Showing 246 items matching "engine parts"

-

Moorabbin Air Museum

Moorabbin Air MuseumManual - CAC Commonwealth Aircraft Corporation, Engine Division Standard Parts Catalogue Pratt & Whitney

... Engine Division Standard Parts Catalogue Pratt & Whitney ... Moorabbin melbourne Engine Division Standard Parts Catalogue Pratt ... -

Moorabbin Air Museum

Moorabbin Air MuseumAdministrative record (Item) - CAC Engine Factory Finished Parts Output Graphs 1941-1943

... CAC Engine Factory Finished Parts Output Graphs 1941-1943...Administrative record CAC Engine Factory Finished Parts ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - RAAF Petrol Engine Villers Mk 15 Manual, Schedule of Spare Parts for Engine Petrol Mk 15 Villers C41AC/8

... Schedule of Spare Parts for Engine Petrol Mk 15 Villers... Schedule of Spare Parts for Engine Petrol Mk 15 Villers C41AC/8 ...Australian Air Publication (AAP) 7760.015-4 -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Aircraft Engine R-1830-92 Parts Catalogue, Parts Catalog for Aircraft Engines Model R-1830-92

... Aircraft Engine R-1830-92 Parts Catalogue... Engine R-1830-92 Parts Catalogue ...Commonwealth Aircraft Corporation Library -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Rolls-Royce Nene Engine Schedule of Spare Parts List of Amendments, Nene - Schedule of Spare Parts

... Rolls-Royce Nene Engine Schedule of Spare Parts List of... Nene - Schedule of Spare Parts Manual Rolls-Royce Nene Engine ...Incomplete document mostly containing lists of amendments to the schedule of spare parts. -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Roylls-Royce Nene Engine Schedule of Spare Parts, Schedule of Spare Parts for Nene II-VH Aust

... Roylls-Royce Nene Engine Schedule of Spare Parts... Nene Engine Schedule of Spare Parts ... -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Roylls Royce Nene Engine Schedule of Spare Parts, Schedule of Spare Parts for Nene II-VH Aust

... Roylls Royce Nene Engine Schedule of Spare Parts... Moorabbin melbourne Clear lever-arch folder Schedule of Spare Parts ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - (SP) AAP 7111.009-4 Viper engine11 Mk22 series spare parts list. Viper engine schedule of spare parts

... parts list. Viper engine schedule of spare parts... spare parts list. Viper engine schedule of spare parts ... -

Moorabbin Air Museum

Moorabbin Air MuseumManual - (SP) AAP RAAF Pub 711:47.20 CAC avon aero engine Mark 1 spare parts vol 3 part 1 schedule catalogue

... (SP) AAP RAAF Pub 711:47.20 CAC avon aero engine Mark 1...Manual (SP) AAP RAAF Pub 711:47.20 CAC avon aero engine ... -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - (SP) AAP 7760.050-4 RAAF Pub 776:27 Schedule of Spare Parts for Engine, Petrol J.A.P Model 55 (C41V/2)

... (SP) AAP 7760.050-4 RAAF Pub 776:27 Schedule of Spare Parts... of Spare Parts for Engine, Petrol J.A.P Model 55 (C41V/2) ... -

Moorabbin Air Museum

Moorabbin Air MuseumManual - (SP) AAP RAAF Pub 711:47-1 CAC avon aero engine Mark 1 spare parts vol 3 part 1 schedule catalogue

... (SP) AAP RAAF Pub 711:47-1 CAC avon aero engine Mark 1...Manual (SP) AAP RAAF Pub 711:47-1 CAC avon aero engine Mark ... -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Lycoming Overhaul Manual Go-435-C2 Engines

... . Published December 1962. Lycoming 0-540 & 10-540 Engines Parts... Lycoming. Published December 1962. Lycoming 0-540 & 10-540 Engines ...Description: 50 pages. Published by Avco Lycoming. Published December 1962. Lycoming 0-540 & 10-540 Engines Parts Catalogue Level of Importance: World. -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - Wright Cyclone Series Gr-1820G-200 Engines

