Showing 202 items

matching body making

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood smoothing plane, G Davis, 1821-1876

A smoothing plane used for making a flat and smooth finish to timber items predominantly used in furniture or cabinet work or other wooden objects. Traditionally, planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile or a flat and smooth finish with the blade secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of smoothing and moulding planes for the full range of work to be performed. For example large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about George Davis is he and his successors made planes in Birmingham, England, from about 1821 to 1876. There are many of his tools including smoothing and decorative moulding planes of all sizes and designs for sale around the world and that his wood working planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a smooth finish to timber. These types of planes came in various shapes and sizes to achieve the required finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Smoothing plane known as a coffin plane due to it's shapeStamped GM inside W (owner) maker possibly G Davisflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, moulding, single bead reeding plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Richard Routledge, 1869- Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding plane size No 2Marked Routledge Birmingham. Stamped JAS Burden (Owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane side beadStamped Mathieson and Son also ( size "W" & ¾" )also GN (previous owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing wood Plane, Mid to Late 19th Century

A smoothing plane is a wood plane used for making a smooth surface to wood surfaces traditionally, these planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape or size required. The blade, or iron was likewise formed to the intended flat or level profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Large crown mouldings or smoothing plane surfaces required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by an unknown maker, that was made commercially for firms and individuals who worked in wood and needed a tool that could produce a flat or level finish to timber. These types of planes came in various shapes and sizes to achieve the required finish to timber surfaces used in cabinet making. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Smoothing Plane Coffin typeMaker J Moseley & Son London and 2¼" also has OS stamped on side (probably an owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Round Moulding plane size 12 Alex Mathieson & Son Glasgow makerflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Sander, c. 1930-1955

This burgundy coloured, portable electric belt sander is stored in its own heavy duty cardboard box. It was made in England and, according to the label on the lid of the box, it is a Portrix Sander-Polisher, all-electric, portable, sands wood metal and polishes. Its uses include decorating, carpentry and polishing. It has a complete with electric unit with flex. The price of 75/- (75 shillings) is printed on the label of the box. The model and the brand of the sander have been removed from the manufacturer’s information embossed on the side of the sander. The sander is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker.This vintage Portrix sander-polisher represents tools used for the hobby and skill of ship model making that has been carried as a leisure activity out for generations. Ship model making was also a pastime for sailing crew, who often made a model of the ship in which they were sailing. This sander was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage.Belt sander, electric. Portable power tool, Portrix model Sander–Polisher, burgundy coloured body with swivelling, black electric cable, 250V 1 / 4 amp. For sanding wood and metal, and for polishing. (Stored in original box.) Made in England. Part of a collection of tools and accessories used by Mr. Jim Williams to build ship model of the “Sovereign of the Sea” and other models. c. 1930-1955. Moulded into body “ - - - SANDER –POLISHER / 1 / 4 amp. PRODUCT OF - - - MANUFACTURING CO. LTD. 50 CYCLES / MADE IN ENGLAND PAT. PEND. 200/250 volts A.C.” (the Brand and Manufacturer’s name have been removed)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, portrix sander-polisher, portrix power tool, portrix belt sander, woodworking equipment, ship modelling equipment, jim williams, james bernard williams, ship model, hobby, ship model tool, sovereign of the seas, english war ship -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Mrs Potts No. 1

A clothes iron is used, when heated, to press clothes to remove wrinkles and creases.The early irons were heated over a stove or in a fire. Irons were used very early in time and cast-iron irons during the 18th century. Mrs. Potts invented many irons starting from an early age thus making a difference to the clothing industry. She invented clothes irons with detachable wooden handles. Her first patent was in October 1870.This iron was used in the Kiewa Valley.Vintage cast iron body invented by Mrs Mary Florence Potts 1890s to 1940s. Detachable wooden handle (not attached) was cooler than a metal handle. It is double pointed for ironing in both directions. Body is hollow the top part being held by two screws. It can be filled with a light material. The No. 1 size is for specific ironing task. compared with No. 2 or No. 3. One handle with other bases enabled some to be reheating while using one. This iron has a stand. Formerly KV88B)Mrs Potts / No. 1 / Iron"" embossed on the topmary florence potts iron, cast iron, laundry, mrs potts -

