Showing 695 items

matching wool manufacture

-

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

National Wool Museum

National Wool MuseumWool Jack

Similiar to the operation to the reasonably common trewalla jack used in the construction and maintenance industries by Riggers and also in the building/house removalist trade. Makers cast indicates it was manufactured by Poole and Steel of Balmain, NSW.AIXI -

National Wool Museum

National Wool MuseumContainer

Manufactured by Ford Sherington Ltd. Used at Foster Valley Mill for storing top and carded sliver. -

National Wool Museum

National Wool MuseumMedicine container

Manufactured by Foster McLellan Co., Sydney. Collection originally owned by Strauss family of Waverley Rainbow (on road to Lake Albaculya, 12 miles from Rainbow).Doan's Backache Kidney Pills (label) -

National Wool Museum

National Wool MuseumJacket

Australian womens jacket from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Saba Pty Ltd with wool from Macquarie Textiles.fashion, woolmark company saba pty ltd, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumSkirt

Australian womens skirt from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Saba Pty Ltd with wool from Macquarie Textiles.fashion, woolmark company saba pty ltd, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumT-shirt

Australian womens top/t-shirt from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Blossom Road Pty Ltd from Colana yarn (a wool/cotton blend) from Rocklea Spinning Mills Pty Ltd.fashion, woolmark company blossom road pty ltd, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumScarf

Australian womens scarf from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Vixen Australia.fashion, woolmark company vixen australia, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumBag

Australian womens bag from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Spencer and Rutherford.fashion, woolmark company spencer and rutherford, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumShoes

Australian womens shoes from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Rivers Shoes.fashion, woolmark company rivers shoes, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumShoes

Australian mens shoes from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Rivers Shoes.fashion, woolmark company rivers shoes, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumSydney 2000 Olympic Games Men's Belt, c.2000

Australian men's belt from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Le Sac de Mode.Polished black leather belt with silver metal buckle.Inside: 4837 / 200 OLYMPIC / TEAM MEMBER / GENUINE LEATHER / MADE IN AUSTRALIA / 85 / cmfashion, woolmark company le sac de mode, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumSocks

Australian mens socks from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Holeproof.fashion, woolmark company holeproof, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumTie

Australian mens tie from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by The Australian Tie Company.fashion, woolmark company australian tie company, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

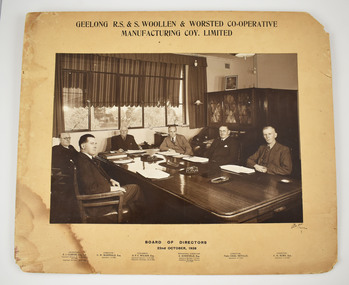

National Wool MuseumPhotograph, Geelong R.S.&S. Woollen & Worsted Co-operative Manufacturing Co. Limited Board of Directors, 22 October, 1938

Photo depicts the Geelong Returned Soldiers and Sailors Woollen and Worsted Mill Board of Directors in 1938. Pictured are: Secretary - E.J. Fairnie; Director - G.W. McDonald; Chairman - D.P.C. Wilson; Managing Director - A. Schofield; Director - Padre Charles Neville; Director - F.H. BurnRSS Mill Board of Directors, 1938.GEELONG R.S. & S. WOOLLEN & WORSTED CO-OPERATIVE / MANUFACTURING COY. LIMITED / BOARD OF DIRECTORS / 22nd OCTOBER, 1938 The / Lockwood Studios / Geelongtextile mills, returned soldiers and sailors mill, fairnie, mr edward john - returned soldiers and sailors mill schofield, mr albert m.b.e. - returned soldiers and sailors mill wilson, mr d. p.c. - returned soldiers and sailors mill -

National Wool Museum

National Wool MuseumJacket

Australian mens suit jacket from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Berkeley Apparel Pty Ltd under their own label, Studio Italia.fashion, woolmark company berkeley apparel pty ltd, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumTrousers

Australian mens suit trousers from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Berkeley Apparel Pty Ltd under their own label, Studio Italia.fashion, woolmark company berkeley apparel pty ltd, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

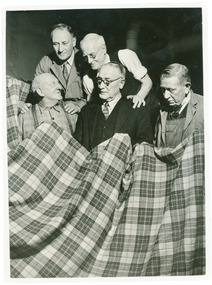

National Wool MuseumPhotograph

Photo depicts male members of staff examining first piece of Harek tweed to be manufactured. Adrian Boddington Photography.textile industry, textile design, photographs -

National Wool Museum

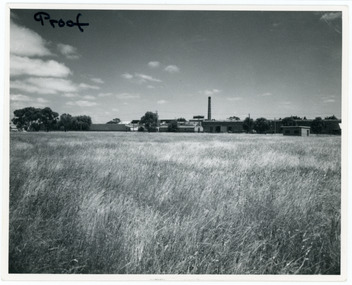

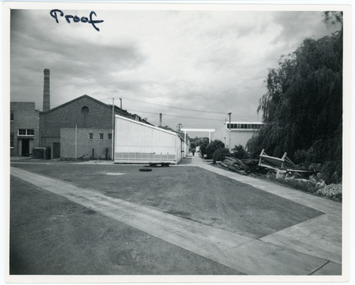

National Wool MuseumPhotograph

Exterior view of the Barwon Mill (built 1874; taken over by Godfrey Hirst and renamed Excelsior One in 1890) in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

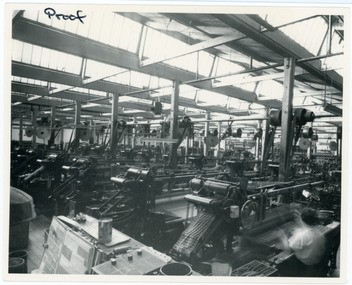

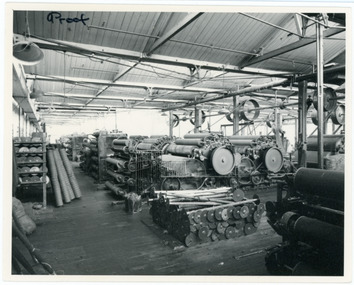

National Wool MuseumPhotograph

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

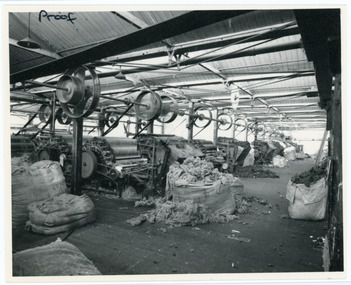

Depicts the woollen carding room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, carding -

National Wool Museum

National Wool MuseumPhotograph

Depicts the woollen carding room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, carding -

National Wool Museum

National Wool MuseumPhotograph

Depicts the woollen carding room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, carding -

National Wool Museum

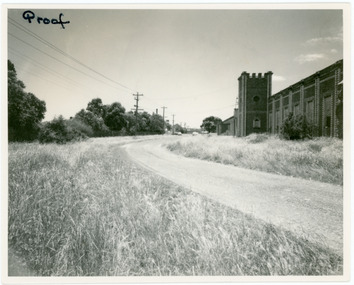

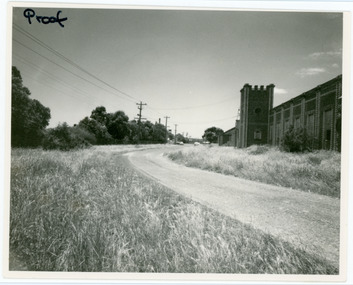

National Wool MuseumPhotograph

Depicts the west wall of the Barwon Mill, looking north in Factory Road. The Barwon Mill was built in 1874 and taken over by Godfrey Hirst and renamed Excelsior One in 1890. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

National Wool MuseumPhotograph

Depicts the west wall of the Barwon Mill, looking north in Factory Road. The Barwon Mill was built in 1874 and taken over by Godfrey Hirst and renamed Excelsior One in 1890. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

National Wool MuseumPhotograph

Depicts a northern view of the Victorian Woollen Mill. This was the first woollen mill in Victoria and was producing cloth by 1868. It became defunct and was purchased by Godfrey Hirst and his partners in 1899, who renamed it Excelsior Mill No. 2. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, victorian woollen mill, excelsior mill no. 2 -

National Wool Museum

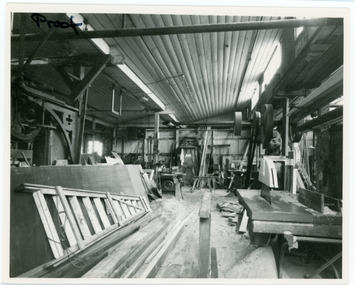

National Wool MuseumPhotograph

Depicts the carpenters shop from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd -

National Wool Museum

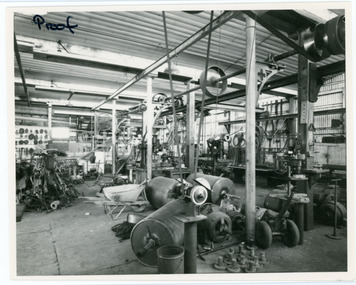

National Wool MuseumPhotograph

Depicts the engineering shop from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd