Showing 1306 items matching "manufacturing industry"

-

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1970

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White lacework baby romper suit with long sleeves and legs, and enclosed feet. Closes at centre back with two plastic buttons. Zips open around leg inseam. Size 00 .2 is a retail tag marked with the price and size, and refers to the label sewn into the garment for washing instructions..2 [Retail Swing Tag] [Obverse] KATHRYN Children’s Knitwear STYLE PRICE [handwritten] $18 SIZE [handwritten] 00 [Reverse] WASHING INSTRUCTIONS Refer to label sewn in Garment Designed and manufactured by ROBERT BLAKE PTY. LTD., Melb., Aust.children's knitwear, children's clothing, baby clothing, baby knitwear, clothing, knitwear, romper, jumpsuit, manufacturing, fashion textile production, machine knitting, machine lace, baby clothes -

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1960

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Long sleeved cream baby romper suit with patterned stitch on bottom half and diamond emblem on chest. Closes with two pearlescent plastic buttons at centre back and with three pearlescent plastic buttons at crotch.Kathryn Reg’d / 100% orlon / 20 [handwritten]children's clothing, children's knitwear, clothing, knitwear, romper, jumpsuit, baby clothing, baby clothes, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Baby Swimwear, Kathryn Knitwear, c.1960

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White baby’s swimming shorts with stripes on front in navy, cyan and yellowchildren's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, machine knitting, colourwork, swimwear, baby swimwear -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1962-1964

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Pink three piece legging suit, consisting of cardigan, lettings and beanie. Cardigan is knitted with textured stitch and has stocking stitch panel bordered with garter stitch at centre front. Two rows of buttons on garter stitch tab, with a fifth button under left collar. Leggings are plain garter stitch with an elastic waistband and a flap that extends onto the top of the foot with elastic to keep it held under the sole. Hat is in same patterned stitch as cardigan, has ear flaps with ties and a white pompom.1) [Label at back neck with blue lettering woven into label] KATHRYN REGD ORLON / 20 /CREATED BY ROBERT BLAKE [sample label] [OBVERSE] STYLE LS/PWO – 3 PCS – LEGGING SUIT – PEARL PATT. – 80% ORLON 20% WOOL SIZE 18” 20” PRICE 48/6 51/6 COLOR BLUE. LEMON. PINK. WHITE. [REVERSE] KATHRYN Garments are • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNEknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, pom poms -

National Wool Museum

National Wool MuseumTextile - Children's Dress, Kathryn Knitwear, c.1960

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream baby dress with long sleeves, blue stripe and cream faux cable textured details at yoke and hem. Body is gathered and attaches at yoke. Dress has a drawstring tie at neck accented with cream pompoms and closes at centre back with three pearlescent plastic buttons. Back opening is reinforced with grosgrain ribbon. .2 is a sample tag with manufacturing information, including sizes and colours available .3 is a retail tag with style, care instructions and brand marketing[label stitched into back neck] KATHRYN 100% Orlon .2 [sample label] [Obverse] 802/F – BABIES ORLON FROCK. 16” – LENGTH 24/6 BLUE/WHT LEMON/WHT PINK/WHT WHT/BLUE WHT/LEMON WHT/PINK .3 [Obverse] KATHRYN Children’s Knitwear STYLE [handwritten] 802/F SIZE PRICE [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLYclothing, children's clothing, knitwear, children's knitwear, manufacturing, fashion textile production, colourwork, pom-pom, pom poms -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1970

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Children’s two-piece outfit set, consisting of a top and leggings. Knitted in colour blocks of navy, red and white. Top has ribbed navy bodice section with white stripe separating red skirt and closes at back neck with two navy plastic buttons. Leggings are primarily red, with a white stripe at the ankle and navy-blue feet. Leggings are constructed primarily as one piece and seamed up at centre back and inseam, with additional gusset piece..1) [tag stitched into back neck of top] KATHRYN REGD 100% ACRYLIC FIBRE SIZE 0 WEIGHT 10 LENGTH 76 MADE IN AUSTRALIA .3) [blue sample label] STYLE 574/ Pop Top and B’tts S.26. Acrylic. SIZES: 00 0 PRICE: $8.95 COLORS: Navy/Wht/Red Red/Wht/Navy P.Blue/Wht/Navy Dec on Del.knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, c.1980

