Showing 76 items

matching cogs

-

Mont De Lancey

Mont De LanceyTool - Hay Knife, Unknown

A steel curved double bladed silage or hay knife with two wooden handles at the top attached by rivets. The long blades have sharp points at the end. The handle bracket is joined to the steel blades by a nut and bolt. It has a cog mechanism to move the blades. It was used to cut hay when it is dry. Blocks were cut for the ? or stack as needed for stock feed. Silage is an animal feed cut and stored while still green.agricultutal tools, hay knife, agricultural equipment -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - INNER WHEEL CLUB SOUTH BENDIGO COLLECTION: CERTIFICATE OF APPRECIATION

Mottled cream Certificate of Appreciation awarded to the Inner Wheel Club of Bendigo South for their support of the Margaret Roberts Motor neurone Disease Research Scholarship, signed by Jay ? and dated June 2006. At the top of the certificate is the logo of the Australian Rotary Health Research Fund which is a dark blue microscope in front of a yellow sphere. and in the bottom left corner is the dark yellow and dark blue logo of Rotary International which is the shape of a cog. Certificate is laminated.bendigo, clubs, inner wheel club south bendigo, inner wheel club south bendigo: certificate of appreciation, australian rotary health research fund, margaret roberts motor neurone disease research scholarship, rotary international -

Flagstaff Hill Maritime Museum and Village

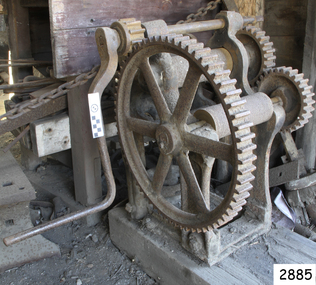

Flagstaff Hill Maritime Museum and VillageTyre Bender, 1884

A tyre bender is used to bend and shape metal rims for wooden wagon wheels. This tyre bender’s model first appeared in the Day Bros catalogue in 1884 as the “Giant” model. The catalogue of 1883 only showed a lighter duty model called the “Lion”. It can be assumed that this later “Giant” model was a heavy duty improvement over the 1883 "Lion" and other smaller models which were still being advertised for sale in 1884. The Day Bros foundry, makers of this tyre bender, was operating as the manufacture of wheel right and blacksmith tools and general machinery in the 19th century in the USA and successfully exported their goods all over the world. Wagon tyre benders would have been very common circa 1850-1920, so there were probably many makers over the years. Early on, it would have become clear to the blacksmiths about which designs worked best so, eventually, the various makers would have made similar products to each other. This tyre bender was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The tyre bender is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The machine or tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Steel tyre bender mounted on timber base, used for wagon wheel steel rims. Made from cast iron and steel, double geared with four cogs to unite the upper and lower steel rollers. There are adjustable guide collars to keep the iron in line while it is being bent. It can also be used with two cranks for heavy duty work utilising the use to two operators. It is the Giant model, made in 1884 by Day Bros. of Philadelphia. This tyre bender once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria. “DAY BROS. PHILAP. PA” cast into the side of machineflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, machinery, wagon wheel, wheelwrights, blacksmith, steel rim wheels, tyre bender, tire bender, the giant tyre bender, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, wagon tyre bender, day bros. philadelphia pennsylvania, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Medal, Anniversary of National Service 1951-1972, 2001

Bronze Anniversary of national Service medal and miniature on striped ribbons: central yellow and blue stripes ( Australia's national colours of the era), white, green, and pale blue stripes ( represent Navy, Army Air Force) ochre edge for the soil of Australia. Emblem on front represents the Australian defence forces with the crossed swords of the Army at the forefront. Around the outer edge are the words "ANNIVERSARY OF NATIONAL SERVICE 1951-1972". The reverse side has a stylised cog with the Southern Cross Stars over it to represent the cooperation between the machinery of the armed forces and the people of Australia. These medals were introduced in 2001. Accompanied by covering letter addressed to NE Swainston and dated '4 May 2011', the set is completed by the original hard black plastic box in white card slipcase.'3801127 N E Swainston' engraved around bottom edge of large medal.medal, national service - australia -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

Federation University Historical Collection

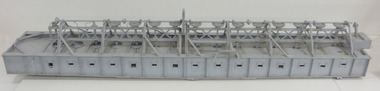

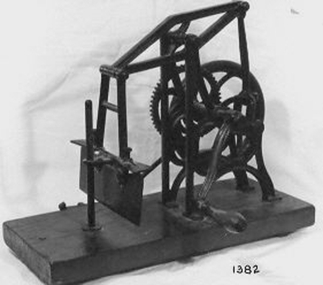

Federation University Historical CollectionUnknown - Model, Edwards' Ore Reduction Furnace Model, pre 1924

