Showing 121 items matching "cooking equipment"

-

Greensborough Historical Society

Greensborough Historical SocietyDomestic object - Egg-beater, Propert, Swift Whip, 1932c

Used for beating eggs or other cooking mixtures.Egg beater, chromed metal with wooden handlesSwift Whip. A Propert product made in Australia Pat. Ball drive 9033/32egg-beaters, whisks, kitchen equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales, Imperial, Spring, 'Salter Household Scale’ 28lb, c1920

In the 18th century, spring scales appeared. To produce these scales, a manufacturer would use the resistance of a spring to calculate weights, which could be read automatically on the scale’s face. The ease of use of spring scales over balance scales is what led most post offices to outfit their clerks with spring postal scales. One of the most common types of spring scales was the kitchen scale—also known as a family or dial scale. Designed for horizontal surfaces, these scales used the weight of goods in a pan at the top of the scale to force the spring down. Such scales were common in early-20th-century households and were sold by Sears and Montgomery Ward. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks made both. SALTER HOUSEWARES began in the late 1760 in the village of Bilston, England. At this time Richard Salter, a spring maker, began making 'pocket steelyards', a scale similar to the fisherman's scale of today. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. and later established a large, well equipped manufacturing site in the town of West Bromwich. The business thrived throughout the 1900s, and in 1972 the company was purchased by Staveley Industries Plc. In 2002, the management team at Salter Housewares Ltd, backed by Barclays Private Equity, bought the company out from the group, to concentrate on its consumer businesses. In 2004 was sold to the US-based HoMedics company, and in 2006, Salter Housewares USA and Taylor Precision Products Inc (also owned by HoMedics) merged.Salter Brand No. 46 Household Spring Balance Kitchen Scales made of green painted metal with a white large clock face dial marked in 1oz graduations and with a shallow metal bowl placed on the flat top connected to the mechanism. An adjustable screw tightened or loosened the spring to bring the pointer to zero, prior to adding the material to be weighed.. A common piece of kitchen equipment as most families used this type of scale when measuring goods for cooking or storing. HOUSEHOLD SCALE / NO. 46 / SALTER / TO WEIGH 28 LB / ( rope & arrow TM) BRITISH MADE Base rope & anchor S (trade mark) weights, measures, shops, scales. balances, grocery stores, early settlers, moorabbin, bentleigh, cheltenham, salter housewares pty ltd, west bromwich, england, salter george, salter richard, bilston england -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, meat platter 'CETEM WARE', c1930

The Maling Pottery of Newcastle upon Tyne, England, was in production from 1762 to 1963. In its heyday it claimed to be the biggest pottery in the world. The first Maling pottery was established at North Hylton, near Sunderland, in 1762 by William Maling. William’s descendants who moved to the Newcastle area and built a succession of larger works. The last of these – the Ford B pottery – was begun in 1878 and occupied a 14 acre site... Maling’s stock in trade was everyday white ware – marmalade jars for Keillers and Coopers, crockery for railways, shipping lines and hotels, and a huge variety of domestic kitchenware. With a significant export trade in the 1920s they had showrooms in Australia, New Zealand and Denmark. Mary Ford, daughter of an Edinburgh glass manufacturer, married Christopher Maling. Christopher Thompson Maling’s initials form one of the company’s early factory marks – the letters CTM inscribed vertically inside a triangle. The Maling name (which had first appeared with the castle mark in the 1920s) and extended to the trade name “Cetem Ware” when the company adopted its well known trademark of a castle in the early years of this century. The “Cetem” name continued to be used into the 1930s. the Maling name continued to be used as a trademark until the factory finally closed in 1963 The outbreak of World War 11 in 1939 marked the beginning of a long decline. Many of the factory’s workers were called up for military service, and wartime restrictions prevented decorative ware being produced for the home market.A larger oval china platter with blue garland around the rim ‘ CETEM WARE’ EMPIRE c1930 On base ; CETEM WARE / over a Castle / EMPIRE / Rd No 519757 china, pottery, cetem ware, maling pottery co ltd., maling william, maling christopher thompson, ford mary, newcastle upon tyne uk, crockery, north hylton sunderland uk, moorabbin, bentleigh, market gardeners, early settlers, cheltenham, world war 11 1939-45, cooking -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Scales,Spring Balnce Imperial ‘Household’ Salter, 20thC

In the 18th century, spring scales appeared. To produce these scales, a manufacturer would use the resistance of a spring to calculate weights, which could be read automatically on the scale’s face. The ease of use of spring scales over balance scales is what led most post offices to outfit their clerks with spring postal scales. One of the most common types of spring scales was the kitchen scale—also known as a family or dial scale. Designed for horizontal surfaces, these scales used the weight of goods in a pan at the top of the scale to force the spring down. Such scales were common in early-20th-century households and were sold by Sears and Montgomery Ward. Many had flat weighing surfaces but some were topped by shallow pans. Companies such as Salters, Chatillon, and Fairbanks made both. SALTER HOUSEWARES began in the late 1760 in the village of Bilston, England. At this time Richard Salter, a spring maker, began making 'pocket steelyards', a scale similar to the fisherman's scale of today. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. and later established a large, well equipped manufacturing site in the town of West Bromwich. The business thrived throughout the 1900s, and in 1972 the company was purchased by Staveley Industries Plc. In 2002, the management team at Salter Housewares Ltd, backed by Barclays Private Equity, bought the company out from the group, to concentrate on its consumer businesses. In 2004 was sold to the US-based HoMedics company, and in 2006, Salter Housewares USA and Taylor Precision Products Inc (also owned by HoMedics) merged. Salter Brand No. 44 Household Spring Balance Kitchen Scales made of green painted metal with a large clock face dial marked in 1oz graduations and with a shallow metal bowl placed on the flat top connected to the mechanism. An adjustable screw tightened or loosened the spring to bring the pointer to zero, prior to adding the material to be weighed.. A common piece of kitchen equipment as most families used this type of scale when measuring goods for cooking or storing.On Clock face ; NO. 44 / HOUSEHOLD SCALE / TO WEIGH 14LB X 1OZ / Pro. Pat. No. 30819 / 32 / MADE IN ENGLAND / SALTER / S in trademark rope with arrow market gardeners, early settlers, fruit, vegetables, farmers, cooking, recipes, scales, weights, measures, brass, balance beam, moorabbin, cheltenham, bentleigh, kitchen scales, dairy products, cereals, wheat flour, salter housewares pty ltd, west bromwich england -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, meat mincer, c1900

This meat mincer was a common kitchen utensil used by housewives for the preparation of meat when cooking food for their familiesA 'Universal' steel, meat mincer with clamp to attach to table or bench, funnel top, and an adjustable screw - to cut meat - that is operated by a steel crank with a wooden handle.Front ; 2 'Universal' Crank arm : L.F&C. NEW BRITAIN, CONN, USAearly settlers, pioneers, market gardeners, moorabbin, bentleigh, housewives, home cooking, meat preparation, thatcher frank, l f & c pty ltd conneticut, butchers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, 'Vulcan' vitamizer, c1940

A machine fitted with sharp blades, for mashing, crushing or liquefying food ingredients. i.e vitamizing. The jug, made of glass, steel, aluminium or plastic, contains rotor blades that engage with a bit protruding from the base containing an electric motor. When activated by the switch on the base the sharp rotor blades chop, mix , mince, pulverize the ingredients in the jug . The degree of mince depends on the time the motor is running. The jug is easily removed from the base to pour the mixed ingredients where needed and the rotors are safely and easily cleaned by rinsing under water.c1940, an electric, 'Vulcan' Vitamizer, with the original cloth covered flex and bake-lite lever switch at front of the cream bake-lite base . The jug- shaped chrome blender has a red, thick, rubber lid. Front: : Vulcan / LM1 Base ; VULCAN / TYPE LM1 / Patent Pending Design / Volts 220 Amps 8vitamizer, food preparation, cooking, vulcan pty ltd australia, moorabbin, bentleigh, cheltenham, ormond, housekeeping -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomCook Set, LEYSE

Since 1960's, standard issue for vehicle crews of Royal Australian Armoured Corps units for field cooking. Three piece aluminium cook set consisting of two nested cooking pots with top for use as a lid or frying pan. Top fitted with fold out handles Stamped on bottom: " U.S 1962 DSA 4-138 LEYSE" catering, cook set, field equipment -

Flagstaff Hill Maritime Museum and Village

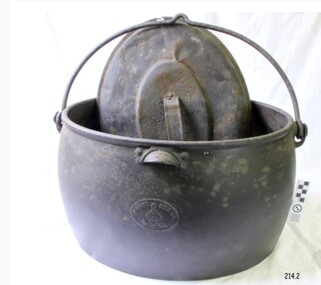

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Firedogs

Firedogs is the common name for andirons and Chenets and have been in use since ancient Greek times. Firedogs are the decorative metal supports or stands that hold logs in a fireplace, allowing air to circulate around the fire to keep it burning, and preventing logs from rolling out of the fireplace. They are usually made of metal, cast iron or steel, but are sometimes ceramic. They have two feet joined across the front and one at the back. Some firedogs, mainly for kitchen use, were plain with forked uprights so that a bar could rest between them on which a cooking pot or a roasting spit could hang. Some firedogs are made in the likeness of animals, shields, crosses, figures and keys. This pair of firedogs are representative of the firedogs that were common to domestic use in previous centuries when home heating and cooking were only possible with open fires. Firedogs or andirons, pair of two decorative cast iron log supports for use in a fireplace hearth. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, fire dogs, firedogs, fire grates, log stands, domestic furniture, open fireplace equipment, andirons, chenets, domestic heating -

Australian Commando Association - Victoria

Australian Commando Association - VictoriaEquipment - Aluminum cooking kit

... . melbourne Equipment Aluminum cooking kit ... -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Dairy Equipment, thermometer, 20thC

Dairy Thermometers are used for testing the temperature of milk while making yogurts and cheese. Early settler families owned a 'House cow' to provide milk ,cream, cheese for their familiesA typical milk thermometer used by early settlers in Moorabbin Shire c1900A graduated Dairy thermometerDAIRY THERMOMETER / MADE IN GERMANY early settlers, market gardeners, dairy farmers, milk products, cheese making, thermometers, cooking utensils, kitchenware, castiron cooking pots, blacksmiths, slow cooking, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Dairy Equipment, doiley, 20thC

Early settler women were skilled craft workers and crocheted doilies and other napery for their household. This Doiley is a cover for a jug or cup, with the glass beads providing the weight to secure it, to protect the contents from flies, insects and dust while on the kitchen table.Early settler women were skilled in dressmaking, crochet, knitting as they made clothes, furnishings, drapery and tableware for their families c1900A cotton, crocheted doily with a teapot pattern and green beads at edges to keep it in place when protecting contents of a jug or cupkitchen equipment, crochetwork, napery, doilies, milk jugs, early settlers, market gardeners, cooking utensils, kitchenware, castiron cooking pots, blacksmiths, slow cooking, moorabbin shire, bentleigh, mckinnon, highett, cheltenham, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, 'Brockoff' SR flour bag

