Showing 6114 items matching " tools"

-

Koorie Heritage Trust

Koorie Heritage TrustBook - Guide, Blake, Celia comp, Collections in Melbourne: A concise guide [Guide No. 8], 1998

This guide provides ... a portable and accessible overview of ... the collection and the associated reference tools and services available in the Melbourne office. The guide introduces you to the diversity and strength of the collection and invites you to explore it. The guide concentrates on records more than 30 years old (at the time of 1998).p.71 appendix; subject index; illus.30cm.This guide provides ... a portable and accessible overview of ... the collection and the associated reference tools and services available in the Melbourne office. The guide introduces you to the diversity and strength of the collection and invites you to explore it. The guide concentrates on records more than 30 years old (at the time of 1998).australian archives -- catalogs. | archives -- australia -- catalogs. | australia -- archival resources. -

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

NJ Phillips was the first Australian company to invent a drench gun that overcame the problem of drench going the 'wrong way' down the throat and onto a sheep’s lungs. This was the drench gun that they developed. It had an ingenious double action on the handpiece. The first squeeze projected a long nozzle that went right down the oesophagus before delivering the dose of drench automatically once this was in place. It also had a readily adjusted dose lever seen at left which minimised overdosing. This company dominated the market for many yearsSilver metal with black finishing drench gun. Minimal curvature tips on gun protrude from the body. Features a thin squeezable trigger to the rear of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney” in circular design. On top of this body is a large silver chamber in which both tips meet. This chamber is for the liquid to be transferred from the tube and into the tip of the drench gun for delivery onto the ewe’s tongue. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.Right circular lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

National Wool Museum

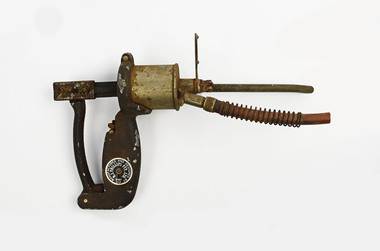

National Wool MuseumTool - Drench Gun, 1940-1950

There are several different designs of drench guns within the NWM Collection that show the change in their development over time. This drench gun has a large diameter curvature suggesting this gun was typically used for dosing ewes as opposed to lambs. The attached spring-loaded hose is the only example in our collection how this mechanism works. The hose will be screwed into the liquid which is used to drench the sheep. This liquid is typically located on the back of the operator who will wear a large container in a backpack. This gun also has a adjustable dosing mechanism located on the right side of the gun.Silver metal with black finishing drench gun. Large curvature tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney”. Behind this body is silver cylinder featuring attachment point for the tubing which would have carried the liquid drench into the gun. The attached tubing has a yellow/orange appearance from remanence of drench which would have been this colour.Left rotated lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

There are several different designs of drench guns within the NWM Collection that show the change in their development over time. On the left side of this gun white paint indicates the adjustable dose lever. It is a sliding scale from 10 to 0 cubic centimetres of liquid (now typical measure in millilitres). It also has a small and straight tip suggesting this gun was typically used for dosing Lambs as opposed to ewes. The manual adjuster helped to minimise cases of overdosing which can be fatal for livestock while the additional curvature helped to ensure the liquid reached the desired location within the sheep’s mouth. This desired location is on the left rear of the sheep’s tongue (from the sheep’s point of view) as this is where the oesophagus is located. The main risks are that drench may be delivered into the lungs via the trachea or “windpipe”, which can also prove fatal. The opening to the trachea which leads to the lungs is in the middle of the back of the throat. Another risk is the throat can also be damaged due to rough handling.Silver metal with black finishing drench gun. Straight tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards has silver cylinder on top of the handle where tubing carrying the liquid drench into the gun attaches. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.sheep drenching, veterinary instruments -

National Wool Museum

National Wool MuseumTool - Metal Files, c. 1920

Selection of metal files used for cutting wool bale stencils with an accompanying box. Not all files belong to this box as some are too long to fit within. Used in Denny’s Lascelles Bow Truss building by Maurice Dalton who was the foreman of the building for 34 years. Files are ‘Cup Brand’ – ‘Best refined steel files’ and were manufactured by the no longer trading Moss & Gamble Brothers LTD at the Franklin works in Sheffield, England.12 steel files of varying length, thickness and shape. The longest and thickets are in a flat half circle with some files being fully flat, others complete cylinders, one is a complete square and others are in the shape of a triangle. Cardboard box is brown with black inscription on lid of box.stencils, denny’s lascelles bow truss building -

National Wool Museum

National Wool MuseumTool - Water Pump, c.1960

A windmill may be considered one of the most iconic sights of Australian Farming life. A pump like this rest at the heart of all such windmills, turning wind energy into water for farmers both here in Australia and worldwide alike. The water windmills access is referred to as an aquifer, an underground layer of water trapped in rocks but accessible with use of water wells and windmills. Australia is home to an underground aquifer known as the Great Artesian Basin. It is the largest and deepest aquifer in the world. Stretching over 1,700,000 square kilometres, the Basin underlies nearly a quarter of the continent including most of Queensland, the south- east corner of the Northern Territory, the north-east part of South Australia and the northern part of New South Wales. The basin is 3,000 metres deep in places and is estimated to contain 64,900 cubic kilometres of groundwater. To try and give this number context, a megalitre is a million litres. The Great Artesian Basin contains 65,000 million megalitres of water. This would be enough to cover all the land on the planet in almost half a metre of water.Lift style piston pump typical of an Australian farm connected to a multi-bladed windmill. Bronze cylindrical construction coming up from removable wood base. Rotating lever is above outlet pipe which would send water to the storage tank.windmill, australian farming, great artesian basin, aquifer -

National Wool Museum

National Wool MuseumTool - Sickle, Pre. 1988

Feed for sheep farming is crucially important. Whether growing a sheep for breeding, wool or meat, it is vital to ensure that all sheep at whatever stage of life are maintaining or growing in weight. Sheep are often pictured grazing in paddocks; however, the grass available in a paddock is often not enough to maintain a sheep’s weight. In addition, if a sheep eats grass too low in a paddock then corrosion can affect the soil preventing any grass from growing in this location. For these reasons, supplementary feed is introduced to sheep’s diets. In most occasions’ food high in protein such as Lupins is sought. In times such as drought or to makeup a sheep’s roughage; feed such as silage, hay and straw may be required in the feeding of sheep. This is where the sickle is introduced to sheep farming. Although modern-day machines are used to harvest cereals, in times past the sickle was used for harvesting these crops. Once harvested, these crops can be fed to sheep freshly cut or dried. This sickle has been on display for 30 years at the National Wool Museum. It was at the entrance to Gallery One in the “A New Europe” wood hut display case. It was taken off display in 2021 with the “On the Land” redevelopment of this gallery space.Curved Metal serrated blade extending from carved dark wooden handletools of the trade, sheep feed, sheep farming -

National Wool Museum

National Wool MuseumTool - Spinning Wheel, c.1980

This spinning wheel originates from New Zealand; however, it has no distinguishing features relating to its creator such as an inscription, so its exact maker is not known. Gill Stange remembers buying the wheel on Bridge Road in Richmond, approximately 30 years ago. Gill had joined her local Spinners and Weavers Guild after the Ash Wednesday bushfires of 1983. She was a then resident of Mount Macedon and lost everything in the fires. Moving to Melbourne to get away from the scene of much pain, Gill was also in need of a new hobby to help occupy her mind. That is when spinning and weaving entered her life. The local Spinners and Weavers Guild was a great support network for her and with their recommendation, she purchased her own spinning wheel. Her passion was started, and the wheel was to become a treasured item in Gill’s home. She had several spinning wheels within her possession over the years, however, this wheel was her first and always her favourite. When the time came for Gill to downsize, there was simply no longer room for her spinning wheel. This is when she decided to donate the wheel to the National Wool Museum. Gill remembers one highlight was weaving a tablecloth from a traditional German design. It took her two years to complete, with Gill spinning all the wool herself on this wheel. The tablecloth won the first prize in the Melbourne Show in 1987. Gill also used the wheel to teach programs to school children on how to spin and knit wool. She would take the easily transported little wheel, and its accompanying seat, with her to schools. Its small size enabled her to teach children to knit and spin, bringing others the joy that spinning had brought her. Not just limited to schools, Gill also taught programs with the wheel here at the National Wool Museum. It is a fitting home for the wheel, which Gill donated to the National Wool Museum in 2021.Dark varnished wood in a Castle style spinning wheel. The wheel has 8 small spokes which meet a thick outside rim. The outside rim has four golden disc weights on the bottom edge, to aid in the turning of the wheel. The spinning wheel has four legs of turned wood giving a sculptural form, a design pattern which is continued throughout. The wheel has a single medium sized foot pedal. This pedal is well worn with varnish missing from years of use. The wheel is completed with its accompanying chair. Made of the same dark varnished wood, its legs are also of turned wood, continuing the design pattern and uniting the two objects. The chair is very simple outside of the legs, with a medium size base and a thin backrest ending in a rounded head. The chair’s varnish is also starting to fade from years of use. The chair is small, designed to keep the spinning wheel operator at the appropriate height when spinning on the equally small and compact Castle style spinning wheel. Additional parts were donated with the Spinning Wheel. - 3 x Lazy Kates - Spare Maiden. - 450mm Niddy Noddy - Steel teeth brushspinning wool, spinning wheel, ash wednesday, mount macedon, textile production -