Orbost & District Historical Society

Orbost & District Historical Societycorset, c. 1900 - 1920

This item was worn by Marjorie McKeown (nee Ford)Until well into the 20th century, the corset was an essential element of fashionable dress. Corsets were worn by women (and much earlier by men) to enhance their figures and to hold their stockings in place. Although still sometimes used they were mainly used prior to the making of pantyhose approximately 1960.A corset of pink/apricot coloured cotton with small flowers embroidered onto the fabric, with whale bone stays, and with suspenders and metal clasps attached to the bottom. It has tape lacing and metal eyelets as can be seen in the photograph. It is marked as size 32, Jenyns Patent Corsetry.Size 32, Jenyns Patent Corsetrywomens-corsetry body-shaping womens-appareil -

Orbost & District Historical Society

Orbost & District Historical Societysewing machine, late 1860's - 1870's

The early settlers of Orbost had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. Many women were skilled dressmakers and craft workers. This item reflects that time.A small black hand-cranked lockstitch sewing machine. It has a backwards C-shaped body. The wheel and base are decorated with a gold pattern. On the end above the needle assembly is a brass plate The balance wheel has a handle. The pattern on the wheel is a gold border with two gold, red and green stars formed by interwoven triangles. On the cloth plate is stamped "Patent March 1867 Heron Gresham" with some indecipherable marks.sewing-machine needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Moulding Plane, Late 19th to early 20th Century

A smoothing or wood plane is a wood plane used for making a smooth or decorative moulding to the surface of wood. Traditionally these planes were made from blocks of wear resistant hardwood, often beech or maple, which were worked to the shape or size required. The blade, or iron was likewise formed to the intended flat or ornamental profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Large crown Mouldings or smoothing plane surfaces required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. This plane is a coffin pattern smoothing plane and is unmarked so the maker is unknown however it's design and patina indicate it was probably made in the mid to late 19th century and would be regarded as a vintage or antique item sought after today by collectors of vintage tools. A vintage tool made by an unknown maker, that was made commercially for firms and individuals who worked in wood and needed a tool that could produce a flat or level finish to timber. These types of planes came in various shapes and sizes to achieve the required finish to timber surfaces used in cabinet making. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Complex moulding wood planeNoneflagstaff hill, warrnambool, plane, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, plane, moulding plane, complex moulding plane, cabinet makers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, Routledge, 1869-1910

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by an early tool manufacturer Richard Routledge, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc. or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century by a known maker that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane Side Bead 5/8 type with a single Box 5/8" "Routledge Birmingham " also inscribed "J.A.S. Burden" (owner of the plane)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, plane, moulding, routledge, side bead, single box, moulding plane, richard routledge, jas burten -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking mallet, Mid 19th to early 20th centuries

The subject item is a vintage Nautical Shipwrights Ship Boat Caulking Hammer Mallet, Unusual Small Size. These mallets were routinely used in the 1800s when ships were made of wood. This mallet was used with caulking irons to drive the oakum (caulk) between the ship's bottom planking to seal them up. The mallet has slots to dampen the vibration of the mallet blows on the user's elbows. The head is made of a very hard wood, possibly Lignum Vitae or another dark tropical wood. The item seems to be of a very early design with the two preened-over metal rods for reinforcing the head. Item appears to be of early manufacture by an unknown maker from the mid to late 19th century and is significant as tools of this era are quite rare. This tool is also significant as it gives an insight into how ships made of wooden planks were made sea-worthy by inserting caulking material between the boards thereby making the vessel watertight. Caulking Mallet Wooden with iron ferrules on each end. Wooden head with two large bolts passing through body. Stamped W Milne. James S Steele tool box.Stamped W Milne & James S Steele tool box.mallet, flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking mallet, caulking, james steele, shipwrights tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This hand made, green glass bottle is representative of bottle making before mass production and is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Late 18th to Early 19th Century

A block, jack or smoothing plane is used for making a smooth finish to timber that is used to make furniture or other wooden objects. Traditionally, wood planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the intended shape of the item being worked on. The blade or iron was likewise formed to a flat shape and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of smoothing and moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. A vintage tool by an unknown maker, this item was made for cabinet-making firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack, block or dressing planes as they were known came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of mechanical smoothing planes and came in many sizes. A significant tool from the late 18th to early 19th century that's pattern or shape is still in use today. Early models of this type of woodworking plane are sought after by collectors today. This tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools used by craftsmen of the time. Tools that were themselves handmade, demonstrating the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce either a decorative or even finish for timber items. Smoothing Plane blade and wedge present. Raised handle at front end. Right-hand wedge guide broken away. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, wood plane, cabinet makers tools, furniture making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Collar Box, Rexbilt Leather Company, 1924-1930

The evolution of the stiff shirt collar occurred in the 1830s when the detachable collar was "invented." At this time, the detachable collars were simply normal shirt collars like you’d see today, but sold separately from the shirt itself and needed to be kept in a container to keep them clean and accessible. The detachable collars were a way to avoid the weekly laundry. Because collars and cuffs were both the most visible parts of shirts and the parts most likely to get dirty, separating them allowed people to do the shirt equivalent of only washing your armpits after you go to the gym. That meant that the main body of the shirt could remain soft while the collar and cuffs that were visible could be starched and shaped. The popularity of detachable collars and starched collars, in general, began to fade in the 1920s and 30s. As shirt styles began to change. The advent of central heating, lighter weight fabrics, and a more relaxed social attitude to fashion all contributed to making men’s clothes more comfortable and less formal.An item that was used to store detachable men’s shirt collars from the early 20th century at a time when men's fashion was more formal and how a person dressed especially for formal occasions dictated a person's social standing. The subject item comes from a time that gives a snapshot into the past at the social norms of the time.Collar box, leather, cylindrical, includes strap, buckle, stitching and cardboard lining and man's white collarCollar inside box marked "CF652 Rexbilt Size 16 1/2 x 1 3/4" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, collar box, men's collar box, men's collar, leather collar box -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

Bunjil Park Aboriginal Education & Cultural Centre

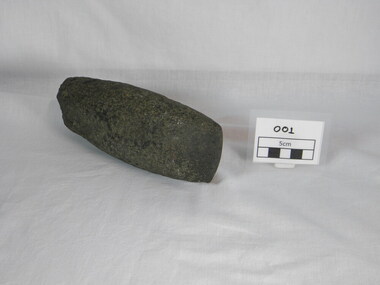

Bunjil Park Aboriginal Education & Cultural CentreAxehead, 40,000 B.P

Green stone granite axehead highly sharpened and beautifully fashioned at one end with rough hewn markings over the body of the object. Axe has a "waist" mid section where handle would have been attached. Also evidence of extensive wear from use. This axehead was quarried at one of only two green stone granite sights in Australia both in Victoria. Scarring at one end of the axehead where it has been split from larger piece of granite.defence, food, preparation, green stone granite, axehead, mt camel, jaara jaara people, jaara, waisted, quarries, tree cutting, weapon making -

Federation University Historical Collection

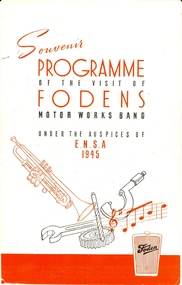

Federation University Historical CollectionBooklet - Programme, Souvenir Programme of the Visit of Fodens Motor Works Band, 1945

Frank Wright was a renown resident of Smeaton, where he was born. He lived at Laura Villa, and attended Smeaton State School. His father William was a gold miner and his mother's name was Sarah. Their family won many singing and instrumental awards. Frank was tutored by Percy Code and was awarded a gold medal for the highest marks in the ALCM examinations in the British Colonies at the age of seventeen years. He became the Australian Open Cornet Champion by the age of eighteen. A year later, Frank conducted the City of Ballarat Band, and later the Ballarat Soldiers’ Memorial Band. He formed the Frank Wright Frisco Band and Frank Wright and his Coliseum Orchestra. These bands won many South Street awards, and Frank as conductor won many awards in the Australian Band Championship contest. In 1933 Frank Wright sailed to England to conduct the famous St Hilda’s Band and was later appointed Musical Director of the London County Council (the GLC or Greater London Council), where he organized many amazing concerts in most of the 150 parks, in and around the London district. He was also responsible for some of London’s major concerts at Kenwood, the Crystal Palace and Holland Park. He was made Professor of Brass and Military Band Scoring and conducted at the Guildhall of Music and Drama. Frank was often invited to adjudicate Brass Band Championships around Europe, in Australia, including South Street and in New Zealand. The Frank Wright Medal at the Royal South Street competition is awarded to an individual recognized as making an outstanding contribution to brass music in Australia.A printed souvenir programme which details the history and successes of the brass band set up at the Fodens Motor Body Works in 1900. On the back cover is a photograph and details of the band personnel and the Managing Director of the company. Also shown are two photographs, one of the 1902 Foden Steam Wagon and one of the World War 2 Centaur Tank which had been built by the company.frank wright, foden diesel, fodens motor works band, brass band, centaur tank, foden steam wagon -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Black and White, The Wallace Hartley Titanic Memorial in Coine, 2/8/1934

Frank Wright was a renown resident of Smeaton, where he was born. He lived at Laura Villa, and attended Smeaton State School. His father William was a gold miner and his mother's name was Sarah. Their family won many singing and instrumental awards. Frank was tutored by Percy Code and was awarded a gold medal for the highest marks in the ALCM examinations in the British Colonies at the age of seventeen years. He became the Australian Open Cornet Champion by the age of eighteen. A year later, Frank conducted the City of Ballarat Band, and later the Ballarat Soldiers’ Memorial Band. He formed the Frank Wright Frisco Band and Frank Wright and his Coliseum Orchestra. These bands won many South Street awards, and Frank as conductor won many awards in the Australian Band Championship contest. In 1933 Frank Wright sailed to England to conduct the famous St Hilda’s Band and was later appointed Musical Director of the London County Council, where he organized many amazing concerts in parks, in and around the London district. He was made Professor of Brass and Military Band Scoring and conducted at the Guildhall of Music and Drama. Frank was often invited to adjudicate Brass Band Championships around Europe, in Australia, including South Street and in New Zealand. The Frank Wright Medal at the Royal South Street competition is awarded to an individual recognized as making an outstanding contribution to brass music in Australia.Two black and white photographs, one of a bust of a man, William Hartley, with a pair of angelic bodies atop a marble pillar on which is written the position held by him aboard the R.M.S. Titanic, that of bandmaster. It is set in the grounds of a garden, next to the main road through the town of Colne in the United Kingdom. the second is a photograph of the printers shop in Colne Lanes within the same town.1). Monument at Colne Lanes, August 2nd 1934, Colne is in Lancashire 2). Colne Lanes, August 1934frank wright, wallace hartley monument, colne lanes, bandmaster, titanic -

Flagstaff Hill Maritime Museum and Village

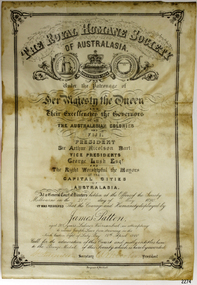

Flagstaff Hill Maritime Museum and VillageAward - Certificate of Merit, Royal Humane Society of Australia, James Patten, 21-05-1890

The Bronze Medal and Certificate of Merit of the Royal Humane Society of Australasia were awarded to James Patten for the bravery he displayed on 18th April 1890, and presented to him on 21st May 1890. The Royal Humane Society of Australasia was founded in 1874 with the aim to recognise those who risked their lives to save others and to assist those whose acts of bravery caused them or their surviving dependants to be disadvantaged in some way. The producers of the certificate were Fergusson & Mitchell, a Melbourne organisation established by 1858 that was an engraver, lithographer and printer. Details of the incident were published in the Argus, Saturday 19 April 1890, page 11 - "FATAL BOATING ACCIDENT, (BY TELEGRAPH FROM OUR CORRESPONDENT.), WARRNAMBOOL, FRIDAY A fatal boating disaster occurred in Lady Bay this morning, the victim being Joseph Lowe, licensee of the Bay View Hotel, South Warrnambool. The deceased, in company with two lads named James Ferrier and James Patten, went out in a small dingy to shoot musk ducks. The water was perfectly smooth, and the party were tempted to proceed as far as the mouth of the Hopkins River. In their eagerness they neglected to keep clear of the breakers, and were presently carried in on the crest of a large wave, and the boat cap sized within a cable's length of the shore, precipitating the occupants into the water. Patten and Lowe stuck to the overturned boat, Ferrier striking out for the shore, which he reached in an exhausted state. In the meantime his companions had been washed off the boat, and were struggling in the breakers. Lowe was unable to swim, and Patten kept him afloat, at the same time making gallant attempts to get him ashore, but finally had to leave him to his fate. Ferrier, seeing Lowe's danger, undressed and swam out, but became exhausted. Ferrier and Patten were both found in a fainting condition by persons who saw the catastrophe from the jetty, and ran along the beach to render assistance. Attempts were subsequently made to rescue Lowe's body, which could be seen washing abort in the surf. These proved unsuccessful, and no hope is now entertained of recovering it. Lowe was a smart young man, 28 years of age, and unmarried. He was formerly bar-man at the Commercial Hotel here, having been engaged in Melbourne...." The bronze medal and accompanying certificate of the Royal Humane Society of Australasia recognise the bravery of James Patten, a Warrnambool citizen who risked his life in the attempt to save the life of his friend Joseph Lowe.Certificate, cream paper, rectangular, decorative border and headings, printed and handwritten in pen and ink. Letterhead of The Royal Humane Society of Australasia. Awarded on 21st May 1890 to James Patten of Warrnambool. for his bravery on 18th April 1890.Print and writing includes - "The Royal Humane Society of Australia under the patronage of Her Majesty the Queen and their excellencies, the Governors of all the Australian Colonies and Fiji. At a general court of directors holden at the Offices of the Society Melbourne on the 21st day of May 1890, it was resolves that the courage and humanity displayed by James Patten, aged 20 years, labourer Warrnambool in attempting to rescue Joseph Lowe from drowning in the North Eastern bight of Lady Bay 18th April 1890. Call for the admiration of this court and justly, entitles him to the Bronze Medal of this society which is hereby awarded." Signatures [Secretary] and [President]flagstaff hill, warrnambool, flagstaff-hill, maritime museum, maritime village, shipwreck-coast, flagstaff hill maritime museum & village, bronze medal 1890, royal humane society of australasia, james patten, medal, australian award medal, commemorative medal, numismatics, life saving, lifesaving, rescue, bravery, drowning, joseph lowe, james ferrier, lady bay, hopkins river, boating accident, certificate of merit, lithograph, north eastern bight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Teapot, Unknown

In the 1650s, the newest exciting development had arrived on Britain’s shores, this time it was tea from China. As it was brought back from overseas, tea was incredibly scarce and as such its price was very high; in 1664, the cost of tea was already 40s per pound, although this is not as high as what it would become when taxed in the 18th century. This resulted in only the social elite enjoying a cup of tea, and most commonly tea was enjoyed in coffee houses, and teapots were therefore not yet a household item. As the East India Company imported larger quantities of tea, it became more widely available and a larger section of the British population were able to enjoy it meaning that, by 1669, tea was available nearly everywhere. Likely due to the fact that tea was first enjoyed in coffee houses, the first known teapot resembles a coffee pot, with a tapering cylindrical shape and standing much taller than what we now know as a teapot at 13.5 inches tall. Into the 1680s, these teapots were given a conical cover for the spout that was fixed to the pot via a chain. As Queen Anne took the throne in 1702, teapots had become much more widely used and had formed two common groups. The first style of teapot was the pear shaped style which began to appear in 1705. The pear shaped pot usually had a domed lid and sometimes featured a finial. This form was generally supplied with a heater and stand as well as having a baluster shaped handle on one side. This iteration would disappear by 1725 but does make a reappearance in the 1740s, only this time as an inverted pear shape. The second group was the more spherical, or globular, shape which appeared in 1710. The globular teapot had a flush, hinged lid as well as a narrow moulded rim foot and a straight sided, tapering spout. Both generalised groups of teapots have polygonal examples – that is, teapots that are made up of straight sided segments – but six or seven sided teapots are incredibly rare. There is one known example of a seven sided globular teapot, made by Isaac Ribouleau in 1724. This is so unique because polygonal teapots are much more technically difficult and time consuming to make. Other than the occasional band of engraving round the shoulder of the teapot, they remain quite plain until c.1740 when scrollwork and chased shells begin to be applied for decoration. ‘Chasing’ is the process of decorating the front of a piece of metal by indenting the back, without cutting or engraving. From 1755 until 1770, silver teapots became incredibly uncommon and it is likely that this either reflects a change in drinking habits or changing trends producing a favour for porcelain. This dip in popularity could also be in response to the outrageous taxes placed on tea, up to 119%! In 1765, the Leeds creamware globular teapot seemed to kickstart a resurgence and this, combined with the Commutation Act of 1784 – which reduced tax on tea from 119% to 12.5% – saw teapots return in all their forms. It’s around this time, in 1780, that a form of teapot with a detachable, openwork stand appeared; however, the plain, oval teapot remained the most popular in the 1780s and 90s. In the later years of George III’s tenure on the throne, during the last decade of the 18th century, there was a revival of chasing and embossing teapots with flower and foliage designs. At the turn of the century, the spherical, partly fluted teapot with classical decoration was superseded by a more oblong shaped pot that sat on four spherical feet. This was then changed again when teapots became more melon shaped. It was at this time that the capacity of a teapot greatly increased and the previously wooden or ivory handles were replaced by silver handles with ivory washers for insulation. As Britain entered into the Victorian era, the design quality often suffered as there was a tendency to over-decorate the silver. In the early 19th century, the last major addition to the shape of the teapot, a raised collar was added between the cover and body. Whilst this seems to just be for decoration, there is some speculation that it could also be to prevent overspills. https://www.marklittler.com/silver-teapots-history/ This item shows that silver and silver plated teapots were used for tea making.Plain sliver teapot. Heavy oxidation. Dented.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, teapot, silver, siver plate, tea -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding plane, Bewley Leeds, 1785 -1847

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Robert Bewley and his successors is that they made planes in Leeds, England, from about 1785 to 1847. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his moulding planes are well sought after by collectors of vintage tools.A vintage tool made by a known maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve a decorative finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Round Moulding plane number 8 Stamped Bewley Leeds (maker)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1903

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Wertheim sewing machine in carry case, hand operated with two spindles, handle with locking pin, which turns lever between spokes of main handle, hand brake. The machine is table-mounted with a Turkish walnut base. The base can be attached to a cast iron table with a foot treadle as an optional extra. The walnut base has marquetry to the front set out as a measure for material. There is also an accessory box inside the carry case containing 20 additional items for use with the machine. Wertheim brass trademark badge riveted to the body of the machine of a crouching dwarf with a hammer with the name of the company Wertheim and Frankfurt. Gold filigree decoration in gold paint adorns the main body of the machine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated sewing machine, crank handle sewing machine, wertheim, dressmaking, taylor, domestic, clothing, hugo wertheim, joseph wertheim -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Net Floats, 20th century

These net floats are handmade from lightweight cork wood and are used for suspending fishing nets in the water. Newspaper articles dated from 1848 to 1916 mention net fishing in Warrnambool's Hopkins and Merri rivers and Lady Bay. The Melbourne Argus dated January 11, 1848, published a quote from Captain Theobald of the vessels ELLEN and ELIZABETH, made on his first visit to Warrnambool "“…Fish are very plentiful here; on Christmas day a net was thrown into the Hopkins, and, after two or three draws, a boat load of beautiful fish was obtained…” The Argus, Melbourne, Sat. 29 May 1858, forwarded from The Examiner newspaper; "Extraordinary Fish. We have been presented with a very singular fish, caught by Mr. Meek in the Hopkins [Hopkins River, Warrnambool] last week. It is about three inches long, with a slate-coloured body, and a beautiful wing on each side. It was caught with other fish at night, in a net, and its eyes shone as bright as diamonds." A method for making cork net floats mentioned, in a 15th-century book, advised cutting the corks and then burning a hole through the centre of each one with a hot iron. The prepared corks were then joined together with a horsehair line. The cork's size and the line's thickness depended on the net's weight.The net floats are an example of fishing equipment used for many centuries and still in use today. In Warrnambool net fishing was a common practice from 1848 and became a livelihood for many fishermen. Net floats; cylindrical blocks of 16 corks threaded onto string with a hook-holding device at the end. warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, net floats, cork net floats, fishing, fisheries, fishing equipment, handmade, net fishing, fisheries act, andrew ferrier, william flett, warrnambool breakwater, merri river, hopkins river, captain theobald, ellen, elizabeth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Net Floats, 20th century

These net floats are handmade from lightweight cork wood and are used for suspending fishing nets in the water. Newspaper articles dated from 1848 to 1916 mention net fishing in Warrnambool's Hopkins and Merri rivers and Lady Bay. The Melbourne Argus dated January 11, 1848, published a quote from Captain Theobald of the vessels ELLEN and ELIZABETH, made on his first visit to Warrnambool "“…Fish are very plentiful here; on Christmas day a net was thrown into the Hopkins, and, after two or three draws, a boat load of beautiful fish was obtained…” The Argus, Melbourne, Sat. 29 May 1858, forwarded from The Examiner newspaper; "Extraordinary Fish. We have been presented with a very singular fish, caught by Mr. Meek in the Hopkins [Hopkins River, Warrnambool] last week. It is about three inches long, with a slate-coloured body, and a beautiful wing on each side. It was caught with other fish at night, in a net, and its eyes shone as bright as diamonds." A method for making cork net floats mentioned, in a 15th-century book, advised cutting the corks and then burning a hole through the centre of each one with a hot iron. The prepared corks were then joined together with a horsehair line. The cork's size and the line's thickness depended on the net's weight.The net floats are an example of fishing equipment used for many centuries and still in use today. In Warrnambool net fishing was a common practice from 1848 and became a livelihood for many fishermen.Net floats; cylindrical blocks of 18 corks of various sizes threaded onto string.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, net floats, cork net floats, fishing, fisheries, fishing equipment, handmade, net fishing, fisheries act, andrew ferrier, william flett, warrnambool breakwater, merri river, hopkins river, captain theobald, ellen, elizabeth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Plane, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will named his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard's estate when he died in 1856. From John's will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool-making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield.A vintage tool made by a well-known company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items.Jack Plane metal body with rose wood filler.Mosley & Sons London No 2flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john moseley & son, jack plane, woodworking tool, carpenders tools, cabinet makers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Sides & Skinner, First half of the 20th century

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheelwrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. A now vintage tool made by an Australian manufacture in NSW who specialised in making pruning shears, hacksaw frames and heel shaves under the Erskin brand name. This tool is now sought after by collectors even though it was probably made in the first quarter of the 20th century. It gives a snapshot of how carpenters work with wood by hand showcasing their craftsmanship. Hollow face Spokeshave, metal body with black enamel finish. Erskin stamped on frontflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, cabinet makers tools, wood working, cutting tool, shaping tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Ogee Complex Moulding Plane Alex Mathieson & Son. Stamped W Worrel, (owner) & No 2.flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alexander mathieson & sons, complex moulding plane, carpenders tools, cabinet makers tools, wood working tools, wood planes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910