This model of a mechanical ore roasting and chloridising furnace was invented and patented by Thomas Edwards of the Edwards Pyrites Smelting and Ore Reduction Company. This new type of furnace produced a high standard of sulphur free ore known as ‘sweet roasted’. Edwards used this model for demonstrations in the USA. Of note is the central large vertical cogwheel (externally driven) which drives small vertical cogwheels via angled cogging drives. These in turn drive a horizontal wheel. Each side of the vertical wheel is set on an opposite side to the horizontal wheel of its neighbours, resulting in opposite direction rotation of neighbouring horizontal wheels. Each horizontal wheel turns a rabble (set of vertical iron paddles) within the furnace. These rabbles, each turning in opposite direction to its neighbours, move the roasting ore in a zig-zag path through the furnace. The elongated furnace with its line of rabbles produced a much ‘sweeter’ roasted ore than could be obtained from a typical tank-shaped furnace. In 1924, when the model was donated to the Ballarat School of Mines, Ballarat’s Courier newspaper reported, ‘Apart from its historical and education value, the gift should serve to stimulate the inventive faculties of the students who have to win fame for the school and for themselves in the metallurgical world.’ The furnace model was donated to Ballarat School of Mines and used as an educational prop from 1924. The model relates to the mining industry which is a significant part of Ballarat's history and heritage. Ballarat School of Mines is the oldest Technical School in Australia and is celebrating 150 years in 2020.Metal model of Edwards' Ore Reduction Furnace. The model includes cogwheels, rabbles and other details. Scale is thought to be around 1:20M259ballarat school of mines, edwards, pyrites, ore reducation, edward retallack, mining, model -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Farm Machinery, Horse-drawn Plough Potato Digger, c1900

Circa late 1800s early 1900s a horse-drawn plough, potato digger, is one example of the implements that were widely used by early market gardeners in the Shire of Moorabbin. The flat plate, seen to the right of the photo, dug down into the ground below the potatoes and "scooped" them up. Behind the plate, two driving chains on cogs, (these chains are missing from our exhibit), then "rocked' the dug potatoes to loosen the soil from the "spuds". The potatoes were then harvested by hand. Very large tracts of land in the Shire of Moorabbin were planted with potatoes. Harvesting commenced in October, into November and on into December. Potatoes were a necessary food staple. The market gardeners were always in a rush to be first to get their potatoes to market, and hence the best price. Some market gardeners were so keen to be the first to market, (and get the most money), that they dug their potatoes "green" (or new). The only downside of this practice was that these early potatoes had to be handled with extreme care as their skins were very loose, and came off easily - so decreasing their profits.As well as taking their produce to the Melbourne and St Kilda markets, they also sent produce off to Sydney markets. It is interesting to note that a group of Chinese market gardeners were the first to access the Sydney market. .Following the 'Dendy's Special Survey' 1841 and the Crown Land Sale of 1852, land allotments were sold to pioneer settlers who established market gardens in the area of Moorabbin Shire. During the 1850s gold-rush population boom the number of market gardeners increased significantly spreading throughout the Moorabbin Shire. Potatoes were considered a staple foodstuff, so crops were regularly sown throughout the whole Moorabbin area. Circa late 1800s early 1900s. A horse-drawn plough potato digger is an example of the machines used by early market gardeners in Moorabbin Shiremelbourne, sydney, markets, vegetables, potato, dendy henry, st kilda, market gardeners, gold rush, moorabin, chinese gardeners, ploughs -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Household Chopping Machine, Mechanical Chopper, c1886

