Showing 267 items

matching hands up for hands on

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph Topping Tobacco, Tobacco being topped (removal of flower), Circa mid to late 1900's

This promotional photograph by the Tobacco Growers Association was in response to a 1935 meeting of tobacco growers from Victoria, South Australia and Queensland which produced four major resolutions for the industry covering the remainder of the 1900s. These four resolutions were: (1) Adequate tariff protection (2) Control of pests and diseases (3) Orderly marketing (4) The formation of an advisory council of growers. History has produced the following results. (1) adequate tariff protection was never achieved,(2) control of disease through benzol vapour (CSIRO) breakthrough, was later identified as carcinogenic, (3) orderly marketing was achieved through (4) the establishment of the Tobacco Growers Association(1984). In October 2006, by way of Government buy back of tobacco leases from growers, resulted in the end of Tobacco farming in Australia (after 136 years of planting the first crop). It was also significant that the major tobacco companies such as Philip Morris and The British American Tobacco Australasia advised the industry that it would source its tobacco requirements overseas by 2009.The remnants of the Tobacco Industry can still be viewed throughout the Kiewa Valley and adjacent regions on the former tobacco farms which still have the tobacco drying sheds and now converted into hay sheds. The problems from the large quantities of carcinogenic infused soil of farmlands in the region, still remains a problem now and for future generations. This particular photograph shows the lack of understanding by farmers and the contracted labour, at that time, and is demonstrated by the lack of protection of hands when handling seedlings and attached soil. Hand and foot protection was rarely used, even when later warnings were issued of the carcinogenic toxicity of the soil. The majority of farm owners, up until Health authorities stepped in the latter stages of 1900s, were skeptical of city scientists' "carcinogenic" health warnings and it was only after the younger generation of farmers, who had graduated from Agricultural colleges, encompassed the scientific approach to farm management. The "she'll be right mate" attitude of the farming/rural community has since the 1970s been slowly dissipating. Stricter controls of herbicides and pesticides used in agriculture are now in force. The death of the tobacco industry(2006) resulted in the expansion of the dairy , sheep, beef cattle, venison and lama wool producers in the Kiewa Valley and surrounding regions.Coloured photograph pasted onto a thick wood chip backing. Two galvanised eyelets at the top of the frame, 50mm from each end, with a twine cord stretch from each, for hanging purposes. See also KVHS 0054A ,KVHS 0054B and KVHC 0054D to KVHS 0054F A sign, which has been removed from the picture at some previous point in time is "The Tobacco crop being topped (flower removed)". tobacco, farming, rural industry, licences, ollie mould, blue mould, benzol vapour -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph Tobacco plants, Tobacco fully grown prior to start picking, Circa mid to late 1900's