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Sample of Kathryn Knitwear Collection, Label style suggests it may not be manufactured by Kathryn Knitwear, but was retained as a sample. Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Two Piece pale blue suit, consisting of jumper and leggings with all-over pattern in double moss stitch and garter stitch border. Jumper opens down the back and closes with three pearlescent plastic buttons. Scalloped motif at bottom and cuff has white accent. Leggings have closed feet and decorative ties at ankle, and are constructed primarily as one piece and seamed up at centre back and inseam, with additional gusset piece.1) [ label at neck of cardigan] SIZE 000 .2) [some letters cut off label] FIT AGE 0-3 MONTHS WEIGHT 6KG ACRYLIC HAND WASH OR GENTLE MACHINE WASH COLD RINSE [D]O NOT TUMBLE DRY WARM IRON [D]RY CLEANABLE (A) [MA]DE IN AUSTRALIAknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1962-1966

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. The colourwork dogs from this design are a very popular motif, and were available in both wool and Orlon in multiple styles from at least 1961-1972, including a cardigan and a pullover, selling 4346 of these in winter 1961. This example most likely dates from 1962-1966. An Illustration depicting this style is catalogued under NWM-09026. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children’s machine-knit jumper with white dog motif and green grass colourwork, closes with three red plastic buttons at left shoulder .2 and .3 are sample tags with manufacturing information, including sizes and colours available .4 is a swing tag with manufacturer care instructions.1) [label stitched at back neck] KATHRYN REGD. / 100% ORLON / 24 .2) STYLE: 44/OP – ORLON PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. WHITE. / 20” – 24” SKY BLUE. LEMON. WHITE. REDCOAT. BOTANY BLUE. SULTRY GREEN. NUTTY BROWN. OATMEAL .3) STYLE: 44/PW – WOOL PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. / 20” – 24” SKY BLUE. LEMON. REDCOAT. BOTANY BLUE. / SULTRY GREEN. NUTTY BROWN. NED KELLY GREEN. / .4) Obverse: [handwritten] 5/10 (unintelligible) Kathryn / ORLON KNITWEAR / Style : 44/OP / DESIGNED & MANUFACTURED BY / Robert Blake / MELBOURNE Reverse: STANDARD MEASUREMENTS / FIT EXACTLY / LAUNDER PERFECTLY / HOT WATER WILL DAMAGE / THIS GARMENT / WASHING INSTRUCTIONS / 1. Use lukewarm water and mild soap. / 2. Squeeze water out by hand – DO / NOT WRING. / 3. DO NOT ROLL. Hang on / Clothes hanger to dry. / To keep brushed garments like / new, brush frequently with / Nylon brush. / IRONING [m (handwritten)] ORLON garments require little / or no ironing if drip-dried. If / ironing is necessary, it may be done damp or dry, using / a warm iron. / DO NOT USE / STEAM IRON /knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, dog motif, animal motif, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1953-1961

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. This style of “brushed wool leginette suit” was produced by Kathryn from at least 1953-1964, though this example likely dates from before 1962. In the winter of 1961, the brand sold 4376 suits of this style. It came with an included nylon brush in order to keep the brushed finish of the garments, which can be found under NWM-09016 Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history. This style of “brushed wool leginette suit” was produced by Kathryn from at least 1953-1964, though this example likely dates from before 1962. In the winter of 1961, the brand sold 4376 suits of this style.Four-piece legging suit consisting of cardigan, leggings, hat and mittens in fuzzy yellow brushed wool. Cardigan is double breasted and closes with two rows of yellow plastic buttons, with a fifth button under the collar. Fold-over collar and cuffs are not brushed wool and provide contrasting texture. Leggings have elastic at waist and ankle to go under foot. Bottom of leg has foot flap. Hat is in a bonnet style and has turnback around face and ties under neck. Mittens are each construced in one piece with no additional thumb pocket, and tie at wrists..1) [label at back neck of cardigan] KATHRYN REGD. CREATED BY PURE WOOL / 20 / ROBERT BLAKE .5) [sample label] [OBVERSE] STYLE: LS/W. LEGGING SUIT – BRUSHED WOOL SIZE: 18” 20” PRICE: 39/9 42/6 3 PCE: 42/9 45/6 4 PCE: COLOR: BLUE. LEMON. PINK. WHITE.knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, brushed wool, wool, fluffy -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

... for female workers in the textile manufacturing industry (£12 11s 4d... for female workers in the textile manufacturing industry (£12 11s 4d ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. In a world where wool garments all had to be washed by hand, the invention of machine-washable acrylic fibres and widespread adoption of washing machines in ordinary Australian homes in the 1950s and 60s posed a major risk to the wool industry, and by extension the entire Australian economy. With the price of wool falling, the CSIRO and the Australian Wool Board worked together from the 1950s on a number of developments to keep Australian wool competitive and desirable to the public, many of which came out of the Geelong research labs. While progress had been made in the preceding decades, 1970 saw a major breakthrough; the invention of a new method of making wool washable and shrink-proof, most commonly known as ‘Superwash’. It is a technology that is still highly used to this day, and is very recognisable to those who use commercial wool yarn to knit or crochet. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Blue wool turtleneck ‘skivvy’ jumper in all over rib pattern with long sleeves. .2) swing tag with woolmark logo for ‘Superwash Wool’1.)[white label at back neck with blue writing] KATHRYN REGD. (Woolmark Logo) PURE NEW WOOL Superwash SIZE 2 HGT. 92cm MADE IN AUSTRALIA 2.)[retail swing tag for ‘Superwash Wool’] [OBVERSE] [woolmark logo] [handwritten in blue pen] 314 [printed] PURE NEW WOOL [handwritten] 2 Superwash Wool Machine Washable [INTERNAL] [woolmark logo] PURE NEW WOOL YOU ARE NOW THE OWNER OF A SUPERWASH WOOL GARMENT That has been specially treated to withstand a lifetime of machine washing. SUPERWASH WOOL has all the desirable qualities of wool – soft handle, comfort, warmth and style. Not all wool knitwear has the SUPERWASH treatment so remember always to look for the special “SUPERWASH” label and swing ticket. To was SUPERWASH WOOL just follow the instructions of the garment label. [woolmark logo] PURE NEW WOOL SUPERWASH WOOL THE WOOL YOU WASH IN THE MACHINE.knitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, csiro, national wool board, superwash, australian wool innovation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Bed Pan, R. Fowler, 1927-1935

... owned by Caroma Industries Ltd, manufacturing only sanitary... operating in 2002 but is now owned by Caroma Industries Ltd ...The company R. Fowler Limited was established in Ultimo, Sydney, in 1837 when Enoch Fowler (1807-1879) came to Australia from Ireland and is known today as the oldest pottery still in operation in Australia. They were mostly known for producing bottles, jars, and pipes. The pottery was originally located at Abercrombie Place on Parramatta Street, Chippendale, NSW before they relocated to Glebe in 1847. Later the pottery manufactured building materials such as tiles, pipes, and chimney pots. As the business grew, they moved to Parramatta in the 1850s. Enoch's son Robert (1839-1906) had joined the company, and took over its management in 1873, changing the name to “R Fowler Sydney” in 1880. Robert, introduced the black under glaze trademark with the archer as shown on the subject item. He went on to opened further sites at Marrickville and Bankstown, with the company becoming R. Fowler Limited in 1919. The factory at Thomastown, Melbourne was opened in 1927. Fowler also owned a Pottery somewhere near Lithgow, where they produced clay pipes that look like salt-glazed Earthenware pipes. There have been numerous developments to the company over subsequent decades, and the company was still operating in 2002 but is now owned by Caroma Industries Ltd, manufacturing only sanitary fixtures. An item made by an Australian company during the first half of the 20th century and quite rare today. The item is significant as it gives a snapshot of the early development of manufacturing companies in Australia. This informs our social history in Australia marking Australia's evolution into an independent country and no longer a colony of England. Bed pan ceramic white glaze handle at one end.Marked R Fowler Ltd and trademark a person sitting with a bow and arrow "00"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Puffing Billy Railway

Puffing Billy RailwayExplosives Wagon, unkown

... 1875 for various forms of manufacturing and storage... since circa 1875 for various forms of manufacturing and storage ...This 2 foot 6 inch (762mm) gauge wagon was used for carrying explosives and was used with the Greenbat Battery loco. It was donated to the Walhalla Goldfields Railway on long term loan in 2013 along with a large quantity of narrow gauge trollies and light rail from Orica’s now closed munitions factory in Melbourne’s western suburbs. Orica - Deer Park Munitions factory Orica Deer Park in Melbourne’s west has been used since circa 1875 for various forms of manufacturing and storage of chemicals. Although the site is bounded by Ballarat Road, Station Street, Tilburn Road and the Western Ring Road, the current entry point for industrial operations is situated at Gate 6 of Tilburn Road. Operations include: • a specialty chemicals facility producing products for mining services operations • quarry services • other chemical manufacture activities. The Deer Park factory complex The factory complex is of historical significance for the major role it played in Australia's manufacturing and mining industries through the development of progressively more efficient and safer explosives. It also contributed to wartime production in ammunition, initiators and the development of synthetic ammonia production and construction of the Defence Explosives Annexe No 5 (later the Albion Explosives Factory) during World War Two. The factory complex is also of technical significance for the unusual and specialised design of many of the buildings and structures, both in the layout of the works and the individual design of buildings. Blast protection and safety measures such as mounds around the buildings, 'cleanways' and buffer zones between production areas were employed extensively. A characteristic of many production buildings was the elimination of cavities where explosive compounds could lodge. The combination of concrete barriers and light-weight construction was designed to direct explosion debris away from operators or other buildings. The narrow gauge tramway, which ran through the explosives section, is a rare survivor of nineteenth century materials-handling methods. Historic - Industrial Narrow Gauge Railway - Wagon for carrying Explosives at the Orica - Deer Park Munitions factory, Deer park, Victoria, Australia Wagon for carrying explosives made from Timber and steelwagon for carrying explosives, puffing billy, industrial narrow gauge railway, orica - deer park munitions factory, explosives wagon -

The Beechworth Burke Museum

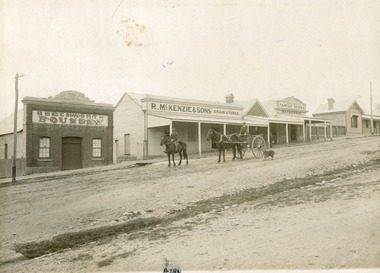

The Beechworth Burke MuseumPhotograph, 1910

Taken in 1910, this photograph depicts a scene of Bridge road in Newtown, Beechworth. Walking on the road are two men on horseback, one of which is pulling a carriage with a small dog standing beside it. Behind them are a line of small buildings and shops. Small industries began to expand dramatically in Beechworth, particularly during the 1860s, leading to a strengthening of the towns economy. As early as 1853, areas surrounding the waterway known as Spring Creek were surveyed with the intent of mapping out plans for new roads and building allotments. Land was sold and new buildings were erected, creating an expansion of the Beechworth township and retail services. One building shown in this photograph is Straughair and Duncan's Beechworth Foundry. This business was established in 1858 through the partnership of Mark Straughair and John Duncan. It dealt mostly in the manufacturing of castings and mining machinery, receiving orders from all over the Ovens district. The Business eventually collapsed after the deaths of Straughair in 1882 and Duncan in 1896 but was reopened by W.H. Phillips in 1905. The two other buildings are both associated with the name McKenzie. Evidence suggests that the McKenzie family has a long association with the town of Beechworth. This photograph is historically significant as it provides insight into the nineteenth and twentieth century industrial expansions that happened in the area of Newtown, leading to the urbanisation of Beechworth. Black and white rectangular photograph printed on matte photographic paper mounted on card.Reverse: Newton / 1997.2648 / 33 Newton Beechworth / 84-219-1 / McKenzies / BMM3055 / newtown beechworth, bridge road, 1910, j. duncan, r. mckenzie, m. straughair, industrial growth, ford street, beechworth foundry, straughair and duncan, mckenzie and sons grainstore, mckenzie family store -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1900

The Beechworth Foundry was vital to the industry of the town and surrounding district in the early years of the town’s development. Originally opened as the New Ford Street Foundry by A. Roger in 1858, J Duncan and M Straughair amalgamated and established the Beechworth Foundry in 1867. The business was extensive and operated out of many buildings, each with their own specialisation. All of the buildings pictured in this image are part of the larger Beechworth Foundry. In the late 1860s it employed 16 men. The foundry was fundamental to the running of the town and surrounding district, as it manufactured all manner of items, including tools and machinery for the mining and agricultural industries. The foundry business collapsed in 1896 after the death of it’s founder, John Duncan, the same year (Straughair had died in 1882). The foundry was reopened by W H Phillips in 1905 and taken over by H Delora in 1906 This image is significant as it shows some of the many buildings of the Beechworth Foundry, which was a fundamental business to the running of the town and surrounding district, and supplied many of the tools and machines required for the mining and agricultural industries, as well as other aspects of life between the 1850s and early 1900sSepia rectangular photograph printed on paper. It has rough, torn-looking edgesReverse 97.2321 / BMM A03115duncan, john duncan, j duncan, m straughair, straughair, foundry, beechworth foundry, industry, factory, newtown, new ford street foundry, a roger, roger, w h phillips, phillips, w phillips, h delora, delora, metalwork, farming and agriculture, tools, mining, workmen -

The Beechworth Burke Museum

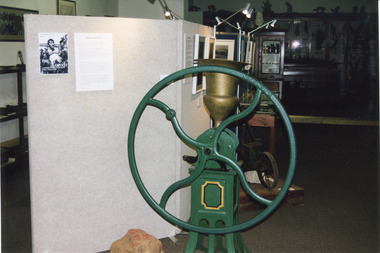

The Beechworth Burke MuseumPhotograph, Estimate 1999

This photograph was taken in 1999 at 'The Harvest' exhibition at the Burke Museum for members of Baking Industry Victoria. The grain mill, manufactured by B.M. Purshouse in Wolverhampton, England, was of special interest.This photograph is of primary social significance to the Beechworth community because it depicts a 19th-century grain mill, manufactured by B.M. Purshouse in Wolverhampton, England, which was probably used at flour mills in the Ovens District, such as that at Tarrawingee, which opened in 1866. The purchase of agricultural machinery such as the grain mill accompanied the expansion of agriculture, including grain growing, in the Ovens District following the gold mining prosperity of the 1850s. This photograph may be of interest to researchers who wish to observe an image of the Purshouse grain mill.Colour rectangular photograph printed on matte AGFA photographic paper.Obverse: THE HARVEST / THE HARVEST Reverse: 2854beechworth, burke museum, promoting settlement, living in country towns, making regional centres, preserving traditions and commemorating, farming and agriculture, exhibitions, burke museum exhibitions, building local economies, transforming land, victorian agricultural history, marketing and promoting agricultural products, the harvest exhibition, harvests, victorian gold rush towns, grain mill, bm purshouse, crops and grain, baking industry victoria -

The Beechworth Burke Museum

The Beechworth Burke MuseumFunctional object - Ladies Coin Purse

Specific historical and contextual information pertaining to this object is unknown. There are no hallmarks or documentation to indicate provenance or historical significance. This coin purse appears to have a covering made of mother of pearl. Evidence of interest from over 20,000 years ago mark Aboriginal groups in Australia as some of the first people to value the power and beauty of pearlshell, while evidence of Australian pearlshell being taken across the sea to other countries dates back as early as the 1500s. The 1850s-60s saw the beginnings of the Australian pearling industry. Following the popularisation of plastic for items such as buttons the pearlshell market waned in the mid-twentieth century but was soon after began to re-forge in Australia with a new industry of cultured pearl farms. Most of Australian's pearling industry was initially located in Western Australia and off the Torres Strait Islands. The Australian War Memorial notes on their website that many tokens made from mother of pearl were sent home to loved ones throughout World Wars One and Two from the Middle East, England, the South West Pacific, Australia and elsewhere, but that unfortunately provenance such as the manufacture and sale of many of these items is not recorded.The social history objects held in the Burke Museum's collection help to tell the stories of Beechworth's past by showing the social, cultural, and economic aspects of the town's history.A small rectangular purse with silver edging and half clasp, covered in white and cream coloured shell (mother of pearl?)A01154burke museum, social history, accessories, mother of pearl, nacre, australian industry -

