Historical information

When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel.

The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn.

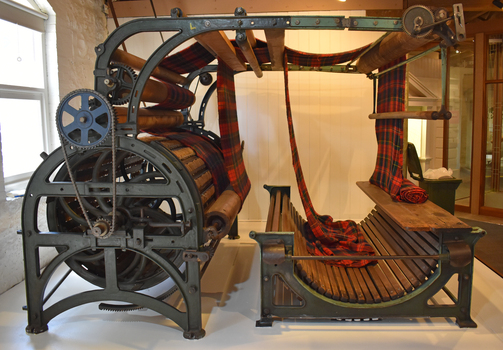

For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig.

The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.

Physical description

Large metal machine with wooden rollers and teasel covered drum.