Showing 670 items

matching jewellery

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and Villagebadge - Rostrum badge, Angus & Coote, 1939-1945

This Rostrum lapel badge is one of a set of badges collected by Dr W R Angus from the organisations in which he was involved. The set of badges is now part of Flagstaff Hill’s comprehensive W.R. Angus Collection, donated by the family of Dr W R Angus, surgeon and oculist. This badge represents the Rostrum organisation, the longest-running public speaking organisation in the world. Rostrum has a Warrnambool branch, Warrnambool Club 24, which currently meets at the rear of the South Warrnambool Presbyterian Church building at 11 MacDonald Street, Warrnambool. The original Rostrum club was formed in England in 1923 and the first Australian Rostrum meeting was in 1930. The maker, Angus & Coote, is an Australian company that was founded by Edmund James Coote in Sydney in 1895. The firm made insignia during WWII and is famous for its high-quality jewellery. The W.R. Angus Collection includes historical medical equipment, surgical instruments and material belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) and Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. It includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. During World War II He served as a Military Doctor in the Australian Defence Forces. Dr Angus and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Both Dr Angus and his wife were very involved in the local community, including the planning stages of the new Flagstaff Hill and the layout of the gardens there. Dr Angus passed away in March 1970.This badge is significant for connecting Doctor Angus with organisations that he supported. The badge also associates Dr Angus with the Rostrum Club in Warrnambool. The badge is of interest as the maker, Angus & Coote, only made badges during WWII. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The Collection includes historical medical objects that date back to the late 1800s.Lapel badge; a square gold-coloured metal and blue enamel badge. The blue enamel covers three-quarters of the top of the square badge and has a bold 'R' embossed onto it. The remaining quarter is gold with the organisation's name in blue letters. The maker's name is embossed on the back. The Rostrum badge was made by Angus & Coote.This badge is part of a set of badges collected by Dr W R Angus. the set represents organisations that he was involved in, and is part of the W.R. Angus Collection.Front “R” above “ROSTRUM”. Reverse; “ANGUS & COOTE”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, w.r. angus, badge, organisation badge, flagstaff hill maritime museum and village, badges, buttons, lapel badge, rostrum, warrnambool club 24, angus & coote sydney, rostrum club 24, public speaking club, rostrum lapel badge, wwii badge, 1939-1915 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, from mid-19th century to 1902

This ink bottle is ‘boat’ shaped, which was a common design from the mid-1840s. It was crudely made; maybe it was rejected as a practice bottle or perhaps heat or pressure has distorted it. The bottle was recovered from the wreck of the Inverlochy and is part of the John Chance collection. Ink in the 1700s ink could be purchased in powdered or block form from apothecary shops, to be mixed with water as needed. Then in the mid-1800s chemists began selling ink in liquid form, in small, inexpensive and often attractive bottles. The small glass ink bottles were handmade, blown into a cup shaped mould, and sharply broken off from the blow-pipe at the neck, referred to as the English-made ‘burst-off’ finish. The neck was then filed, filled with liquid ink and sealed with a cork or wax. It was a quick, affordable container and made pen and ink writing available to the public. The name ‘penny ink’ bottles was a common title due to their low cost. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This boat shaped handmade ink bottle is historically significant for its association with communications and record keeping in the mid-to-late 19th century. The bottle is socially significant as an example of making a useful product affordable to every day people. This handmade glass ink bottle is significant for its connection with the John Chance Collection, which is historically significant as an example of artefacts from wrecks that had been lost in the coastal waters of Victoria from thirty to over one hundred years before John Chance and others discovered them. These artefacts are a sample of goods carried as cargo or personal possessions, and of ship hardware of that era. The ink bottle is significant through its connection with the barque, Inverlochy, The Inverlochy is significant for its cargo, which is a snapshot of the array of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The Inverlochy is historically significant and is registered on the Victorian Heritage Database, VHR S338. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history.Ink bottle, thick clear glass, rectangular base with small round mouth, long sides have have a U shaped groove along the shoulders (used for resting pen handles). The outside surface has a white clay-type reside over it. Bottle is very bent and distorted. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, boat ink bottle, cottage ink, penny ink, glass ink bottle, pen rest, writing accessory, victorian, antique, ink well, sheer lip, distorted body, handmade, mould blown, statoionery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Glass Bottle, mid-19th century to 1902

