Showing 692 items

matching measurements

-

Kew Historical Society Inc

Kew Historical Society IncClothing - Black moiré silk faille day dress, 1880

This dress belonged to Mary Ann Henty [nee Lawrence] (1821-81), the wife of Francis Henty (1815-89). Her husband, Francis Henty, was the youngest son of Thomas Henty, who with his family, their retainers and property moved to the Australian colonies between 1829 and 1832. In 1834, Francis’ older brother, Edward, sailed from Launceston in Van Diemen’s Land to what was to become Portland in the western part of Port Phillip District [Victoria]. Francis, together with the first flock of Merino sheep [in Victoria], followed some months later. The first and second generations of the Henty family established vast pastoral properties in the Western part of the Port Phillip District. Francis Henty managed ‘Merino Downs’ near Casterton, while also living in his retirement at ‘Field Place' in Kew. The Henty Collection of nineteenth and twentieth century clothing, including outerwear and underwear, was collected, stored and exhibited over time by female family members descended from Francis and Mary Ann Henty. During the twentieth century, items from the collection were modelled in two fashion parades by various descendants [1937, 1959]. The items in the collection are historically and aesthetically significant, with provenance provided by oral and written tradition within or held by the family. A number of the items in the collection are very rare survivors, and provide researchers with the evidence needed to reconstruct the lives of notable women in the Port Phillip District [later Victoria] during the nineteenth and early twentieth century.A two-piece, moiré silk faille day dress, owned and worn by Mary Ann Henty, aged 59, while resident at Field Place, Kew. The fitted and panelled bodice on the day dress features wide velvet ribbon, hand sewn to form ‘V’ detailing at front and back. The front bodice hook and eye closure is decorated with handmade velvet covered buttons. The high round neckline is trimmed with pleated ivory fine tulle lace. The wide long sleeves of the bodice are also trimmed with velvet ribbon and buttons forming exquisite cuff detailing. The full length skirt and train are tucked into a fitted waistline band. The hemline is hand finished with wide velvet ribbon. A separate attached peplum is worn over the full bustle of the skirt. Measurements (mm): DRESS: Girth - Neck 355.6, Chest 889, Waist 673.1, Cuff 279.4, Hem circumference 4292.6. Vertical - Front neck to hem 1447.8, Front waist to hem 1117.6, Back neck to hem 1765.3, Back waist to hem 1346.2 , Sleeve length 590.55. Horizontal - Neck to sleeve head 196.85, Chest back 469.9, Underarm to underarm 457.2. PEPLUM Girth - Waist 711.2, Hem circumference 1066.8. Vertical - Back waist to hem 406.4.mary ann lawrence, francis henty, fashion -- 1880s, day dresses, women's clothing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Navigational Sextant, 1882-1890

A sextant is an astronomical instrument used to determine latitude and longitude at sea by measuring angular distances, especially the altitudes of the sun, moon, and stars. It is a doubly reflecting navigation instrument and used mainly by sailors to measure the angular distance between two visible objects. The name comes from the Latin sextans, or “sixth part of a unit,” because the sextant’s arc can be 60° or 120° of a circle depending on the model used. The primary use was to measure the angle between an astronomical object and the horizon for the purposes of celestial navigation. The estimation of this angle is known as sighting or shooting the object, or taking a sight. This angle and the time when it was measured is used in order to determine Greenwich Mean Time and hence longitude. Sighting the height of a landmark on land can also give a measure of distance from that object. History: The development of the sextant was as an improvement over the octant, an instrument designed to measure one's latitude. The octant was first implemented around 1731-present but can only measure angles up to 45°. As larger angles were needed to allow the measurement of lunar objects - moon, stars and the sun - at higher angles, the octant was superseded by the sextant. The sextant is a similar instrument but better made and allows larger angles from 60° to 120°. This improvement allows distances to be accurately calculated thereby giving longitude when used with a chronometer. The sextant was derived from the octant in 1757, eventually making all previous instruments used for navigational positioning obsolete. The sextant had been attributed to by John Hadley (1682–1744) and Thomas Godfrey (1704–1749), but reference to the sextant was also found later in the unpublished writings of Isaac Newton (1643–1727). Earlier links can be found to Bartholomew Gosnold (1571–1607) indicating that the use of a sextant for nautical navigation predates Hadley's implementation. In 1922, the sextant was modified for aeronautical navigation by Portuguese navigator and naval officer Gago Coutinho. It should be noted that the octant and quadrant are in the same family as they were, and all are, regarded as sextants. The sextant is representative of it's type and although not fully complete it demonstrates how 18th,19th and 20th century mariners determined their latitude and longitudinal to determine their position on a chart, allowing them to navigate there way across the world's oceans. It also demonstrates the skill and workmanship of the early instrument makers that operated scientific instrument businesses from London and other areas of England to provide most of the navigational instrumentation used by commercial and military navies of the time.Sextant with square, fitted box of polished wood, "Hezzanith" brand. Box contains many parts for the sextants use. On certificate "Heath & Co, London. Sextant Number Y 822". Catch on lid "DEFIANT LEVER" and "PATENT NUMBER 187.10". Maker's certificate is attached to the inside of the box.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sextant box, sextant, hezzanith, heath & co, navigational instrument, george wilson heath, astronomical instrument, instrument manufacturers, scientific instrument, navigation, celestial navigation, octant, quadrant, lunar navigation -

Brighton Historical Society

Brighton Historical SocietyClothing - Dress, Day dress, circa 1875-1876

This dress belonged to Ethel Nina Blundell (1876-1949), having been first made for her mother Jane Blundell (nee Burkitt, 1845-1878). Born in Dublin, Jane married James John Blundell Jr at the Black Street Congregational Church in Brighton on 16 March 1874. The Blundells were a socially prominent Brighton family who played an important role in the development of the area. James' father, publisher and bookseller James John Blundell Sr, served as a Brighton Borough Councillor between 1862 and 1867 when the local government was still in its formative years, including holding the position of Mayor in 1864. He was involved in the foundation of the Brighton Volunteer Rifle Corps and was also a strong supporter of the Brighton Ladies Benevolent Society. The Blundell family were active members of the Brighton Congregational Church and supported the construction of the Black Street church, where James Jr served as a deacon for sixty years, in addition to his work in the Crown Land and Survey Department. The dress is believed to have been made for Jane in 1875 or 1876 during her early pregnancy, likely by a local dressmaker. Jane died in 1878 when Ethel was very young, and Ethel was then raised by her father and paternal grandmother. As she never married, Ethel remained living in the family home of 'Eumana', 164 Church Street, and as an adult she assumed the role of hostess whenever she or her father had guests. On these occasions, she reportedly wore her mother's dress. The family home was sold on James Jr’s death in 1924 and Ethel was living at 52 Black Street Brighton when she died in 1949. In the 1930s, Ethel gifted the dress to a close family friend, Dr Jean Kelly. She told Jean that the garment held precious memories, perhaps due to the connection it provided to the mother she had never known. Jean donated the dress to the Merimbula Old School Museum in NSW in 1987, where it was on display for many years. The Museum donated the dress to Brighton Historical Society in 2023.This is a good example of a late nineteenth century day dress, made from two different patterns of russet brown silk brocade and featuring a lobster tail style bustle. The lack of boning combined with waist and hip measurements indicates it may have been made as a maternity dress. It is lined with beige leaf pattern cotton fabric. The princess line fitted bodice of herringbone pattern brocade has a high round neck with small 'mandarin' style collar and buttons down the front to below the waist where it forms an overskirt which is bordered with a band of coffee bean patterned brocade. The overskirt drops down to hem length at the back but from the centre front it is draped up to the back to a point below the waist level. Here it is sewn to the edge of the lobster tail style bustle which is also bordered by the coffee bean fabric. There is a concealed pocket with the opening under the right edge of the bustle. The buttons on the front of the dress have a decorative circlet of small blue flowers around a russet silk covered dome. The long sleeves are set in and slightly full with a contrasting three pleat band of coffee bean fabric with an ornamental turn back from the pleats sewn just above the wrist. The skirt section of the dress is in four 20 cm bands of alternate fabric patterns with the top and third band of coffee bean pattern slightly gathered and the second and fourth bands of herringbone forming pleated ruffles.1870s, ethel nina blundell, jane blundell, jane burkitt, eumana -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageOctant, Late 18th to mid-19th century

An Octant is a doubly reflecting navigation instrument used primarily by sailors to measure the angular distance between two visible objects and was a forerunner of the sextant. The name comes from the Latin octo, or “one-eighth of a circle,” for the Octant’s arc which spans 45°, or one-eighth of a circle. The primary use of an Octant is to measure the angle between an astronomical object and the horizon for the purposes of celestial navigation. The estimation of this angle is known as sighting or shooting the object, or taking a sight. The angle, and the time when it was measured, can be used to calculate a position line on a nautical chart (latitude), for example, sighting the Sun at noon or Polaris at night (in the Northern Hemisphere) gives an angle by which the latitude can then be estimated. Sighting the height of a landmark on land can also give a measure of distance. History: The principle of the Octant as an instrument to measure ones latitude was first implemented around 1742-present but was superseded by the improvement of the octant to a sextant, a very similar instrument, better made and able to measure bigger angles 120°, allowing the measurement of Luna distances to give longitude when used with an accurate chronometer. The sextant started to appear around 1730 and had been attributed to by John Hadley (1682–1744) and Thomas Godfrey (1704–1749), but reference to the sextant was also found later in the unpublished writings of Isaac Newton (1643–1727). Earlier links can be found to Bartholomew Gosnold (1571–1607) indicating that the use of a Sextant for nautical navigation predates Hadley's implementation. In 1922, the sextant was modified for aeronautical navigation by Portuguese navigator and naval officer Gago Coutinho. Henry Hemsley was a lesser-known instrument maker and optician working in London in the late 17th and early 18th century. However, it should be noted that there were two Henry Hemsley opticians and instrument makers around this period. (Henry Hemsley 1, 1786-89, who had premises at 85 Fleet St London and Henry Hemsley 2, 1828-56), whose workshop was at 135-138 Radcliff Highway London. Therefore, based on the inscribed workshop address Henry Hemsley 2 is responsible for making this example.The octant is representative of its type and although not fully complete it demonstrates how 18th and 19th-century mariners determined their latitude on a chart to navigate their way across the world's oceans in the 18th and 19th century. It also demonstrates the skill and workmanship of the early instrument makers that operated from London at this time and provided most of the navigational instrumentation use by commercial and military navies of the time.Octant, ebony wooden frame and handle. Scale is missing from recess in frame. "H. Hemsley 135-138 Ratliff Highway, London", no box"H. Hemsley 135-138 Ratcliff Highway, London"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, navigation, navigational instrument, instrument used for navigation, sextant, henry hemsley, instrument maker, london, octant -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBowl

According to Lloyd's Shipping Register 1837-1839, the CHILDREN was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. London registered number 123/1837. James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered 1837”. Launceston registered number 6/1837. In 1838 the CHILDREN, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year (carrying a general cargo including the house bricks). On the 11th January 1839, the CHILDREN sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the CHILDREN “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane force storms, eventually clearing on the early morning of the 14th to “west force 10”, but too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The CHILDREN collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost (including 8 children). The Henty’s contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for the Henty’s, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of settlement: “Six stations have been occupied, one at Portland Bay…three at the open country about 60 miles inland called ‘Merino Downs’…They have erected two houses at Portland Bay and two others at Merino Downs”. The shipwreck of the CHILDREN is of State significance ― Victorian Heritage Register S116Part of terracotta bowl from the wreck of the Children, 2 segments have been glued together.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, children -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBrick

According to Lloyds Shipping Register 1837-1839, the CHILDREN was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. London registered number 123/1837. James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered 1837”. Launceston registered number 6/1837. In 1838 the CHILDREN, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year (carrying a general cargo including the house bricks). On the 11th January 1839, the CHILDREN sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the CHILDREN “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane force storms, eventually clearing on the early morning of the 14th to “west force 10”, but too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The CHILDREN collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost (including 8 children). The Hentys contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for the Henty’s, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of settlement: “Six stations have been occupied, one at Portland Bay…three at the open country about 60 miles inland called ‘Merino Downs’…They have erected two houses at Portland Bay and two others at Merino Downs”. The shipwreck of the CHILDREN is of State significance ― Victorian Heritage Register S116Fired brick from the wreck of the Children, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, children -

Puffing Billy Railway

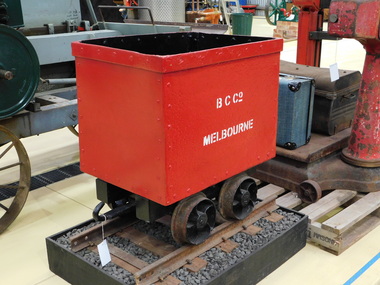

Puffing Billy RailwayBenwerrin Coal Company Coal Skip, circa 1899 - 1904

BENWERRIN COAL COMPANY SKIP This quarter ton coal truck or skip was used at a small mine situated at Benwerrin near Deans Marsh in Victoria’s Otway Ranges. The mine first opened in 1899 and closed in 1904. With the fuel shortages due to World War 2, the Benwerrin Coal Company reopened the mine in 1941. The coal was loaded into skips and winched out of Box’s Creek valley on a narrow gauge incline to a loading point that was close to the Deans Marsh-Lorne Road. It was then taken by road to the Deans Marsh Railway station. The average gradient of the tramway was 1 in 4 over a length of just under 500 metres (1600 feet). The gauge of the tramway has often been referred to as 375mm (or 15 inches) as shown on the map opposite taken from “Sawdust and Steam”. However, actual measurements of the wheels show the gauge to be 400mm (or 16 inches), which is quite unusual as is the small size of the skip itself. The mine produced up to 30 tonnes of brown coal each week until it closed in 1949 and the incline tramway and its skips were abandoned. Preservation of this coal truck came as a result of interest by the Tramway Museum Society of Victoria (TMSV) in the Barlow or Box type rails that it ran on. These rails had originally come from the Beaumaris Horse Tramway and were obtained by the Benwerrin Coal Company from Hayden Bros’ abandoned timber tramway at nearby Barwon Downs. Members of the TMSV visited the mine in the 1960s only to find that most of the tramway had recently been recovered for scrap. There remained a significant number of relics around the mine adits including most of the skips. One of these remained in good condition and it was recovered for preservation in May 1967. It was restored but never displayed and a second restoration took place by the author over 2012/13 so that it could be placed in the Menzies Creek Museum where it was delivered in February 2013. Little remains of the mine today with trestles and sleepers destroyed in the “Ash Wednesday” Bushfires in 1983. References: Houghton, N (1975), Sawdust and Steam, Light Railway Research Society of Australia. Historic - Industrial Narrow Gauge Railway - Benwerrin Coal Company , Benwerrin , Victoria, AustraliaCoal Skip - made of Iron sheet and wrought iron frame & wheelsB,C.Co Melbournepuffing billy, coal skip, benwerrin coal company, narrow gauge -

Bendigo Military Museum

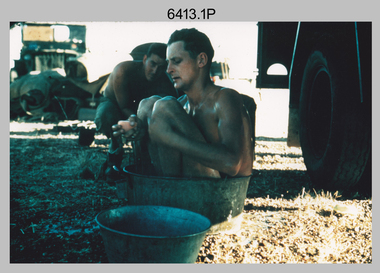

Bendigo Military MuseumPhotograph - Royal Australian Survey Corps Surveyors in the Field – North Queensland, 1958

This is a set of seven photographs of surveyors and support staff in the field undertaking duties in North Queensland in 1958. The surveyors were employed in the establishment of mapping and geodetic control. In this era surveyors used theodolites to observe horizontal and vertical angles and chains to measure base line distances between survey stations. Bob Skitch shown in photos .4P to .6P was in the 2nd year of his career in the Australian Army. He achieved the rank of Lieutenant Colonel and his last appointment was the CO of the Army Survey Regiment from 1976 to 1980. The annotation on the back of photo .5P ‘Black foreground is where Bob Skitch boiled billy and started a grass fire’.This is a set of seven photographs of surveyors and support staff in the field undertaking duties in North Queensland in 1958. The photographs were printed on photographic paper and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 300 dpi. .1) - Photo, colour, 1958. Surveyor in Nth QLD enjoying a bath. L to R: Don Cocker, Bob Thompson. .2) - Photo, colour, 1958. Don Cocker surveyor in Nth QLD, enjoying a bath. .3) - Photo, colour, 1958. Surveyors Nth QLD undertaking survey observations, using MRA1 tellurometer to measure base-line distances. L to R: Len Davies, Lou Sommer, John Van De Graff. MRA1 was covered to stop overheating. .4) - Photo, colour, 1958. Surveyors south of Richmond, QLD digging holes for the erection of a Bilby observation tower. L to R: John Van De Graff, Bob Skitch, Kev Moody, Mal Hayes, Don Gray .5) - Photo, colour, 1958. Surveyors south of Richmond, QLD erecting a Bilby observation tower. L to R: Tom Royle, Bob Skitch (on ground level), Mal Hayes. .6) - Photo, colour, 1958. Surveyors south of Richmond, QLD erecting a Bilby observation tower. L to R: Tom Royle, Bob Skitch, Mal Hayes, Jim McGill (on ground level). .7) - Photo, colour, 1958. Surveyors south of Richmond, QLD undertaking survey measurements from a Bilby observation tower..1P to .7P annotated on back – personnel names, the year and the location. Annotated on back of .5P ‘Black foreground is where Bob Skitch boiled billy and started a grass fire’.royal australian survey corps, rasvy, army survey regiment, asr, army svy regt, fortuna, surveying -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Loch Torridon, Early 20th century

The Loch Torridon was built in response to the need for a large cargo-carrying ship in the 1870s becoming famous for being one of the most per4fect four-masted barques ever built. She was built for the Loch Line in 1880 by Messrs. Barclay, Curle, and Co. Her measurements were 287 feet in length and 42 feet in beam, and 24 feet depth of hold. She was well sparred and her sail plan was so perfectly balanced that she was a very handy ship, easy on her helm, which was not a common virtue amongst large four-masted ships of her day. Her sails were interchangeable on all three masts, which was common in the last days of sail for both economical and practical purposes. The Loch Torridon was considered one of the most graceful and elegant ships ever launched from the Glasgow shipyards. The first master was Captain Pinder, the first cargo was bound for Melbourne Australia, after which she went on to Calcutta with a cargo of horses. On August the 22nd 1882 with a cargo of Jute onboard loaded in Calcutta the Loch Torridon ran into a storm. Sailing in heavy seas the captain, the second mate also the man at the wheel, and a boy was washed overboard with the first mate just escaping the same fate. Captain Pinder and the crew members could not be rescued and were never seen again with the first mate having to bring the ship home. The next Captain was Robert Pattman who was regarded as a fine navigator and seaman who sailed the Loch Torridon for the next twenty-six years and nine months. He had made 25 voyages around the world during this time without any serious mishap. In 1909 Captain Pattman resigned his command of the ship to switch to a steam vessel but unfortunately was injured on his first voyage and had to be landed at Falmouth, he dies of his injuries shortly afterwards. The Loch Torridon kept on sailing until 1915 after having been sold to a Russian company two years earlier. Near the end of January 1915, the ship sprang a leak of the west coast of Ireland and was abandoned sinking shortly afterwards. For further information regards possible maker of the model see Provenance sec this document: The item is of significance as an item made possibly by a man who served on the original ship making the item of historical significance given that the original craft was a well-known and respected trade vessel making voyages between England and Australia as well as the near East. Ship model Loch Torridon 4 masted, hull is black, grey and white. Ship in full sail with 4 lifeboats on deck. Ship sits on textured base. Has plain blue background. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Clay Bricks, Circa 1838

These bricks are a sample of “5000 house bricks from London” carried by the CHILDREN as ballast, and intended for the Portland Bay settlement of her owners Henty Bros. Flagstaff Hill divers recovered them from Childers Cove in February 1974, and noted, “These bricks are the major feature of the wreck site. Subsequent notes indicate “The hull structure has broken up, leaving few visible remains, except for piles of house bricks intended for the Hentys of Portland”. According to Lloyds Shipping Register 1837-1839, the CHILDREN was built in 1825 at Liverpool and operated by owners Gordon & Co, of London, London registered number 123/1837; James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered 1837”. Launceston registered number 6/1837; in 1838 the CHILDREN, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year (carrying general cargo including the house bricks). On the 11th of January 1839, the CHILDREN sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the CHILDREN “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane-force storms, eventually clearing on the early morning of the 14th to “west force 10”, but too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The CHILDREN collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost (including 8 children). The Hentys contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for the Hentys, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Hentys summarised their work over the previous six years of settlement: “Six stations have been occupied, one at Portland Bay…three at the open country about 60 miles inland called ‘Merino Downs’…They have erected two houses at Portland Bay and two others at Merino Downs”.These bricks are significant as a sample of 5000 house bricks carried from London as ballast by the Children and were intended for the Portland Bay settlement of her owners James Henty & Co. The CHILDREN was one of the first vessels to be lost in the Western District of Victoria, east of Warrnambool, on January 14th 1838, breaking up within twenty minutes. The wreck is also significant as one of the first vessels to have been lost in the Western District of Warrnambool and as such is registered on the Victorian Heritage Register S116.Five ‘house bricks from London’, some with white marine encrustation, recovered from the wreck of the ship CHILDREN. The bricks are oblong shaped and constructed of a blue-coloured and coarse-grained conglomerate. One brick is higher, shorter and narrower, than the other four bricks.Nonewarrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, london house bricks, children shipwreck, james henty and co, henty brothers, childers cove, early shipowreck -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageShip Log, 1900-1920

The Excelsior IV Log is a nautical instrument for measuring a vessel’s speed and distance travelled. When navigating a ship it is essential to be able to estimate the boat’s speed and distance travelled to determine its position at sea. In times past the only way to measure a ship’s speed was to throw a wood log into the water and observe how fast it moved away from the ship. In the 16th century, the log was fastened to a rope knotted at set intervals. The log was thrown over the stern (back) of the vessel and a crew member counted the number of knots that were paid out in a set time. From this, they could estimate the speed of the vessel through the water. This was known as streaming the log and is also the derivation of the knot as a measurement of nautical speed. The Walker’s Excelsior Mark IV instrument was designed for smaller vessels, such as yachts, launches and fishing vessels. Historical: Thomas Walker & Son was internationally renowned in the manufacturing of ships logs, founding father , Thomas Walker (1805–1871), an engineer in Birmingham, patented a mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kick starting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ship’s log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (British-based organisation promoting ties and trade with the British Caribbean), being the most common log in use for two generations. It took until 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By the time of his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log and the Walker factory was one of the first to introduce the 48 hour work week for employees. The ship log was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades.Ship's Taff Rail Log, rope attached. Walker's Excelsior IV Log model. Nautical miles dials: units and 10's. "Walker's Excelsior IV Log", "Made in England by Thomas Walker, Birmingham"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, log register, taff rail log, taffrail log, marine navigation, a1 harpoon log, cherub’ log, walker’s excelsior mark iv log, ship’s log instrument, mechanical ship’s log, measure ship’s speed, nautical instrument, navigation instrument, massey & sons, thomas walker, blue brick walker, thomas walker & son, thomas ferdinand walker, 48 hour work week -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Nail, circa 1825

Nails such as this solid copper nail were forged by blacksmiths. A nail of this length could have been used for the ship's decking. It was recovered from the shipwreck of the barque Children. The Children wrecking: The barque Children was one of the first vessels to be lost in the Western District the vessel was wrecked to the east of Warrnambool on 14th January 1838. When it ran ashore in hurricane-force winds, 22 passengers and crew were fortunate to escape being battered to death on the rocks. The Children broke up within 20 minutes, sweeping sixteen of those on board to their deaths. After eleven days, the survivors, all of whom were injured, were rescued and taken to Portland. According to Lloyd's Shipping Register 1837-1839, the Children was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. Registration number 123/1837, James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered in 1837” at Launceston registered number 6/1837. In 1838 the Children, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year carrying a general cargo including house bricks used for ballast. On the 11th of January 1839, the Children sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the Children were “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane-force storms, eventually clearing on the early morning of the 14th. However, it was too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The Children collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost including 8 children. The Henty brothers contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for James Henty and his brothers, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of establishing the Portland settlement stating. “Six stations have been occupied, one at Portland Bay three at the open country about 60 miles inland called ‘Merino Downs’ They have erected two houses at Portland Bay and two others at Merino Downs”.This nail is significant as part of the vessels original fixtures. The Children was delivering cargo intended for the Portland Bay settlement of her owners the James Henty brothers The wreck is also significant as one of the first vessels to have been lost in the Western District of Warrnambool. As a result the shipwreck of the Children is registered with the Victorian Heritage Register S116. Ship's nail, copper, with a washer attached. The nail has a round head, solid round shank and a flat end. It is bent, twisted and has indentations in the centre section. The nail was recovered from the wreck of the CHILDREN.warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, shipwreck artefact, the children, nail, copper nail, ship's nail, children shipwreck -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Ship Log, Early 20th Century

In times past the only way to measure a ship’s speed was to throw a wood log into the water and observe how fast it moved away from the ship. In the 16th century, the log was fastened to a rope knotted at set intervals. The log was thrown over the stern (back) of the vessel and a crew member counted the number of knots that were paid out in a set time. From this, they could estimate the vessel's speed through the water. This was known as streaming the log and is also the derivation of the knot as a measurement of nautical speed. Various manufacturers of nautical equipment had sought over the years to perfect the operation of determining a ship's speed and it wasn't until Thomas Walker and his son Ferdinand developed a mechanical system that eventually made this task became easy for marine navigators. Thomas Walker & Son were internationally renowned in the manufacturing of ship logs the founding father, Thomas Walker (1805–1871), an engineer in Birmingham, patented his mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial then recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kickstarting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ship’s log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (a British-based organisation promoting ties and trade with the British Caribbean), being the most common log in use for two generations. It took until 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log (Trident) and the Walker factory was one of the first to introduce the 48-hour work week for employees.The ship log was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades.Ships Log, Walker Trident electric motor, in wooden box with instructions inside box. The motor dial with electric cord is still inside box.Inscription "Admiralty patent number 3332" and "Walker Trident Electric Ship Log (Mark III), 15-25 volt". On top of lid, hand written, is "G TAYLOR"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ships log, thomas walker & son, electric ships log, marine navigation, thomas ferdinand walker, ship log -

Alfred Hospital Nurses League - Nursing Archive

Alfred Hospital Nurses League - Nursing ArchiveFunctional object - Syringe and Needle Kit - Parke Davis & Co, Parke, Davis & Co

Most nurses had their own syringe and needle kits before the advent of disposable syringes. They were used by Alfred Hospital visiting trained nurses to administer medication in the patient's home. The analgesic tablets in the glass vials were dissolved in sterile water prior to administration.This item belonged to Louisa Mann, 6th Matron of the Alfred 1912-1928.Silver coloured metal flip up case containing: 1. a glass and metal syringe with metal cap 2. a small glass vial containing 6 hypodermic needles 3. 6 vials with cork stoppers containing analgesic tablets 4. 2 perished rubber washers used in the syringe 5. 1 wire stylet to clean needles 6. Screw on needle hubOn the base of the kit engraved - Parke, Davis & Co. Detroit & New-York Markings on the vials: No 2 Apomorphine Hydrochlorate 1-10 gr - Parke, Davis & Co. Detroit & New York No 3 Atropine Sulphate 1-50 gr - Parke, Davis & Co. Detroit & New York No 5 Cocaine Hydrochlorate 1-4 gr - Parke, Davis & Co. Detroit & New York No 13 Morphine sulphate 1-4 gr - Parke, Davis & Co. Detroit & New York No 16 Morphine sulphate 1-4 gr & Atropine sulphate 1-150 gr - Parke, Davis & Co. Detroit & New York No 72 Strychnine Nitrate 1-40 gr - Parke, Davis & Co. Detroit & New York Glass vial with needles (Patient July 7, '96): 1st line - Aseptic Hypodermic Needles 1/2 Doz. 2nd line - Schimmel's Patent Best Seamless Steel Tubing 3rd line - CAUTION - Do not return a needle once used to the vial. 4th line - Remove needles by a slight tap on vial with a pencil. 5th line - PARKE, DAVIS & CO. GENERAL AGENTS 6th line - DETROIT MICH U.S.A. Syringe inscription - on barrel, Parke Davis &Co PAT. AUG 25 1885: on plunger, measurement markings injection kit -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Urinal, circa 1825

It is probable that the urinal was situated in the forward part of the ship rather than the stern, being one of two placed on either side of the deck and housed immediately adjacent to the doors into for-castle, or crew sleeping quarters. The toilets on maritime vessels were (and still are) called the ‘heads’, after the sanitation arrangements common until the end of the eighteenth century. The name was given to the ‘head’ of the ship, forward of the forecastle and around the beak or bowsprit. These first lavatories were floored with grating or nets so the force of the sea could wash them clean, and they were always used on the lee or non-weather side so the effluent fell directly into the water rather than back on board. The Children wrecking: The barque Children was one of the first vessels to be lost in the Western District the vessel was wrecked to the east of Warrnambool on 14th January 1838. When it ran ashore in hurricane-force winds, 22 passengers and crew were fortunate to escape being battered to death on the rocks. The Children broke up within 20 minutes, sweeping sixteen of those on board to their deaths. After eleven days, the survivors, all of whom were injured, were rescued and taken to Portland. According to Lloyd's Shipping Register 1837-1839, the Children was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. Registration number 123/1837, James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered in 1837” at Launceston registered number 6/1837. In 1838 the Children, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year carrying a general cargo including house bricks used for ballast. On the 11th of January 1839, the Children sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the Children were “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane-force storms, eventually clearing on the early morning of the 14th. However, it was too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The Children collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost including 8 children. The Henty brothers contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for James Henty and his brothers, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of establishing the Portland settlement stating. “Six stations have been occupied, one at Portland Bay three at the open country about 60 miles inland called ‘Merino Downs’ They have erected two houses at Portland Bay and two others at Merino Downs”.This urinal is significant as part of the vessels original fittings he Children was delivering cargo intended for the Portland Bay settlement of her owners the James Henty brothers The wreck is also significant as one of the first vessels to have been lost in the Western District of Warrnambool. As a result the shipwreck of the Children is registered with the Victorian Heritage Register S116. A lead urinal with a rounded back at the top splash plate with an attached semi-circular receptacle or basin (20cm deep and projecting forward 30cm). At the sides are flanges with bolt holes connecting to a ship's wall. The urinal is drained by a funnel-shaped outlet also made of lead, reducing from a 10cm radius to a joined 5 cm pipe. The urinal was recovered from the wreck of the CHILDREN.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, shipwreck artefact, the children, lead ship’s plumbing, crew urinal, the ‘heads’, ship plumbing, james henty, portland bay, urinal, ship's urinal -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red ribbed skirt with elastic waistband.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red wide ribbed pleated skirt with a plain yoke, navy blue band at bottom edge and elasticated waistband. A purple x is located inside to mark centre back of skirt.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Men's Coat, c1940s

Franco Liburti was wearing this coat when he farewelled his wife Assunta in Naples, Italy in 1957, the day she departed for Australia. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Men's coat featuring a charcoal herringbone weave, with three buttons down the front and on each sleeve cuff.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community, naples -

National Wool Museum

National Wool MuseumTextile - Child's Pinafore, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red and green plaid children's pinafore with green hem binding and in-built petticoat with lace edging.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000