This promotional photograph by the Tobacco Growers Association was in response to a 1935 meeting of tobacco growers from Victoria, South Australia and Queensland which produced four major resolutions for the industry covering the remainder of the 1900s. These four resolutions were: (1) Adequate tariff protection (2) Control of pests and diseases (3) Orderly marketing (4) The formation of an advisory council of growers. History has produced the following results. (1) adequate tariff protection was never achieved,(2) control of disease through benzol vapour (CSIRO) breakthrough, was later identified as carcinogenic, (3) orderly marketing was achieved through (4) the establishment of the Tobacco Growers Association(1984). In October 2006, by way of Government buy back of tobacco leases from growers, resulted in the end of Tobacco farming in Australia (after 136 years of planting the first crop). It was also significant that the major tobacco companies such as Philip Morris and The British American Tobacco Australasia advised the industry that it would source its tobacco requirements overseas by 2009.The remnants of the Tobacco Industry can still be viewed throughout the Kiewa Valley and adjacent regions on the former tobacco farms which still have the tobacco drying sheds and now converted into hay sheds. The problems from the large quantities of carcinogenic infused soil of farmlands in the region, still remains a problem now and for future generations. This particular photograph shows the lack of understanding by farmers, at that time, and is demonstrated by the lack of protection of hands and no masks over their noses, when handling plants. Hand, nose and foot protection was rarely used, even when later warnings were issued of the carcinogenic toxicity of the soil. The majority of farm owners, up until Health authorities stepped in the latter stages of 1900s, were skeptical of city scientists' "carcinogenic" health warnings and it was only after the younger generation of farmers, who had graduated from Agricultural colleges, encompassed the scientific approach to farm management. The "she'll be right mate" attitude of the farming/rural community has since the 1970s been slowly dissipating. Stricter controls of herbicides and pesticides used in agriculture are now in force. The death of the tobacco industry(2006) resulted in the expansion of the dairy , sheep, beef cattle, venison and lama wool producers in the Kiewa Valley and surrounding regions.Coloured photograph pasted onto a thick wood chip backing. Two galvanised eyelets at the top of the frame, 50mm from each end, with a twine cord stretch from each, for hanging purposes. See also KVHS 0054A to KVHS 0054C and 0054E to KVHS 0054FA sign, which has been removed from the picture at some previous point in time is "The Tobacco fully grown prior to start picking"tobacco, farming, rural industry, licences, ollie mould, blue mould, benzol vapour -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph Tobacco drying leaves, Inspecting Drying tobacco leaves, 1950's to 1999

This promotional photograph by the Tobacco Growers Association was in response to a 1935 meeting of tobacco growers from Victoria, South Australia and Queensland which produced four major resolutions for the industry covering the remainder of the 1900s. These four resolutions were: (1) Adequate tariff protection (2) Control of pests and diseases (3) Orderly marketing (4) The formation of an advisory council of growers. History has produced the following results. (1) adequate tariff protection was never achieved,(2) control of disease through benzol vapour (CSIRO) breakthrough, was later identified as carcinogenic, (3) orderly marketing was achieved through (4) the establishment of the Tobacco Growers Association(19840. In October 2006, by way of Government buy back of tobacco leases from growers, resulted in the end of Tobacco farming in Australia (after 136 years of planting the first crop). It was also significant that the major tobacco companies such as Philip Morris and The British American Tobacco Australasia advised the industry that it would source its tobacco requirements overseas by 2009.The remnants of the Tobacco Industry can still be viewed throughout the Kiewa Valley and adjacent regions on the former tobacco farms which still have the tobacco drying sheds and now converted into hay sheds. The problems from the large quantities of carcinogenic infused soil of farmlands in the region, still remains a problem now and for future generations. This particular photograph shows the lack of understanding by farmers and the contracted labour, at that time, and is demonstrated by the lack of protection of hands when handling the tobacco leaves and nose from tobacco dust. Hand and foot protection was rarely used, even when later warnings were issued of the carcinogenic toxicity of the soil. The majority of farm owners, up until Health authorities stepped in the later stages of 1900s, were skeptical of city scientists' "carcinogenic" health warnings and it was only after the younger generation of farmers, who had graduated from Agricultural colleges, encompassed the scientific approach to farm management. The "she'll be right mate" attitude of the farming/rural community has since the 1970s been slowly dissipating. Stricter controls of herbicides and pesticides used in agriculture are now in force. The death of the tobacco industry(2006) resulted in the expansion of the dairy , sheep, beef cattle, venison and lama wool producers in the Kiewa Valley and surrounding regions.Coloured photograph pasted onto a thick wood chip backing. Two galvanised eyelets at the top of the frame, 50mm from each end, with a twine cord stretch from each, for hanging purposes. See also KVHS 0054A to KVHS 0054D and KVHS 0054Ftobacco, farming, rural industry, licences, ollie mould, blue mould, benzol vapour, photograph -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTelephone - Wall Mounted 184, Circa mid 1900s