... . Wright Cyclone R-1820 Naval Aircraft Engines Parts Catalogue.... Wright Cyclone R-1820 Naval Aircraft Engines Parts Catalogue ...Description: 99 pages. Published by U.S Bureau of Aeronautics, Navy Department. Published 1/9/1942. NAVAER 02-35GZ-4. Wright Cyclone R-1820 Naval Aircraft Engines Parts Catalogue with Prices Level of Importance: World. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BASIL WATSON COLLECTION: LETTER OF ACKNOWLEDGEMENT FROM THE INDUSTRIAL AND TECHNOLOGICAL MUSEUM (RE B WATSON AIRCRAFT ITEMS), 1919

... aeroplane engine; spare parts, aeroplane propeller 'and other parts' ..... Acknowledges receipt of 50 HP Gnome rotary aeroplane engine; spare ...Letter of acknowledgement from Curator of The Industrial and Technological Museum (re Basil Watson aircraft items), addressed to J. I. Watson, Esq, St Kilda St, Elsternwick, dated 29th October, 1919. Relics of Basil Watson's ill fated bi-plane that crashed into the Bay at Point Cook. Acknowledges receipt of 50 HP Gnome rotary aeroplane engine; spare parts, aeroplane propeller 'and other parts' .person, individual, basil watson -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Victorian Railways Oil Can/Feeder

... various parts of engines of trains as part of the maintenance... various parts of train engines, with a long spout, handle... to oil various parts of train engines, with a long spout, handle ...The Victorian Railways oil can/feeder was used to oil various parts of engines of trains as part of the maintenance of trains. This would have been carried out by employees in the 'Rolling Stock Branch' of Victorian Railways, which included the maintenance and operation of locomotives and rolling stock. It was donated by a resident of Wodonga, and the Wodonga train line and train station opened in November 1873 when the section of the line from Wangaratta to Wodonga was completed. The expansion of Victorian Railways to the northeast of Victoria occurred after the Victorian Government took over the railways in 1867 and the trains serviced large towns such as Seymour, Wangaratta and Wodonga, as well as smaller towns along the way.The oil can/feeder has local significance as it was donated by a resident of Wodonga, as well as state significance as an example of the equipment used by the Victorain Railways.Grey metal Victorian Railways oil can/feeder used to oil various parts of train engines, with a long spout, handle and a chain attached to the lid."V↑R" on the proper left side.oil can, oil feeder, vintage oil cans, vintage oil feeders, victorian -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Report, I. Macmeikan, Melbourne and Metropolitan Tramways Board, "Melbourne Cable Tramways - General Report on their Construction Operation and Maintenance", mid 1950's?

... or winding houses or engine houses, route colours, parts... or winding houses or engine houses, route colours, parts ...Report - 114 pages, photocopied from an original, black comb bound with front clear plastic cover and rear mania cover titled "Melbourne Cable Tramways - General Report on their Construction Operation and Maintenance", prepared by I. Macmeikan - Assistant Superintendent Cable workshops 1920 - 1930 and Manager Preston Workshops 1951 - 1956. Has details of the construction of the system, car depots, car workings and maintenance, power houses or winding houses or engine houses, route colours, parts for the trams, grip mechanisms and its operations including the actual calculations for their operation. Published by the MMTB.trams, tramways, cable trams, mmtb, grip tram, winding houses, operations -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Digital image, 8/03/1955 12:00:00 AM

... died and it may have been sold. They had a V12 petrol engine... died and it may have been sold. They had a V12 petrol engine ...Yields information about the preparations undertaken by the Ballarat Fire Brigade to form a welcoming arch for a visiting Governor General..Digital image from the Wal Jack Ballarat Album of Ballarat No. 20 passing under the two LaFrance fire brigade ladders forming an arch outside the Ballarat City Fire station on 8/3/1955 to greet the Governor General Sir William Slim, Sturt and Raglan Streets. Wal's album notes say "No. 20 passing under 2-100' extension ladders as an arch to welcome Sir William Slim, Governor General. Sturt and Raglan St 8-3-1955." See image i2 for rear of photograph. See image i3 for hi res scan of print. See image i4 for hi res scan of negative\ Neville Britton of the BTM advised 2/5/2020: Seven LaFrance 100' ladders built by the American LaFrance Company, of Elmira, New York arrived in Australia in 1942 as part of the WW2 lend lease program. One each to Perth, Brisbane and Adelaide. Four initially to the MFB but within a short period of time went to the CFA. One each to Geelong City FS, Ballarat City FS and Bendigo FS. The fourth was a stand in and was located at the Ballarat FS when not required. Thus the two ladders in the photo at the Ballarat City FS. I was a volunteer at Ballarat City FB from 1967 and commenced my career employment there in 1970. The two LaFrance ladders were still in Ballarat at that time. In the mid 70's the 'spare' was allocated to the Dandenong FS. They were retired in the 1980's. The four Victorian ladders still survive. Ex Geelong City is at the Fire Services Museum Victoria. They have a second one that was acquired by a private collector. It was neglected and returned to the FSMV in poor condition. Ex Ballarat City was driven to Sydney and remains at the Museum of Fire at Penrith. The fourth one was acquired by a private collector and stored in a shed in North Geelong and never moved. He recently died and it may have been sold. They had a V12 petrol engine with all ignition parts duplicated. So two Distributors, two ignition coils and two spark plugs per cylinder. Splash feed engine lubrication.On rear in ink. Top right hand corner "T175" within the Wal Jack stamp. "SEC Ballarat No. 20 passing under the two LaFrance yank extension ladders ( to greet the Governor General Sir William Slim) Sturt and Raglan Streets. and the date "8 Mar 1955"trams, tramways, sturt st, governors, fire station, ceremonies, tram 20 -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Embraer - EMB 110 Aircraft Bandeirante - Collection of manuals See under "Description" Section

