Showing 553 items

matching metal trade

-

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Five cell metal torch c. 1950s

The five cell metal torch from c. 1950s has local significance due to being used by Wodonga resident, Bill Harris, in his youth, as well as historical significance due to its age and representativeness.Metal torch with a plated yellow surface around the light bulb and a long grip with repeated bands of three lines in the surface and a sliding on-off button."EVEREADY / TRADE-MARK / MADE IN HONG KONG" - on the base of the torch.1950s torches, metal torches, eveready torches, five cell torches, vintage torches -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Stiff & Gannon Money Till c. 1940s

The money till was used in the Stiff & Gannon General Store, Hardware, Draper and Grocery Merchants in High Street, Wodonga, which opened in August 1946 and closed on 28 February 1970.Local significance as Stiff & Gannon was a major retail outlet and employer in Wodonga from the mid 1940s. A wooden money till with two drawers. The bottom drawer has a metal handle and both drawers are lockable. Paper slot in lid for invoices"TRADE Docket Co. MARK / DOCKET BOOK Co. [AUST] /DISTRIBUTORS FOR W.A." on a plaque attached to one end of the top surface.business, hardware, drapery, wodonga, stiff & gannon, general store -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Balloon Flashlight Magnifying Glass

The Balloon flashlight magnifying glass was donated by a resident of Wodonga and is an unusual example of glass magnifiers with an inbuilt light made by the Balloon company.The flashlight magnifying glass has local significance due to its donation by a resident of Wodonga. It also has historical significance as an example of a relatively rare type of vintage Balloon magnifying glass with an inbuilt light.Metal and plastic flashlight magnifying glass, with a light attached to the interior end of the handle, to illuminate the magnified area."TRADE MARK / BALLOON / MADE IN HONG KONG" on the dark brown plastic end of the handle.magnifying glass, flashlight magnifying glass, balloon magnifying glass, balloon hong kong -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Branding Hammer issued to FCV overseer Jim Browning at Beechworth

Metal branding hammers were the most common way to control the sale and movement of hardwood timber produce like logs, railway sleepers, fence posts, and poles from Victorian State forests. Royalty was also paid on this basis. The hammer has a crown stamp on one end with a unique number in the middle (453) which identified its owner, and a crows foot or broad arrow on the other. The broad arrow was a symbol traditionally used in Britain and its colonies to mark government property. Forest regulations state that an authorised officer may use the crown mark to identify produce which has been sold and may be removed from the forest, whereas the broad arrow can be used to brand and mark trees which are not to be felled, or to indicate forest produce which has been seized. Hammers were traditionally only ever issued to forest officers and were an important, and closely guarded tool-of-trade. They were not transferred between staff and lending hammers was not permitted. But it was an onerous task for staff to hammer and tally hundreds of logs, or thousands of fence posts each week, so in about 1990 a system was introduced whereby hammers were allocated to logging contractors to grade logs and tally them instead. But there was still spot checking by authorised officers. A register was kept, and contractors paid a substantial deposit to make sure they didn't lose them, but they occasionally turn up by fossickers with metal detectors. While branding hammers are still used in some smaller locations, plastic tags and barcodes are now more common.Metal log branding hammer with a crown stamp on one end with a unique number (453) in the middle which identified its owner, and a crows foot or broad arrow on the other. The unusual bent metal handle was designed to protect user from banging their fingers on the log. It was also fitted with a rubber hand grip. Most FCV branding hammers were issued with wooden handles. The branding hammer 453 was initially issued to Wally Cowell at Beechworth. It was reissued to Jim Browning upon Wally’s retirement The hammer still had a wooden handle, but the it broke and became loose inside hammer head. Russel Pritchard from the Beechworth Depot replaced the handle with a new metal one and put a dog leg in it It mainly branded forest produce cut in Mt. Pilot and Reedy Creek areas. The main logging contractors were Gordon Habeck from Chiltern and Steven Goldsworthy from BeechworthCrown mark one end (453) and Crows foot other endforest harvesting, forests commission victoria (fcv) -

Bendigo Historical Society Inc.

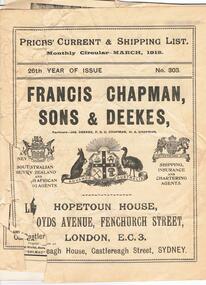

Bendigo Historical Society Inc.Document - ABBOTT COLLECTION: CATALOGUE FOR FRANCIS CHAPMAN,SONS & DEEKES, 1918

Francis Chapman, sons and Deekes was initially a London company but also had an office in Castlereagh St., Sydney. They were makers of Locks, galvanised iron, Fencing wire and rabbit traps. The Australian Trade Mark was applied for in 1904.Paper catalogue for Francis Chapman, sons & Deekes, Hopetoun House, Lloyds Avenue, Fenchurch Street London. 18 pages with the cover torn and separate from the rest of catalogue.. Contains Illustrations, B&W hotographs and listing for metal related products It also has the shipping and freight costs from London, Liverpool,Bristol and Glasgow to various ports around Australia. There are two metal staples in the spine. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - C.J. Clover Soda Bottle

.A clear glass bottle with eight one centimetre wide vertical groves in most of its length. Painted on the bottle in white is, C.J.GLOVER ,TRADE MARK PROGRESS REGISTERED, which has a coat of arms over it, BENDIGO, BRITISH SYPHON CO, LTD LONDON, REGNO 762. The bottle is 10.5 centimetres diameter at its base and tapers to eight and a half diameter, in the next 20 centimetres, the next eight centimetres tapers to three and a half centimetres the last eight centimetres to two and a half centimetres, the next three centimetres it rounds off to three centimetres. There is a red metal cap on top which is three centimetres diameter for two centimetres then tapers for two centimetres to one and a half centimetres which continues for two and a half centimetres with a slight flair at the top There is a small wooden cap on the top and a four by one centimetre curved wooden handle is attached near the top. On the tapered part of the cap there is metal tube protruding down at a 45-degree angle and is four centimetres long and one centimetre diameter. The bottle has a small amount of liquid in it.bottle, c.j.glover, soda bottle -

Churchill Island Heritage Precinct

Churchill Island Heritage PrecinctMachine - Wool Press

The Churchill Island collection includes objects from the 18th and 20th centuries. The collection is presented in sets and series, of which this object belongs to the National Trust sub-collection.Wool presses were used in shearing sheds around the country to create bales of wool by hand in preparation for transport to the wool markets for purchase and distribution. Bales have been used to store and were a standard trading unit for wool for centuries. A standard wool bale holds about 60 compressed wool fleeces and weighs a minimum of 120 kgs. The square shape and weight enabled them to be stacked on wagons or in warehouses, and a large pack horse could carry one on each side. Large, retangular upright metal wool press, unpainted with some surface rust.farm machinery, wool, wool press, hand operated, shearing, national trust -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDecorative object - Metal Vase, c. 1920

Metal, appears to be copper, tapered vase with a relief frieze of roses, appears to be brass, circling the vase approximately 8cm down from the top of the vase. Top opening of the vase also appears to be brass. Marked on the base MADE IN ENGLAND Beldray Trade mark serial numbers 2398 KA/TS 1506 -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumStapler

Had four feet, Now Two Rusty Made of Metal Dome hand Press Hedged Still has Staples insideVelas Trade, park Model "c" Made in England Reg Design NO 813111 -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Survival knife, US

Sapper L S Sempel of Royal Australian Engineers traded an Australian Army shirt for this knife, then used it to probe for mines during his service, 1966-1967.Knife with metal blade attached to a wooden handle and bolt hilt. The handle is made up of six wooden spheres joined to the blade. A wooden bolt secures the spheres.Shelham 4131 Japan inscribed on the knife blade.knife, mines, survival knife, us army kabar knife, kabar, engineer, sapper, vietnam, trade, sempel, ka-bar -

Northern District School of Nursing. Managed by Bendigo Historical Society Inc.

Northern District School of Nursing. Managed by Bendigo Historical Society Inc.Uniform - Nurse's Trainee Uniform

Northern District School of Nursing trainee nurse's base uniform from 1972Nurse's one piece dress in yellow with yoke and central front chest panel in white. Dress fastens with full back zip to waist and metal hook and eye. There are two pockets at sides below waist. There is a gusset to each side of back to sleeve. There is a long sleeved, waist length jacket, satin lined, with round neck with five yellow buttons and button holes at front. The fabric is of stretch cotton. Dress has a white label with 'Florgale Uniforms, Permanent Press' and washing instructions printed in red and blue and stitched to left rear neck facing. A trade mark, a ball in red and blue with the word 'Koratron' is also on this label. The jacket has a white label stitched to the lining at base of neck with 'Florgale Uniforms, Melbourne, Sydney" in gold. 'SW' and a female figure in long dress is embroidered in navy blue on the label.nurses uniform, northern district school of nursing, dress, jacket -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Edison Home Phonograph

... TRADE MARK On large metal plate: Detailed inscription of Patent... On outer case' Edison On metal plate: Thomas A Edison TRADE MARK ...Thomas Edison was one of the world’s most prolific inventors, holding over 2,000 different patents. One of his earliest inventions was the phonograph. The Edison Phonograph Company was formed on October 8, 1887, to market Edison's machine. The original machine went through many modifications. The Patent information on this machine indicates that it was manufactured after May 1906. Sound was recorded on wax cylinders. Edison cylinders were the earliest commercial medium for recording and reproducing sound. These hollow cylindrical objects have an audio recording engraved on the outside surface which can be reproduced when they are played on a mechanical cylinder phonograph Beginning in 1889, pre-recorded wax cylinders were marketed. They featured professionally made recordings of songs, instrumental music or humorous monologues in their grooves. The earliest cylinders were made from soft wax and later hard wax was utilised. Further developments by several companies, led to the introduction of celluloid cylinders. In late 1908, Thomas Edison had introduced wax cylinders that played for about four minutes (instead of the usual two) under the Amberol brand. The Amberols were manufactured with flat rim-ends, to prevent confusion with the earlier bevel-edged two-minute version. In 1912, the Edison company eventually acquired patents to the celluloid technology, and almost immediately started production of the new brand as Edison Blue Amberol Records. Cylinder records continued to compete with the growing disc record market into the 1910s. In 1912, Columbia Records, which had been selling both discs and cylinders, dropped the cylinder format, while Edison introduced his Diamond Disc format, played with a diamond stylus. From 1915, new Edison cylinders were re-recordings from Edison discs. Although his cylinders continued to be sold in steadily dwindling quantities, Edison continued to support the owners of cylinder phonographs by making new titles available in that format until the company ceased manufacturing all records and phonographs in November 1929.This item is significant because it is representative of early home entertainment in the late 19th and early 20th century.An Edison Home Phonograph in a wooden case. No trumpet included.On outer case' Edison On metal plate: Thomas A Edison TRADE MARK On large metal plate: Detailed inscription of Patent informationphonograph, thomas edison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bellows, 1862-1875

This bellows was used at the Warrnambool Racecourse by Master Farrier, Brian Chapman (1931-2017), during the 1970s but its history before then is still being investigated. The bellows have continued to be used from 1978 at Flagstaff Hill's blacksmith's workshop. Even today, in 2021, this same bellows are used by a volunteer blacksmith as he demonstrate the skills and tells of the importance of the blacksmith trade to colonial Australia. This 1860s double-action bellows is a typical form of blacksmith's or shipsmith's bellows. The end is forge-fitted with an iron nozzle or tube, called a tuyere or Tue iron, which concentrates the air to fan the fire or furnace. Tuyeres were traditionally made of cow horn. The double-action design of this bellows efficiently moves air both in and out of the chambers in the one movement of the long handle. The bellows was manufactured by John C. Onions of Birmingham, England, between 1862 and 1875. The stamp with the text, Gold Medal 1862, was also used on the business’ advertising. In 1875 the company was registered and began using the name John C. Onions Limited. JOHN C. ONIONS - John C. (Collingwood) Onions (1841-1904) was the son of a bellows maker of the same name. Onions (born 1841) and his wife Helen married in 1867 and they named one of their children John Collingwood Onions (1868-1913), as was the family tradition. He was well known as a Birmingham manufacturer of patented bellows and other forge-related equipment. He sold to the wholesale and retail markets for both local and overseas customers, including the British colonies. An 1862 advertisement points out that John C. Onions was a “Bellows manufacturer and contractor to Her Majesty’s Honourable Board of Ordinance” and His Imperial Majesty the Emperor of the French [Napoleon Bonaparte]”. The advertisement includes a sketched portrait of the Emperor Napoleon III, and an Imperial Autograph Letter dated May 23, 1854, from Napoleon, Palace of the Tulleries to Mr J C Onions of Bradford Street, Birmingham. In 1863 the company registered a patent on portable forges. In 1871 there were eight employees. John C. Onions Limited became a registered company in 1875. In 1876 an advertisements included that the company were smiths for hearths and tools in general and showed a row of six medallions including one with “Napoleon III, Emperor” and his portrait, and another “ _ _ _ 1862 MEDAL”. Their advertising motto was “For Excellence of Quality”. In 1885 the company merged with William Allday and Sons to become Allday and Onions. This mid-19th century bellows has local historical significance as it were once used by blacksmiths at the Warrnambool Racecourse in the annual racing event that continues today. This bellows is significant as a working example of equipment used in the 1800 and 1900s in the trace of blacksmiths and other metal working smiths. The bellows is technologically significant as it shows the progress from simple bellows to the double-action bellows, a time saving and efficient improvement. The manufacturer John C. Onions is historically significant as a family business that began in the 1600s and continued up until the 1980s.Bellows; large, oval, mechanical double-action smith’s bellows, manually operated, in working condition. The paddles of wood that form the top, middle sections and base of the bellows have flexible leather pieces attached firmly between them, forming airtight double lungs. Cut-outs in the panels allow the bellows to fill with air then force it out. A long handle is connected to pump the bellows and control the quantity and force of the air. The blasts of air are forced through the metal nozzle or tuyere at the end of the bellows and into the forge’s fire. Inscriptions are impressed into the wood on the upper paddle or board of the bellows. There are three circular stamps containing text. Text impressed in the wooden upper paddle of the bellows has been assumed to read “JOHN C. ONIONS, PATENTEES & MANUFACTURERS, BIRMINGHAM””?” “EXTRA” “AWARDED FOR EXCELLENCE OF QUALITY”, made from the following readable text :- “JOHN C ONIONS“ “PATENT - - - & MAN - - - - - - - - -“, “BIR - - - - HAM“, “ _ ERA - - - - “- XTRA-“, “- - - - - - - FOR EXCELL-“ “OF - - - - ITY” Text in the stamp “ - - ECE - - “, “ - - - - - / 1862 / MEDAL”, “- ITY” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john collingwood onions, john c onions, allday and onions, bellows, smith’s bellows, 19th century bellows, double-action bellows, double-acting bellows, double lung bellows, double chamber bellows, blacksmith tools, blacksmith trade, blacksmith craft, blacksmith equipment, forging equipment, john c onions patented double-action bellows, brian chapman, warrnambool racecourse, blacksmith, shipsmith, iron smith, mechanical bellows -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Wooden Trousers Hanger

Items such as this clothes hanger were widely used throughout Australia from the late 19th Century onwards. Francis (Frank) Stuart (1844-1910), manufacturer and politician, was born on 21 May 1844 at Penrith, New South. At 13 Frank was apprenticed to a Sydney draper. In 1866 he moved to Melbourne where Stuart joined the fashionable Collins Street mercery store of Alston & Brown. In 1884 he joined McIvor & Lincoln; on the death of the senior partner, Lincoln Stuart & Co., clothiers, was registered as a limited company in February 1889; when Lincoln retired, Stuart became sole proprietor. Among the business’ early success was a contract to supply uniforms to the New South Wales Sudan contingent. Stuart recognized possibilities in the rubber industry and joined with Barnet Glass & Sons Co. to manufacture waterproof clothing; he became a director of the company which was later taken over by Dunlop. Stuart was president (1885) of the Victorian Chamber of Manufactures and chairman (1887) of the Clothing and Manufacturers' Association. In April 1889 he was elected to the Victorian Legislative Assembly serving until 1894. In June 1904 he was returned to the Legislative Council as member for North Melbourne. He resigned in May 1907 to have more time for business. Frank Stuart died in 1910 and the business was carried on by his son Frank Jr. The company was taken over by John Snow & Co. Ltd in 1926, but continued to trade under Lincoln Stuart & Co. until it was finally deregistered in 1994.This item is representative of a range of clothing items and accessories popular throughout Australia and provided by a renowned Australian clothier. A wooden, leather and metal trouser hanger. It is inscribed with information about the manufacturer on both sides. it is made of two lengths of wood, connected by a leather strap and a metal buckle.Side 1: Lincoln Stuart & Co. Pty. Ltd. Wholesale and Retail Clothier Side 2: Flinders St. Melbourne Made in Germanydomestic appliances, lincoln stuart & co. -

Port of Echuca

Port of EchucaInstrument - Steering Wheel, PS Success, 1877

This steering wheel is from the PS Success. The PS Success was built in Moama in 1877 by GB Air for Westwood & Air. The Success towed barges of sawn red gum, wool & other cargo along the Darling and Murray Rivers as well as running as a passenger boat from Swan Hill to Mildura during 1915-16. The Success ended her working life in 1957 and was put up on the bank at Neds Corner, 80kms west of Mildura. The PS Success was donated to the Riverboat Historical and Preservation Society of Mildura with plans for full restoration but with funds becoming extremely difficult to secure, the Shire of Campaspe was approached to take ownership in 2009 to enable further restoration when possible. The Riverboat Preservation Society also donated this original steering wheel.The PS Success was an important vessel built in the Echuca area during the height of the Riverboat trade in the 1870s. She had a long, colourful history towing barges on the Murray River and in particular in the Mildura, Wentworth and Ned's Corner regions. Importantly, the Success was the last paddlesteamer to be working on the river system right up until the 1956 floods rescuing sheep and wool. The steering wheel is an important original element of the PS Success and her hopes for restoration one day. Red metal steering wheel with 10 spokes sitting on a heavy iron wheel stand. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Mont De Lancey

Mont De LanceyDomestic object - Four Medicinal Bottles, Sigma, Unknown

These medicinal products were used in the 1900's. Eucalyptus oil was used both externally for Lumbago, Rheumatism, Sciatica, Sprains, Cuts, Bruises and Burns and for all Throat and Cough disorders. McKean's Camphorated Oil was to be used carefully and under strict Accordance with the instructions. Adults to rub briskly on part affected, Infant use to be massaged gently. McKean's were in operation from 1890's - c1960's. The company appeared to have ceased in 2012. Friars Balsam similarly was used externally for Cuts, Wounds, etc. Could be taken internally for Coughs, Colds, Bronchitis, etc. 10 drops to one teaspoonful. The Bosisto bottle probably contained eucalyptus oil.Four glass medicinal bottles: 1. A small clear glass McKean's "Helping Hand' Eucalyptus Oil bottle, with a faded paper label with Trade Mark surrounding a hand illustration with leaves. Unadulterated is printed at the bottom of this label. Pure Eucalyptus Oil with its uses is included. On the back is a paper label with further instructions for use. The screw top bakelite lid is broken. 2. An angular shaped small brown SIGMA Camphorated Oil bottle with a stained paper label of the manufacturer details and uses. It has 'NOT TO BE TAKEN' stamped into one of the edges on the side of the bottle. Two other sides have three rows of crosses as a pattern. The metal screwtop lid is rusted. F1071 is stamped on the base. 3. A very small round brown Rolfe's Friars Balsam bottle with a broken cork stopper. It has a faded paper label with uses and the manufacturer's details. 4. A small blue tinted clear glass J. Bosisto medicine bottle with rounded corners and flattened sides on the front and back surfaces.The flat lip at he opening could have been sealed with a stopper. The sides of the bottle have a vertical joining line.1. 'McKean's 'Helping Hand' Eucalyptus Oil'. It has a faded paper label with 'Trade Mark (Registered) surrounding a hand illustration with leaves. Pure Eucalyptus Oil' 2. 'SIGMA Camphorated Oil SIGMA CO. LTD Melbourne'. 3. 'Rolfe's FRIARS BALSAM Rolfe & Co. Ltd. Melbourne'. 4. 'J. Bosisto Richmond' is stamped on front side of the front. On the base is stamped ' "English Bottles" '.medicines, medicine bottles, medicinal containers -

Mont De Lancey

Mont De LanceyFunctional object - Tea Caddy, Griffiths Bros Ltd, 1934

The tin was made for Griffiths Bros who were Australian merchants of tea, coffee and cocoa. They had branches in Melbourne, Sydney, Brisbane and Adelaide. The tins when emptied became useful storage containers.A large rectangular Griffiths Bros Choice Tea Net 7lbs. 1834 - 1934, metal storage tin with a hinged lid. Victoria's Centenary 1934 -5 is printed on the top left corner of the label. The Griffiths Bros label is in yellow script on the front with other text related to the contents, as well as a Trade Mark "SIGNAL" illustration and text at the bottom right. The label is outlined in green and yellow edging with country landscape at the top and city views at the bottom. The tin has much information as noted above, as well as - 'Packed by Griffiths Bros Ltd 30 Flinders St. Melbourne.'food containers, tea, tea caddies, tins, containers -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Reeves Fletcher Soda Syphon, 1920s

This is a soda syphon for holding soda water used by the aerated waters business of Reeves of Warrnambool (possibly bottled in the 1970s or 80s). It is a Fletcher bottle. John Davis established a cordial business in Warrnambool in 1859 and this business was taken over by John Fletcher. Ralph Reeves purchased the Fletcher business from the estate of the late John Fletcher in 1931 and continued to use the Fletcher bottles. The business of Reeves soft drinks continued in Koroit Street until the 1980s.This soda syphon is of considerable importance as it links two prominent soft drinks makers in Warrnambool – Fletcher and Reeves. It will be useful for display as it tells of a time when this sort of soda syphon was in use.This bottle is a soda syphon with an oblong-shaped glass base and a metal spout. It has a solid glass base and a pink-coloured tube inside the bottle. It has a chip on the base and the spout is a little corroded. The name and logo (scrolls and patterns) of J. Fletcher of Warrnambool is etched into the glass. There is also a red and cream paper label of Reeves.Paper label: ‘Reeves soda water’ Glass etching: ‘J. Fletcher, Warrnambool, F. Trade Mark’ john fletcher, reeves family -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

National Wool Museum

National Wool MuseumMachine - Donald's Patent No. 4 Wool Press, Donald and Co, 1930s

Donald & Co. Paddington, Sydney, Patent No. 4. Serial No. 87086 wool press. From the Penna's property at Meredith.Wood and metal wool press. No. 87086 / DONALDS / PATENT / No. 4 / WOOL PRESS / PADDINGTON / SYDNEY / TRADE / DONALDS / MARKwool growing wool brokering wool bales, donald and co., wool press, wool growing, wool brokering, wool bales -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Memorabilia - DIETZ LANTERN LABEL

See Items 7545 & 7544Dietz Lantern Label: Orange label oval in shape with a pink cotton thread through a small hole for attaching. Red print with red border line around the label. The label reads *The bottom of every Dietz lantern is made of heavily and thoroughly coated steel especially adapted for such use. DIETZ. Trade Mark. Stamped in the metal of each genuine DIETZ lantern. Look for it. On the back DIETZ with a red oval border and how to care for the lantern. Box 625R. E. Dietz Company. Largest makers of Lanterns in the World. Founded 1840 New York. U.S.A.business, retail