to achieve better conditions for railway workers. Fred worked for many years as a fireman and then worked his way up the ranks to driver, experiencing many changes from the days of steam locomotives through to diesel trains, locomotives and even the modern XPT train. He worked throughout Victoria at different stages of his career, with his final working years focused on the northeast of Victoria and the Albury to Melbourne line. After his retirement, Fred continued to share his love of steam miniature trains with the community.This collection has local and statewide significance as it captures images of trains, locomotives and personnel who operated the railway services in Wodonga and throughout Northeast Victoria. The railways played a critical role in opening up Victoria and connecting Australia for trade, business, social communication and transport.The space on the left was storage space for machinery for the Snowy Mountains Hydro Electric Scheme. A special train was used to cart wide loads such as turbines, and trucks were made for widening when required. Equipment was loaded onto trains t the docks in Melbourne. Cudgewa Line -The Cudgewa railway line opened in stages between 1889 and 1921. The first section from Wodonga to Huon opened on 10 September 1889. It was extended to Bolga on 18 July 1890, Tallangatta on 24 July 1891, Shelley on 13 June 1916 (the highest station in Victoria), Beetomba on 10 April 1919 and Cudgewa on 5 May 1921. In 1919, the line was used to carry materials for the construction of Hume Weir, and three years later a spur line connecting Ebden to the weir was opened. In the 1960s, Cudgewa became the railhead of materials for the Snowy Mountains Scheme. The last passenger service from Wodonga to Tallangatta ran on 30 September 1961 The turntable and passenger platform at Cudgewa were abolished in 1976.railways wodonga, fred rochow, cudgewa station, snowy mountains hydro electric scheme -

Wodonga & District Historical Society Inc

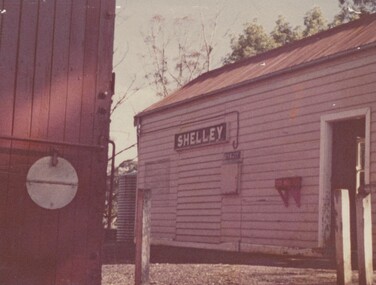

Wodonga & District Historical Society IncPhotograph - Fred Rochow Railways Collection - Shelley Station

The Fred Rochow Railways Collection incorporates photos related to the operation of the Wodonga Railway Station including different types of trains and railways staff C. 1930 – 1990. It was donated to the Wodonga Historical Society by Fred Rochow, a railwayman who spent many years based in Wodonga. He joined the Victorian Railways on 17th June l947 and retired in 1988. For some time, he was a member of the Australian Federated Union of Locomotive Enginemen and served a term as a member of the Trades Hall Council. He had an extensive knowledge of the struggles that took place to achieve better conditions for railway workers. Fred worked for many years as a fireman and then worked his way up the ranks to driver, experiencing many changes from the days of steam locomotives through to diesel trains, locomotives and even the modern XPT train. He worked throughout Victoria at different stages of his career, with his final working years focused on the northeast of Victoria and the Albury to Melbourne line. After his retirement, Fred continued to share his love of steam miniature trains with the community. Shelley Railway Station - Shelley was once Victoria's highest railway station, located 781 metres above sea level. The Shelley Railway Station was opened in 1916 and closed in 1979. The railway was used early in its life to transport farmer’s livestock from the Upper Murray to Wodonga. From the 1950s the railway was used heavily to transport equipment and machinery from Wodonga to the Upper Murray to help build the Snowy Mountains Hydro Electric Scheme. The Snowy Hydro Scheme was completed in 1974 and after several years of low level use, the railway was closed. Some remnants of the Shelley Station passenger platform can still be seen today, along with some information boards. The Shelley Railway Station now forms part of the High Country Rail Trail.This collection has local and statewide significance as it captures images of trains, locomotives and personnel who operated the railway services in Wodonga and throughout Northeast Victoria. The railways played a critical role in opening up Victoria and connecting Australia for trade, business, social communication and transport.Shelley Railway Station. This image shows the tank where the hand brakes were lifted. They were applied again at the "up" side of Koetong for about another 10 miles then lifted near Bullioh.railways wodonga, fred rochow, shelley station, high country rail trail -

Wodonga & District Historical Society Inc

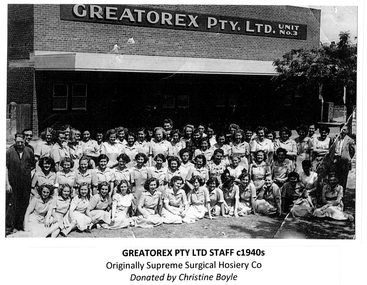

Wodonga & District Historical Society IncPhotograph - Greatorex/ Supreme Surgical Hosiery Co. Wodonga

The Greatorex company came to Wodonga in August 1945 under the Cain Government decentralisation policy. It initially had premises in Beechworth Road, around the corner from Tallangatta Road (now Thomas Mitchell Drive). Due to expansion they later relocated to the corner of Tallangatta Road and Anne Street Wodonga in 1952. Greatorex had its main manufacturing plant in Melbourne, Victoria. At their peak Greatorex Pty Ltd. which also operated as Supreme Surgical Hosiery Co., manufactured brassieres, swimsuits, elastic thread, surgical hosiery and employed 90 staff in Wodonga. The company which was operated by Thomas Greatorex with Mr M. P. Brain as Manager, also owned Fulflex Yarns Pty. Ltd. Fulflex produced elastic yarns to be used in the manufacture of garments at Supreme Surgical Hosiery. In 1960, due to the increasing cost of freight charges for moving raw materials and manufactured goods to and from Melbourne, the company was forced to close down. Plant and machinery valued at over £30,000 was moved to Melbourne. Some personnel were given the opportunity to also transfer to the parent company. In 2024, the company still operates as Greatorex Textile Industries P/L in Moorabbin, Victoria.These images are significant because they document an industry which operated in Wodonga in the 1940s and 1950s.A collection of black and white photos of workers at the Greatorex / Supreme Surgical Hosiery Co. in Wodonga.Names listed beneath one of the images.greatorex industries, wodonga industries -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRega fire knapsack for use with bulldozer

Spraying units were manufactured in Australia by REGA Products Ltd. from 1926. REGA established themselves as leaders in the production of agricultural and horticultural spraying machines, including smaller knapsacks.Plastic fire knapsack usually attached to the back of machinery Brass pump handle and adjustable nozzle attached.REGAforests commission victoria (fcv), bushfire, planned burning, fire pump -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRega fire knapsack for use with bulldozer

Spraying units were manufactured in Australia by REGA Products Ltd. from 1926. REGA established themselves as leaders in the production of agricultural and horticultural spraying machines, including smaller knapsacks.Metal fire knapsack usually attached to the back of machinery Brass pump handle and adjustable nozzle attached.REGAforests commission victoria (fcv), bushfire, planned burning, fire pump -

Churchill Island Heritage Precinct

Churchill Island Heritage PrecinctFunctional object - Horse-drawn grader

The Churchill Island collection includes objects from the late 1800s. The collection is presented in sets and series, of which this horse-drawn grader represents the Jenkins era. Churchill Island has been variously imagined and used to make a permanent settler colonial space since the mid-1800s. The history of the island offers a rich example of the complexity of private settlement in Victoria up until 1976 when it was sold to the Victorian Government.Yellow and red horse-drawn grader attached to an unpainted wooden pole. Four steel wheels connected into pairs by axles are linked through the long arched metal piece, where a seat, crank, and levers are attached. The grader itself sits directly below the seat, and consists of a length of metal perpendicular to the ground, designed to move and level the ground.farm, machinery, grader, horse drawn, churchill island -

Churchill Island Heritage Precinct

Churchill Island Heritage PrecinctVehicle - Wheat wagon, 1925

The Churchill Island collection includes objects from the late 1800s. The collection is presented in sets and series, of which this farm item represents the late Amess era.These horse-drawn wagons were early transport vehicles used for hay or heavy loads of timber or related farming goods. Designed in the early 18th century, these items found within the Churchill Island heritage collection were used throughout the private ownership periods of the Island.Blue wooden wagon with red metal wheels suitable for one horse - a bag lifter is operated from side of wagon.farm machinery, wheat, horse drawn vehicles, wagon, 1800s -

Churchill Island Heritage Precinct

Churchill Island Heritage PrecinctVehicle - Wagonette, 1900

The Churchill Island collection includes objects from the late 1800s to the mid-1970s. The collection is presented in sets and series, of which this image shows an object representing the Amess era.Churchill Island has been variously imagined and used to make a permanent settler colonial space since the mid-1800s. The history of the island offers a rich example of the complexity of private settlement in Victoria up until 1976 when it was sold to the Victorian Government.Black four-wheeled carriage with a front-facing seat for the driver, along with two side-facing benches for passengers. Carraige is sheltered by an awning or roof enclosure and features two glass encased lamps.farm machinery, horse drawn vehicles, wagonette -

Churchill Island Heritage Precinct

Churchill Island Heritage PrecinctVehicle - Hay wagon, 1920

The Churchill Island collection includes objects from the late 1800s. The collection is presented in sets and series, of which this wagon represents the Amess era.The horse-drawn dray was an early transport vehicle used for loads of hay or timber or related farming goods.Large wooden wagon with four steel-shod wooden wheels and a bracket at front to allow harnessing to horse or horses.farm machinery, hay, horse drawn vehicles, wagon -

Buninyong & District Historical Society

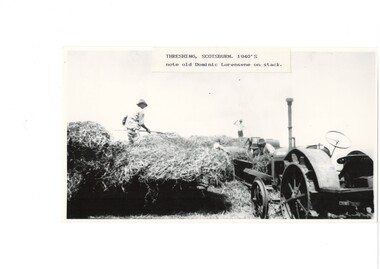

Buninyong & District Historical SocietyPhotograph - Copy of B/W photograph, Threshing machine at Scotsburn in 1940's, Not known

... Scene showing farm machinery in use. Threshing machine... of the machines used at this time Scene showing farm machinery in use ...Photograph shows early farming method and illustrates some of the machines used at this timeThreshing machine in operation at Scotsburn in the 1940's. 3 workers and tractor visbleThreshing machine. 1940's. Note old Dominic Lorensene on stack.scene showing farm machinery in use. threshing machine vdriven by belt from stationary tractor., several man are working on the equipment, l -

Bendigo Historical Society Inc.

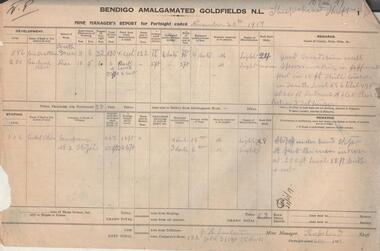

Bendigo Historical Society Inc.Administrative record - Bendigo Amalgamated Goldfields N.L. Mine Manager's Reports, 1917 - 1920

In 1917 Bendigo Amalgamated Goldfield Ltd was formed from the amalgamation of 35 companies with operations on the Garden Gully, Sheepshead, Deborah and Derby lines of reef hoping to increase profits of these existing operations through economies of scale. This was difficult to achieve as the shafts involved were spread throughout the goldfield. Diamond drilling and good geological practices were introduced (Pabst was Chief Geologist) leading to some exploration success. However costs were rising rapidly and in 1923 the directors, deciding that mining would soon become unprofitable, dissolved the company returning assets to the original vendors. J.H. Lenten, Mine Manager, received his second class Mine Manager's certificate in September, 1914 at an examination held at the Bendigo Law Courts. One hundred pages of fortnightly manager's reports for Bendigo Amalgamated Goldfields N.L., Sheepshead Shaft. Reports consist of two pages for each fortnight, signed by J.H. Lenten, Mine Manager. Dates of reports range from November 20th, 1917 to 5th May 1920. Categories reported on include: development, stoping, tons from tributors, tons Company's stone, plant and machinery, underground workings, number of rock drill shifts, firewood used, coal burnt, and general remarks. charcoal burnt., lifting waterbendigo, margaret roberts, , goldmining, bendigo amalgamated goldfields, sheepshead shaft, j.h. lenten, mine manager -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Entrance Beach, Bulmer H D, 1910c

... extension to western pier showing cranes and machinery in use... showing cranes and machinery in use. People on beach and piers ...One other copy slightly sepia tinted 12 x 19cmBlack and white photograph showing piers and entrance to Gippsland Lakes from ocean Bass Strait. Work in progress on concrete extension to western pier showing cranes and machinery in use. People on beach and piers. Lakes Entrance VictoriaLakes Entrancewaterways, beaches, piers, machinery -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Tramline, Fish Marie, 1977

Date made 18 January 1977.Colour photograph of Rex Fish standing beside the boiler which provided steam power to drive the winch to transfer rock from the tram, trucks to the barge at North Arm. This rock quarried at Mississippi Creek was used to stabilise the entrance piers, and build rock groynes around the lakes. Lakes Entrance Victoria waterways, historic sites, public works, machinery