Showing 1081 items matching "metal manufacture"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chain Drill Attachment, Millers Falls Co, 1900-1931

An auxiliary tool for use with a breast drill or bit brace, when extra power is needed, or where pressure cannot be easily applied. The drill is automatically fed into the work by an adjustable friction feed which is automatically regulated by the resistance the drill encounters. These were made to fit on breast drills, and used for drilling metal, particularly round sections like a pipe. The chain is run around the object being drilled and gradually tightens as the hole is drilled, maintaining pressure while being a bit easier on the operator. Millers Falls Co. is a tool manufacturing company originally based in Millers Falls, Massachusetts, USA. It was established in Greenfield, Massachusetts in 1868 as Gunn & Amidon by Levi J. Gunn and Charles H. Amidon. Gunn and Amidon, along with a third partner, Henry L. Pratt built a factory in the north of Greenfield. After the Greenfield factory burned down, the company was reorganized as the Millers Falls Manufacturing Co. It merged with Backus Vise Co. in 1872 to form Millers Falls Co. In 1931 Millers Falls tools purchased the majority of the shares of Goodell-Pratt tools and merged with that manufacturer in 1932. In 1962 the company was acquired by Ingersoll Rand. In 1982, Ingersoll Rand sold the Millers Falls business to the newly created Millers Falls Tool Co. The company was head quartered in Alpha, New Jersey. Since 2002 the company trademark has belonged to Hangzhou Great Star Industrial, of Hangzhou, China. The item is associated with a tool manufacturing company established in the mid-19th century that pioneered the development of many types of tools used in many differing trades. The company grew to become a major supplier of tools around the world and today its tools that were produced during the mid-19th and early 20th centuries are now collectable items. Drill attachment with chain No 717 from 1925 catalogue 1/2 socket hole Millers Falls, Massachusettsflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, chain drill, mast drill, millers falls, drilling attachment, drilling tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking mallet, Mid 19th to early 20th centuries

The subject item is a vintage Nautical Shipwrights Ship Boat Caulking Hammer Mallet, Unusual Small Size. These mallets were routinely used in the 1800s when ships were made of wood. This mallet was used with caulking irons to drive the oakum (caulk) between the ship's bottom planking to seal them up. The mallet has slots to dampen the vibration of the mallet blows on the user's elbows. The head is made of a very hard wood, possibly Lignum Vitae or another dark tropical wood. The item seems to be of a very early design with the two preened-over metal rods for reinforcing the head. Item appears to be of early manufacture by an unknown maker from the mid to late 19th century and is significant as tools of this era are quite rare. This tool is also significant as it gives an insight into how ships made of wooden planks were made sea-worthy by inserting caulking material between the boards thereby making the vessel watertight. Caulking Mallet Wooden with iron ferrules on each end. Wooden head with two large bolts passing through body. Stamped W Milne. James S Steele tool box.Stamped W Milne & James S Steele tool box.mallet, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking mallet, caulking, james steele, shipwrights tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Cocoa Tin, First half of 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin. https://www.shilohplastics.com.au/history-of-metal-packaging/The use of tin to protect and store food and other items, revolutionised the world.Tin base and external tin lid, with round internal lid .Colour printed. Used for cocoa. Caption of a woman drinking cocoa, red Australian flag and British flag on other faces. Top embossed "H". Marked - "Old Dutch Cocoa", "Net Weight 8 ozs," (Display side) "Manufactured by Hoadley's Chocolates Ltd, Australia.Top embossed "H". Marked - "Old Dutch Cocoa", "Net Weight 8 ozs," "Manufactured by Hoadley's Chocolates Ltd, Australia.warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, tin, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLeisure object - Toy Soldier, circa 1878

The toy soldier is a relic from the shipwreck of the LOCH ARD in 1878. It has a companion piece in the Flagstaff Hill collection. The toy soldier is unpainted, but the style of uniform, and the weapons carried (a musket and a basket-handled cutlass), indicate it is a representation of the Napoleonic Wars period from the beginning of the nineteenth century. Mass-produced toy soldiers made of cast metal (lead or tin) became popular during the 1800s. Heyde of Germany manufactured silhouette-shaped flat toy soldiers early in the century. Mignot of France released three-dimensional solid figures and later around 1893 W. Britain, a toy company became known for its die-cast lead toy soldiers. These innovations were designed to make sets of toy soldiers more affordable for middle and lower-class children, extending the market beyond the intricately made and hand-crafted replicas that were the preserve of the rich in the eighteenth century. Wooden military figures, specially carved and unpainted ones, were therefore not particularly common at the time when the Loch Ard foundered on Victoria’s southwest coast. Mignot was the first to sell unpainted soldiers, leaving their customers to fill in the colours according to their own patriotic preferences. It is, therefore, possible the two figures in the Flagstaff Hill collection were part of a new set intended for sale, rather than part of a passenger’s existing collection. Loch Ard History: The Loch Ard got its name from ”Loch Ard” a loch that lies to the west of Aberfoyle, and the east of Loch Lomond. It means "high lake" in Scottish Gaelic. The vessel belonged to the famous Loch Line which sailed many vessels from England to Australia. The Loch Ard was built in Glasgow by Barclay, Curle & Co. in 1873, the vessel was a three-masted square-rigged iron sailing ship that measured 79.87 meters in length, 11.58 m in width, and 7 m in depth with a gross tonnage of 1693 tons with a mainmast that measured a massive 45.7 m in height. Loch Ard made three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of 29-year-old Captain Gibbs, who was newly married. The ship was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were other items included that were intended for display in the Melbourne International Exhibition of 1880. The voyage to Port Phillip was long but uneventful. Then at 3 am on June 1, 1878, Captain Gibbs was expecting to see land. But the Loch Ard was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4 am the fog lifted and a lookout aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head-on into the wind, the ship lost momentum, the sails fell limp and Loch Ard's bow swung back towards land. Gibbs then ordered the anchors to be released in an attempt to hold their position. The anchors sank some 50 fathoms - but did not hold. By this time the ship was among the breakers and the tall cliffs of Mutton Bird Island rose behind. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves subsequently broke over the ship and the top deck became loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of Loch Ard and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as Lochard Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael a passenger had raced onto the deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke the open case of brandy which had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a complete state of exhaustion, he told the men of the tragedy. Tom then returned to the gorge while the two men rode back to the station to get help. By the time they reached Loch Ard Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost family in the disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. Ten days after the Lochard tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of Lochard still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some items were washed up into Lochard Gorge. Cargo and artefacts have also been illegally salvaged over many years before protective legislation was introduced in March 1982. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton majolica peacock- one of only nine in the world. The peacock was destined for the Melbourne 1880 International Exhibition. It had been well packed, which gave it adequate protection during the violent storm. Today the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck, it has now become Australia's most valuable shipwreck artifact and is one of very few 'objects' on the Victorian State Heritage Register.The toy soldier represents a 19th-century child's interest in military history. The item is one of two toy soldiers recovered from the Loch Ard in Flagstaff Hill's collection. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck of which the subject items are a small part. The collections of objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history, allowing us to interpret Victoria's social and historical themes. Through is associated with the worst and best-known shipwreck in Victoria's history.An unpainted, cream-coloured toy soldier, recovered from the Loch Ard. The figure wears a Napoleonic Wars-era uniform, a plumed helmet, a short jacket with tails, bib-front trousers with button closure, straps crossed at the front and back, and epaulettes. The figure is in marching posture with one foot extended forward, and is bearing a musket at the slope-arms position, with a sabre or cutlass slung behind. It is unable to stand on its own. There are reddish-brown and orange-brown stains on the head and body. The body has seams along both sides that are uneven at the lower leg. There is a hole in the back and the inside is hollow. The material has a rough texture.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch ard, toy soldier, napoleonic uniforms, military toy, moulded soldier -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1880 to 1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had.Kettle, cast iron ware, black with some rust. . With lid of questionable origin. Made by "T & C Clark "C" inside 6 pointed star, England RD 665875 3 quarts No 3 First Quality"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGlue Pot, T & C Clark, Late 19th Century

T. & C. Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enameled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councillor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enameled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enameled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enameled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.An item that was made by a British foundry that was a pioneer and innervated many new processes in the manufacture of enamel ware, producing many items for every day use.Glue pot with inner pot, metal, corroded, both pots have handles."T & C CLARK & Co Ltd, ENGLAND, 55279 RD" and "FIRST QUALITY No. 4/0"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t& c clarke, cast iron, foundry, sanitary ware, ironware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Printing Press, Harrild and Sons, 1866

This Albion printing press was manufactured by Harrild & Sons of London and exported in 1868 from London to the colonial Western Victoria town of Coleraine, population of 700 at that time. It was installed in the Colerain Albion printing office. It was used to print the first edition of the Coleraine Albion newspaper in 1868 and continued until publication ceased in 1974. The Albion Press is still being used today by a volunteer printer in the “Examiners Office” in the village at Flagstaff Hill. Amongst the items produced are printed paper bags for the Tea Rooms and posters for visitors. ALBION PRINTING PRESS The Albion press was invented and manufactured in London by Richard Whittaker Cope around 1820 and was still being produced in the 1930s. The Albion was manufactured under licence by several companies from the 1850s onwards, one of which was Harrild & Sons of Fleet Works, London. Harrild & Sons describes its business as “printing materials manufacturer”. The business was established in 1807 by Robert Harrild and named R. Harrild & Co. In 1813 he showed that rollers could be used to ink a printing plate instead of inking balls, the method in use at the time. He then established a company to make the rollers. Eventually his company would make other printing materials and equipment. Robert’s sons joined him in the 1830s, when the company was renamed Harrild & Sons, and they continued to run the company after his death in 1853 and up until the mid-1900s. COLERAINE ALBION PRINTING OFFICE The Coleraine Albion Printing Office was established by W.L. Ambler. The first issue of the Coleraine Albion was dated 4th January 1868. Arrangements had been made to receive news from Melbourne, nearby provinces, other colonies and England. The second issue on 18 January 1868 printed articles from many agencies, including the Melbourne Age and the Warrnambool Examiner. The Albion office was sold to William Hatherleigh, formerly of Portland, in October 1868. Thereafter the Albion office had many owners. The last was L. A. & E. Oliver, who took over in January 1972 and was the last to be stated as printers and publishers of the Coleraine Albion. The office was wound up in 1974. The Albion Press and other equipment was distributed to Star printing in Terang. Star Printing donated the Albion press to Flagstaff Hill Maritime Village around 1980 and Stan Philp, owner of Philprint in Warrnambool, transported it to Warrnambool, brought it up to good working order and organised the supply of appropriate printer’s type. The Albion hand operated printing press is significant for producing the first newspaper in Coleraine, Western Victoria and continuing production for over 100 years. The Albion is technologically significant as a working example of a hand operated printer from the mid-19th century. The use of the printer is demonstrated by volunteers at Flagstaff Hill, printing items such as lolly and treat bays for use in the Village. The Albion is socially significant for its role in the isolated provincial colony, providing communication with the outside world, both in Australia and overseas. Newspaper printers were often amongst the first businesses of a small town. Printing press; hand operated Albion Press, Patent 2105. The machine has an upright iron frame at the back that supports the upper press that has a wooden handled metal bar is attached. The frame and legs support a thick metal flatbed. A metal leg supports the front of the press bed. The iron work is painted black with gold highlights. The decorative legs are finished with the golden feet of an animal. The frame above the metal bed includes a crown shaped finial symbol above the maker’s emblem. The maker’s details and the name of the printer are embossed on the upright frame. A plaque with the patent number is below a Lion and Unicorn emblem.Embossed maker’s emblem [A red cross - above a double ring – square inside ring – three banners below ring]. - Inside the double rings “PRINTING MATERIALS MANUFACTURE” - Inside the square, intertwined text “H & S” [representing Harrild & Sons] - Inside the three banners ““FLEET” “WORKS.” “LONDON.E.C.” Embossed across the shoulders “ALBION PRESS / HARRILD & SONS, / MAKERS LONDON.” Emblem above plaque [Lion and Unicorn] Embossed on the plaque “PATENT / 2105” Stamped into upright machine part above the printing bed “2105 / 1866” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, albion press, printing press, 1866 printing press, printing equipment, communications, coleraine albion printing office, coleraine newspaper, albion newspaper, south west victoria newspapers, harrild and sons london, richard whittaker cope, star printing terang, philprint, coleraine albion, hand operated press -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor, John Clarke Ltd, 1930s

In 1848, 43-year-old John Clarke launched a cutlery business in Harvest Lane in Neepsend, Sheffield UK. Clarke entered the trade late in life he was indenture and apprenticed to Octavius Twigg, a razor maker. Clarke was granted his Freedom in 1856 and began using the trademark 'NEVA'. By the 1860s, Thomas Clarke's son by his wife Elizabeth had joined the firm. When John Clarke died at his home at Augusta Place, Rock Street, Sheffield on 25 July 1873 (aged 68), he only employed six workmen. By 1881, Thomas had expanded this number to twenty. He sold a wide range of cutlery and was also an ‘emigration agent’, the Sheffield Independent, of 7th September in 1886 had an article published stating Thomas helped to recruit personnel from England for cutlery centers in America. In 1893 Clarke’s showroom displayed miniature knives from '5/16ths-inch long to the most expensive sportsman's knives, that were gold and silver mounted. Table knives and carvers were also manufactured (or factored). Agencies were opened in London, New York, and Melbourne. Besides ‘NEVA, the ‘EXPRESS’ and ‘RING’ marks were used on razors; and Clarke’s marketed the American ‘GEM’ safety razor. By 1901, the firm had moved to Mowbray Street, where its Mowbray Works overlooked the River Don. Thomas Clarke died at Harrogate on 26 April 1902, aged 62, and was buried in the same Burngreave cemetery as his parents. Thomas’s sons, John Roome Clarke (1860-1925) and Thomas Edward Clarke, were directors, another son George William Clarke was a shareholder. John Roome Clarke died on 3 February 1925, aged 64 his son, John Clarke, of Crimicar Lane, remained as the senior partner. Clarke’s was one of the last producers of hand-made pocket knives and it also produced a large output of sheath knives for scouting associations. The firm was liquidated in 1964, but the company name was resurrected and Its last address after 1980 was at 65 Garden Street Sheffield. The company trademark passed on to Meteor Industries and then to Egginton Ltd. Weber & Co: The Clarke company purchased or (factored) many of its blades for razors and knives from Weber & Co of Solingen Germany. The full name of the firm originally was Jowika Stahlwarenfabrik Eugen Weber & Altenbach KG. It was founded in Solingen prior to 1928, under the name Johann & Wilhelm Kleinewefers GMBH, Messerfabrik. JWK for short, hence JoWiKa. The company was sold to Eugen Weber in the 1930s. Weber was married to a woman named Altenbach, from a family that manufactured innovative low-priced pocketknives, as well as other cutlery items. In 1960 Weber opened a branch factory in Listowel Ireland. It was sold to Albert M. Baer of Imperial Schrade in 1978. The Listowel factory was closed about a year and a half before the U.S. Schrade factory closed in 2004 and the Jowika factory in Solingen had closed in 1984.An item with an interesting manufacturing history from the 1930s showing how one man can grow a business into a successful concern that made quality products that stand the test of time.Razor metal folding blade with horn handle in its original cardboard box Inscription Made by John Clarke and Son England. "Champion" razor. On box " The Champion 10/6d" and "Weber Lohmann & Co SOLINGEN".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Cot, Late 19th to early 20th century

Iron beds made from metal or wrought iron have been around since the late 18th century when they were hand made by craftsmen and artisans. The iron castings were always hand poured and originated from sand cast molds, more ornate beds are associated with the Victorian period. Later in the Edwardian era cast iron beds and cots had much less decoration and were quite plain .An relatively early domestic piece of furniture used as a babies cot giving a snapshot into domestic life around the end of the 19th century and beginning of the 20th. The item is not associated with a significant event, person or place and would have been common place in most homes of the time made by many different manufactures.Cot, metal, with chrome knobs and removable sides. Has wheelsNoneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cot, metal cot, iron bed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Enterprise Manufacturing Company, circa 1911

This particular food mincer was manufactured by Enterprise Manufacturing Company. Located in Philadelphia, this company specialized in making hardware products. The company was especially known for its cherry pitters, apple peelers, and coffee mills. The company was founded in 1864 and was located on the corner of Dauphin, 3rd, and American Streets. Enterprise Manufacturing Co. remained in business until 1956 when it was bought by Silex Co.A mass produced early domestic item made for home food preparation this item's first patent design was approved in 1897. Manufactured by a well known company in the USA the "Enterprise Manufacturing Company” up until 1956. They specialised in making kitchen appliances of various types for domestic use and for export. Food mincers of the subject items design are still being produced today under the brand name of "Universal" made by Universal Trading Inc USA.Food mincer, metal, clamp on bench style, with rotating wooden handle. Inscriptions stamped on metal.Marked "Enterprise tinned Meat Chopper" "No. 10" "Enterprise MF'G Co. PHILA. USA" "PAT. JAN.30.83" flagstaff hill, warrnambool, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mincer, food mincer, meat mincer, food preparation, kitchen utensil, domestic object, enterprise manufacturing company, kitchen appliance -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, Kande Kitchenware, Circa 1924

... and successful Australian company that manufactured metal kitchen items ...Kande Kitchenware was established by Patrick Kavanagh and William English (the name Kande was formed from their initials, K and E) in 1922 and had its Sydney factory in Little Collins Street, Surrey Hills. Kavanagh and English, a subsidiary of Kande Kitchenware, became a limited company in 1924, with both founders as directors. Another director was Test cricketer Jack Gregory, an all-rounder who slipped easily into the role of businessman. Gregory enjoyed success in business as on the cricket field, helping the company grow from a tiny operation to a major manufacturer and exporter that employed 80 people in 1931. They managed to survive the Depression and kept manufacturing at least until the late 1960s.An appliance made by an early and successful Australian company that manufactured metal kitchen items during the first half of the 20th century. Colander enamel rusty holes in base of bowls, 2 handles, bowl shape.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, colander, kitchen item, domestic item, kitchen strainer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking Pot, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had.Cast Iron cooking pot with lid separate Straight rod handle painted black.On base "T&C Clark and Co Ltd, RD455270 First Quality"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, iron cooking pot, cook ware, saucepan, kitchen utensil, cast iron enamel ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1800-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had.Kettle lid solid metal, handle and spout - has been painted black. Badly rusted on base"T C Clark, England"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, iron kettle, cook ware, kitchen ware, cast iron enamel ware, t c clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. Cast Iron Kettle straight metal handle painted black. Rusted inside and holed in the bottom, "T C Clark England" RD665876, 3 quarts No3" and other unreadable inscriptions.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, iron kettle, kitchen ware, t c clark, enamel cook ware, cast iron kettle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lamp, After 1950

The lamp has been manufactured for decorative used, representing lamps of the late 19th and early 20th century used for lighting.The lamp is an example of a 19th century ships lamp. It is currently not associated with a historical event, person or place at this time and is being used to augment Flagstaff's village display.Metal lamp with circular base, 8-sided glass section and conical lid topped by a frilled metal cone and handle made from a strip of metal bent into a 'u' shape and attached so that it can swing back and forth..Cone hinges to side to give access to candle, which is seated in a short ring in the centre of the base. There is a ring of air holes around the circumference of the cone, about half way up the height of it. A shard of glass missing from one of the glass panels and the metal parts are corroded.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lighting, candle lamp, domestic lighting, ship lamp -

Flagstaff Hill Maritime Museum and Village

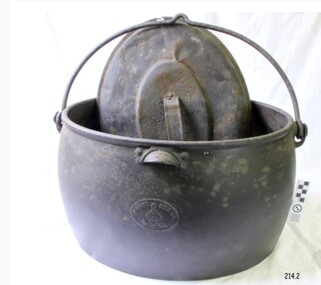

Flagstaff Hill Maritime Museum and VillageDomestic object - Pressure Cooker, T & C Clarke and Co Ltd, Late 19th to early 20th century

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to cook food safely without the concern that the metal interior may contain lead or arsenic as earlier cooking utensils had. Pressure cooker, cast iron , pressure vent on top. Removable lid held down by 3 riveted heart shaped clips where they join the base. Metal drop down carry handle.T & C Clarke and Co. on base & size 2 1/2 gallonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pressure cooker, cook ware, cooking pot, clarke and co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, 1900-1920

A colander, sieve or cullender is a kitchen utensil used to strain foods such as pasta or to rinse vegetables. The perforated nature of the bowl allows liquid to drain through while retaining the solids inside it is sometimes also called a pasta strainer or kitchen sieve. Conventionally, colanders are made of a light metal, such as aluminum or thinly rolled stainless or plated steel, colanders are also made of plastic, silicone, ceramic, and enamelware. The word colander comes from the Latin Colum meaning sieve.Early 20th century kitchen item possibly of French manufacture due to the design and shape of the bowl this design appears to have been favoured by the French around 1910 for smaller Colanders. This item gives a snapshot into domestic life around the late 19th and early 20th centuries and the types of kitchen equipment in use.Strainer or colander, metal, with concave base and wood handle, plated metal construction with welded or folded seams. Handle painted black, perforated base.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, strainer, food strainer, seive, food preparation, kitchen ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Kettle, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen item to boil water safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. Cast Iron Kettle no lidT and C Clark and Co, London. No. 2, 5 pints capacityflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, cooking pot, cook ware, kitchen ware, cast iron kettle, t c clark ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking Pot, T & C Clarke and Co Ltd, 1840 to 1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The items are significant as they were used as domestic kitchen items to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. This is due to the enamel lining pioneered by TC Clark Pot set; set of three pots. Iron pots, enamelled on the inside with a pouring lip and capacity label on each pot. Pot set a capacity label on each pot. Three pots in set labelled 17 qts and 14 qts on base and flat spot opposite lip - handle for pouring. 12 qts is missing flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pot set, cooking pot, pouring pot, cook ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sharpening Steel

A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to 30 centimetres (1 ft) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if not superior, method for accomplishing the same daily maintenance tasks; manufacturers replaced steels with ceramic (and later, manufactured diamond abrasive) sharpening "steels" that were actually hones. Use Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side. Steeling It is often recommended that steeling be performed immediately before or after using a knife and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing. There has long been speculation about the efficacy of steeling (re-aligning the edge) vs honing (removing minor deformation with abrasives); studies tend to favour abrasives for daily maintenance, especially in high-carbide-volume "stainless" steels (such as the popular CPM S30V steel, which tends to "tear out" when steeled rather than re-forming an edge.) Small honing steel for outdoor activities Usage trends Steels have traditionally been used in the West, especially in heavy-use scenarios (e.g. butchering, where the edge deforms due to forceful contact with bone). These scenarios also lead Western trends toward blades tempered to a lower level of hardness (and thus lower brittleness). In East Asia, notably Japan, harder knives are preferred, so there is little need for steeling intra-day, as the edge does not deform as much. Instead, the blade is honed as needed on a waterstone. While tradition has kept the practice of steeling alive in Western kitchens, the majority of honing steels sold are abrasive rather than smooth, and knives are harder and more frequently made of stainless steel, which does not respond to traditional steeling techniques as well as high-carbon/low alloy tool steels.The sharpening steel is essential to maintain the sharpness of carving and other knives.Steel knife sharpener with bone handle. Part of a carving set.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening steel, carving set, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, Circa 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early rural and industrial manufacturing became established in Australia.Rectangular butter churn, a footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Lettering in black on a transfer "CHERRY & SONS PTY LTD. GISBORNE VICTORIA". Model 00warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, butter churn, gisborne, edward cherry, george cherry, thomas cherry, ann appleby, dairy equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture.Compass saw with wooden handle and metal blade. Small teeth. flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw with wooden handle broken and metal blade. Small teeth.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Porcelain Insulators, Mid-twentieth century

White Porcelain “Made in Occupied Japan” electrical insulators. Insulators can be dated from September 1945 to April 1952 during the allied occupation of post WWII Japan. Pin insulators were manufactured specifically for Australian export. Pin insulators are made of non-conductive porcelain and were used to create a barrier between outer wrapped suspended wiring and threaded wood or metal dowel. Pin insulators such these have been found on utility poles around Australia.Porcelain insulators stamped with “Made in Occupied Japan” are often viewed with much interest by collectors given their connection to WWII and short seven year manufacturing time span. Pin insulators such as these are an example of Australia’s continued electronic development which began in the late 19th century. Collection of seven white porcelain insulators made in Occupied Japan. Insulators are cylindrical in shape, with indentation at top. The indentation creates a flat mushroom top head. Insulators display a manufacturer stamp at the bottom of the cylinder. Insulators are single walled and hollow inside with threading at the enclosed top end. flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, insulators, porcelain, electrical insulators, occupied japan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCurrency - Coin, Robert Hyde & Co. Shipping Merchants, 1861

The donor (a local resident.) of this coin found this penny token coin in the sand dunes of Lady Bay, Warrnambool, in 2023. The coin could have come from a local shipwreck, passengers, or members of the community. Trade was carried out along the southwest coast of Victoria between Melbourne and Portland, with the Port of Warrnambool receiving passengers and goods by coastal traders, the steamboat that set off from ports every few days. One such vessel was the steamship SS Edina that made her first voyage from Melbourne to Portland in 1863. For around a decade or so in the Gold Rush period in Australia there was a shortage of official government currency. It was acceptable during this time to use token coins minted by local businesses to be used within their store, much like the loyalty and rewards cards that businesses give their customers in modern times. The tokens were also a good way to advertise their wares and details. The first token was introduced in Melbourne in 1848 and were used until 1868, when they became illegal in New South Wales. They were minted in Australia and overseas. The token was issued by Robert Hyde & Co. who traded in second-hand goods such as old clothes, sheets, metal items and glass, which they resold to be re-manufactured, or "recycled".A token such as this one identifies businesses existing in the post-Gold Rush period in Australia. Round copper coin. Penny token coin bearing the Australian Coat of Arms and motto. The coin also has the company's name, location, nature of business and motto. The coin has grooves around the edge. It was made in 1861.OBVERSE: Logo: (Australian Coat of Arms), Motto: "PEACE & PLENTY", Date: 1861 REVERSE: "ROBERT HYDE & CO MELBOURNE", "GENERAL MARINE STORE, SHIPPERS OF RAGS GLASS METALS &.C"flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, merchant token, melbourne, token, australian token, trade token, coins, merchants, medal, colonisation, gold rush, robert hyde & co., general marine store, shippers of rags glass metals etc., numismatics, second-hand scrap, scrap goods -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeWash Board, Unknown

A washboard is a tool designed for hand washing clothing. The traditional washboard is usually constructed with a rectangular wooden frame in which are mounted a series of ridges or corrugations for the clothing to be rubbed upon. For 19th century washboards, the ridges were often of wood; by the 20th century, ridges of metal were more common. A "fluted" metal washboard was patented in the US in 1833. Zinc washboards were manufactured in the US from the middle of the 19th century. In the late 20th century and early 21st century, ridges of galvanized steel are most common, but some modern boards are made of glass. Source: wikipedia.comWooden framed wash board - slatted. The glass insert is corrugated and nailed to the wooden frame.Nonewood, glass, laundry, wash board, soap, housewife, domestic item -

Gippsland Vehicle Collection

Gippsland Vehicle CollectionVehicle Tail Light, 1940 (estimated)

Lucas Electrical manufactured light and electrical components for many vehicle manufacturers in England and many manufacturers used them as accessories or added extras.Lucas granted Richards Body Builders of Adelaide, Australia, permission to use the phrase 'King of the Road' as their trade nick name.Kidney shaped metal & glass, four lens number-plate & tail light combinationKing of the Road maker's marktail light, stop light, light tail, king of the road light, number plate light