Used in kitchen to cut carrots, cheese slices, onions. boiled eggs, etc.Painted black guillotine on a wooden stand. An iron pole keeps the guillotine in vertical position at one end of the block. Driven by two wheels when a handle is turned. A tilting beam moves the guillotine up and down to cut vegetables, etc. Blade 18cm long by 6.5cm wide. Metal plate missing under blade. A rotatable drum to contain the food to be chopped, which is rotated by a cog at the base (also missing) turns the container. The upright holding chopper blade e is a modification made because of the missing container.|The following description is from Ken Turner Booklet referred to under 'Reference'. ----|The Starrett food chopper would certainly have to be considered one of the more interesting inventions, which incidentally is now considered the ultimate in kitchen collectables. Laroy Starrett in later years' told of how the design of his food chopper was inspired by the action of the walking beam engine used on the Mississippi steam boats. When the crank handle of the chopper is turned, this sets in motion a mechanism which is just fascinating to watch. The crank activates a flywheel which in turn, by a series of cogs and levers, simultaneously rotates a food holding container and raises and lowers within the rotating container, a guillotine like 'chopping blade - the action does not only look like that of a beam steam engine, it even in a way sounds like one, although somewhat noisier. Starrett produced seven different models of these choppers, ranging in size appropriate for domestic use to heavy duty models for butchers, restaurants and for hotel use. The small model was capable of chopping 3lbs in three minutes, and the largest had a capacity for chopping something like 100 lbs in an hour. The mechanical chopper, which became affectionately known as the 'hasher', was the first of some one hundred of Starrett's inventions, and these include a washing machine patented in 1865 which had a similar action to his food chopper, a food press patented in 1873, and a device for lacing shoes he patented in 1886.domestic items, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Medical container, Late 19th century or early 20th century

THE DISCOVERY OF STAINLESS STEEL Harry Brearley Since the dawn of man colonies have raced against each other to uncover new technologies, to be the first to stamp their names on a discovery, and although we’ve evolved over millions of years, the urge to be the first remains at the very core of our nature. This sense of passion and pride can lead some of the more unscrupulous humans to claim others discoveries as their own. Of course many breakthroughs are genuinely made in tandem, or are simultaneously occurring, but unless you can categorically prove that you were the pioneer of these incredible findings, then the other party involved will always dispute the fact. And so we come to stainless steel. The first point to note is that ‘inventor’ is a very ambiguous term. Is this the first person to think, to document, to patent, or to produce? The second point is that stainless steel wasn’t truly defined until 1911, so are we to cast aside those chromium-iron alloys that don’t quite meet the minimum requirement of 10.5% chromium? It seems like anyone and everyone has a different claim to being labelled the ‘inventor’ of stainless steel; from Britain, Germany, France, Poland, the U.S.A., and even Sweden. The cogs were set in motion by Englishmen Stoddart and Faraday circa 1820 and Frenchman Pierre Berthier in 1821. These scientists, among others, noted that iron-chromium alloys were more resistant to attack by certain acids, but tests were only carried out on low chromium content alloys. Attempts to produce higher chromium alloys failed primarily because of scientists not understanding the importance of low carbon content. In 1872 another pair of Englishmen, Woods and Clark, filed for patent of an acid and weather resistant iron alloy containing 30-35% chromium and 2% tungsten, effectively the first ever patent on what would now be considered a stainless steel. However, the real development came in 1875 when a Frenchman named Brustlein detailed the importance of low carbon content in successfully making stainless steel. Brustlein pointed out that in order to create an alloy with a high percentage of chromium, the carbon content must remain below around 0.15%. Thus ensued two decades of stagnation for the development of stainless steel, and while many scientists attempted to create a low carbon stainless steel, none succeeded. Hans Goldschmidt It wasn’t until 1895, when Hans Goldschmidt of Germany developed the aluminothermic reduction process for producing carbon-free chromium, that development of stainless steels became a reality. In 1904 French Scientist Leon Guillet undertook extensive research on many iron-chromium alloys. Guillet’s work included studies on the composition of what would now be known as 410, 420, 442, 446 and 440-C. In 1906 Guillet went on to analyse iron-nickel-chrome alloys, which would now be considered the basics of the 300 series. However, while noting the chemical composition of his alloys, Guillet failed to acknowledge the potential corrosion resistance of his materials. Albert Portevin In 1909 Englishman Giesen published an in-depth work regarding chromium-nickel steels, while the French national, Portevin, studied what is now regarded as 430 stainless steel. However, it wasn’t until 1911 that the importance of a minimum chromium content was discovered by Germans P. Monnartz and W. Borchers. Monnartz and Borchers discovered the correlation between chromium content and corrosion resistance, stating that there was a significant boost in corrosion resistance when at least 10.5% chromium was present. The pair also published detailed works on the effects of molybdenum on corrosion resistance. It is at this point we introduce Harry Brearley, born in Sheffield, England in 1871, he was appointed lead researcher at Brown Firth Laboratories in 1908. In 1912 Brearley was given a task by a small arms manufacturer who wished to prolong the life of their gun barrels which were eroding away too quickly. Brearley set out to create an erosion resistant steel, not a corrosion resistant one, and began experimenting with steel alloys containing chromium. During these experiments Brearley made several variations of his alloys, ranging from 6% to 15% chromium with differing levels of carbon. On the 13th August 1913 Brearley created a steel with 12.8% chromium and 0.24% carbon, argued to be the first ever stainless steel. The circumstances in which Brearley discovered stainless steel are covered in myth; some enchanted tales of Brearley recite him tossing his steel into the rubbish, only to notice later that the steel hadn’t rusted to the extent of its counterparts, much like Alexander Fleming’s experience 15 years later. Other more plausible, (but less attractive), accounts claim it was necessary for Brearley to etch his steels with nitric acid and examine them under a microscope in order to analyse their potential resistance to chemical attack. Brearley found that his new steel resisted these chemical attacks and proceeded to test the sample with other agents, including lemon juice and vinegar. Brearley was astounded to find that his alloys were still highly resistant, and immediately recognised the potential for his steel within the cutlery industry. The Half Moon Brearley struggled to win the support of his employers, instead choosing to produce his new steel at local cutler R. F. Mosley. He found difficulty producing knife blades in the new steel that did not rust or stain and turned to his old school friend, Ernest Stuart, Cutlery Manager at Mosley’s Portland Works, for help. Within 3 weeks, Stuart had perfected the hardening process for knives. Brearley had initially decided to name his invention ‘Rustless Steel’, but Stuart, dubbed it ‘Stainless Steel’ after testing the material in a vinegar solution, and the name stuck. And that’s how Harry Brearley discovered stainless steel…. well, not quite… During the 5 year period between 1908 and Brearley’s discovery in 1913 many other scientists and metallurgists have potential claims to Brearley’s title. In 1908 the Germans entered the fray, the Krupp Iron Works in Germany produced a chrome-nickel steel for the hull of the Germania yacht. The Half Moon, as the yacht is now known, has a rich history and currently lies on the seabed off the east coast of Florida. Whether the steel contains the minimum 10.5% chromium content remains inconclusive. Employees of the Krupp works, Eduard Maurer and Benno Strauss, also worked from 1912-1914 on developing austenitic steels using <1% carbon, <20% nickel and 15-40% chromium. Not happy with Europe hogging the glory, the USA got in on the act. Firstly, Elwood Haynes, after becoming disenchanted at his rusty razor, set out to create a corrosion resistant steel, which he supposedly succeeded in doing during 1911. Two other Americans, Becket and Dantsizen, worked on ferritic stainless steels, containing 14-16% chromium and 0.07-0.15% carbon, in the years 1911-1914. Elwood Haynes During 1912 Max Mauermann of Poland is rumoured to have created the first stainless steel, which he later presented to the public during the Adria exhibition in Vienna, 1913. Finally, a recently discovered article, which was published in a Swedish hunting and fishing magazine in 1913, discusses a steel used for gun barrels, (sound familiar?), which seems to resemble stainless steel. Although this is purely speculation, the Swedes have still made an audacious claim that they were in fact responsible for the first practical application for stainless steel. That concludes the shambolic discovery of stainless steel! Although there is much mystery and speculation behind the discovery of this wonderful material, there is no question that without the combined effort of all the above scientists and metallurgists, (and all the many more that were not mentioned), we would not have such a rich and versatile metal at our fingertips. https://bssa.org.uk/bssa_articles/the-discovery-of-stainless-steel/#:~:text=On%20the%2013th%20August%201913,the%20first%20ever%20stainless%20steel. This stainless steel container was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he would take time to further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . The organisation began in South Australia through the Presbyterian Church in that year, with its first station being in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill where he’d previously worked as Medical Assistant and purchased a share of the Nelson Street practice and Mira hospital from Dr Les Middleton one of the Middleton Brothers, the current owners of what was once Dr Tom Ryan’s practice. Dr L Middleton was House Surgeon to the Nhill Hospital 1926-1933, when he resigned. [Dr Tom Ryan’s practice had originally belonged to his older brother Dr Edward Ryan, who came to Nhill in 1885. Dr Edward saw patients at his rooms, firstly in Victoria Street and in 1886 in Nelson Street, until 1901. The Nelson Street practice also had a 2 bed ward, called Mira Private Hospital ). Dr Edward Ryan was House Surgeon at the Nhill Hospital 1884-1902 . He also had occasions where he successfully performed veterinary surgery for the local farmers too. Dr Tom Ryan then purchased the practice from his brother in 1901. Both Dr Edward and Dr Tom Ryan work as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He too was House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. Dr Tom Ryan moved from Nhill in 1926. He became a Fellow of the Royal Australasian College of Surgeons in 1927, soon after its formation, a rare accolade for a doctor outside any of the major cities. He remained a bachelor and died suddenly on 7th Dec 1955, aged 91, at his home in Ararat. Scholarships and prizes are still awarded to medical students in the honour of Dr T.F. Ryan and his father, Dr Michael Ryan, and brother, John Patrick Ryan. ] When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery states “HOURS Daily, except Tuesdays, Fridays and Saturday afternoons, 9-10am, 2-4pm, 7-8pm. Sundays by appointment”. This plate is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. Dr Edward Ryan and Dr Tom Ryan had an extensive collection of historical medical equipment and materials spanning 1884-1926 and when Dr Angus took up practice in their old premises he obtained this collection, a large part of which is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. During his time in Nhill Dr Angus was involved in the merging of the Mira Hospital and Nhill Public Hospital into one public hospital and the property titles passed on to Nhill Hospital in 1939. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. ). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (The duties of a Port Medical Officer were outlined by the Colonial Secretary on 21st June, 1839 under the terms of the Quarantine Act. Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. Their interests included organisations such as Red Cross, Rostrum, Warrnambool and District Historical Society (founding members), Wine and Food Society, Steering Committee for Tertiary Education in Warrnambool, Local National Trust, Good Neighbour Council, Housing Commission Advisory Board, United Services Institute, Legion of Ex-Servicemen, Olympic Pool Committee, Food for Britain Organisation, Warrnambool Hospital, Anti-Cancer Council, Boys’ Club, Charitable Council, National Fitness Council and Air Raid Precautions Group. He was also a member of the Steam Preservation Society and derived much pleasure from a steam traction engine on his farm. He had an interest in people and the community He and his wife Gladys were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Medical box; rectangular stainless steel base and separate lid, from the W.R. Angus Collection.warrnambool, flagstaff hill maritime museum, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, medical treatment, stainless steel medical container, medical container, stainless steel -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 12, September 1981 to November 1981

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 30 September 1981 to 25 November 1981.Book with white cover, front, spiral bound. courses available, teaching position advertised, lack of tradesmen cost jobs, daisy theme for tafe campaign, medal comes back, allan bernaldo artist, steamrail restoration, mt clear technical high school, gaol opens its doors to students, smb spreads out across the city, painting by a bernaldo presented to smb, opening of amenities building ., lindsay thompson opens mt clear tech high, skills in demand program begun, art gallery to get $40000, maurice cogger wins photographic contest, smb boating course, smb appeal target, earthworks serve two aims, florence nightingale's china to gold museum, china donated by miss darby former typing teacher at smb, sir arthur nicholson dies, japanese educators visit smb, indonesian school principals visit smb, replica bricks raise funds, contract signed for smb computer, rokewood's new fire truck built by students, local employers asked to boost apprenticeship intake, minister for employment and training, ballarat's education broker graham beanland, smb art and design show -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumCog/Gear

Mass Amounts of Rust Corroded -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncLoad Adjuster, Bomb Load Adjuster No. 31629, 1945

1945 Slide Rule US Army Air Force from Prof. Allan Bromley.Works by adding Angular moments together to find centre of gravity (COG) of a plane (adds bombs, ammunition and crew on board).Brown Leather Case with 'Slide Rule' inner.Load Adjuster, Property of US Government. 102630 on case. 81629. Airplane serial No. 44-4-1195, Model B-24Jbomb load adjuster, a16 -

Rutherglen Historical Society

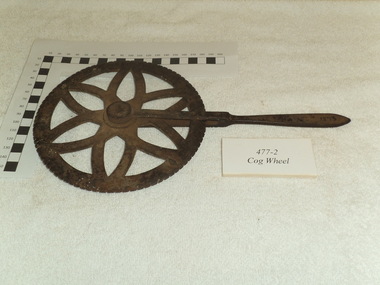

Rutherglen Historical SocietyCog wheel

A wheel with a handle and uniform teeth on the circumference. Purpose unknown. -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncNewsletter, The Cog Issue 1

-

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncNewsletter, The Cog Issue 2 - September 2017

-

Federation University Art Collection

Federation University Art CollectionArtwork-Ceramics, Cogger, Anne, 'Fish Jug' by Anne Cogger, 1991

This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Blue glazed ceramic jug. If you can assist with information on this artist or artwork please use the comment box below.art, artwork, anne cogger, ceramics, available, tafe ceramics collection