... . Illustrated Parts Breakdown. Engine and related systems. T.O.... Illustrated Parts Breakdown. Landing Gear Components. August, 1988 ... -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ships' Telegraph section, Milne Brothers, Copper and Brass Works, Early-to mid-20th century

This Engine Room section of a ship's telegraph system was part of the equipment of the Ports and Harbour ship the SS Rip. The vessel serviced and maintained the lights and buoys at Port Phillip Bay and Queenscliffe. The SS Rip was possibly the former gunboat "Albert". The ship’s communication system that was used from the late 19th century to early-to-mid-20th-century is called an Engine Order Telegraph (E.O.T.) or ship’s telegraph. The system has two parts, the Bridge Section and the Engine Room Section. The Bridge Section is usually mounted on top of a pedestal, and the Engine Room Section is often attached to a vertical surface. The standard commands printed or stamped onto the dial are the directions of AHEAD and ASTERN, and the speeds of STOP, FULL, EASY, STD. BY. and FIN. ENG. The ship’s pilot on the Bridge of a vessel sends his Orders for speed and direction to the to the Engine Room with the E.O.T. He moves the lever or levers, depending on the number of engines the ship has, to change the indicator on the Bridge Section’s dial to point in the new direction and speed of travel. This change causes the Orders to be duplicated on the Engine Room Section’s dial and a bell to signal the change simultaneously. The engineer then adjusts the ship’s engines and steering equipment to follow the pilot’s Order. The manufacturer, Mulne Bros., was a copper and brass works at 166 Sussex Street Sydney, in December 1892, and previously from 1870 at 128 to 130 Sussex Street. The company made and sold a wide range of equipment including machinery and gauges for the Railways.The Engine Room section is significant for being part of the communications system on the ship SS Rip, owned by Melbourne's Ports & Harbours department and used to service and maintain the navigation signals of Port Phillip Bay and at Queenscliffe in the mid-20th century. The dial is an example of marine equipment made in Australia and used for the safety of Victorian vessels. It is also significant for being made by an early Australian manufacturer, Milne Brothers of Sydney.Engine Room Section of a ship’s telegraph or Engine Order Telegraph (E.O.T.). The round metal dial has inscriptions stamped around the edges. The inscriptions are nautical terms for direction and speed and include the maker’s details. The dial was made by Milne Bros. of Sydney. It was part of the equipment on the "SS Rip" in Victoria.Black paint around dial: "MILNE BROS. / MAKERS / SYDNEY" "FULL EASY STD. BY " "FIN ENG. EASY FULL" ""ASTERN" "STOP" "AHEAD"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, marine technology, marine communications, engine order telegraph, e.o.t., ship’s telegraph, bridge section, engine room section, ship’s engine telegraph section, marine telegraph, milne bros., milne brothers, sydney, copper and brass works, ports & harbours ship, ss rip, gunboat albert, service ship, maintenance ship -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Scale and weights, 1860-1900

The subject item was made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broaden the renown of the Avery brand and transform the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix.An item used by grocers and merchants throughout the then British colonies of England to weigh store-bought goods around the mid to late 19th century. This item gives an insight into the daily lives of early colonial settlers and is a significant part of the era’s social history of the time.Balance scale and weights with removable dish, two round weights glued to tray 4oz and 8oz. Scales 'to weigh up to 28lb. Printed in gold on black labels each side "W & T AVERY LTD", "BIRMINGHAM" warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scale and weights, food preparation equipment, w t avery ltd, balance scale, grocers scales, james ford, william & thomas avery, birmingham uk -

Eltham District Historical Society Inc

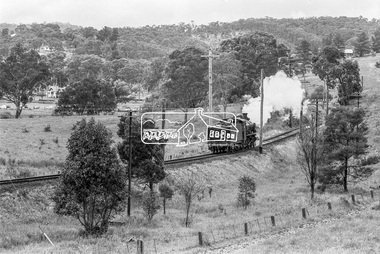

Eltham District Historical Society IncPhotograph, Steam locomotive D-639 Vintage train excursion, Hurstbridge to Eltham, near Wattletree Road, Eltham North, c.1970, 1970

View appears to be from near Coolabah Drive looking northwest across parts of Edendale Farm and to the oval near the present day Adventure Playground and Wattletree Road. Possibly run in conjunction with the Eltham Community Festival or the Hurstbridge Wattle Festival; the steam train would conduct trips between Eltham and Hurstbridge Railway stations. As there is no turning table at Hurstbridge, the locomotive would simply shunt from one end of the carriages to the other to reverse direction, hence the locomotive is running in reverse as it approaches Eltham Station.Digital TIFF file Scan of 35mm Ilford HP4 black and white transparencyd-639, edendale farm, eltham festival, eltham north, eltham north adventure playground, george coop collection, hurstbridge wattle festival, steam engine, vintage train excursion, wattletree road -

Nhill Aviation Heritage Centre

Nhill Aviation Heritage CentreMemorabilia - Ignition coil / shower of sparks, 26/2/45

commonly known as 'shower of sparks' this buzzer type ignition coil is connected via the distributor and spark plug leads to generate a continuous spark while crank starting the Cheetah aero engine. The type of ignition coil fitted to the Cheetah engine fitted to an Avro Anson, Parts stock unused.electronic ignition coil with high tension outlet and set of adjustable breaker points and connectors. New in original box.D-5271BA Adjust to 2.5 volts with standard secondary load for use on 12 volt system. On Box 'Booster Coil Type 512 Model 1 Style E' serial number 1552 ignition coil, shower of sparks, ignition, garth rohdes -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 30, February 1987 to June 1987

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 18 February 1987 to 6 May 1987.Book with Blue cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, smb dressmaking student's banner, val d'angri teacher, lisay pither, melinda wyres, andrea vendy, jodie fletcher, begonia festival, trevor williams motor mechanic apprentice, top student, kerrie cross smb vice-president of council, tafe women's policy launch at smb, institute of professional secretaries branch, wendy ivanusec, allison lanigan, mollie peel, minister launches tafe women's policy at smb, indonesian educators visit smb, newsletter "network" launched by joan kirner and caroline hogg, liz gurrie a woman of many parts, women in early ballarat, alice cornwell alias princess midas, women's trade and technical program, margaret o'mara, tracey coleman, smb collection leads nation, aboriginal programs in equal opportunity, co-ordinator lily saylor, adult horticulture course, christine uptown, intriguing stories ballarat old cemetery, australian wheat board gives smb tractor, dr john sharphan next bcae head, smb helps small business, engines for training apprentices, the age of uncertainty, smb reopens its museum, lily saylor helps her people learn, smb plans to help its disabled students -

Frankston RSL Sub Branch

Frankston RSL Sub BranchTrench Art

Made by Cpl. Charlie Dawes 116777 R.A.A.F from parts got while serving at Goodenough and Thursday Isalnds WW2Miniature model of a WW2 era Lockheed P-38 Lightning twin engine aircraft mounted on a trench art ashtray made from various used munitions. This model was made during WW2 by Corporal Cyril 'Charlie' Dawes, RAAF service number 116777, from parts found whilst serving at Goodenough and Thursday Islands in the Torres Strait. The aircraft is supported by a 0.50 inch calibre bullet fixed to the inside of a section of an artillery case which forms the base. The base has three 0.303 inch calibre bullets attached vertically around the circumference and a metal matchbox holder with a RAAF hat badge insignia attached to the front. The items have been made from chromed metal materials. The RAAF was equipped with a small number of these aircraft, commencing in 1942, which were used for front line photographic reconnaissance duty. The first version of the Lockheed P-38 was introduced in 1941 by the USA Lockheed aircraft company as a heavy fighter.RAAF chrome cap badge (WW2 era with the kings crown)plane, trench art, ashtray -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878