Orbost & District Historical Society

Orbost & District Historical Societybottle, Pre 1970's

... chipped. This bottle is an example of a product manufacture ...Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips and Stone continued to manufacture soft drinks at Orbost until the early 1970's when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of a carpark. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass bottle with a screw thread top. The label and print ( in upper case) are white.Front- Refreshing Drinks Back-Manufactured by Phillips & Stone Base-1121 P&S Bairnsdale and Orbost Ask for Phillips and Stone Artificially Coloured & Flavoured Net Contents 30 fld ozscontainer beverage bottle phillips-and-stone -

Orbost & District Historical Society

Orbost & District Historical Societyjar, late 1800's

... by an early Australian food manufacturing industry. glass jar jonathon ...This item is an example of a glass food container used by an early Australian food manufacturing industry.A wide necked clear glass jar. It is seamed and has a circle on the base. There are some manufacturing signs near the bottom.In a diagonal banner across the glass - JONATHON REEVE PTY LTDglass jar jonathon-reeve food pickles-condiments -

Orbost & District Historical Society

Orbost & District Historical Societybottle, before 1975

... chipped. This bottle is an example of a product manufacture ...Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips and Stone continued to manufacture soft drinks at Orbost until the early 1970's when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of a carpark. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass bottle with a metal screw cap. on the front is a painted red and white label. It contained lemonade.Lid - Lemonade Base - AGM M 6 inside a circle 9 Front - 30 fl ozs Back - Manufactured by Preservative added M21 A1 P & S Phillips and Stone 28 flavour LOK Ask for Bairnsdale and Orbost Phillips and Stone Preservative added Refreshing drinks Artificially coloured and flavoured Bairnsdale and Orbost bottle phillips-and-stone beverage lemonade container -

Orbost & District Historical Society

Orbost & District Historical Societybottle, after 1929

... of a product manufactured by a local industry which no longer exists ...Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufactured by a local industry which no longer exists.A clear glass bottle which has a broken top. The bottle is seamed.Base - AGM F516 Front (written sideways) - A DROSSOU ORBOST Bottom (written around whole bottle) This bottle is the property of A Drossou Orbost M bottle drossou container soft-drink -

Orbost & District Historical Society

Orbost & District Historical Societybottle, 1930's

... of a product manufactured by a local industry which no longer exists ...Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufactured by a local industry which no longer exists.A clear glass soft drink bottle with a crown seal top. The bottle is seamed.A DROSSOU ORBOST This bottle is the property of A DROSSOU ORBOST Base - AGM F 860 Mbottle container drossou -

Orbost & District Historical Society

Orbost & District Historical Societybottle, D. Drossou, 1930's

... chipped. This bottle is an example of a product manufacture ...Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips and Stone continued to manufacture soft drinks at Orbost until the early 1970's when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of a carpark. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped. This bottle is an example of a product manufacture by a local industry no longer existing.A clear glass cylindrical bottle with a tapered neck.D. DROSSOU ORBOSTbottle drossou orbost-cordial-factory food beverages -

Orbost & District Historical Society

Orbost & District Historical Societybottle, D. Drossou

... of a product manufacture by a local industry no longer existing ...Dross Drossou established a cordial factory in Orbost in the 1930s. He sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Glass bottles were refillable until the 1960s, creating a demand for their collection and onsale back to beverage manufacturers via ‘bottle merchants’. A deposit on the bottles was added to all sales as they left the factory. The returned bottles were washed and the old label removed. The inside was cleaned by pushing the bottle onto a revolving brush. The reusing of the bottles went on until the bottle was broken or the top became chipped.This bottle is an example of a product manufacture by a local industry no longer existing.Drossou lemonade bottle. Large bottle tinted light blue.Front - D. Drossou, Orbost Bottom G938, 647drossou bottle glass lemonade-bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Mortice Machine, Mathieson and Son, 1910-1940