Showing 4207 items matching " engines"

-

Stawell Historical Society Inc

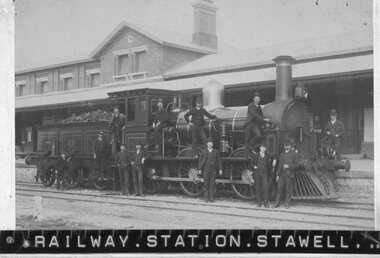

Stawell Historical Society IncPhotograph, E Class Steam Engine in front of Stawell Railway Station c1880

Engine E Class 345 Photo late 1880's to 1890's?Steam Engine in front of Station with about 12 Gentlemen in suites.Railway Station Stawell R A Leslie Art Photographerrailways -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncHorizontal Oil Engine, Early 20th century

Horizontal cylinder oil engine in working condition. Mounted on a steel and timber chassis with 4 wrought iron wheels. Axles are fixed to timber spacer beams. Two flywheels. Cylindrical cooling water tank, cast iron exhaust system and vertical exhaust pipe mounted at crankshaft end. Engine painted dark green, crankshaft balance weights red, flywheels black, cooling water tank black. Oval brass plate on cylinder - "The "Blackstone" / Carter's Patent / 92393 / Quote This No. / When Ordering Parts / Oil Engine". Brass plate on engine frame - "British Patents / Nos. 19640-02 / 24611-03" Oval brass plate on Balance weight guard - "The "Blackstone" Oil Engine / Clutterbuck Bros / Adelaide / South Australia". engines .... horizontal cylinder ....oil engine, machinery - engines, oil -

Stawell Historical Society Inc

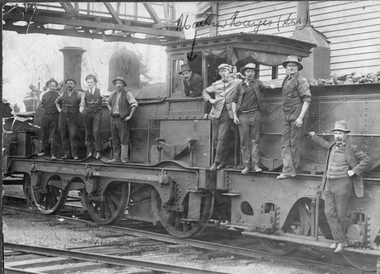

Stawell Historical Society IncPhotograph, Steam Rail Engine & Workers standing on steam engine. c1900

Steam Rail Engine & 9 workers standing on a Steam Engine. Martin Hayes (Snr.) driver leaning out of cabin. John McInerney left of M. Hayes and below Frank Dunn. The steam engine is under a rail bridge and in the background is a timber building. c1900.Old sepia photo on a damaged mount of 9 railway workers standing on a Steam engine c1900.Martin Hayes (Snr.)stawell railways transport -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Sloane's & Scotchman United Mining Co in Stawell looking North West with Poppet Heads & Sheds 1914 -- Photo & Colured Painting

Poppet Heads, Ore bin Winding Engine Shed Sloane's & Scotchmans United Quartz Mining Co looking North West Moonlight dams in background. Mine on left is the old Extended mine where the winding engine shed has been destroyed by fire. Just behind that is the Winding Engine Shed of the Oriental Mine without the poppet head.View of two mine sites with poppet heads and engine sheds. Settling dams in background.mining, panorama -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - colour, Clare Gervasoni, Morphett's Engine House, Burra, South Australia, 29/05/2013

Morphett's Engine House was restored and opened to the public in 1986.Three colour digital images of Morphett's Engine House, Burra, South Australia -

Mont De Lancey

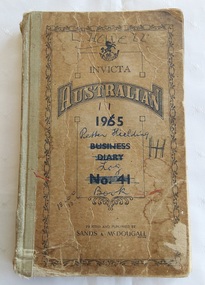

Mont De LanceyBook, Sands & McDougall Pty Ltd, Invicta Australian 1965 Petter Fielding Log Book Log Book, 1955

... Engines ...On the front cover, 1955 Business Diary No.41 is crossed out and 1965 Petter Fielding Log Book is written over them in blue biro. Log Books were used and still are these days to record information for many different work needs.A damaged small brown Invicta Australian 1955 Business Diary No.41 with two days on a page. The front cover lists the brand, and detail already mentioned, with 1955 Business Diary No.41 crossed out and 1965 Petter Fielding LOG book written over them in blue biro. The printer and publisher is printed at the bottom. There is tan cloth tape holding the covers together on the left. Inside it has the calendar for 1955, postal, money order and telegraph Information along with other miscellaneous information. It was used as a Log Book for a Petter Fielding engine which was manufactured in 1952. The entries start 21/7/65 and finish Sun 2/3/2008. On the page Monday 4 July 1955 there is an entry dated Mon6/7/59 with little or no information apart from a few names and costs.There is a Cash Account section at the back.non-fictionOn the front cover, 1955 Business Diary No.41 is crossed out and 1965 Petter Fielding Log Book is written over them in blue biro. Log Books were used and still are these days to record information for many different work needs. books, documents, notebooks, log books, engines -

Federation University Historical Collection

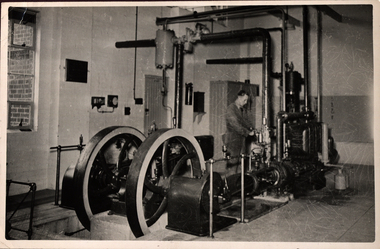

Federation University Historical CollectionPhotograph - Photograph - Black and white, Ballarat School of Mines Model Steam Engine

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine installed at the Ballarat School of MInes. steam engine, model steam engine, davey paxman, thomas bath, experimental steam engine -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Photograph, The Big Red, 1/09/1969 12:00:00 AM

Colour Photograph of RAAF Flt Lt Ron Slater starting left engine of OV-10 aircraft at DiAn, South Vietnam September 1969. Ron supported the 2nd Brigade of US 1st Infantry Division 'The Big Red'.Plaque with details of the engine start Donated by Flt Lt Peter Condonov 10 aircraft, photograph -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph, Tatura Railway station

Three photos of Tatura Railway station & one of the Rosella Siding, with steam engines.Three photos of Tatura Railway station & one of the Rosella Siding, with steam engines. -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

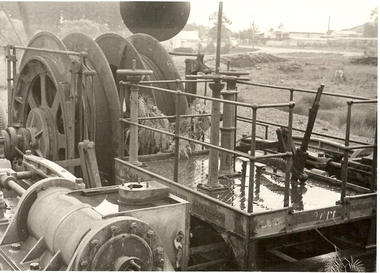

... engines ...Cocks Pioneer Engine c1930s. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1,,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mining, gold, tin, gold mining, tin mining, machinery, engines, men, cocks pioneer, el dorado, eldorado -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - ALF 502R Series Turbofan Engine Manual: High Pressure Compressor, ALF 502R Series Turbofan Engine Manual: Chapter 72-34- High Pressure Compressor Section

... engines ...Lycoming ALF 502R series turbofan engine manual: High Pressure Compressor section. Lycoming engine repair manual engines, aircraft, lycoming, turbofan engine manual, alf 502r -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - NELL GWYNNE MINE

Black and white photograph. Nell Gwynne Reefs; Mine winding engine. Walker and Coy. Dwellings in background. Machinery, winding drums, steel platform, lever, etc. Plant growing up between. Inscriptions: on back - in ballpoint pen 'Nell Gwynne Reef's Mine, winding engine, Walker & Co'.mining, surface equipment, nell gwynne, bendigo, mines and mining, mines, place, gold, surface equipment -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph, HMAS Sydney, July 1940, 1940

An original photograph made available to crew members. HMAS Sydney, photograph 1940 with signatures of some of the engine room crew.Black and white photo sealed into black frame.HMAS Sydney. The ship, and some Engine Room Department signatories, July 1940.hmas sydney, hsk kormoran, photography, photograph, slides, film -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ships' Telegraph section, Milne Brothers, Copper and Brass Works, Early-to mid-20th century

This Engine Room section of a ship's telegraph system was part of the equipment of the Ports and Harbour ship the SS Rip. The vessel serviced and maintained the lights and buoys at Port Phillip Bay and Queenscliffe. The SS Rip was possibly the former gunboat "Albert". The ship’s communication system that was used from the late 19th century to early-to-mid-20th-century is called an Engine Order Telegraph (E.O.T.) or ship’s telegraph. The system has two parts, the Bridge Section and the Engine Room Section. The Bridge Section is usually mounted on top of a pedestal, and the Engine Room Section is often attached to a vertical surface. The standard commands printed or stamped onto the dial are the directions of AHEAD and ASTERN, and the speeds of STOP, FULL, EASY, STD. BY. and FIN. ENG. The ship’s pilot on the Bridge of a vessel sends his Orders for speed and direction to the to the Engine Room with the E.O.T. He moves the lever or levers, depending on the number of engines the ship has, to change the indicator on the Bridge Section’s dial to point in the new direction and speed of travel. This change causes the Orders to be duplicated on the Engine Room Section’s dial and a bell to signal the change simultaneously. The engineer then adjusts the ship’s engines and steering equipment to follow the pilot’s Order. The manufacturer, Mulne Bros., was a copper and brass works at 166 Sussex Street Sydney, in December 1892, and previously from 1870 at 128 to 130 Sussex Street. The company made and sold a wide range of equipment including machinery and gauges for the Railways.The Engine Room section is significant for being part of the communications system on the ship SS Rip, owned by Melbourne's Ports & Harbours department and used to service and maintain the navigation signals of Port Phillip Bay and at Queenscliffe in the mid-20th century. The dial is an example of marine equipment made in Australia and used for the safety of Victorian vessels. It is also significant for being made by an early Australian manufacturer, Milne Brothers of Sydney.Engine Room Section of a ship’s telegraph or Engine Order Telegraph (E.O.T.). The round metal dial has inscriptions stamped around the edges. The inscriptions are nautical terms for direction and speed and include the maker’s details. The dial was made by Milne Bros. of Sydney. It was part of the equipment on the "SS Rip" in Victoria.Black paint around dial: "MILNE BROS. / MAKERS / SYDNEY" "FULL EASY STD. BY " "FIN ENG. EASY FULL" ""ASTERN" "STOP" "AHEAD"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, marine technology, marine communications, engine order telegraph, e.o.t., ship’s telegraph, bridge section, engine room section, ship’s engine telegraph section, marine telegraph, milne bros., milne brothers, sydney, copper and brass works, ports & harbours ship, ss rip, gunboat albert, service ship, maintenance ship -

Stawell Historical Society Inc

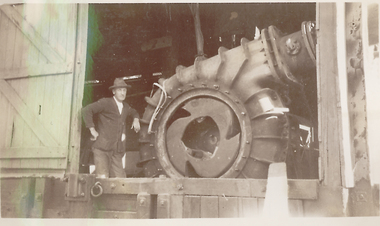

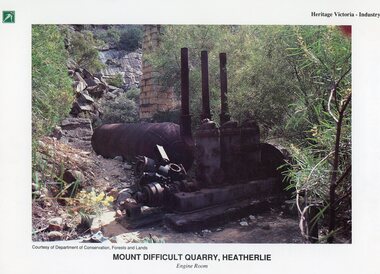

Stawell Historical Society IncPhotograph, Heatherlie Quarry -- Coloured

Coloured Photo Heatherlie QuarryColour Photograph of old engine and brick chimney surrounded by trees."Heritage Victoria - Industry" on top right. Unknown Logo on top Left. Courtesy of Department of Conservation, Forests and Lands. Mount Difficult Quarry, Heatherlie Engine Room On reverse information about Mount Difficult Quarry, Heatherlie, including two photgraphs.stawell grampians industry -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Sloane's & Scotchman United Quartz Mining Company remains of Poppet Head, Chimney & Engine Mounts

Sloane's & Scotchman Mining Co remains Poppet Head Chimney and Engine Mounts.Derelict mine site at upper main street. Engine housing brickwork and Chimney at right partly demolished.stawell mining -

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye Single Cylinder Horizontal

Builders Number 4767 Used for steam engine driving instruction at the Royal Melbourne Institute of Technology build date of approximately 1884 +/- 1 year. worked out from http://www.internationalsteam.co.uk/mills/burmamill22.htm Donated by The Royal Melbourne Institute of technology in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine EquipmentSteam Engine - Cast Iron (painted) Steel (raw) Bronze (Raw) Timber (Oiled)Tangye Birminghampuffing billy, steam, rmit, tangye, horizontal engine -

Puffing Billy Railway

Puffing Billy RailwayPortable Compound Steam Engine, Marshall & Son's - Builders Number 48317, circa 1908 / 1909

Portable Compound Engine - Marshall & Son's. Builders Number 48317 Built by Marshall Sons & Co., Ltd., Gainsborough, England (Builder’s Number 48317 of approximately 1908/1909), to the order of Robison Brothers, Engineers, South Melbourne. It was used for operating a pump to supply irrigation water at Robinvale in Northern Victoria. Robison Bros & Co. P/L was founded by James McFarlane Robison and his brothers in 1854, initially as plumbers and coppersmiths, the firm expanded into general engineering, boiler-making and brass, iron and steel founders and became one of Melbourne's most important engineering firms. They constructed railway bridges, gold mining equipment, railway locomotives, pumping stations, brewing vessels, abattoir machinery, amongst much else and including the first turnstiles at the Melbourne Cricket Ground. A portable engine is either a steam engine or an internal combustion engine, that remains in one place while operating (providing power to machinery), and can be easily moved from one work site to another. Mounted on wheels or sometimes skids, it is required to be towed between work sites.Historic - Industrial Portable Compound Engine - steam engine - Marshall & Son's. Marshall & Son's Portable Compound Engine - Builders Number 48317 made of steel Marshall & Son's. Builders Number 48317puffing billy, state rivers and water supply commission of victoria, portable compound engine - marshall & son's., portable compound engine, marshall sons & co., ltd., robison bros & co. p/l -

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye single cylinder vertical, Circa 1920

Used by the Malvern city council until 1969 to drive a rock crushing plant. While large horizontal steam engines predominated in major factories, small vertical steam engines like this were the workhorses of industries that had modest power requirements. This reliable little engine, made by leading UK manufacturer Tangye Bros of Birmingham Steam engines had the advantage that any fuel could be used to fire their boilers, but they were less convenient and efficient than internal combustion engines, required operators with higher skill levels, and had lower power to weight ratios. Tangye Limited was founded in 1857 in Birmingham by businessman Richard Tangye (1833-1906) and his mechanic brothers James and Joseph; brothers Edward and George joined them later. Richard was born near Redruth in Cornwall and educated at the Friends School at Sidcot, Somerset, where he became a pupil-teacher. From there he moved to Birmingham to work as a clerk for an engineering firm. In 1856 he started a hardware factor and commission agent business in Birmingham whose customers were mainly Cornish mine-owners in the Redruth district. From 1858 Tangyes concentrated on the manufacture of machinery and secured the sole right to manufacture Weston's differential pulley block (object 2003/45/1). They established their Cornwall Works in the Birmingham suburb of Smethwick in 1864 and soon developed a huge range of products. It was stated that 'there are perhaps no other works in the kingdom so largely employed upon so great a variety of specialities as the Cornwall Works of Messrs Tangye Bros.' The Tangyes attracted creative people to work for them. They wrote: 'We are in a position to offer unusual facilities to Inventors for carrying out their patents.' Info about Tangye Bros of Birmingham from Powerhouse Museum https://ma.as/207954 Donated by Malvern City Council in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine Equipmentsingle cylinder vertical Steam Engine made of Cast Iron, (Painted)Tangye Birmingham Builder's number 2462tangye, vertical steam engine, steam engine, puffing billy, stone crushing, george and george, malvern -

Federation University Historical Collection

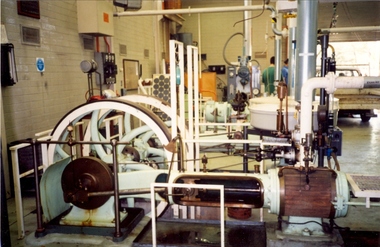

Federation University Historical CollectionPhotograph - Colour photograph, Davey Paxman Experimental Steam Engine in the Mount Helen Workshop, c1994

The Davey Paxman Experimental Steam Engine was purchased by the Ballarat School of Mines as the result of a bequest from Thomas Bath.The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.davey paxman experimental steam engine, model steam engine, steam, thermodynamics laboratory, thomas bath, bequest -

Federation University Historical Collection

Federation University Historical CollectionEngineering, Steam Engine Indicator, Late 19th Century

For an explanation about the history of steam engine indicators, visit: http://www.archivingindustry.com/Indicator/contentback.htm [last viewed 20 May 2013]. For information about the Richards' Improved Patent Steam-Engine Indicator see John Walter's publication 'The Engine Indicator: a short history of the autographic patterns from 1800 to the present day' - available online via: http://www.archivingindustry.com/Indicator/chaptertwo.pdf Information on Casartelli, Manchester is also available online via: http://www.archivingindustry.com/Indicator/chapterfour.pdf Refer pp.21-22 [last viewed 20 May 2013]Brass steam-engine indicator 125mm tall - accompanied by four steel piston springs - and a wooden measuring ruleIndicator [a] Casartelli Manchester [b] 41 ; Ruler [a] 12 to the Inch [b] No.2 [c] Casartelli & Son Manchesterrichards improved patent steam engine indicator, casartelli manchester -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncAirspeed Oxford aircraft (Replica under construction), c.1940

This type first flew in 1937 and by the start of WWII it was the preferred aircraft in all Empire Air Training Schemes for multi-engine pilot training. By the beginning of WWII the Airspeed Oxford was the preferred aircraft in all Empire Air Training Schemes for multi-engine pilot training. As of April 2014, no Airspeed Oxfords remain in the world in airworthy condition and there are very few complete air frames. There are reportedly some restoration-to-fly projects underway, one in New Zealand.Full-sized replica of an Airspeed Oxford aircraft. This type of aircraft was described as a multi-engine three-seat advanced military trainer monoplane. It was a wooden construction using plywood and fabric covering and powered by two 375 HP Armstrong Siddeley Cheetah 10 engines. Parts originally used a base for this reconstruction were reckoned to be from an Oxford Mk 2 with registration A25 LX181 which was based at Point Cook and used extensively in training from the Werribee Aerodrome. -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncOil Engine, 1912

10 HP horizontal cylinder oil engine in working order. Mounted on a steel chassis with 4 wrought iron wheels. Two flywheels and one flat belt pulley. Rectangular cooling water tank and cast iron exhaust pot with vertical exhaust pipe mounted at crankshaft end. Engine painted green with pale yellow trim. Blow torch start on compression when hot bulb is of certain temperature. Mechanical water and fuel pumps. Oval brass plate fixed to cylinder "The "Blackstone" / Carter's Patent / 61892 / Quote this No. / When ordering parts / Oil Engine"engines horizontal cylinder -

Kyneton Fire Brigade

Kyneton Fire BrigadeMemorabilia - Trophy

Awarded for 4 Man Engine Y Coupling Warrnambool 1929Part of Kyneton Fire Brigade trophy collection Heavy clear glass bowl on filigreed silver metal base with two handles and four feetBOWL : 168-268 Upper rim STAND : Warrnambool 1929 4 Man Engine Y Coupling Won by KYNETONkyneton fire brigade, country fire authority, fire brigade demonstrations, trophy -

Melbourne Tram Museum

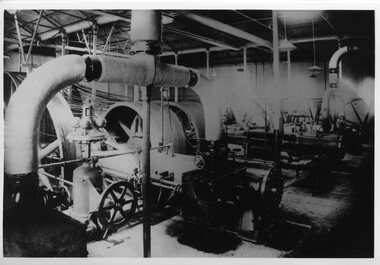

Melbourne Tram MuseumPhotograph - Black and White - Nicholson & Gertrude Street Engine House interior

Shows the interior of the cable tram engine house that was located on the corner of Gertrude Street and Nicholson Street in Fitzroy. Shows the steam pipes to two of the engine cylinders, the control equipment, and large cable winding wheels. An MMTB poster titled Melbourne Tramways Past and President (see Reg Item 6368), captions the photo as "Nicholson Sreet Power House - the last to operate" The facility ceased operation in 1940 though the equipment was retained until 1941. Yields information about the interior of the Gertrude Street or Nicholson Street cable tram engine houseBlack and white photograph - interior of the Engine house on the corner of Gertrude and Nicholson Streets prior to closure in 1940.tramways, trams, coburg, cable cars, engine house, nicholson street, gertrude street, steam engines -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, Brodribb / Howlett, 1900 c

Identified are Andrew Brodribb and Arthur Howlett at the chaff cutter, James, Maud, Ethel, Ivy Howlett near steam engine Punt Rd Metung VictoriaBlack and white photograph showing chaff cutting at Howlett property Inglewood using steam engine power.genealogy, families, farm -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship's Telegraph section, A. Robinson & Co. Ltd, Late-19th to mid-20th centuries

The ship’s communication system that was used from the late 19th century to early-to-mid-20th-century is called an Engine Order Telegraph (E.O.T.) or ship’s telegraph. The system has two parts, the Bridge Section and the Engine Room Section. The Bridge Section is usually mounted on top of a pedestal, and the Engine Room Section is often attached to a vertical surface. The standard commands printed or stamped onto the dial are the directions of AHEAD and ASTERN, and the speeds of STOP, SLOW, HALF, and FULL. The ship’s pilot on the Bridge of a vessel sends his Orders for speed and direction to the to the Engine Room with the E.O.T. He moves the lever or levers, depending on the number of engines the ship has, to change the indicator on the Bridge Section’s dial to point in the new direction and speed of travel. This change causes the Orders to be duplicated on the Engine Room Section’s dial and a bell to signal the change at the same time. The engineer then adjusts the ship’s engines and steering equipment to follow the pilot’s Order. The manufacturer, A. Robinson & Co. Ltd of Liverpool, established his business in 1780 and continued until 1968 when the business was purchased by marine products maker Chadburns, established in London in 1870.This Engine Room section is part of a ship's telegraph communication system and represents marine technology used in the late-19th to mid-20th-century. Engine Room Section of a ship’s telegraph or Engine Order Telegraph (E.O.T.). The round brass dial has inscriptions stamped around its edge and centre. Red inlaid glass plates have inscriptions in white paint on them. The inscriptions are nautical terms for direction and speed and include the maker’s details. A rotating pointer is joined to the centre of the dial. The maker is A. Robinson & Co. Ltd of Liverpool. Stamped: “FULL / HALF / SLOW / STOP / FULL / HALF / SLOW / STOP”, “AHEAD / ASTERN” Printed: “FULL / HALF / SLOW / STOP / FULL / HALF / SLOW / STOP” Stamped on the dial: “A. ROBINSON & CO. LTD / MANUFACTURERS / LIVERPOOL”flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, marine technology, marine communications, engine order telegraph, e.o.t., ship’s telegraph, bridge section, engine room section, ship’s engine telegraph section, marine telegraph, a. robinson & co. ltd, liverpool -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, Wooden engine drivers chair from Magdala Mine

Used by winding engine driver at Magdala Mine. Painted dark reddish colour with arms bolted to frame with metal bolts., peg dowel jointed. Wooden Chair - Engine Drivers. Magdala Cum Moonlight Mine. Initials Carved on it include J Gilchrist 1911Names and initials carved into woodwork. Including J Gilchrist 30.12.1911(?) On arm W.H.A., PW and TN on back V.T., V.T., A.H, down side.stawell -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Steam Engine in a cutting

Steam Train Engine in Hills cutting c 1940. Photo from "Boothey" EstateTwo identical photos of a steam engine & goods trucks heading towards Melbourne. The larger photo a copy of the smaller photo c 1940A543 printed on the back of one of the photos.railways -

Hume City Civic Collection

Hume City Civic CollectionPhotograph, 1980s

This is possibly a photograph which records trips made around Victoria of the 'Flying Scotsman' engine which was brought to Australia in late 1980s.A coloured photograph of a steam engine painted blue, black and red travelling under full steam along a rail track.steam engines, the flying scotsman, railways, george evans collection