Circa early 1900s. Flour was a staple ingredient of bread, as well as being used for general cooking. This 7lb bag of flour would have been purchased for domestic use by a housewife living in the Moorabbin district. Used bags were often made into shade blinds, underwear, sleepwear, aprons by the industrious early settlers who could not afford to waste any material.This flour bag is typical of the type that would have been found in every housewives' kitchen in the Moorabbin district. It recalls the fact that flour was being made in Melbourne. Unbleached, cotton bag., with faded black lettering. Bag held 7lbs of flour.A.F.BROCKOFFS / 7 LBS / coat of arms – spread eagle with flags - /Trade mark / SELF FLOURS/ RAISING/ FACTORIES / MELBOURNE / SYDNEY AND FREMANTLE flour, cooking, kitchen, moorabbin, housewife, housewives. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Kitchen equipment, fire bellows, c1900

Early settlers had to daily maintain a fire in their kitchen hearth for cooking and heating purposes. Preservation of meat entailed curing by smoking in the kitchen hearth, hence domestic bellows were an important item of kitchen equipment. These domestic fire bellows were used to maintain the fire in the kitchen hearth for cooking,preserving and heating purposes by an early settler family in Moorabbin Shire.A small, domestic, fire bellows for maintaining a fire in the kitchen hearth for cooking and heating. brighton, moorabbin, cooking, pioneers, market gardeners, early settlers, kitchen equipment, bellows, meat, betleigh, fireplaces, farm equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, spirit-fuelled sad iron, c1920

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Late in the 19thC designers experimented with heat retaining fillings for these irons. William Coleman began selling Kerosene lanterns in 1900 in Kingfisher, Oklahoma, USA. He moved to Wichita, Kansas in 1902 and the company became world wide. The company also produced a range of cooking stoves and domestic irons. This spirit- fuelled flat iron was very popular in 1920s - 30s These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin ShireA) spirit- fuelled, sad iron with chrome plated sole c1920, and metal trivet The iron is blue enamel with a white speckled body, with a hemispherical tank for the Coleman 'Lighting Petrol' that provided the heat for smoothing the material B) Coleman Fuel measuring can and funnellMetal Trivet/stand " COLEMAN" ; Petrol can " COLEMAN" / MEASURING CAN / for INSTANT LIGHTING IRON/ with printed instructionssad iron, kitchen equipment, coleman william, kansas, oklahoma, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, petrol fuelled irons, spirit flat irons, coleman lamp stove co. ltd. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, 'the edmay' Pot mender, c1930

Early settlers in Moorabbin Shire used large cast iron pots, pans and kettles, that were suspended over the open fire in the kitchen, for cooking meals. They had to be frugal and self-sufficient and so repaired the equipment to prolong its useful lifetime. Blacksmiths also made and repaired household equipment. James McEwan & Co 1852 - 1993 once dominated the the hardware retailing scene in Victoria. Established in 1852 to service the booming gold rush in Victoria the company went on to become one of the longest established retailers in Australia. Over it’s 140 year history the company went through many booms and busts. The McEwans name finally left the Australian retail scene with little fanfare when the last store was re-badged Bunnings in 1993Early settlers were frugal and self sufficient so they repaired their kitchen equipment when possible . McEwans Pty Ltd. was an established hardware company in Melbourne 1852-1993. Bunnings Pty Ltd is currently a successful hardware retailer for trade and public customers.Two metal discs with screw and nut for mending holes in cast iron pots, pans and kettles c1930 packing strip; THE edmay POTMENDER / Price tag ; McEWANS 77 - 11early settlers, market gardeners, cooking utensils, kitchenware, castiron cooking pots, blacksmiths, slow cooking, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Blacksmith Anvil

This anvil is typical of the type used by Blacksmiths in Moorabbin Shire c1850 - 20thC Blacksmith were needed to make machinery, tools, farm and household equipment, wheels and wagons, horseshoes and saddle irons.This anvil is an example of the type used by blacksmiths in Moorabbin Shire 1840- 20thC as early settlers developed the land. built homes, shops and schoolsSolid steel single horn shaped block used by a Blacksmith to make tools, horseshoes, kitchenware, farm equipment, wagon wheelsmarket gardeners, early settlers, moorabbin shire, dendy special survey 1841, bentleigh, moorabbin, cheltenham, tools, anvils, steel, horses, wagons, washing pots, cooking pots, blacksmiths, county of bourke -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchHexamine Stove