This handset appeared via Australia Post Office and was to some degree manufactured in Britain just prior to 1939. During and after World War II these handsets were made in Australia. The handset belonged to the SEC Victoria and later the Kiewa Hydro Electricity Scheme. As this unit has a winder arm (to notify the switchboard) it would have resided in a workshop/machine shop and not in an office. The durability of the bakelite covering gave good protection in any environment. In years later the bakelite came in colours. This type of handset being able to endure rough handling was ideal for the surroundings of the alpine terrain. It would have been at the various outside outposts or foreman posts as swift communications was essential and communications with all sectors of work in the Hydro Electricity Scheme was mandatory, not only for safety reasons but also for efficient operational day to day progress. Also refer to article in "This Week" Newsletter 30th June 2023. Article attached to paper copy.This Australian Post Office 184 black coloured bakelite wall mounted phone was initially developed by Ericsson Telephones Ltd Britain. It was used by the SEC Office based at Mount Beauty and therefore has a winder (for power and notification to the switchboard. The hand piece (large ear and voice receptors)is placed vertically above the dial up winder.On the winder plate in hand writing is" turn handle lift handset" and below the handle "when finished replace handset turn handle"sec communications, wall telephone, internal communications kiewa hydro electricity scheme -

Warrnambool RSL Sub Branch

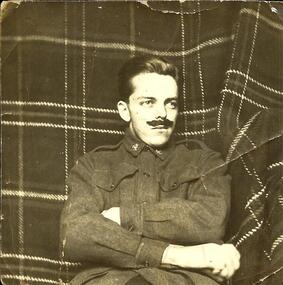

Warrnambool RSL Sub Branchc.1924. A self-guided battlefields tour retracing his brothers' footsteps? Young brother, FRANK SNAPE dressed up in Army uniform, for the photo opportunity, just for fun. "You didn't think I could grow one like this, did you?" is written on the back of the photograph, posted home to Bob. (As a small child, whilst playing with the fire in his family sitting-room, Frank accidentally burnt his hand badly on the fire-grate. Unable to properly open and close his hand, Frank would later have proven to be medically unfit for military service.)

snape collection -

Warrnambool and District Historical Society Inc.

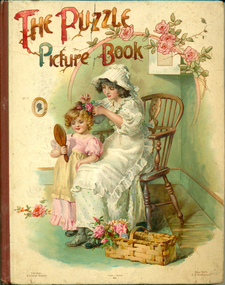

Warrnambool and District Historical Society Inc.Book - Book: The Puzzle Picture Book, Ernest Nister, The Puzzle Picture Book, 1900

The book, awarded to Ethel Henderson in 1903, from Christ Church, Warrnambool is an example of a Sunday School prize given to children attending Sunday School at the time. Christ Church Anglican Church was one of the early churches in Warrnambool.The Puzzle Picture Book is a rare 'movable' children's book from 1900. It contains 6 chromolithic dissolving scenes (also called slats/transformations). It is unusual due to its educational content. It was published by Ernest Nister in London, E F Dutton & Co in USA and is also thought to have been published in German under the title 'Ueberraschungen Aller Art'. [source: The Little Book Store]Child's picture book with full colour cover depicting a mother dressed in long white spotted dress, white apron, white bonnett and black button-up shoes, sitting on a wooden armchair while dressing a young girl's hair with pink flowers. The girl is dressed in a pink frock with puffed sleeves and frill around the hem, and cream apron. She is looking in a brown wooden-backed hand mirror. A woven straw basket with pink roses sits on the floor. A framed silhouette picture is on the wall. The title is in a display typeface mimicking rose stems; a swag of pink roses decorates the top right hand corner. The publishers' names are printed on the bottom left and right hand corners at the bottom, and the printer in the centre. The inside cover has a book plate. The title page shows two boys arguing over the book. The verses are by Clifton Bingham, the pen and ink illustrations by Hilda K. Robinson. The story has a monochrome page with rhymes opposite a colour page with cut-out boxes showing four small pictures, each with a question. By pulling the tab at the bottom of the page the answer to the questions is revealed. There are six chromolithic 'dissolving scenes'.Book plate: Christ Church. Sunday School, Warrnambool. 1st Prize Girls Class II. Awarded to Ethel Henderson. S M George Vicar. Warrnambool, May 1903children's picture books, ethel henderson, children's picture books, puzzle books, christ church anglican church, sunday school prizes, ernest nister london, warrnambool, ethel henderson, e f dutton & co new york -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkClothes wringer, Acme Wringers Ltd, mid 19th century

... on hand crank, two fold-up grey and white guides on either side.... Emerald yarra-valley-and-the-dandenong-ranges Hand operated ...Hand operated clothes wringer, white enameled steel with red and chrome detailing. Two screw attachments for mounting on a trough, white rubber rollers with screw adjustment, wooden handle on hand crank, two fold-up grey and white guides on either side. -

Sir Reginald Ansett Transport Museum

Sir Reginald Ansett Transport MuseumHeadwear - Hat, Pillbox, 1972-1977

Donated to Sir Reginald Ansett Transport Museum by Shirley Boles Ansett Airlines of Australia 1969-1972 Uniform designed for Hostess/Stewardess uniform. Complements the collection of air flight crew attire 1969-1972.Shirley Boles was an air hostess with ANA in the early days of Ansett. Shirley has made a considerable contribution of items to the Sir Reginald Ansett Transport Museum. She was a popular staff member who worked for many years with the company.Beige coloured pillbox hat , with flat crown and straight, upright sides. Turned up brim featuring peaked detail on one side. Piped edging. Heavy-duty poly-cotton (?) fabric with reinforcing stitching. Fawn grosgrain ribbon interfacing inside. Cream bemsilk lining. Gold coloured badge features 1968-1981 Ansett Logo A Delta "by Nivek Headwear Reg. Melb" on label inside. Pencil numeral 20 & 1/2 hand written on label. Commercial Name Tag hand sown Shirley Boles customer service staff, pill-box hat, 1970s, beige, hostess, stewardess, shirley boles, flight attendants, 1969-1972 -

Streatham and District Historical Society

Streatham and District Historical SocietyPicture Post Card, Oman Family

This picture shows a group of people outside of a weatherboard house. There are four persons sitting on a metal seat. Two male and two female. Both boys have a boat neck collar on their shirts and button up boots on. One girl has a light coloured dress with a money purse across one shoulder, her hair tied up with a ribbon. The older girl has white uniform on with watch hanging from the bolice, her hair is up. A youth is standing leaning on the house with his thumbs in his vest holding a whip. He has on foot resting on the seat and is wearing short pants and boots. Standing behind the seat is a large framed women wearing a dress with her hair up and a man wearing a suit with facial hair, hands behind his back. To the side another youth with his hands in his pants. Next to him another man with his hands behind his back, dressed in a suit with facial hair. Lace can be seen on the windows.Shows a typical family and housing of the period.Black and white rectangular picture post card.In black ink, stamped on back "Post Card, Correspondence, Address. Written in black ink " Robert Oman, Clifton, Jack, Roy, Jean, Gladys, Evelyn, Father John, Mother. R Oman 5 Locjhart Ter Edwardstown SA". In blue pen "Dos Dunn". -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Main Road, Eltham, looking south from Bridge Street, 1906-1907

Looking south along Main Road from the south side of the intersection of Bridge Street with Main Road. Anne Hunniford's Post Office and Burgoyne's store on left. Miss Harriet (Minnie) Williams's Cash Drapery Mart (est. 1902 and enlarged in 1906), also known as Eltham House on the right. Harriet (Minnie) Williams was born London, 1857, the daughter of George John Williams (1812-1895) and Jane Mansfield (1812-1895). In September 1885 she was operating Williams’s Drapery Establishment in premises on Main Road owned by R. Wallis who advertised them to let in September 1885. In 1902 she opened Williams’s Cash Drapery Mart at the southwest corner of Bridge Street and Main Road (opposite the Post Office), owned by W.J. Taylor. In 1906 she bought the premises and one quarter acre of land and expanded the business with a re-opening in April 1906. Harriet was also well-known and esteemed as an active worker in Methodist circles and also Superintendent of the Sunday School. Harriet fell ill in August 1907 and died 15 August. She is buried in Eltham Cemetery with her good friend Ada Ford. Note also the gas street lamp on right. Watson's Hotel on corner of Pitt Street visible in distance. The CBA bank building is hidden behind trees, the chimney and part roof visible. The photo was possibly taken by John Henry Clark of Clark Bros Photographers who operated from 25 Thompson Street, Windsor near Prahan 1894-1914. Evelyn Observer and Bourke East Record (Vic. : 1902 - 1917), Friday 30 March 1906, page 5 ________________________________________ ELTHAM. (FROM OUR OWN CORRESPONDENT.) For over three years Miss Williams has carried on a drapery business in very small and inconvenient premises opposite the Eltham post-office. Recently she bought the building and a quarter-acre of land from Mr. W. J. Taylor. Thus having a free hand, she at once matured plans to enlarge and improve the premises to make them suitable for her growing business. The result being that she consulted Mr Roach, contractor, of Heidelberg, put the matter in his hands, and now he has completed in a very satisfactory manner and up-to-date style extensive improvements. A large addition, of very neat and attractive design, with three large windows, has been built right along the front of the old building, and the counters and inside fittings are very neat and convenient, harmonizing well with the attractive outside appearance. Miss Williams has now got in a large now stock of goods, and is making extensive arrangements for a “reopening week," commencing 2nd April, during which time she will make 10 per cent reduction on all cash purchases in the form of gifts of that value. Miss Williams has gone to considerable expense and liability both, in the enlargement and improvement of the premises and in purchasing additional stock. We therefore trust that the public will stand by her by heartily and en masse patronizing her re-opening effort to show their appreciation of pluck in this advance movement. Google Street View Feb 2017: https://www.google.com.au/maps/@-37.7191341,145.1462046,3a,50.5y,191.91h,88.27t/data=!3m6!1e1!3m4!1sARwwqEQfMSfH9oTWWapPgQ!2e0!7i13312!8i6656 This photo forms part of a collection of photographs gathered by the Shire of Eltham for their centenary project book,"Pioneers and Painters: 100 years of the Shire of Eltham" by Alan Marshall (1971). The collection of over 500 images is held in partnership between Eltham District Historical Society and Yarra Plenty Regional Library (Eltham Library) and is now formally known as the 'The Shire of Eltham Pioneers Photograph Collection.' It is significant in being the first community sourced collection representing the places and people of the Shire's first one hundred years.Digital image (x2) 4 x 5 inch B&W Neg B&W Print 16 x 25 cmsepp, shire of eltham pioneers photograph collection, eltham, main road, anne jane hunniford, burgoyne store, christopher watson, commercial bank of australia, drapery store, eltham house, gas lamp, harriet (minnie) williams, post office, street lamp, watson's hotel, williams's cash drapery mart, clark bros. photo -

Orbost & District Historical Society

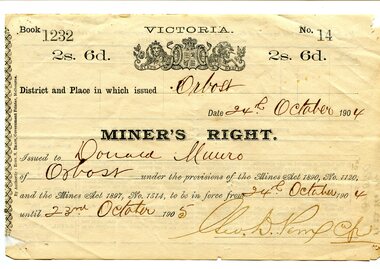

Orbost & District Historical Societycertificate, 24.10.1904

This miner's right certificate was issued in Orbost to Donald Munro of Orbost. It was valid from 24.10.1904 until 23.10.1905 and cost two shillings and sixpence. Donald Munro, with his brother, Archie carried on a boot-making business in one of the rooms of a three-storeyed barn at Lochiel. The Munros were musically inclined and through them a band was formed in 1889. Donald Munro was involved in many of the town's activities. (More in Mary Gilbert's Personalities and Stories of the Early Orbost District). The Miner's Right was introduced in 1855 in the colony of Victoria, replacing the Miner's Licence. Protests in 1853 at Bendigo with the formation of the Anti-Gold Licence Association and the rebellion of Eureka Stockade in December 1854 at Ballarat led to reform giving the right to mine gold, the right to vote, and the right to own land. This new system proved economical and sustainable, operating substantially unchanged up until 1975. This item is of historical significance as it is associated with positive outcomes for gold miners brought about by the Eureka Stockade rebellion and its subsequent democrat changes. It is also associated with the Munro family who were early settlers in Orbost.A white paper miner's right certificate. It has black print with hand-written details. It is an elaborate document with the Victorian coat-of-arms at the top.on back- date, hand-written notescertificate-miner's-right munro-donald -

Ringwood and District Historical Society

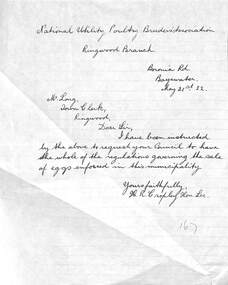

Ringwood and District Historical SocietyDocument, H.R. Cropley, Ringwood Poultry Breeders Association, miscellaneous correspondence, 21/05/1932

Hand written letter to Mr. Long, Town Clerk, from H.R. Cropley, Hon Sec of National Utility Poultry Breeders' Association. Letter dated May 21st 1932.0 Hand written letter to Mrs Pullin from Nunawading Historical Society re setting up a Ringwood Branch of the National Utility Poultry Breeders Association. Letter dated 19th July, 1986, and signed by Andrew Hillier, Assistant Secretary. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Adze, Mathieson and Son, First quarter of the 20th Century

An adze is an ancient and versatile cutting tool similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. Adzes are used for smoothing or carving wood in hand woodworking, and as a hoe for agriculture and horticulture. Two basic forms of an adze are the hand adze (short hoe) a short handled tool swung with one hand and the foot adze (hoe) a long handled tool capable of powerful swings using both hands, the cutting edge usually striking at foot or shin level. Mathieson & Sons Maker: In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicholson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicholson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river Bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Coopers Adze steel with wooden handle No 194 A Mathieson & Sons Glasgowflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Router Plane, A Mathieson & Son, Mid 19th to early 20th centuries

The subject router is commonly referred to disparagingly as the ‘old woman’s tooth’ or ‘hag’s tooth.’ It is a router that houses a plough plane iron instead of a purpose made shoe-type cutting iron. They work fine but rarely give the type of clean surface required for veneer inlays. These types of tools are adjusted by the same hammer-tap tapping method used generally on wooden-bodied planes on the iron or plane body. These tools are effective and practical when used in general carpentry and joinery. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used for making timber veneers or smoothing a trench in a piece of timber that was then used in some form of cabinet manufacture or wood working enterprise. A significant item from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made and required considerable skill in their use. Old Woman's Tooth Router Mathieson. Single iron cut down from a larger plane iron. Has Marked A Mathieson & Son also stamped inscription on side G Hill. (owner)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, plane, old woman's tooth, router, hag's tooth router, cabinet making, woodworking tools, a mathieson & sons, cabinet tool makers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Royal Doulton, Late 19th to early-20th century

The Royal Doulton company began as a partnership between John Doulton, Martha Jones, and John Watt was an English ceramic and home accessories manufacturer founded in 1815. Operating originally in Vauxhall, London, later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. The business was specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stonewares, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware's made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone China table wares and decorative items. An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects. This ink well is historically significant as it represents the method of hand written communication that was still common up until the mid-20th century, before fountain pens and ballpoint pens took over in popularity and convenience.Ceramic, salt-glazed, mid-brown ink bottle. It has a small round mouth, rounded lip that extends past neck, wide shoulders, straight sides, flat base. Handmade. The surface is matt. there are flecks of dark brown in the clay. The bottle has marks on the side.Noneflagstaff hill, warrnambool, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, shipwreck artefact, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, ink bottle, dwarf ink, salt glazed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Ship Log, 1880-1890

The John E. Hand & Sons Company was founded in Philadelphia in 1873, quickly gaining a reputation as competent manufacturers of nautical instruments and compass adjusters. In fact, John Enos Hand, the company founder, is recognised as the first man in America to adjust a compass aboard an iron ship. The Hand Company built navigational equipment for all varieties of floating vessels, and operated a chain of retail outlets with “service stations” in numerous port cities, including Baltimore and New Orleans, until 1956. Service stations sold Hand instruments as well as other nautical paraphernalia and provided compass adjusting services. Additionally, John E Hand and his two sons, John L Hand and Bartram Hand, were inventors in their own right who patented design improvements for numerous instruments that were employed in the company’s work. Commercial and private contracts dominated the firm’s business until the late 1930s when the United States military began preparations for World War II. Although the Hand Company never completely abandoned its involvement with private industry, after World War II, military contracts monopolised their business. The Company obtained contracts with the Navy, Coast Guard and Marines to develop new instruments, and to build military-engineered nautical equipment. Of note are the wrist compass, developed for the Navy beginning in the 1950s, and the Mark VII Model 5 Navy Standard Binnacle. Although it moved numerous times, the Hand Company headquarters and factory remained in the Delaware Valley, occupying several buildings in Philadelphia and southern New Jersey. Maintaining its central office in Philadelphia well into the 1900s, the factory was moved to Atco, New Jersey around the turn of the twentieth century and subsequently to Haddon field, New Jersey. It moved one last time in the 1960s to Cherry Hill, New Jersey. In 1997, California-based Sunset Cliffs Merchandising Corporation purchased the Hand Company and all its assets for $100,000. "HAND" brand taffrail log by John F. Hand and Sons Co. Register is enclosed in log, has a glass front and 3 dials on an enameled surface, the first dial registers the miles up to 100, the second registers the units up to 10 mile, the third registers quarters of a mile. The item is rocket shaped with a three blade rotor and a rope ring attachment at one end; the rotor will spin when a rope is attached, allowing the apparatus dials to measure the ship's speed when it is dragged behind a ship. Diagram of the 'Hand' trademark with a compass card in the middle, inscription reads "John F Hand and Sons Co" and "PHILA-BALTO" ( Abbreviation for: Philadelphia / Baltimore) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bartram hand, john enos hand, john f. hand and sons co, john l hand, john hand & sons instrument makers, john hand & sons of philadelphia, marine instrument, marine service station, mechanical ship log, nautical instrument, nautical navigation, navigational equipment, scientific instrument, ship log, ship log register, ship’s speed, sunset cliffs merchandising corporation, speed log, rocket log, harpoon log, taffrail log, taff rail log -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Froe, Late 19th to Early 20th century

A froe was used for splitting, or riving, wood in the early days and was a skill practiced by craftsmen who made boards, shingles, c lapboards, fences, basket splints, chair parts, wagon spokes, lath, and more. Our ancestors used axes, gluts or wedges, froes, draw knives and spelk planes for splitting wood. The froe was designed in many sizes and designs for splitting timber. It is typically an L-shaped tool made up of a wedge-shaped blade with a dull, but not blunt, knife edge and a wood handle. Blades were usually straight with a socket forged at one end for a handle, but curved blades were also made. Most handles were round and tapered and were inserted up through this socket. But some froes had eyes similar to those on axes for handles that were wedged. The froe handle is held in an upright position in one hand while the other hand drives the top of the blade downward with a wood froe club or mallet. After a split is started, the froe is wiggled downward to lengthen it until the split is complete. Most old froes were hand forged, but they were also available in many catalogues. The 1873 D.R. Barton American catalogue offered straight froes at 12 1/2 cents per inch. You can still buy new froes from many tool manufacturers today.A tool that has not changed in design or use since its inception several hundred years ago to split timber for various uses.Froe, also called cooper's froe or stave froe, without handle.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, froe, cooper's froe, stave froe, wood splitter, carpenders tools, coopers tool, splitting timber -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Printing Press, Harrild and Sons, 1866

This Albion printing press was manufactured by Harrild & Sons of London and exported in 1868 from London to the colonial Western Victoria town of Coleraine, population of 700 at that time. It was installed in the Colerain Albion printing office. It was used to print the first edition of the Coleraine Albion newspaper in 1868 and continued until publication ceased in 1974. The Albion Press is still being used today by a volunteer printer in the “Examiners Office” in the village at Flagstaff Hill. Amongst the items produced are printed paper bags for the Tea Rooms and posters for visitors. ALBION PRINTING PRESS The Albion press was invented and manufactured in London by Richard Whittaker Cope around 1820 and was still being produced in the 1930s. The Albion was manufactured under licence by several companies from the 1850s onwards, one of which was Harrild & Sons of Fleet Works, London. Harrild & Sons describes its business as “printing materials manufacturer”. The business was established in 1807 by Robert Harrild and named R. Harrild & Co. In 1813 he showed that rollers could be used to ink a printing plate instead of inking balls, the method in use at the time. He then established a company to make the rollers. Eventually his company would make other printing materials and equipment. Robert’s sons joined him in the 1830s, when the company was renamed Harrild & Sons, and they continued to run the company after his death in 1853 and up until the mid-1900s. COLERAINE ALBION PRINTING OFFICE The Coleraine Albion Printing Office was established by W.L. Ambler. The first issue of the Coleraine Albion was dated 4th January 1868. Arrangements had been made to receive news from Melbourne, nearby provinces, other colonies and England. The second issue on 18 January 1868 printed articles from many agencies, including the Melbourne Age and the Warrnambool Examiner. The Albion office was sold to William Hatherleigh, formerly of Portland, in October 1868. Thereafter the Albion office had many owners. The last was L. A. & E. Oliver, who took over in January 1972 and was the last to be stated as printers and publishers of the Coleraine Albion. The office was wound up in 1974. The Albion Press and other equipment was distributed to Star printing in Terang. Star Printing donated the Albion press to Flagstaff Hill Maritime Village around 1980 and Stan Philp, owner of Philprint in Warrnambool, transported it to Warrnambool, brought it up to good working order and organised the supply of appropriate printer’s type. The Albion hand operated printing press is significant for producing the first newspaper in Coleraine, Western Victoria and continuing production for over 100 years. The Albion is technologically significant as a working example of a hand operated printer from the mid-19th century. The use of the printer is demonstrated by volunteers at Flagstaff Hill, printing items such as lolly and treat bays for use in the Village. The Albion is socially significant for its role in the isolated provincial colony, providing communication with the outside world, both in Australia and overseas. Newspaper printers were often amongst the first businesses of a small town. Printing press; hand operated Albion Press, Patent 2105. The machine has an upright iron frame at the back that supports the upper press that has a wooden handled metal bar is attached. The frame and legs support a thick metal flatbed. A metal leg supports the front of the press bed. The iron work is painted black with gold highlights. The decorative legs are finished with the golden feet of an animal. The frame above the metal bed includes a crown shaped finial symbol above the maker’s emblem. The maker’s details and the name of the printer are embossed on the upright frame. A plaque with the patent number is below a Lion and Unicorn emblem.Embossed maker’s emblem [A red cross - above a double ring – square inside ring – three banners below ring]. - Inside the double rings “PRINTING MATERIALS MANUFACTURE” - Inside the square, intertwined text “H & S” [representing Harrild & Sons] - Inside the three banners ““FLEET” “WORKS.” “LONDON.E.C.” Embossed across the shoulders “ALBION PRESS / HARRILD & SONS, / MAKERS LONDON.” Emblem above plaque [Lion and Unicorn] Embossed on the plaque “PATENT / 2105” Stamped into upright machine part above the printing bed “2105 / 1866” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, albion press, printing press, 1866 printing press, printing equipment, communications, coleraine albion printing office, coleraine newspaper, albion newspaper, south west victoria newspapers, harrild and sons london, richard whittaker cope, star printing terang, philprint, coleraine albion, hand operated press -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century