National Wool Museum

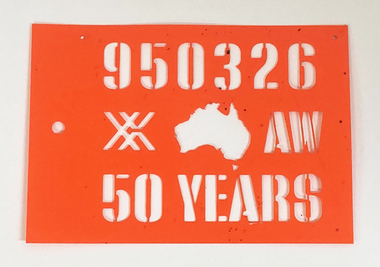

National Wool MuseumTool - Stencil, c.2018

The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. Thin sheet of orange plastic with letters and numbers moulded to produce a consistent pattern for the surface below through the application of ink. This wool classing stencil once belonged to Denis Hucker. The top number is Denis’ Wool Classing Stencil Number. On the next line is the emblem of the Australian Wool Exchange, followed by an image of Australia, and finally the letters AW. The final line reads 50 years, indicating Denis’ experience in the profession of wool classing. This stencil is reserved for wool classers who have held their stencil and been actively classing wool in Australia for more than 50 years. Wool classers sort, classify, and grade wool into various lines so that it can be sold at best market price. They also manage and supervise wool-handling teams. The stencil is used in the final step of preparing a bale of wool for sale. It is branded across the front of a wool bale to indicate the quality of the wool, with the classers number used as a seal of approval. Accompanying the stencil are two sheets of white A4 paper with printing in gold and black ink. The first sheet was presented by the Australian Council of Wool Exporters & Processors to Denis Hucker for achieving 50 years of wool classing. Surrounded by a thin gold boarder, the page is made up of black text with gold headings. In the top right corner, an image of a sheep with an outline of Australia is found. The second piece of paper was presented by the Australian Wool Exchange to Denis Hucker for achieving 50 years of wool classing. Two thirds of the page is made up of a gold stencil which reads “50 years”. Accompanying the stencil is black text. Moulded letters, numbers, emblem, and imagery. “950326 / (emblem AWEX) (Image Australia) AW / 50 Years” A4 Paper. Printed. See Multimedia A4 Paper. Printed See Multimedia wool classing, stencil, 90 years wool classing between father & son -

National Wool Museum

National Wool MuseumTool - Stencil, 1983

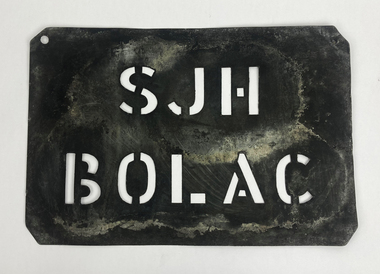

The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. Thin sheet of metal with letters and numbers cut to produce a consistent pattern for the surface below through the application of ink. In small text on the top edge of the stencil two separate phrases are engraved.” A.W.C. PROPERTY NOT TRANSFERABLE” and “PROFESSIONAL“. This wool classing stencil belonged to Stanley Hucker. It was his last Wool Classing Stencil. Dated to 1983, it is 45 years older than his first stencil. The role of a Wool Classer is to sort, classify, and grade wool into various ‘lines’ so that it can be sold for best market price. Wool Classers are typically also tasked with the managing and supervising of wool-handling teams. The stencil is used in the final step of preparing a bale of wool for sale. It is branded across the front of a wool bale to indicate the quality of the wool, with the classers number used as a seal of guarantee.Engraved letters. “A.W.C. PROPERTY / NOT TRANSFERABLE” Engraved letters. “PROFESSIONAL“. Cut imagery. Sheep’s head Cut letters, numbers, and imagery. “83 (Image Australia) P I / 50922”wool classing, stencil, 90 years wool classing between father & son -

National Wool Museum

National Wool MuseumTool - Stencil, 1938

The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. Thin sheet of metal with letters cut to produce a consistent pattern for the surface below through the application of ink. This wool classing stencil belonged to Stanley Hucker. It was his first Wool Classing Stencil. It was used on Stanley’s property named “Yohhatnbu” in Willaura. Stanley gained the property as part of the Returned Soldiers Settlement Scheme for his service in World War 2. The role of a Wool Classer is to sort, classify, and grade wool into various ‘lines’ so that it can be sold for best market price. Wool Classers are typically also tasked with the managing and supervising of wool-handling teams. The stencil is used in the final step of preparing a bale of wool for sale. It is branded across the front of a wool bale to indicate the quality of the wool, with the classers number used as a seal of guarantee.Cut letters. “SJH / BOLAC ”wool classing, stencil, 90 years wool classing between father & son -

National Wool Museum

National Wool MuseumTool - Stamp, 1940s

Note from collector- "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from." Wood and metal stampBlanketsblankets, blanket fever, stamp -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

National Wool Museum

National Wool MuseumTool - Knitting Pins, 1960-69

The donor (Lynn Fitzpatrick) purchased these knitting needles 20 years ago from an opportunity shop. Aero Knitting Pins are a discontinued brand that were popular in the 1960s, 70s and 80s. They are made of smooth, aircraft-quality anodized aluminium. To this day, they are a popular and sort after knitting needle. Being a long-lasting product, they are often given as heirlooms. Abel Morrall was a major needle manufacturer from Studley, a town near Redditch. In 1785, Michael Morrall who was taught the art of needle making by a maternal uncle, moved to Studley. He founded the Abel Morrall company with his brother Abel, and another unnamed brother-in-law. Within five years the company was producing 40% of the 2.5 million needles that were made each week in the Redditch area. In 1811 the company introduced the concept of creating the eyes by using a stamping press. Additional machines were invented by them throughout the 19th century leading to major improvements in the way needles were produced. Abel Morrall demonstrated their needle making machinery at the Great Exhibition of 1851 and Queen Victoria personally inspected it. The company selected the demi-griffin for its trademark in 1861, which can be seen on older products produced by the company. Set of four knitting needles stored within paper packaging. Packaging features black, red, and white ink, detailing the selling points of the Aero Knitting Pins. The packaging folds with 3 main sections, each providing different insights into the knitting needles. Examples of this are " CANNOT SOIL LIGHT WOOL", "...SPECIALLY TAPERED POINTS WHICH WILL NOT INJURE THE FINGERS" and "RUSTLESS-NON-GLITTER FINISH". As the packaging unfolds, the grey knitting needles become visible. The needles can be removed from the packaging by sliding them through small bands of paper that hold the needles secure while in transportation. The four knitting needles are a “NEUTRAL” grey colour finished in a double point style.Printed. Orange, White and Black Ink Numerous, see multimediaabel morrall, knitting needles, knitting pins, 1960s home knitting -

National Wool Museum

National Wool MuseumTool - Shearing Handpiece, c.1890

Ford and McFarlane shearing handpiece c.1890. This shearing handpiece is from ‘Wellington Lodge” in Tailem Bend, South Australia. Wellington Lodge today is an Angus beef farm; however, the property has a long history which includes wool farming. Wellington Lodge has been in the McFarlane family since the 1840’s and was originally around 19000 acres. The donor, Brian Licence, assembled this handpiece out of spare parts he found while classing wool on the property in the 1960s. Brian showed the finished handpiece to the owners once his classing work was completed and was told he could keep the handpiece as a souvenir. Brian also classed wool at “Jockwar” and “Pleasant Park” in Penola for members of the McFarlane family during the 1960s. The handpiece is named after Ford, the name of the engineer who designed the handpiece and McFarlane, the owners of Wellington Lodge Station and employers of Ford. This handpiece was developed as a prototype for use on the property. The handpiece which is made of solid brass is in a “used condition” and has been patched with solder. The handpiece is stamped with the number 10. Internally, the handpiece is powered from a drive mechanism of compressed air, this compressed air was typically produced by burning mutton fat. The handpiece comes from the pre-electrical– steam engine era of shearing. Brass metal shearing handpiece. A three-pronged fitting to hold both the comb and the blade protrudes from one end. A cylindrical stem extends vertically from the other. This is likely where a connecting rod to the shearing plant would be found. Below this vertical stem, the handpiece has an additional threaded hose fitting. This is likely where compressed air was delivered into the handpiece. The inscriptions can be found on the rear, near the previously mentioned vertical stem. Around this stem is also where the repairs of solder can be found. These repairs are unique to this handpiece and are not common practise.Etched. Base of handle. “FORD & McFARLANE . SHEEP SHEARER . Etched. Base of handle. “10”sheep shearing, shearing equipment, ford & mcfarlane, wellington lodge, tailem bend, south australia, shearing handpiece, shearing -

Koorie Heritage Trust

Koorie Heritage TrustBook, Bourke, Colin, Before the invasion, Aboriginal life to 1788, 1980

Blurb: Before the Invasion gives a vivid overview of traditional Aboriginal life. It describes what Aborigines wore, their houses, weapons, tools, canoes, and shows their practical ingenuity and resourcefulness in making the most of what their environment offered. It also covers families, clans, roles of men and women, attitudes to children and the old; and the religious world-view which determined the rhythm of their life and underlay all their laws art and music. The authors bring out the broad patterns Australia-wide, but they are careful to note the differences between groups in different areas and to give specific documented examples...112 p. : ill. ; 21 x 23 cm.Blurb: Before the Invasion gives a vivid overview of traditional Aboriginal life. It describes what Aborigines wore, their houses, weapons, tools, canoes, and shows their practical ingenuity and resourcefulness in making the most of what their environment offered. It also covers families, clans, roles of men and women, attitudes to children and the old; and the religious world-view which determined the rhythm of their life and underlay all their laws art and music. The authors bring out the broad patterns Australia-wide, but they are careful to note the differences between groups in different areas and to give specific documented examples...1. aborigines, australian -- social life and customs. schools - project referencers. i. johnson, colin, joint author. ii. white, isobel m., joint author. iii. title -

Koorie Heritage Trust

Koorie Heritage TrustBook, Basedow, Herbert, The Australian Aboriginal, 1925

Contents: Introduction to an Australian Tribe; Racial characteristics; The breast and abdomen; The face and its skeleton; The mouth; The skull and brain; Colour of Aboriginal's skin; The hair; Likely origin of the Australian Aboriginal; An Aboriginal's Birth; Childhood; The Day's March; Camp life; Hunting; Vegetable Diet; Beverages; Pitjuri; Navigation; Duels; Warfare; Spears; Spear-Throwers; Burial and mourning customs; Tribal organizations; Tribal administration; Initiation; Religious ideas; Aboriginal art; Stone implements; Music and dance; Language.xx, 422 p., 55 leaves of plates : ill., map, ports. ; 22 cm.Contents: Introduction to an Australian Tribe; Racial characteristics; The breast and abdomen; The face and its skeleton; The mouth; The skull and brain; Colour of Aboriginal's skin; The hair; Likely origin of the Australian Aboriginal; An Aboriginal's Birth; Childhood; The Day's March; Camp life; Hunting; Vegetable Diet; Beverages; Pitjuri; Navigation; Duels; Warfare; Spears; Spear-Throwers; Burial and mourning customs; Tribal organizations; Tribal administration; Initiation; Religious ideas; Aboriginal art; Stone implements; Music and dance; Language.human biology -- physiology -- reproduction -- social organisation -- life cycle -- birth -- childhood -- religion and magic -- ritual -- initiation -- mortuary -- politics, tribal law and social control -- arts -- performing arts -- music -- dance -- language and communication -- economics and material culture -- economic life -- division of labour -- subsistence -- hunting -- gathering-- weapons -- spears -- spearthrowers -- tools -- stone -- -

National Wool Museum

National Wool MuseumTool - Secateurs

Foot paring, scissor style foot parring secateurs with replaceable blades and self spring action. -

National Wool Museum

National Wool MuseumTool - Shears

Well known make of shears.Steel and iron hand shears with leather keeper. Brand "Combination U.T.S. Sheffield".Combination U.T.S. Sheffieldhand shears -

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

There are several different designs of drench guns within the NWM Collection that show the change in their development over time. On the left side of this gun white paint indicates the adjustable dose lever. It is a sliding scale from 10 to 0 cubic centimetres of liquid (now typical measure in millilitres). It also has a large diameter curvature suggesting this gun was typically used for dosing ewes as opposed to lambs. The manual adjuster helped to minimise cases of overdosing which can be fatal for livestock while the additional curvature helped to ensure the liquid reached the desired location within the sheep’s mouth. This desired location is on the left rear of the sheep’s tongue (from the sheep’s point of view) as this is where the oesophagus is located. The main risks are that drench may be delivered into the lungs via the trachea or “windpipe”, which can also prove fatal. The opening to the trachea which leads to the lungs is in the middle of the back of the throat. Another risk is the throat can also be damaged due to rough handling.Silver metal with black finishing drench gun. Large curvature tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney”. Behind this body is silver tubing featuring attachment point for the tubing which would have carried the liquid drench into the gun. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.Left lettering: 10CC 5CC 0/ 7.5 2.5/ Left rotated lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

National Wool Museum

National Wool MuseumTool - Elastrator

Elastrator. Registered trade mark - 3 parts incorporated. This is your seal of quality. For the original and genuine 'Elastrator' Marking Instrument Reg Trade Marktextile mills -

National Wool Museum

National Wool MuseumTool - Lamb Marker

Used for sheep castration.Lamb marker with bakelite handle, sharp blade at one end and double clamp with serrated edges at other end.dalgetys -

National Wool Museum

National Wool MuseumTool - Finishing machine

Variable speed cloth puller, used for tightening and smoothing blanket edges, prior to them being sewn or bound. Used at Collins Bros Mill.Textile finishing machine. Horizontal, made from grey steel with a small encased gear box and two attached rollers. Separate belt drive and nine other rollers. Enclosed in original brown cardboard box, used for shipping.SUISIE / VARIABLE SPEED / VERSATILE CLOTH PULLERtextile machinery, collins bros mill pty ltd, blankets -

National Wool Museum

National Wool MuseumTool

For moving running belt from fixed to free pulley, probably from shearing corunder. See Wolsely overhead equipment. May be related to Accn. No. 6. -

National Wool Museum

National Wool MuseumBag, Tool

Worn and used by Mr de Josselin.Bag worn and used by Mr de Josselin.shearing, de josselin, mr john -

National Wool Museum

National Wool MuseumTool

Used at Foster Valley Mill. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Plane

Donor, George Cox, MLA defeated in 1982. Re-elected to State Upper House, retired 1996Moulding plane made from hardwood and steeltrades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Knife Sharpener, 1950s

Plastic 1950s utensilKnife Sharpener. Square green plastic base; cream plastic pyramid shaped body. Green dial on front for setting the utensil for sharpening.DIAL X SHARPENER. SHARPENS EVERYTHING.domestic items, appliances, utensils -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tape Measure, 1966

Tape measure was donated by donor's niece. It had belonged to her uncle Philip BennetSilver tape measure by Turner, Lufkin and Mezurall. Retractable. Imperial measure.Turner, Lufkinhandcrafts, dressmaking, buildings, fittings -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Shovel

The shovel was probably used at the Burwood Brick Works as it was found during redevelopment of the site.Large steel shovel with steel and wooden handle.Tulloch Phoenix Pat No. 51268. 11-9-51 No 7rural industry, agriculture