This handmade glass bottle was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. The bottle has side seams that extend from base to mouth, indicating that it would have been made in a mould. The parallel, diagonal lines are likely to have been made by the molten glass being mouth-blown into the mould. The mould would have also had the pattern for the embossed numbers in the base. The seamless applied mouth would have been added after the bottle was removed from the two-piece mould. The even neck of the bottle would have probably been sealed with a cork or glass stopper. Bottles similar to this one were used for medical (apothecary) and cosmetic purposes. Bottles with these features date from around the late 19th to early 20th century. Bottles began to have embossed numbers on the bases from the late 19th century and the practice continues into modern times. The numbers may represent the date of manufacture i.e. “4188” may be 4th January 1888. It may instead be the date of the patent or design pattern number. This bottle may have been made around 1888 and the latest it could have been made was 1902, the year of the wreck of the Inverlochy. THE INVERLOCHY (1895-1902) - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This glass bottle is historically significant as it represents methods of storage and manufacture that were used from the 19th century and into the early-20th century, before machine made bottles were becoming common. The shape and size of the bottle are similar to bottles used for medical and cosmetic purposes in that period. The glass bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This glass bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history. Bottle; clear glass, round, handmade. Narrow lip is flat across top and on side edge, neck is straight, about a third of the bottle’s height. The shoulder is rounded, and the body has straight sides with two side seams from below the lip to the base, which is shallow. Outer glass surface is rough, inner surface has areas of dried, light coloured substance. The body has several diagonal parallel lines and areas with opalescent shine. Base has embossed inscription. Embossed inscription on base "4188".flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, ingoldsby reef, handmade, glass bottle, apothecary, cosmetic, mould blown, vintage, two-piece bould, point addis, medicine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Glass Bottle, mid-19th century to 1902

This handmade glass bottle was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. The bottle has side seams that extend from base to mouth, indicating that it would have been made in a mould. The parallel, diagonal lines are likely to have been made by the molten glass being mouth-blown into the mould. The mould would have also had the pattern for the embossed numbers in the base. The seamless applied mouth would have been added after the bottle was removed from the two-piece mould. The even neck of the bottle would have probably been sealed with a cork or glass stopper. Bottles similar to this one were used for medical (apothecary) and cosmetic purposes. Bottles with these features date from around the late 19th to early 20th century. Bottles began to have embossed numbers on the bases from the late 19th century and the practice continues into modern times. The numbers may represent the date of manufacture i.e. “463” may be April 1863. It may instead be the date of the patent or design pattern number. This bottle may have been made around 1863 and the latest it could have been made was 1902, the year of the wreck of the Inverlochy. THE INVERLOCHY (1895-1902) - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This glass bottle is historically significant as it represents methods of storage and manufacture that were used from the 19th century and into the early-20th century, before machine made bottles were becoming common. The shape and size of the bottle are similar to bottles used for medical and cosmetic purposes in that period. The glass bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This glass bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history. Bottle; clear glass with opalescent shine in places, round, handmade. Narrow lip is flat across top and on side edge, neck is straight, about a third of the bottle’s height. The shoulder is rounded, and the body has straight sides with two pronounced side seams from below the lip to the base, which is shallow. Outer glass surface is smooth, inner surface has areas of dried, light coloured substance. Base has embossed inscription. Embossed "463" and logo symbol [trident]flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, ingoldsby reef, handmade, glass bottle, apothecary, cosmetic, mould blown, vintage, two-piece bould, point addis, medicine -

Federation University Art Collection

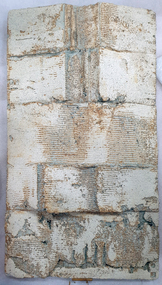

Federation University Art CollectionCeramic, Ian Sprague, [Ceramic Panel] by Ian Sprague, c1977

