Showing 499 items matching "textile machinery"

-

Stawell Historical Society Inc

Stawell Historical Society IncArchive - Laboratory Books, An Introduction to Textile Mechanisms - P Grossberg

... of Machinery An Introduction to Textile Mechanisms - P Grossberg ...From Dye Laborataory AUNDE / Norwellan North Western Woolen Mills became Norwellan Textiles then AUNDERed an Yellow Cover with B/W image of MachineryJohn Bennett 8/10/69manufacturing -

Stawell Historical Society Inc

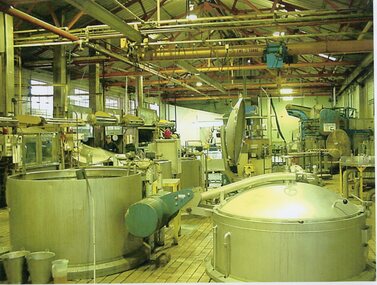

Stawell Historical Society IncPhotograph - Aunde Album 29, Dye House, 2002

Aunde / Norwellan Textiles North Western Woolen Mills became Norwellan Textiles then AUNDEColour landscape photo: Machinery in Dye HouseDye Houseindustry, aunde -

Stawell Historical Society Inc

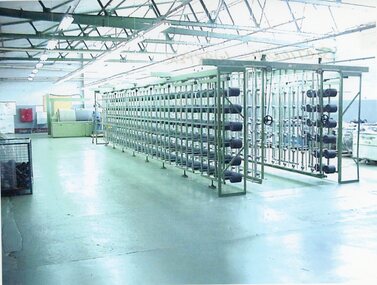

Stawell Historical Society IncPhotograph - Aunde Album 29, Sectional Warper, 2002

Aunde / Norwellan Textiles North Western Woolen Mills became Norwellan Textiles then AUNDEColour landscape photo: Machinery mostly empty of yarn spoolsSectional Warperindustry, aunde -

National Wool Museum

National Wool MuseumPlan - Machinery Layouts, J Dyson & Sons Pty Ltd

... 1617.1 Front: Final Plan / PLAN OF MACHINERY LAYOUT... & Textiles Pty Ltd in Hobson's Road, Kensington. factory machinery ...Two machinery plan layouts for Mimosa Wool & Textiles Pty Ltd in Hobson's Road, Kensington.1617.1 Rectangular blue paper with white lined plan drawing and white text 1617.2 Rectangular blue paper with white lined plan drawing1617.1 Front: Final Plan / PLAN OF MACHINERY LAYOUT / MIMOSA WOOL & TEXTILES PTY LTD / HOBSON'S ROAD KENSINGTON / BY MESSRS J DYSON & SONS / SOUTH GEELONG / Scale 3/32" - 1.0"factory, machinery, wool, textiles, mill, kensington, south geelong, plans, drawings, blueprint, layout, mimosa, j. dyson and sons pty ltd -

National Wool Museum

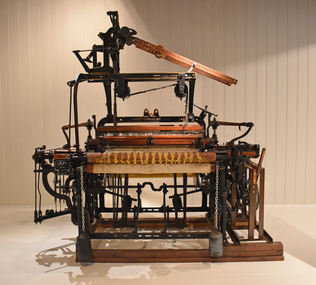

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

... the fabric. weaving george hattersley and sons ltd weaving machinery ...Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

... . Also spelled as Teazel Gig. textile finishing raising raising ...When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

National Wool Museum

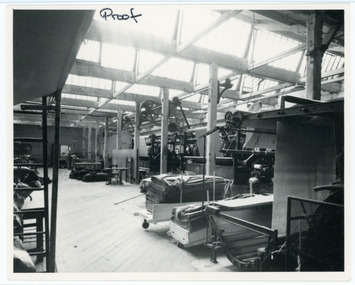

National Wool MuseumPhotograph

Depicts the dry finishing room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile finishing, godfrey hirst and co. pty ltd, dry finishing, raising machinery -

National Wool Museum

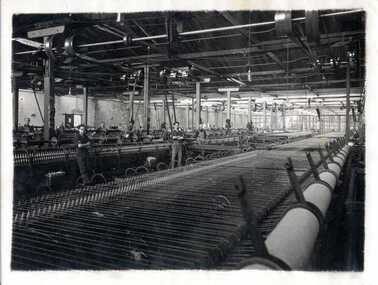

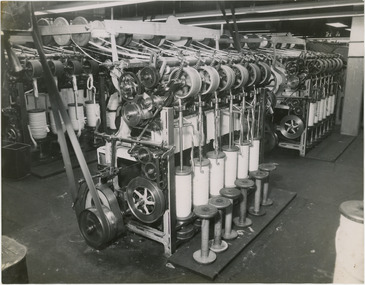

National Wool MuseumPhotograph

... a mill, c.1930s. Textile Mills - staff Spinning Machinery ...Depicts spinning/twisting machinery within a mill, c.1930s.textile mills - staff, spinning machinery, twisting machinery -

National Wool Museum

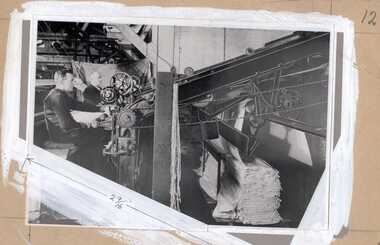

National Wool MuseumPhotograph

Depicts the drying operations within a mill, c.1950s. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, drying, drying machinery -

National Wool Museum

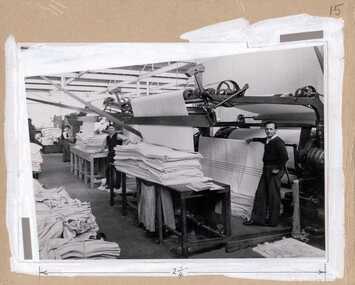

National Wool MuseumPhotograph

... for publication. Textile Mills - operation Folding Machinery Photograph ...Depicts the folding operations within a mill, c.1950s. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, folding machinery -

National Wool Museum

National Wool MuseumBook - The Art of Napping

"The Art of Napping", Woonsocket Napping Machinery Co., c.1924. Catalogue of napping machinery sent to Collins Bros by an American manufacturer of napping machinery. The napping (or raising) done by these machines is all done by wire, not teasels.Book: "The Art of Napping" Woonsocket Napping Machinery Co., c.1924. Letter from The Woonsocket Napping Machinery Company to Mr. Charles W. Ayling, 16 October 1924, page 1. Letter from Woonsocket Napping Machinery Company to Mr. Charles W. Ayling, 16 October 1924, page 2. Blueprint of Napping Machine, Woonsocket Napping Machinery Co. with speeds at which machines should run. Letter from Woonsocket Napping Machinery Co. to Collins Cros. Pty. Ltd., 17 April 1950textile finishing, cotton, woonsocket napping machinery co., raising, raising machinery, lustring, tentering -

National Wool Museum

National Wool MuseumBooklet, Vee Raising Machinery

"Vee Raising Machinery" - Tomlinsons (Rochdale) Ltd, c.1953.Book / catalogue for raising machinery by Tomlinsons (Rochdale) Ltd, 1953.textile finishing, tomlinsons (rochdale) ltd, raising machinery -

Wodonga & District Historical Society Inc

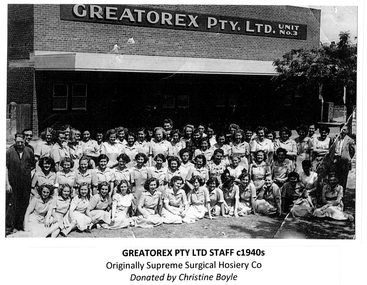

Wodonga & District Historical Society IncPhotograph - Greatorex/ Supreme Surgical Hosiery Co. Wodonga

The Greatorex company came to Wodonga in August 1945 under the Cain Government decentralisation policy. It initially had premises in Beechworth Road, around the corner from Tallangatta Road (now Thomas Mitchell Drive). Due to expansion they later relocated to the corner of Tallangatta Road and Anne Street Wodonga in 1952. Greatorex had its main manufacturing plant in Melbourne, Victoria. At their peak Greatorex Pty Ltd. which also operated as Supreme Surgical Hosiery Co., manufactured brassieres, swimsuits, elastic thread, surgical hosiery and employed 90 staff in Wodonga. The company which was operated by Thomas Greatorex with Mr M. P. Brain as Manager, also owned Fulflex Yarns Pty. Ltd. Fulflex produced elastic yarns to be used in the manufacture of garments at Supreme Surgical Hosiery. In 1960, due to the increasing cost of freight charges for moving raw materials and manufactured goods to and from Melbourne, the company was forced to close down. Plant and machinery valued at over £30,000 was moved to Melbourne. Some personnel were given the opportunity to also transfer to the parent company. In 2024, the company still operates as Greatorex Textile Industries P/L in Moorabbin, Victoria.These images are significant because they document an industry which operated in Wodonga in the 1940s and 1950s.A collection of black and white photos of workers at the Greatorex / Supreme Surgical Hosiery Co. in Wodonga.Names listed beneath one of the images.greatorex industries, wodonga industries -

National Wool Museum

National Wool MuseumPhotograph - Machinery, Classweave, Classweave Industries Pty Ltd, 1980s - 1990s

Acquired when "Classweave Industries" closed down.Colour "polaroid" photograph of machinery and equipment at Classweave H L S POTTER/ PHOTO STORES/...textile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, textile mills, woollen mills -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document - Instruction manual, Details of component parts for Broadbent suspended steam driven Hydro Extractors, C 1926

Thomas Broadbent $ sons Ltd was established in 1864 in Huddersfield England. They are an engineering firm , specialists in heavy duty engineering products. By 1893 Broadbent had progressed to steam powered engines for the textile industry. Some of these machines operated for upwards of 50 years Today Broadbent is a leading world designer in the manufacture and maintenance of advanced centrifuges. This document is a manual for a suspended direct steam driven hydro extractor. It shows the various parts , maintenance instructions and erection and working instructions. While it is stamped as Albion Woollen mills which were situated at Geelong, it is likely to have connections to the Warrnambool Woollen Mills.This document is a good example of machinery manual. It is possibly linked to the Warrnambool Woollen Mill. The fact that the company which manufactured these items is still in existence today after 150 years is testament to the quality of the items produced.Cream coloured document with mainly black text with some red text for headings contained in the document. It is printed front and back and is folded in three sections.Stamp at top "Albion Woollen mills Pty Ltd" .4H x 4 in red pencil in top RHC. Printed on front page. Thomas Broadbent & Sons Ltd Central Iron Works Huddersfield. warrnambool, warrnambool woollen mill, broadbent direct steam driven hydo extractors,, broadbent centrifuge -

National Wool Museum

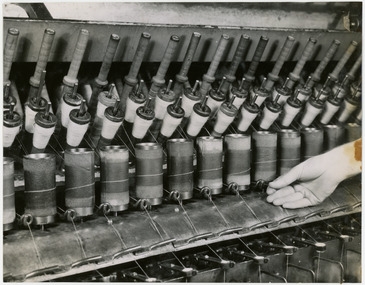

National Wool MuseumPhotograph - Twisting or Doubling, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing detail of machinery with spools of wool. A hand is shown on the right handling a thread of wool.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W18 / W18. Twisting or Doubling.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumPhotograph - Open Drawing, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing machinery with spools of wool.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W16 / W16. Open Drawing.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

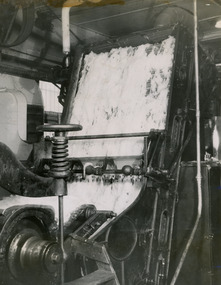

National Wool MuseumPhotograph - From Scourer to Dryer, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a wool moving through machinery.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W11 / W11. From Scourer to Dryer.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

Flagstaff Hill Maritime Museum and Village

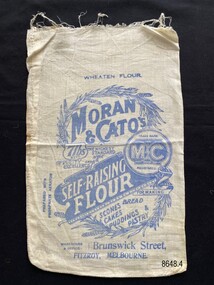

Flagstaff Hill Maritime Museum and VillageTextile - Flour bag - Moran & Cato's

The flour bag is an example of packaging from the grocery store, Moran & Cato's. Moran & Cato's were a large chain of grocery stores operating from the late nineteenth century to the mid twentieth century across Victoria, Tasmania and New South Wales. The address on the flour bag is for the warehouse (wholesale depot) of the business which was a significant building in Brunswick St, Fitzroy.The flour bag provides a snapshot of packaging for a well known grocery store of the early twentieth century. The advertisement on the back for 'Cleaned Fruits' is an example of advertising that highlighted important facts relevant to that time (e.g. "latest Special Machinery" and "with running water").Small calico flour bag for self-raising flour (7lb) supplied from Moran & Cato's in Brunswick Street, Fitzroy, Melbourne. The front of the bag includes not only the detail of the business but ideas for baking, images of wheat and claims as to its excellence. The back of the bag has a written advertisement for 'Cleaned Fruits' another product of the company.Front - Wheaten Flour, Moran & Cato's, Trade mark The M & C Brand Registered, 7lbs Nett, The Highest Standard of Purity and Excellence, prepared with phosphate aerator, Self-raising Flour, For making scones bread cakes puddings & pastry, Warehouse & Office- Brunswick Street, Fitzroy, Melbourne Back - Moran & Cato's, Cleaned Fruits are Perfection, (advertising text), The Same High Quality, The Same Prices at all our Branches.flagstaff hill maritime museum and village, great ocean road, shipwreck coast, calico, domestic object, textile, food storage, moran & cato's, flour bag, self-raising flour