Showing 110 items

matching food processor

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGlue Pot, T & C Clark, Late 19th Century

T. & C. Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enameled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councillor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enameled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enameled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enameled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.An item that was made by a British foundry that was a pioneer and innervated many new processes in the manufacture of enamel ware, producing many items for every day use.Glue pot with inner pot, metal, corroded, both pots have handles."T & C CLARK & Co Ltd, ENGLAND, 55279 RD" and "FIRST QUALITY No. 4/0"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t& c clarke, cast iron, foundry, sanitary ware, ironware -

Flagstaff Hill Maritime Museum and Village

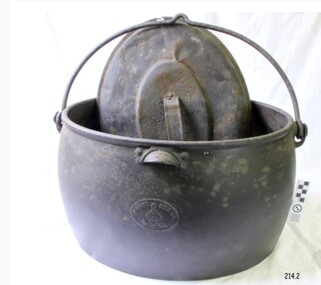

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clark, 1880-1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Oval cast iron boiler or cooking pot, with lid, pot is oval shaped lid is dented and handle buckled.Inscription on base "Clark & Co Patent", "Best Quality", "9 Gallons" and a Trade Mark of a "C" inside two triangles to side of potflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooking pot, stew pot, food, kitchen utensil, shakespeare foundry, tc clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Fred Walker Cresco Foods, 1910

Fred Walker 1884 – 1935 was an Australian businessman and founder of Fred Walker & Co. first in Hong Kong, then in Melbourne as the Fred Walker Company. He also set up Kraft Walker Cheese Co. in partnership with American businessman James L. Kraft in 1926, to market Kraft's patented method of processing cheese in Australia. Fred Walker & Co. is best known for creating Vegemite, a yeast extract-based food spread and Australian cultural icon. Kraft Walker Cheese Co. Is best known for manufacturing a cheese known as Red Coon around 1931, which later became known as Coon cheese. He founded the Fred Walker Company at 54 William Street and later moving to Flinders Street in 1911. This company specialised in canned foods, especially dairy products, exporting them to Asia. It manufactured Red Feather canned foods including butter and cheese from around 1910. He also went on to created Cresco Food Co. for his younger brother, which was the first factory to manufacture "flaked food" or dehydrated food products in Australia.A significant item that catalogues the start of dehydrated food production and sale in Australia was initiated by an Australian businessman and well-known entrepreneur. The history of Fred Walker gives insight into how many food brands in Australia now that we take for granted had his involvement in their early beginnings. Large cylindrical tin with push on lid, painted label on the sides in maroon, black gold and dark fawn colours with text.Palm Flaked Rice manufactured by the Cresco Co. Limited Melbourne Australiaflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, container, food container, kitchen ware, flaked rice, cresco, palm flaked rice, tin, fred walker, dehydrated food -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Storage Tin, Late 19th or early 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Container metal cylindrical plain tin with separate lid. Join line on side of cylinder. Very rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jug, Late 19th or early 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Rusty tin jug with small pouring lip and handle. Very plain and possibly made from a jam tin and handle soldered on side.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Storage Tin, Late 19th or early 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Container metal cylindrical plain tin with separate lid. Join line on side of cylinder. Very rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

Bunjil Park Aboriginal Education & Cultural Centre

Bunjil Park Aboriginal Education & Cultural Centregrinding stone, Double sided grinding stone with multiple hollows

Grindstones like this were not carried but hidden in special places with subtle indicators known only to the same tribe or nation. The small and deep nature of the pits suggests this rock may have been used for ochre with the smaller pits being used for water or fat to mix with the pigments. The very hard and dense nature of the rock means materials would not be contaminated during the grinding process.This rock is likely to be very old and is potentially significant from ceremonial perspective. Stones like this have been known to be passed on through multiple generations and been in use for hundreds and possibly thousands of years.This grindstone has hollows on both sides. One large hollow on one side measures approximately 7 cm across and 2 cm deep. The opposite side is distinguished by 3 pits, one large (5 cm wide by 3 cm deep) and two small indentations 2cm by 1cm. The hollows have been chipped and smoothed. The base rock is in the shape of a flattened and slightly elongated sphere, it appears to have been water worn.The side with three pits also bears recent scratches believed to be cut by a disk plough. It also appears to have a capital "W" inscribed in the largest pit.jaara, hidden, grindstone, ochre, quartzite, multiple hollows, pits, aboriginal food and art -

Glen Eira Historical Society

Glen Eira Historical SocietyLetter - Rosstown Railway

This file contains four items: 1/A black and white photocopy of a letter dated either 07/08/1889 or 09/08/1889, from Robert Lundon to an unidentified recipient discussing an agreement reached between the author – on behalf of the recipient – and Soon Hang Hi in regard, in regards to the allotment known as Webber’s. The agreement is outlined in the letter in what appears to be Chinese characters, and includes the marks of Robert Lundon and Soon Hang Hi. File note from Joy Wu states that the calligraphy is not Mandarin or traditional Chinese. 2/Three sheets of hand-written working notes with information taken from the Victorian Government Gazette on THE ROSSTOWN AND MURRUMBEENA LAND COMPANY LIMITED, THE ROSSTOWN JUNCTION RAILWAY AND PROSPERITY COMPANY LIOMITED, and THE ROSSTOWN JUNCTION, ELSTERNWICK, AND OAKLEIGH RAILWAY COMPANY LIMITED, covering dates between 1887 and 1894. The notes concern meetings and creditors claims relevant to the companies, with reference numbers for the information source. Date and author of the notes are not recorded. 3/A black and white photocopy of the a partial map of the Rosstown Railway and surrounding area, undated. The map includes the names of landholders in the areas of Brighton, Garden Vale and Elsternwick, as well as other railway lines present in the region. 4/A fold-out map and guide of the Rosstown Rail Trail, including a brief general history of Caulfield as well as a more extensive biography of William Murray Ross and the Rosstown Railway. The map marks and describes significant sites along the trail, including photographs of some of these sites, provided by DF Jowett.documents, correspondence, webber’s, lundon robert, chinese characters, ethnic communities, signatures, text, settlements, taxes, fraser john grieves, lovell r.h., price davies, meetings, communication activities, soon hang hi, commercial events and activities, the rosstown and murrumbeena land company limited, victorian government gazette, bulmer richard, parry john, osment henry, shareholders, creditors claims, the rosstown junction railway and property company limited, finch and best, lawyers, the rosstown junction elsternwick and oakleigh railway company limited, cameron w.c., phillips p.d., garden vale, elsternwick, elsternwick railway station, rosstown, rosstown railway, thomas street, bay street, kooyong road, melbourne and brighton railway, hawthorn road, bambra road, caulfield and frankston railway, booran road, grange road, koornang road, murrumbeena road, north road, north road railway station, east brighton railway station, south road, railway routes, railway lines, railways, land transport, murphy j., caulfield, hamilton t.f., dane p., holloway, webb, ailee john, payne t.b., brodie chas, dane john, o’neil h., mccombie john, mcmillane a., smyth c.d., cooper, ebden, landholders, jeffrey j.d., gill j., balcombe a.e., cooper h., mcnab j., white j., sutherland j., greeves a.f.a., newton m.c., chamley f.b., fowler j., inglis p., grant t., stooke j., swanson g., cochrane c., adams e.b., mccombie thas, keyes robert, brighton cemetery, burials grounds and graveyards, war-ein road, were j.b., holland j., mcmahon c., winter t.l.m., dendy henry, mitchell w., jackson s., were j.e., wickham francis dawe, bryant jane, east brighton railway station, railway stations, maps, allotments, land titles, roads and streets, rosstown rail trail, city of glen eira, tourism, trains, tourism information bureaus, tours, pamphlets, elsternwick railway park, oakleigh junction, princes park, ee gunn reserve, packer park, sites, jowett d.f., weickhardt i.g., return to rosstown: railways land sales and sugar beet ventures in caulfield, land sales, walking trails, ross william murray, transport objects, locomotion, walking, cycling, driving, sports, country mansions, people, caulfield john, builders, construction and demolition workers, occupations, careers, professionals, topography, geology, landforms, horticulture, market gardens, primary industry workers, city of caulfield, mood kee, pennington harold, annual general meetings, caulfield town hall, glen eira city council, carnegie, carnegie station, rosstown station, people by circumstance, migrants, sugar beet, sugar beet mill, sugar beet industry, mills, factories, sea beach lines, bent thomas, parliamentary representatives, neville street, miller street, lemann’s swamp reserve, koornang park, cane sugar industry, breweries, rabbit processing plants, health establishments, hospitals, food production establishments, abattoirs, thieves, social problems, vagrants, theft, squatting, financial economics, debt, finance industry, insurance companies, company managers, bentleigh, ross leila, the grange, leila road, wild cherry road, financial trouble, mortgages, gisborne street, archibald street, riddell parade, victoria railways, glen huntly road, clarence street, college street, gladstone parade, parrell street, aileen avenue, seaview street, drion estate, land subdivisions, dover street, sussex street, landfill, marara road, booran road, woodville avenue, dorothy avenue, ormond park, royal avenue, ormond railway station, oakleigh road, melten avenue, miller street, munro avenue, lord reserve, neerim road, toolambool road, the rosstown hotel, rosanna street, murrumbeena crescent, commercial establishments, the national bank, rosstown road, kangaroo road, poath road, freda street, hughesdale kindergarten, oakleigh council, hughesdale community centre, civic establishments, galbally reserve, plaques, warrigal road, out and about brochures -

Glen Eira Historical Society

Glen Eira Historical SocietyBook - GLEN EIRA GUIDE

This file contains one item: 1/A copy of the 1999 edition of the Glen Eira guide. This magazine aims to provide readers with useful information for living and working within the City of Glen Eira. It is divided into five principal sections. The first section, titled Glen Eira City Council Information, provides information pertaining to the local government. It includes information about Council meetings, the names and contact details of the six members of the Council, information about services offered by the Glen Eira Service Centre, the contact details for particular services offered by the Glen Eira City Council, information about rates and valuations, information about the building permit application process, information about waste management, and federal and state electoral maps. The second section, titled Council and Community Resource Guide, consists of a list of the various local community facilities and organizations. The third section, titled City of Glen Eira Safe Food Guide, consists of a list of food venues nominated by the Glen Eira City Council Environmental Health Services Department for their commendable level of hygiene. The fourth section, titled City of Glen Eira Business Development Unit, provides information about the eponymous local government department, which is aimed at providing aid to local businesses. The fifth and final section, titled ‘Think Local, BUY LOCAL’ Guide, consists of a list of local businesses, grouped according to industry, to try and encourage the support thereof.glen eira, city of glen eira, glen eira city council, local government, local officials and employees, kennedy norman cr, mayors, public utilities, community services, local government departments, rates, local government, building permits, waste disposal, community groups, cultural structures and establishments, law and order, libraries, education, educational and research establishments, religious groups, clubs and associations, community centres, food, restaurants, businesses -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tea Tin, First half of 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin. https://www.shilohplastics.com.au/history-of-metal-packaging/The use of tin to protect and store food and other items, revolutionised the world.Tin container painted yellow with printed crosses and circles,. The lid is labelled "Robur Cross Stitch Company" and "R" imprinted in the centre although the lid is badly corroded. ‘Cross – Stitch’ (printed green in small crosses and circles) followed by ‘Nett Weight ¾ lb. (printed beige in crosses and circles). Pure Blended Tea. Robur Tea Co Ltd’ flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, robur tea co ltd, tea, tea caddy, tin, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Hydrometer, 1878 to 1930s

This Sikes brass hydrometer was manufactured by the optical and scientific instrument makers Kasner & Moss of 17 Collins Street West, Melbourne, in the latter part of the nineteenth century. The firm adverted hydrometers, as well as optical instruments, as early as August 13th, 1864, in The Age, Melbourne. This hydrometer set was donated to Flagstaff Hill in 1979 by local wine and spirits merchants Lynch Bros of Fairy Street, Warrnambool. Giffen Russell had established the business in 1878, and Harry Lynch took it over in the 1930s, and after he passed away in 1953 Kevin Matthew Lynch became proprietor of K M Lynch Food and Liquor. The business closed in the 2010s. The hydrometer may date back to the establishment of the business in 1878, as Kasner & Moss were selling hydrometers in Melbourne from 1864. Hydrometers were used to measure the density, or relative density, of liquids from the late 1600s. In 1816 Bartholomew Sikes won the competition for the most useful accurate hydrometer. Hydrometers were commonly used by distillers, vintners, and brewers to establish accurate measures of alcohol concentration in their beverages. Following this manufacturing process, government inspectors and excise officers used them to check that the labelled indications of alcohol-proof were correct and that the right amounts of duty were being paid. This hydrometer and its fitted and hinged wooden container show signs of heavy and protracted use in a working environment. Although the instrument has some parts missing and has been recently repaired, the original quality of the inlaid box and the fine engraving on the instrument and the attachable weights, are indications of the hydrometer’s very real value when new. This Sikes hydrometer, bearing the maker's mark of “Kasner & Moss Melbourne” and the registered number “20373”, was presented to the purchasing public as a precision-made instrument designed for professional use. The Sikes hydrometer is of local significance because of its implied association with the alcohol trade in the southwest region of Victoria. It was donated by a family member of Lynch Bros, a local licensed outlet for wines and spirits in the period before the general relaxation of liquor licensing laws in the State of Victoria. It may have belonged to Griffin Russell who established the liquor store in 1878.Hydrometer; original Sikes brass hydrometer in a polished wooden case with an inlaid plaque on the lid. The brass float is a sphere with a thin flat upper stem and a short, lower stem with a bulb-shaped end. The upper stem is engraved scale on both sides with the numbers 1 to 10, and five divisions between each number. There are ten fixed pegs in the base to secure the thick brass horseshoe-shaped, numbered, various-sized weights (20, 30, 40, 80, 90); the free pegs would have originally stored another five weights (10, 50, 60, 70, and 100). The empty compartment in the box suggests another part in the initial set, probably a thermometer. The fitted, fabric-lined box has two brass closures and two brass hinges. The scientific instrument shows signs of heavy use and repairs. The Serial Number on the float matches the Serial Numbers on the weights. The plaque on the lid, the float and the weights have inscriptions. Made by Kasner & Moss, Melbourne. Plaque: “SIKES HYDROMETER / KASNER & MOSS / MELBOURNE” On float's lower stem: “SIKES 20373” On one thin edge of the float's scale, engraved in script “Kasner & Moss” and stamped “MELBOURNE”, and symbol“P” rotated 90 degrees. On the opposite thin edge of the float: “N20.373”, “SIKES”, “I P % II O” (in ornate capitals). Each weight has s unique number, and the same serial number “20373”.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, sikes hydrometer, scientific instrument, pressure measurement, measuring instrument, ullage tool, customs, excise duty, tax, alcohol content, proof, calibrate, standard weights and measures, tariff, kasner & moss, scientific instrument makers, specific gravity, liquid density, alcohol testing, technology, alcohol measurement, proof spirit, wine and spirits merchants, local business, brass measuring instrument, k m lynch, giffen russell, harry lynch -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clarke and Co Ltd, 1880-1900

T. & C. Clark & Company Limited was based at Shakespeare Foundry in Wolverhampton England and was founded in 1795 by Thomas and Charles Clark. The company grew to be one of the largest iron foundries in Wolverhampton and were pioneering in the manufacture of enamelled cast iron cookware and sanitary wares. The company's product range included thousands of items, both domestic and industrial. T. & C. Clark were pioneers in the use of enamelled cast ironware, after taking out a patent in 1839 guaranteeing their products to be free of lead or arsenic. The company became the largest employer in Wolverhampton employing between 600 to 700 people.The item is significant as it was used as a domestic kitchen or camp fire item used to cook food safely without the concern that the metal may contain lead or arsenic as earlier cooking utensils had. T C Clark innervates the first manufacturing process of cast iron cook ware to have enamel lining in his products to alleviate the possibility of lead or arsenic contamination of food.Cooking pot cast iron with lid and handle and lid pressed sheet steel oval shaped."T & C Clark and Co Ltd" (Star of David) "ENGLAND", "RD 455279" "3 GALLS" "FIRST QUALITY" Lid marked "CLARK" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, kettle, cooking pot, cook ware, kitchen ware, cast iron kettle, t c clark ltd, shakespeare foundry -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBag - Calico

... tatura ww2 food technology processing containers commercial ...Used by internees at Camp 3Calico bag "Gold Crest", Snowwhite". RM Gow Co. Pty. Ltd., Brisbane imprinted on bagbag, calico, camp 3, tatura, ww2, food, technology, processing, containers, commercial -

Victorian Aboriginal Corporation for Languages

Victorian Aboriginal Corporation for LanguagesBook, Pun?u : Yankunytjatjara plant use : traditional methods of preparing foods, medicines, utensils and weapons from native plants, 1988

Encyclopedia style entries for 27 plants with standard scientific description plus description, science and stories in Yankunytjatjara with translations. Includes general and linguistic introduction, and extensive glossaries of botanical names, plant parts, processes etc, all Yankunytjatjara and English (and Latin as appropriate)B&w illustrations, colour illustrations, word listsclimate, landforms, vegetation, vegetable food (mai), fruits, seeds, roots, greens, galls, fungi, nectars, sweet secretions, gums, medicinal plants (punu ngangkari), language, stories, plant use, trees, shrubs, subshrubs, grasses, vines, succulents, mistletoes, plant parts, habitat, plant processing, yankunytjatjara, central australia -

Friends of Westgarthtown

Friends of WestgarthtownChurn, butter

... technology food processing butter milk churn kitchen processing ...Many butter churns were brought to Australia when people immigrated. German butter churns usually have the hand hold and the large gear in the same place, and are usually embossed on the base with the litre size. They usually came with a paper label and did not have embossing on the sides of the jar.large glass jar with lid-mounted geared churning mechanism with rotating paddle and wooden handle.Germany' pressed into lid, 'W 3' cast into inside of turning handle, '2 L.' embossed into bottom of glass containerfood technology, food processing, butter, milk, churn, kitchen, processing, germany, glass -

Friends of Westgarthtown

Friends of WestgarthtownHanging bars

... melbourne food technology food processing smokehouse curing fire ...A single iron bar set into the fireplace near the top. At the centre of the circular bar is an attachment with a hook. From this attachment hangs a ring, through which two shaped bars overlap to forma cross. Each of these smaller, curved bars has an attachment at the end (two with flat, round rings, one with a V-shaped piece with upturned ends) for securing smoking items,No visible markingsfood technology, food processing, smokehouse, curing, fire, meat, hanging, iron -

Friends of Westgarthtown

Friends of WestgarthtownResting bars, parallel

... melbourne food technology food processing smokehouse curing fire ...A pair of iron resting bars built into the smokehouse fireplace. Each bar is cylindrical, and they are placed one behind the other near the base of the fireplace. They both have a large iron bolt which passes through the centre of the rod. The front bar is bent in the middle.No visible markingsfood technology, food processing, smokehouse, curing, fire, meat, iron -

Beechworth Honey Archive

Beechworth Honey ArchivePublication, Food processing industry strategy group: final report of the non-governmental members. (Australia. Department of Industry, Innovation, Science, Research and Tertiary Education. Food Processing Industry Strategy Group). Canberra, 2012, 2012

... -country 188 pages, illustrated. Food processing industry strategy ...188 pages, illustrated. -

Beechworth Honey Archive

Beechworth Honey ArchivePublication, Food processing industry strategy group: final report of the non-governmental members. (Australia. Department of Industry, Innivation, Science, Research and Tertiary Education. Food Processing Industry Strategy Group). Canberra, 2012, 2012

... -country 188 pages, illustrated. Food processing industry strategy ...188 pages, illustrated. -

National Wool Museum

National Wool MuseumMap - World Wool Map, Rabobank International, c.2002

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.Folded world map showing statistics, images and graphics relating to wool in the 1990's.front: World Wool Map / Rabobank / International / Rabobank International / Food & Agricultural Research / Croeselaan 18 / 3521 CB Utrecht / The Netherlands / Telephone +31 (0) 30 2161178 / Fax +31 (0) 30 2161920 / E-mail: [email protected] / Web-site:www.rabobank.com/far / Map produced by G-O graphics / Wijk bij Duurstede, The Netherlands / www.g-o-graphics.nlstuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, training, technical advice, mills, map -

Mont De Lancey

Mont De Lanceysausage maker, Burgess & Key, C1875

... -and-dandenong-ranges Food processing equipment Burgess and key. London S ...Cast iron sausage maker with turned wooden handle mounted with screws on a wooden base. C1875Burgess and key. London S & E Ranssome Sole Wholesale Agents (on a brass plate)food processing equipment -

Mont De Lancey

Mont De LanceyRaisin Seeder, Circa 1880

... are removed by forcing through stretched wires. Food processing ...Raisins are first dampened before the seeds are removed by forcing through stretched wires.Hand-cranked raisin seeder, on a wooden base."Pat June 9, 1881 Wet Your Raisins"food processing equipment -

Mont De Lancey

Mont De LanceyRaisin Seeder, Circa 1895-1910

... -and-dandenong-ranges Raisins are first dampened. Food processing ...Raisins are first dampened.'Boss' raisin seeder, hand-cranked with a wooden know on the handle."Mf'rd by A.C. Williams Ravenna O." "The Boss Raisin Seeder Pat. Pdg."food processing equipment -

Mont De Lancey

Mont De LanceyPeach Stoner, Circa 1895

... -and-dandenong-ranges Food processing equipment "Rollman Mfg. Co. Pat ...Hand operated peach stoner, with a screw hand-plunger mechanism."Rollman Mfg. Co. Pat. Pend. Mount Joy. PA. USA" "Rollman Peach Stoner"food processing equipment -

Mont De Lancey

Mont De LanceyDomestic object - Cherry Stoner, Circa 1890

... -and-dandenong-ranges Food processing equipment Cherry stoners Cherry ...Cherry stoner with screw hand plunger into a porcelain receptacle, on a wooden base."Foreign"food processing equipment, cherry stoners, cherry pitter