Ian SPRAGUE (1920 - 18 April 1994) Born Geelong, Victoria Ian Broun Sprague's initial training was in Architecture, completing a degree at the University of Melbourne in 1950. After a serious car accident in England, Sprague was encouraged to take up a craft to restore the strength in his arms. He studied at the Central School of Arts and Crafts, London for three years, and spent two months at the David Leach Pottery in Devon, before returning to Australia in 1962. In 1964 Ian Sprague established the Craft Centre in Toorak Road, South Yarra, and the Mungeribar Pottery in Upper Beaconsfield, with Robin Welch, Mungeribar being an Aboriginal word meaning 'red clay'. In 1981, he moved to Mooney-Mooney, NSW (Mungeribar was gutted by bushfires shortly after he left), and to Noosa in 1992. The Mungeribar Pottery mark is an impressed 'm', and Sprague's own mark is an impressed 'IS' with the S rendered in Morse code. Ian Sprague's Mungeribar apprentices were Grattan Burley, Victor Greenaway (1969–73), Christopher Sanders (1976-78}, Trevor Hanby (1978–80). In 1981, he moved to Mooney-Mooney, NSW , and Noosa in 1992. Greenaway's mark in his Mungeribar years was an impressed capital G. Grattan Burley (for six months), The Craft Centre in South Yarra was owned and stocked entirely by Ian Sprague, and he travelled all over Australia in search of the best possible textiles, glassware, woodwork and jewellery, not just pottery. The opening exhibition showed the pottery of Robin Welch. Sprague sold the Centre in 1967, but soon started a campaign for a government funded centre, eventually established as the Meat Market Craft Centre in North Melbourne. In 1971 Sprague became president of the recently created Craft Association of Victoria. Dismayed by the quality of teaching in art schools and technical colleges, he ran many workshops around the country on the textural treatment of clay. This work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there.Contemporary ArtTexture fire clay slab and partly glazed wall panel. Ian Sprague produced his hand modeleed wall panels by cutting them from fireclay blocks, heating and scraping them, and applying bold simplified motifs. A strong solution of salted wated was poured onto the rugged clay surfaceswhich produced a warm toasted surface effect. The panels show a clear understanding of the modulation of two dimensional relief sculpture. Artists stamp on lower RH cornerceramics, ian sprague, gippsland campus, jan feder memorial ceramics collection, mungeribar, meat markery craft centre, craft centre south yarra -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Candlestick holder, T. Gaunt & Co, circa 1944

This pair of altar lights is from the St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, and was used during religious services there. The Church was operated by the Mission to Seamen organisation. The par of candlestick holders was originally donated by Mrs. R.J. Ewart,as part of the furnishings for the new St Nicholas Seamen's Church in Williamstown, opened in 1944. The candlestick holders were made by T. Gaunt & Co. of Melbourne, a manufacturer, importer and retailer of a wide variety of goods including jewellery, clocks and watches, navigational and measuring instruments, dinnerware, glassware and ornaments. Thomas Gaunt photograph was included in an album of security identity portraits of members of the Victorian Court, Centennial International Exhibition, Melbourne, 1888 THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. These candlestick holders are significant historically for their origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The connection of the candlestick holders to the Mission to Seamen ighlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support.Candlestick holders or altar lights; pair of two polished brass holders. The wax cup at the top has a scalloped lip, the centre of the stem has a bulbous section, and the base has a cast floral design depicting leaves and grapes. The holders have inscriptions. They were made by T. Gaunt & Co. This pair of Altar Lights is part of the St Nicholas Seamen's Church Collection. Stamped "T GAUNT & CO."flagstaff hill maritime museum and village, flagstaff hill, warrnambool, maritime museum, maritime village, shipwreck coast, great ocean road, religion, religious service, st nicholas seamen’s church, williamstown, missions to seamen victoria, religious worship, candlestick holder, altar light, r j ewart, church furnishing, church lighting, t gaunt & co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Candlestick holder, T. Gaunt & Co, circa 1944

This pair of altar lights is from the St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, and was used during religious services there. The Church was operated by the Mission to Seamen organisation. The par of candlestick holders was originally donated by Mrs. M. Jackson, as part of the furnishings for the new St Nicholas Seamen's Church in Williamstown, opened in 1944. The candlestick holders were made by T. Gaunt & Co. of Melbourne, a manufacturer, importer and retailer of a wide variety of goods including jewellery, clocks and watches, navigational and measuring instruments, dinnerware, glassware and ornaments. Thomas Gaunt's photograph was included in an album of security identity portraits of members of the Victorian Court, Centennial International Exhibition, Melbourne, 1888. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. These candlestick holders are significant historically for their origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The connection of the candlestick holders to the Mission to Seamen highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Candlestick holder, polished brass, pair of two. The wax cup has a scalloped lip, the centre of the stem has a bulbous section, the base has a floral design depicting leaves and grapes. Inscribed. Made by T. Gaunt & Co. This pair of Altar Lights is in our St Nicholas Seamen's Church Collection.Inscribed "T. GAUNT & CO.."flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, candlestick holders, altar lights, mrs. m. jackson, t. gaunt & co., religious service, ladies lightkeepers' auxiliary, mission to seamen victoria, st nicholas seaman’s church williamstown, religious worship, m. jackson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902

This design of ink bottle or ink well was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf ink bottle. It was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century. Up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use. Ink wells, used with steel nib dip pens, were commonly used up until the mid-20th century. The pens only held a small amount of ink so users had to frequently dip the nib of the pen into an ink well for more ink. Hand writing with pen and ink left wet writing on the paper, so blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased, ready to use, or in the powdered form, which needed to be mixed with water. After the invention of fountain pens, which had a reservoir of ink, and then ballpoint pens, which also had ink that flowed freely, the dip pen was slowly replaced. However, artisans continue to use nib pens to create beautiful calligraphy. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This ink bottle is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The Ink bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This Ink bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history.Ink bottle or ink well; cylindrical shaped, salt-glazed, mid-brown ceramic bottle. It has a small round mouth, rounded lip that extend past the short neck, wide shoulders, straight sides, flat bottom. Handmade. Also called a Penny Ink Well.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, ink bottle, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, dwarf ink -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902

This design of ink bottle or ink well was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf bottle. It was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century. Up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use. Ink wells, used with steel nib dip pens, were commonly used up until the mid-20th century. The pens only held a small amount of ink so users had to frequently dip the nib of the pen into an ink well for more ink. Hand writing with pen and ink left wet writing on the paper, so blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased, ready to use, or in the powdered form, which needed to be mixed with water. After the invention of fountain pens, which had a reservoir of ink, and then ballpoint pens, which also had ink that flowed freely, the dip pen was slowly replaced. However, artisans continue to use nib pens to create beautiful calligraphy. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This ink bottle is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The Ink bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This Ink bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history. Ink bottle, glazed, prange-brown ceramic cylinder, ring of clay on top for lip, narrow mouth, very short neck on wide shoulder that reaches out to edge of of straight-sided body, flat base. On the shoulder, close to the neck, are concentric lines in the clay. There are dark areas around the lip and mouth opening. The clay appears to have a fold line on its body. The material has flecks of darker material in it. Sediment around shoulder. Handmade. Also called a Penny Ink Well.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, ink bottle, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, dwarf ink -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Vase, T. Gaunt & Co, circa 1944

This pair of brass altar vases is from the St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. Each vase is inscribed with the donors' names and the year of presentation - Margaret R. Pearson 1944, Mrs B Raybould 1944, - and the maker's name T. Gaunt & Co. The two donors presented the vases to St Nicholas Seamen's Church in Williamstown as part of the furniture and furnishings for the new church that officially opened in 1944. T. Gaunt & Co. engraved on both vases. T. Gaunt & Co. of Melbourne, is a manufacturer, importer and retailer of a wide variety of goods including jewellery, clocks and watches, navigational and measuring instruments, dinnerware, glassware and ornaments. Thomas Gaunt's photograph was included in an album of security identity portraits of members of the Victorian Court, Centennial International Exhibition, Melbourne, 1888. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This par of vases is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The connection of pair of vases to the original donation to the Mission to Seamen highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Vase: pair of two polished brass altar vases, round, pear-shaped, bulbous body on a round pedestal, two neck rings and flared lips. Inscriptions on both vases in script around the base. Made by T. Gaunt & Co. One was presented to the church by Margaret R Pearson and the other presented by Mrs B. Raybould in 1944 The vases are part of the St Nicholas Seamen's Church Engraved on the 625.1 "Presented By Margaret R. Pearson 1944." Engraved on 625.2 "Presented By Mrs B. Raybould. 1944." Both engraved "T GAUNT & Co"flagstaff hill maritime museum and village, flagstaff hill, warrnambool, maritime museum, maritime village, shipwreck coast, great ocean road, religion, religious service, st nicholas seamen’s church, williamstown, missions to seamen victoria, brass vases, metal craft, brassware, altar vase, church vase, mrs r raybould, margaret r pearson, t gaunt & co, church furnishing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rudder Pintles and Gudgeons, Alexander Hall and Son, ca. 1855

This set of pairs of pintles and gudgeons was recovered from the wreck of the sailing ship Schomberg and was part of its rudder steering system. A reconstruction that includes four pairs is currently on display at Flagstaff Hill. The rudder installation of the Schomberg was almost seven metres tall. A pintle and gudgeon pair is a mechanical fitting that works like a pair of door hinges. One of the uses for this type of fitting is for ships’ rudders. On a ship, one or several gudgeons would be attached to the vertical rudder stempost on the rear of the ship’s hull. On the ship's rudder, an equal number of pintles would be fitted onto it. The rudder assembly would then fit down into the gudgeons on the ship and would be connected to its steering mechanism, allowing it to be moved from side to side and steer the vessel. The SCHOMBERG- The three-masted clipper ship Schomberg was built in 1855 by Alexander Hall and Co in Aberdeen, Scotland, for James Baines' famous Black Ball line. It measured 288 feet (88 meters) in length, with a beam of 45 feet (14 meters), a depth of 29.5 feet (8.99 meters) and 2,284 tons. The mainmast was 210 feet (64 meters) high and the ship carried 3.3 acres of sail. The wooden vessel was constructed with three skins; one planked fore and aft, and two diagonally planked. All skins were fastened together with screw-threaded trunnels (wooden rails). The Schomberg was one of only three clippers wrecked in Victorian waters that operated the England-to-Australia run. It was built to outrun Donald MacKay’s two American-built ships, the Empress of the Sea and the Lightning. It was hoped that Schomberg would make Liverpool to Melbourne voyage in sixty days, setting a record for the voyage. The Schomberg sailed from Liverpool on 6 October 1855 on her maiden voyage, under the command of Captain James Forbes. Her general cargo for Australia included jewellery, spirits, machinery, and 2,000 tons of iron rails and equipment for building the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn, and17,000 letters and 31,800 newspapers. She also carried a cow for fresh milk, pens for fowls and pigs, plus 90,000 gallons of water for washing and drinking on board. There were approximately 473 passengers, including migrants for Australia, and a crew of 105. Light winds encountered at the equator dashed the expectations of a record-breaking voyage. On Christmas day the ship sighted Moonlight Head in southwest Victoria and even though there was a deadly combination of wind, currents and unmarked sand spits, the vessel continued on. Then the next day, December 26th 1855, the huge ship gently ran aground on a spit that juts into Newfield Bay, east of Curdies Inlet and the present town of Peterborough. Fortunately, the coastal trader, SS Queen, was nearby and managed to save all passengers and crew. In 1975 Flagstaff Hill’s former Director Peter Ronald and the team of divers recovered many objects and artefacts from the wreck of the Schomberg such as the ship’s fittings, equipment and personal effects including a diamond hidden for years in a communion set. This set of pintles and gudgeons is an example of steering equipment used on ships over 150 years ago, equipment that is still in use in today's shipping industry as well as many other everyday hardware applications.. The equipment is significant for its association with the ill-fated vessel Schomberg, which was wrecked in the local water in 1855 on its maiden voyage. The ship was built for speed and luxury, to sail on journeys with passengers, including migrants, travelling from Liverpool to Melbourne.Pintles and gudgeons, six pairs, plus one single pintle, from the wreck of the SCHOMBERG. Cast iron horse-shoe-shaped fittings with tapered ends. each with metal bars between the long sides. One piece of each pair has a round hollow cylinder and the other has a round solid shank. The single pintle has a tall shank with a pintle hook through it. Some pieces have remnants of grey paint.flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, schomberg, shipwreck, pintles, gudgeons, ship's rudder, ship's steering, clipper ship, james bain, black ball line, alexander hall and co., capt. james bully forbes, rudder pintles and gudgeons, rudder steering, pintles and braces, immigrant ship, maiden voyage, peterborough, 1855, marine technology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Service Bell, 1855

This service bell was recovered from the wreck of the ship Schomberg. The Schomberg was a large three-masted full-ship rigged wooden ship built in 1855 by Alexander Hall and Co in Aberdeen, Scotland for James Baines' famous Black Ball Line at £43,103. The vessel was 288 feet (88 meters) in length, with a beam of 45 feet (14 meters), a depth of 29.5 feet (8.99 meters) of 2,284 tons. The mainmast was 210 feet (64 meters) high and she carried 3.3 acres of sail. The vessel was constructed with three skins. One planked fore and aft, and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). The Schomberg is one of only three clipper wrecks in Victorian waters that operated the England to Australia run. While the other two, Empress of the Sea and Lightning, were built by the famous American shipbuilder, Donald Mac Kay. Schomberg was an attempt to build a faster ship than Mac Kay and a vessel fast enough to break the sailing record to Australia. The Schomberg sailed on her maiden voyage from Liverpool on 6 October 1855, under the command of Captain James Forbes, on its maiden voyage to Australia with a general cargo, jewellery, spirits, machinery, and 2,000 tons of iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, plus 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. There were approximately 473 passengers and a crew of 105. It was hoped that Schomberg would make Melbourne in sixty days, setting a record for the voyage, but light winds at the equator dashed those expectations. The ship sighted Moonlight Head in south west Victoria on Christmas Day but through a deadly combination of wind, currents and unmarked sand spits, the vessel gently ran aground on 26 December 1855 on a spit that juts into Newfield Bay, just east of Curdies Inlet, and the present town of Peterborough. Fortunately, the SS Queen was nearby and managed to save all passengers and crew. The steamers Keera and Maitland were dispatched to salvage the passenger's baggage and the more valuable cargo. Other salvage attempts were made, but deteriorating weather made the work impossible, and within two weeks the Schomberg's hull was broken up and the vessel abandoned. The wrecking of the Schomberg caused quite the public stir particularly in light of the fact the vessel was supposed to be, the most perfect clipper ship ever built. Captain Forbes was charged in the Supreme Court under suspicion that he was playing cards with two female passengers below decks when his ship ran aground. Despite a protest meeting, two inquiries and the court proceedings, he was found not guilty and cleared of all charges. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery at the Flagstaff Hill Maritime museum that also displays ship fittings and equipment, personal effects. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg has historical significance as one of the first luxurious ships built to bring emigrants to Australia to cash in on the gold rush era. And is included on the Victorian Heritage Register (VHR S612). The collection of Schomberg artefacts held at Flagstaff Hill Museum is primarily significant because of the relationship between these recovered items having a high potential to interpret the story of the Schomberg and its foundering during a storm. The shipwreck is of additional historically significance for representing aspects of Victoria’s shipping history and for its association with the first passenger ship, which was designed not only to be the fastest and most luxurious of its day but foundered on its maiden voyage to Australia.Bell; small service bell, brass, with heavy encrustation. Bell has a square loop at the top. The bell was recovered from the wreck of the Schomberg.Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, bell, service bell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Watch Chains, ca 1855

The concretion of silver watch chains was recovered from the wreck of the Schomberg over one hundred years later. Schomberg was a large three-masted full-ship rigged wooden ship built in 1855 by Alexander Hall and Co in Aberdeen, Scotland for James Baines' famous Black Ball Line at £43,103. The vessel was 288 feet (88 meters) in length, with a beam of 45 feet (14 meters), a depth of 29.5 feet (8.99 meters) of 2,284 tons. The mainmast was 210 feet (64 meters) high and she carried 3.3 acres of sail. The vessel was constructed with three skins. One planked fore and aft, and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). The Schomberg is one of only three clipper wrecks in Victorian waters that operated the England -to- Australia run. While the other two, Empress of the Sea and Lightning, were built by the famous American shipbuilder, Donald Mac Kay. Schomberg was an attempt to build a faster ship than Mac Kay and a vessel fast enough to break the sailing record to Australia. The Schomberg sailed on her maiden voyage from Liverpool on 6 October 1855, under the command of Captain James Forbes, on its maiden voyage to Australia with general cargo, jewellery, spirits, machinery, and 2,000 tons of iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, plus 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. There were approximately 473 passengers and a crew of 105. It was hoped that Schomberg would make Melbourne in sixty days, setting a record for the voyage, but light winds at the equator dashed those expectations. The ship sighted Moonlight Head in southwest Victoria on Christmas Day but through a deadly combination of wind, currents and unmarked sand spits, the vessel gently ran aground on 26 December 1855 on a spit that juts into Newfield Bay, just east of Curdies Inlet, and the present town of Peterborough. Fortunately, the SS Queen was nearby and managed to save all passengers and crew. The steamers Keera and Maitland were dispatched to salvage the passenger's baggage and the more valuable cargo. Other salvage attempts were made, but deteriorating weather made the work impossible, and within two weeks the Schomberg's hull was broken up and the vessel abandoned. The wrecking of the Schomberg caused quite a public stir, particularly in light of the fact the vessel was supposed to be, the most perfect clipper ship ever built. Captain Forbes was charged in the Supreme Court under suspicion that he was playing cards with two female passengers below decks when his ship ran aground. Despite a protest meeting, two inquiries and the court proceedings, he was found not guilty and cleared of all charges. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery at the Flagstaff Hill Maritime Museum that also displays ship fittings and equipment, and personal effects. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg has historical significance as one of the first luxurious ships built to bring emigrants to Australia to cash in on the gold rush era. And is included on the Victorian Heritage Register (VHR S612). The collection of Schomberg artefacts held at Flagstaff Hill Museum is primarily significant because of the relationship between these recovered items having a high potential to interpret the story of the Schomberg and its foundering during a storm. The shipwreck is of additional historically significance for representing aspects of Victoria’s shipping history and for its association with the first passenger ship, which was designed not only to be the fastest and most luxurious of its day but foundered on its maiden voyage to Australia.Conglomerated cluster of silver watch chains, encased in concretion at both ends (1 chain is separated). They were recovered from the wreck of the Schomberg.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, watch chain -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Thimble, Circa 1855

The thimble was recovered from the wreck of the vessel, Schomberg. The Schomberg was a large three-masted full-ship rigged wooden ship built in 1855 by Alexander Hall and Co in Aberdeen, Scotland for James Baines' famous Black Ball Line at £43,103. The vessel was 288 feet (88 meters) in length, with a beam of 45 feet (14 meters), a depth of 29.5 feet (8.99 meters) of 2,284 tons. The mainmast was 210 feet (64 meters) high and she carried 3.3 acres of sail. The vessel was constructed with three skins. One planked fore and aft, and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). The Schomberg is one of only three clipper wrecks in Victorian waters that operated the England to Australia run. While the other two, Empress of the Sea and Lightning, were built by the famous American shipbuilder, Donald Mac Kay. Schomberg was an attempt to build a faster ship than Mac Kay and a vessel fast enough to break the sailing record to Australia. The Schomberg sailed on her maiden voyage from Liverpool on 6 October 1855, under the command of Captain James Forbes, on its maiden voyage to Australia with general cargo, jewellery, spirits, machinery, and 2,000 tons of iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, plus 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. There were approximately 473 passengers and a crew of 105. It was hoped that Schomberg would make Melbourne in sixty days, setting a record for the voyage, but light winds at the equator dashed those expectations. The ship sighted Moonlight Head in southwest Victoria on Christmas Day but through a deadly combination of wind, currents and unmarked sand spits, the vessel gently ran aground on 26 December 1855 on a spit that juts into Newfield Bay, just east of Curdies Inlet, and the present town of Peterborough. Fortunately, the SS Queen was nearby and managed to save all passengers and crew. The steamers Keera and Maitland were dispatched to salvage the passenger's baggage and the more valuable cargo. Other salvage attempts were made, but deteriorating weather made the work impossible, and within two weeks the Schomberg's hull was broken up and the vessel abandoned. The wrecking of the Schomberg caused quite the public stir particularly in light of the fact the vessel was supposed to be, the most perfect clipper ship ever built. Captain Forbes was charged in the Supreme Court under suspicion that he was playing cards with two female passengers below decks when his ship ran aground. Despite a protest meeting, two inquiries and the court proceedings, he was found not guilty and cleared of all charges. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery at the Flagstaff Hill Maritime museum that also displays ship fittings and equipment, personal effects. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg has historical significance as one of the first luxurious ships built to bring emigrants to Australia to cash in on the gold rush era. And is included on the Victorian Heritage Register (VHR S612). The collection of Schomberg artefacts held at Flagstaff Hill Museum is primarily significant because of the relationship between these recovered items having a high potential to interpret the story of the Schomberg and its foundering during a storm. The shipwreck is of additional historically significance for representing aspects of Victoria’s shipping history and for its association with the first passenger ship, which was designed not only to be the fastest and most luxurious of its day but foundered on its maiden voyage to Australia. Thimble, metal, some of the dimples are corroded through. flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, schomberg, shipwreck coast. schomberg, 1855, peterborough shipwreck, artefact, thimble, sewing accesdory, sewing equipment, haberdashery, finger protection -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Alexander Hall and Son, ca. 1855

Schomberg was a large three-masted full-ship rigged wooden ship built in 1855 by Alexander Hall and Co in Aberdeen, Scotland for James Baines' famous Black Ball Line at £43,103. The vessel was 288 feet (88 meters) in length, with a beam of 45 feet (14 meters), a depth of 29.5 feet (8.99 meters) of 2,284 tons. The mainmast was 210 feet (64 meters) high and she carried 3.3 acres of sail. The vessel was constructed with three skins. One planked fore and aft, and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). The Schomberg is one of only three clipper wrecks in Victorian waters that operated the England to Australia run. While the other two, Empress of the Sea and Lightning, were built by the famous American shipbuilder, Donald Mac Kay. Schomberg was an attempt to build a faster ship than Mac Kay and a vessel fast enough to break the sailing record to Australia. The Schomberg sailed on her maiden voyage from Liverpool on 6 October 1855, under the command of Captain James Forbes, on its maiden voyage to Australia with a general cargo, jewellery, spirits, machinery, and 2,000 tons of iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, plus 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. There were approximately 473 passengers and a crew of 105. It was hoped that Schomberg would make Melbourne in sixty days, setting a record for the voyage, but light winds at the equator dashed those expectations. The ship sighted Moonlight Head in south west Victoria on Christmas Day but through a deadly combination of wind, currents and unmarked sand spits, the vessel gently ran aground on 26 December 1855 on a spit that juts into Newfield Bay, just east of Curdies Inlet, and the present town of Peterborough. Fortunately, the SS Queen was nearby and managed to save all passengers and crew. The steamers Keera and Maitland were dispatched to salvage the passenger's baggage and the more valuable cargo. Other salvage attempts were made, but deteriorating weather made the work impossible, and within two weeks the Schomberg's hull was broken up and the vessel abandoned. The wrecking of the Schomberg caused quite the public stir particularly in light of the fact the vessel was supposed to be, the most perfect clipper ship ever built. Captain Forbes was charged in the Supreme Court under suspicion that he was playing cards with two female passengers below decks when his ship ran aground. Despite a protest meeting, two inquiries and the court proceedings, he was found not guilty and cleared of all charges. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery at the Flagstaff Hill Maritime museum that also displays ship fittings and equipment, personal effects. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg has historical significance as one of the first luxurious ships built to bring emigrants to Australia to cash in on the gold rush era. And is included on the Victorian Heritage Register (VHR S612). The collection of Schomberg artefacts held at Flagstaff Hill Museum is primarily significant because of the relationship between these recovered items having a high potential to interpret the story of the Schomberg and its foundering during a storm. The shipwreck is of additional historically significance for representing aspects of Victoria’s shipping history and for its association with the first passenger ship, which was designed not only to be the fastest and most luxurious of its day but foundered on its maiden voyage to Australia.Stoneware Bottle, wide mouthed, covered in white encrustation, recovered from the wreck of the Schomberg. warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, stoneware bottle, james baines, black ball, container, clay bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Bilge Pump Barrel, Alexander Hall and Son, 1855

This bilge pump barrel is part of the ship's bilge pump machinery. Bilge or water can find its way into the hull of a ship and if it is not removed the ship will eventually sink. The bilge pump is designed to efficiently remove the bilge water. The Schomberg was a large three-masted full-ship rigged wooden ship built in 1855 by Alexander Hall and Co in Aberdeen, Scotland for James Baines' famous Black Ball Line at £43,103. The vessel was 288 feet (88 meters) in length, with a beam of 45 feet (14 meters), a depth of 29.5 feet (8.99 meters) of 2,284 tons. The mainmast was 210 feet (64 meters) high and she carried 3.3 acres of sail. The vessel was constructed with three skins. One planked fore and aft, and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). The Schomberg is one of only three clipper wrecks in Victorian waters that operated the England to Australia run. While the other two, Empress of the Sea and Lightning, were built by the famous American shipbuilder, Donald Mac Kay. Schomberg was an attempt to build a faster ship than Mac Kay and a vessel fast enough to break the sailing record to Australia. The Schomberg sailed on her maiden voyage from Liverpool on 6 October 1855, under the command of Captain James Forbes, on its maiden voyage to Australia with general cargo, jewellery, spirits, machinery, and 2,000 tons of iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, plus 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. There were approximately 473 passengers and a crew of 105. It was hoped that Schomberg would make Melbourne in sixty days, setting a record for the voyage, but light winds at the equator dashed those expectations. The ship sighted Moonlight Head in southwest Victoria on Christmas Day but through a deadly combination of wind, currents and unmarked sand spits, the vessel gently ran aground on 26 December 1855 on a spit that juts into Newfield Bay, just east of Curdies Inlet, and the present town of Peterborough. Fortunately, the SS Queen was nearby and managed to save all passengers and crew. The steamers Keera and Maitland were dispatched to salvage the passenger's baggage and the more valuable cargo. Other salvage attempts were made, but deteriorating weather made the work impossible, and within two weeks the Schomberg's hull was broken up and the vessel abandoned. The wrecking of the Schomberg caused quite a public stir, particularly in light of the fact the vessel was supposed to be, the most perfect clipper ship ever built. Captain Forbes was charged in the Supreme Court under suspicion that he was playing cards with two female passengers below decks when his ship ran aground. Despite a protest meeting, two inquiries and the court proceedings, he was found not guilty and cleared of all charges. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery at the Flagstaff Hill Maritime museum that also displays ship fittings and equipment, and personal effects. The Schomberg has historical significance as one of the first luxurious ships built to bring emigrants to Australia to cash in on the gold rush era. And is included on the Victorian Heritage Register (VHR S612). The collection of Schomberg artefacts held at Flagstaff Hill Museum is primarily significant because of the relationship between these recovered items having a high potential to interpret the story of the Schomberg and its foundering during a storm. The shipwreck is of additional historically significance for representing aspects of Victoria’s shipping history and for its association with the first passenger ship, which was designed not only to be the fastest and most luxurious of its day but foundered on its maiden voyage to Australia.Bilge pump barrel,; brass cylinder with screw thread at the base and fittings on one side. A piece of the ship's timber is attached. The object was recovered from the wreck of the shipo Schomberg. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, bilge pump, ship's plumbing, bilge pump barrel, bilge -

Flagstaff Hill Maritime Museum and Village

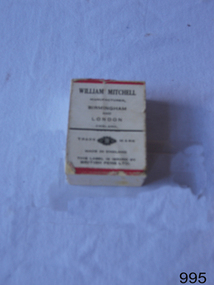

Flagstaff Hill Maritime Museum and VillagePen Nibs, 1920's