Cyrus Chambers was a self-described mechanic who started out winding bobbins in his father's woollen mill and went on to invent machines that changed their industries. Cyrus Chambers came from Quaker parents the ninth of thirteen siblings, he once said a year before his death. “I believe I have succeeded because, first, I was industrious; second, because I made a study of the subject that was before me.” At age 7, Chambers went to work in his father’s mill. His job was to monitor bobbins—wooden spindles around which thread was wound and to remove and replace them as they became full. "There was no child labour law at that time," he later recalled. Chambers loved machinery and always regarded himself as a mechanic rather than an inventor. At age 16, Chambers was sent to learn dentistry with an older brother, (Edwin) who was already in the field and willing to take him on as an apprentice. Chambers was talented at working with small parts. He used his brother's dental instruments to build a miniature high-pressure steam engine of silver. It ran at 3,000 revolutions per minute and weighed less than a half-ounce. At that time it was the smallest engine that had ever been constructed. The engine was displayed at the 1876 Centennial and is now in a permanent collection at the Franklin Institute USA. Chambers major invention was the paper folding machine and came from reading that school teachers made less than the young girls who were employed to fold book pages as they came off the press. He told friends that his first efforts were to make the machine that would fold newspapers after demonstrating his device he met with Horace Greeley of the New York Tribune who advised Chambers would never invent the machine that would be able to fold his newspaper or books. In less than a year Chambers had built a full-size machine capable of folding large newspapers and books and was installed at J B Lippincott & Co folding pages for the "Comly Speller" this machine ran successfully for twenty-five years until the printing works burnt down. Chambers then went into partnership with a brother and they established the firm "Chambers, Brother & Co" at a plant in Philadelphia. It was also observed in 1910 and a fact that there was not a periodical or newspaper printed or recently published book that had not gone through one of Chambers inventions. Chambers went on to produce many mechanical inventions and improvements to existing tools and machinery most notable was his invention for the machine that would make clay bricks. This machine made forty bricks per hour and by the end of Chambers life after many improvements, it could make more than four hundred. Although there were a large number of bold cutters made of this patent at Cyrus Chamber’s foundry in Philadelphia, the item is associated with a notable American inventor of the nineteenth century. This particular patent for a bolt and rivet cutter won Chambers the prestigious Elliott Cresson Medal. This cutter is just one of the many inventions and mechanical improvements that Cyrus Chambers made during his lifetime, contributing to the ongoing development of mechanical improvements that were occurring in American industry of the time and therefore a notable addition to the Flagstaff collection.Cast iron bolt cutter with removable tempered steel cutter. Chambers New No. 2.Raised embossed lettering on cast body of cutter "New No 2" on one side, "Chambers Bros & Co" on the other sideflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cyrus chambers, bolt cutter, paper folding machine, brick making machine, elliot cresson, elliot cresson medal, franklin institute, gold medal, rivet cutter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Balance Scale, 1850s

A Large Rare mid 19th Century Balance Scale (also called a Beam Scale) Made in England by W&T Avery a British manufacturer of weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into a specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs.Then from 1931 to 1973 the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail scales and industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. Item made and used possibly around the 1850s by Victorian colonial government to check weights of goods being sold by early shop keepers on the gold fields item is very rare.James McEwan & Co were the retailers of W & T Avery scales in Victoria from 1852. A very rare item used probably to check weights used by merchants during colonial times by government inspectors in Victoria. A similar example exist in a NSW museum, the item is believed to have been made before W & T Avery expansion to the Soho foundry in Birmingham in 1885 and after 1818.Beam balance scale suspended from a wooden tripod, with metal trays suspended by three chain lengths. embossed on the balance beam W T Avery, Birmingham,flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, scale, avery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Standard avoirdupois weights, Avery Ltd, 1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weights, metal, silver electroplated, 1 x 2lb, 2 x 4lb, 1 x 7lb. (4) all government stamped, made by Avery Ltd.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, imperial weight, imperial standard weights and measures, imperial standard weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Weight Avoirdupois, Avery Ltd, 1940-1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weight, brass, Stamped F27, 2lb.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, brass weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill