Historical information

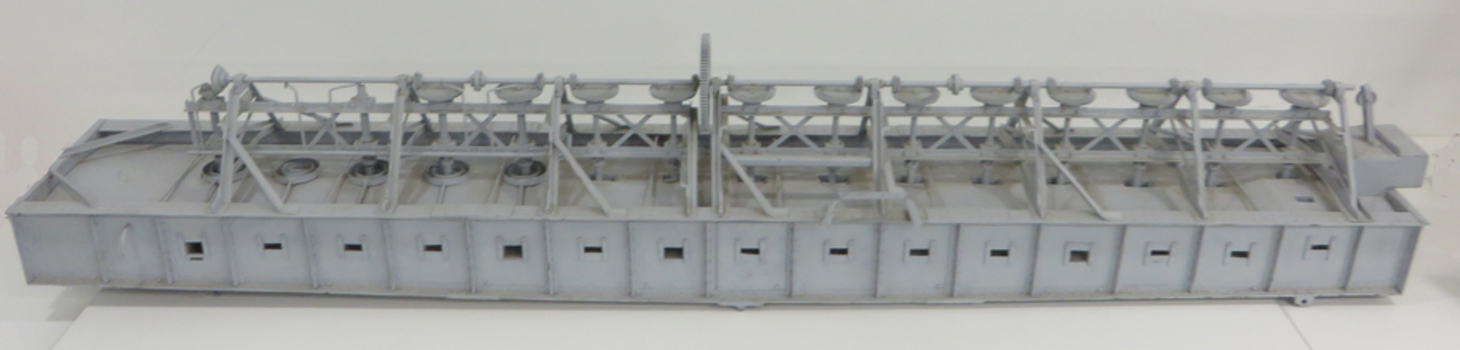

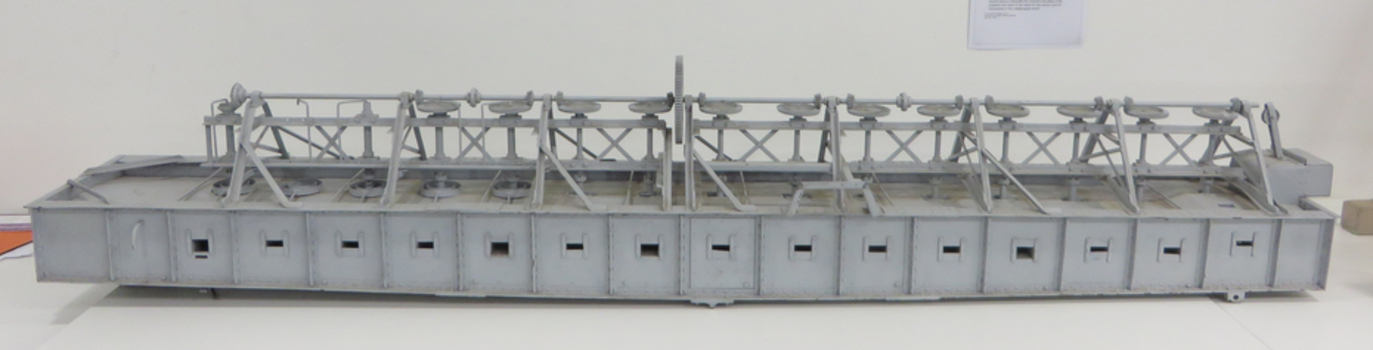

This model of a mechanical ore roasting and chloridising furnace was invented and patented by Thomas Edwards of the Edwards Pyrites Smelting and Ore Reduction Company. This new type of furnace produced a high standard of sulphur free ore known as ‘sweet roasted’.

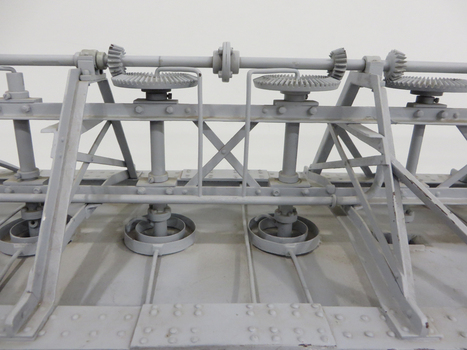

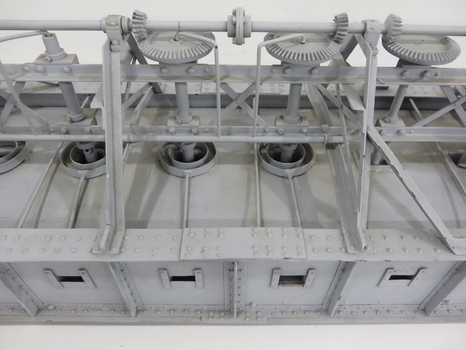

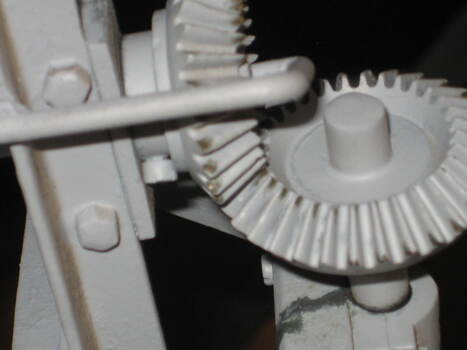

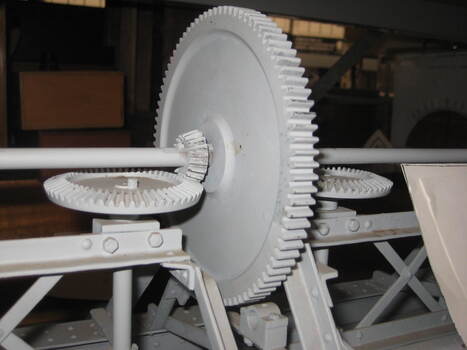

Edwards used this model for demonstrations in the USA. Of note is the central large vertical cogwheel (externally driven) which drives small vertical cogwheels via angled cogging drives. These in turn drive a horizontal wheel. Each side of the vertical wheel is set on an opposite side to the horizontal wheel of its neighbours, resulting in opposite direction rotation of neighbouring horizontal wheels.

Each horizontal wheel turns a rabble (set of vertical iron paddles) within the furnace. These rabbles, each turning in opposite direction to its neighbours, move the roasting ore in a zig-zag path through the furnace.

The elongated furnace with its line of rabbles produced a much ‘sweeter’ roasted ore than could be obtained from a typical tank-shaped furnace.

In 1924, when the model was donated to the Ballarat School of Mines, Ballarat’s Courier newspaper reported,

‘Apart from its historical and education value, the gift should serve to stimulate the inventive faculties of the students who have to win fame for the school and for themselves in the metallurgical world.’

Significance

The furnace model was donated to Ballarat School of Mines and used as an educational prop from 1924. The model relates to the mining industry which is a significant part of Ballarat's history and heritage. Ballarat School of Mines is the oldest Technical School in Australia and is celebrating 150 years in 2020.

Physical description

Metal model of Edwards' Ore Reduction Furnace. The model includes cogwheels, rabbles and other details. Scale is thought to be around 1:20

Inscriptions & markings

M259