... Belgrave RSL Sub Branch 1 Mast Gully Road Upwey melbourne Cooking ...Cooking rations in field.Hexamine Stoveequipment, vietnam, army -

National Vietnam Veterans Museum (NVVM)

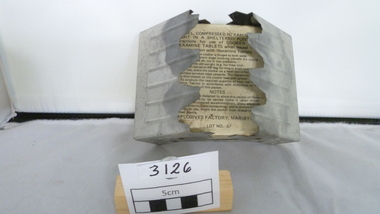

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Stove Hexamine

Small folding hinged metal portable stove with unopened packet of Hexamine tablets inside stove. used by one man for heating food or waterDetailed directions on tablet packagehexamine stove, cooking, sas -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - CAST IRON HANGING GYPSY SKILLET PAN

... DOMESTIC EQUIPMENT Food preparation cooking pot K34 Large cast iron ...Large cast iron hanging Gypsy skillet pan with handle and pouring spout.domestic equipment, food preparation, cooking pot, k34 -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army

Square cooking pot with insert with circular cut outMettersfood container -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, 1967

Steel upright field cooker with curved hinged lid and handles. comprised cabinet, cooking utensils and petrol operated burner. Catering for fifty personnel355051 8. US Armstrong Products Corp 1967field range m59 -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Oven

Steel upright cooker with flat bi-fold hinged lid, handles. Comprising cabinet, cooking utensils (egg slide, ladle, rolling pin), petrol operated burner belowRange 4range cooker, cooker -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Icing set (10 components), Tala icing set, c 1930

... present 1932. Example of 1930's domestic kitchen equipment ...Belonged to Ellen Mary Ryan (Tierney). Wedding present 1932.Example of 1930's domestic kitchen equipment.Boxed metal icing set, container for icing with 8 nozzles. Label on box with Royal icing recipe.:Icing set" on box top lid. Information leaflet including " How to make..."kitchen, cooking, 1930's, domestic skills -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Jelly moulds, Approzimiately 1930's

Donated to Southern Sherbrooke Historical Society by Susan Heywood-Downard. Formed part of kitchen equipment for her mother Elizabeth Cox after marriage in 1937. Was used to encourage daughters to eat gelatine based desserts when they were children.3 individual smaller moulds and one larger star-shaped mould. All made of aluminum. Used to hold jelly-based desserts whilst they set.cooking -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - SMALL COOKING POT

... DOMESTIC EQUIPMENT Food preparation cooking pot Small 1 pint cast ...Small 1 pint cast iron cooking pot with attached tin handle, marked on bottom with a star patent No1 1 pint.domestic equipment, food preparation, cooking pot -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - ENAMELLED SAUCEPAN

... DOMESTIC EQUIPMENT Food preparation cooking pot K25 TS 20 Large ...Large grey speckled enamelled saucepan with handle & holder, no lid.TS 20domestic equipment, food preparation, cooking pot, k25 -

Kew Historical Society Inc

Kew Historical Society IncLeisure object - Toys, Miniature Kitchen Equipment, 1970s

The Kew Historical Society’s collection includes a wide range of leisure objects. Many of the items are European-made, generally of British origin, however there are a number that were made for the Australian market by Australian manufacturers. There were clearly a huge range of toys produced for the Australian and International children’s market in the Nineteenth and Twentieth centuries. The examples of toys in the collection include examples of alphabet toys, arcade toys, baby toys, construction toys, dolls, doll accessories, educational toys, soft toys, tin toys, toy animals, toy blocks, toy machines, toy typewriters, etc. Miniature kitchen stove, cooking utensils and implements. Made of metal and enamel. Orange and black. Eight pieces.miniature toys, toy kitchen equipment, functional toys