Showing 228 items matching "home manufacture"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, early to late 1900's

This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State. In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (H Taylor) and where it originated from. These bottles were recyled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle. This heavy gauged glass ginger beer bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the filling production line. The method of pouring ginger beer into the bottle has been part of the "production line". This bottle has a one and a half pint capacity and is made from "light green" coloured glass(a protection against light penetration). This thick glass bottle, to contain ginger beer, required its thickness because of the extensive handling (man and machine) before final consumption. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck. Ginger beer was a "soft drink" of great demand. On the middle portion of this bottle is a large elongated circle within it and following the spherical line is "H. TAYLOR" ans a star separates this from "MELBOURNE" rounding out the bottom curviture. Within these words are the large initials "T H" . The "T" superimposed onto the "H". On the base and covering the whole bottom is the letter "T". At the opposite side to the manufacturers logo is "THIS BOTTLE CANNOT BE SOLD OR USED BY ANY OTHER PERSON & IS NOT COMPLETE WITHOUT STOPPER" glass bottle, non alcoholic drink, taylor ginger beer bottle, reuseable bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCushion Pin, unknown, circa mid to late 1900's

This pin cushion was in use when home spun "fashion" clothing was manufactured or altered. When this item was used it was in a period when distances from haberdashery stores was too far and mail ordered clothing would take weeks to arrive.The ability to make and alter clothing for families within the Kiewa Valley and its regions was a domestic requirement up until the later period(1960's onwards)This pin cushion, although rarely used in the 21st Century, with the availability of "cheap" throw away clothes, was very important to a well run rural household. The emphasis for girls to be able to sew and repair clothing was generated by mothers and continued at high schools. Part of the role of women(in this time frame) within the family was to manufacture children's clothing and adjust the growing waistline of their men folk. This item is very significant to the rural households in the Kiewa Valley because of the relative isolation of the region and the amount of wear and tear that clothes go through in a typical rural environment.This pin cushion is "home" made, circular and covered in a blue floral material, encircled with a light blue ribbon (glued on) for extra adhesion. The material encloses a padded surface(allows pins to be safely inserted for storage(future use).sewing, pin-cushion, haberdashery -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyKettle Aluminium, mid to late 1900's

This aluminium kettle was manufactured between 1940 to 1960's and replaced the heavier caste iron "open fire" stove ones (in doors or in the bush). A cast iron flat base between the open fires and the kettle was required. This kettle was used extensively with indoor open fire places. It was part of the evolution in "tea" making kettles. These were the only method of making hot beverages before introduction of electric kettles. For the Kiewa Valley the connection to the major electricity grid was post 1950's.This kettle is significant demonstrating the type of kitchen utensils required before electrical home connections became a reality. The aluminium structure of the kettle was an advancement over the heavier caste iron kettles. This type of kettle is still in use for bush and mountain hikers/climbers due to the light weight. This kettle was used by the Tawonga C.W.A. Branch. The C.W.A. motto "Honour our God, Loyalty to the throne, Service to the country, Through country women, For country women, By country women."This 99% aluminium hot plate kettle with lid (bakelite handle) is Australian made for flat stoves (cooking or room heating). It has a "tea style" spout and a bakelite hand grip(knob) on the top of the lid. The lid has nine ridges (for strength) radiating from the central hand grip. The two handle prongs are bop riveted onto the the body of the kettle. The bakelite hand grip has been fashioned to fit the natural contours of a clutching hand.On both sides of the aluminium handle "HOT PLATE WARE" and covering an oblique shaped triangle "99% PURE ALUMINIUM" and below that "MADE IN AUSTRALIA".Within the triangle "DURALIFE"cwa, homeware aluminium kitchen utensils, made in australia cook ware -

Kiewa Valley Historical Society

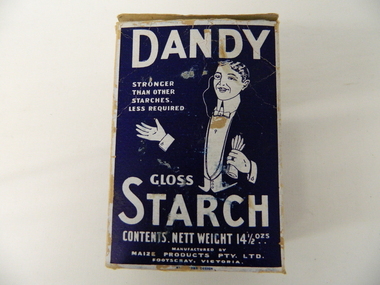

Kiewa Valley Historical SocietyBox Starch, circa 1914 to late 1900's

This brand of starch was first manufactured in 1914, during the First World War, and continued to cover the other wars and military conflicts that followed. It was a time when Australian made was important due to the limited supplies coming from England and Europe. This was a period when the demand for "home grown" produce was at its peak. This was in a time when by necessity not by the "Buy Australian" campaign (of later years) which was the major factor for the demand of goods. It was in a time when starch was used in formal clothing to put a "crisp" or fresh new appearance for clothes. The important social more of "clothes make the person" was in vogue.This box which once contained starch powder is very significant to a rural semi isolated region because it clearly demonstrates that the social mores of the city were also entrenched into the rural population. The fashion of the day, even in remote areas, especially rural, were still a requirement to be maintained on certain special occasions. Cleanliness and stiff "upper lip" persona were just as important in the rural sector as in city and Government circles. Institutions such as hospitals, Government Offices and the legal personnel were bound by the fashion of the starch appearance (no dirt sticks to a personage with the "starch" look). Appearances, especially the first ones, were the judgmental image that remained in the uppermost regions of the viewer. This box with white writing and a "formally clad" man on a navy blue background held Australian grown maize based starch powder(1 LB gross). The package is made from 200 gsm thick cardboard. As production was made during the two World Wars 1914 to 1945 the promotion was heavily focused on Australian made and Australian grown maize.The same cover both front and back, "DANDY" below this a figure outlined in white on a navy blue background "hat and tails" outfit. Next to the sketch in smaller lettering" STRONGER THAN OTHER STARCHES. LESS REQUIRED". Below the figure "GLOSS" and below this in larger print "STARCH". Below this and in smaller print "CONTENTS. NETT WEIGHT 14 1/2 ozs" Below this and in smaller print "MANUFACTURED BY MAIZE PRODUCTS PTY LTD FOOTSCRAY VICTORIA" On one side of the box and in large white print on royal blue background"PURITY, STRENGTH AND UNIFORMITY." On the other side are the manufacturers directions. On the left side "FOR RAW STARCH" Underneath and in smaller print,"Dissolve in warm water a quantity to give the required thickness. Add bluing if required Stir before each using. On the right side "FOR BOILING STARCH" underneath this in small print"Mix well in small quantity of cold water to creamy consistency. Add boiling water, and stir constantly while cooking. Allow to cool, and add blueing if required. Underneath these two sets of instructions is "Make your consistency thinner than if using another kind of Starch"household starch, household cleaning, domestic laundering. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, early to mid 1900's

This cast iron kitchen appliance was made in England in the early 1900's and shipped to the "colony" Australia. This was before World War II and the "growing up" of a colony to an independent member of "the British Commonwealth". It was a period when most appliances (be they household) where manufactured in England and shipped to Australian ports. It was not until the late 1960's that the Asian manufacturing giant woke up and started to dominate the market palce.This domestic kitchen appliance is very significant to the Kiewa Valley because it highlights the "made at home" period when food processing was made "in house" due to inability to source food from specialised shops e.g. the butcher or slaughter houses. It was a period before mass food processing factories were established and roads constructed up to the standard for distribution to semi remote regions such as Kiewa Valley was in the beginning of the 1900's.This cast iron (malleable iron) mincer for meat products has a large "funnel" to direct "chunks" of meat to the grinding "wheels". These "star" shaped wheels with "teeth" of three different cutting surfaces (fine, medium and coarse) provide for texture types of the final meat product. The meat is placed into the "loading" funnel and push downwards(gravity feed) through the mincing chamber and out through the front side. There is a long "screw worm" which is rotated by turning the handle. The appliance is table mounted by a vice "G" screw on clamp (hand operated). "BEATRICE No. 3" and "MADE IN ENGLAND", "P 3181"household cast iron appliances, food processors -

Kiewa Valley Historical Society

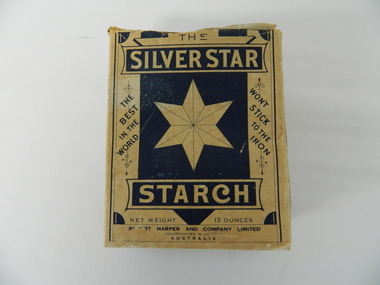

Kiewa Valley Historical SocietyBox Starch, Pre decimal currency date(14th February 1966)

This brand of starch was first manufactured before 1966 and covered the period when Australian made was the preferred clothing due to limited imports from England. This was a period when the demand for "home grown" produce was at its peak. This was in a time when by necessity and ease of supply and not by the "Buy Australian" campaign (of later years), was the major factor for the demand of these type of laundry goods. It was in a time when starch was used in formal clothing to put a "crisp" or fresh new appearance for clothes. This product was in the era and importantly the social more of "clothes make the person" in which starched shirts and dresses was the fashion vogue. Formality of dress was a strictly British "class" up-man-ship which from the 1950's onwards became less and less visible. The Australian "Ocker" or fair "dink'm" bloke became more entrenched after World War II. The national identity was slowly developing.This box of starch is very relevant to the Kiewa Valley because this box highlights the differences ,in this period, between city and rural social standards. Rural areas were deeply entrenched into colonial and the pioneer family structure viz- a-vie social and dress fashion standards. British values and norms lingered on well beyond the changes happening in city fashion. Tradition and English "ties" were the backbone of early colonies and it was only after World War II that these "ties" were becoming irrelevant. Early traditions lingered well past the independence sought by Federation, colony to statehood and trade with other nations eg. USA and Asia. The idea that a change in "status" would automatically change the social mores of Australians, especially in rural ares, was not fully grasped by the "law makers" and those wanting change.This box (capacity 12 ozs) has white(aged into cream) and blue printing and a "white star" on five sides, the sixth side has a laundry scene with two ladies, in early 1900's fashion. The package is made from 200 gsm thick cardboard. As manufacture was made before and during the two World Wars 1914 to 1945 the promotion was heavily focused on Australian made and Australian grown maize. One side of the box has instructions of use and all the other sides are promotional, detailing "the best in the world and won't stick to the iron""SILVER STAR", "THE BEST IN THE WORLD", "WON'T STICK TO THE IRON", "REQUIRES NO BOILING", INSTRUCTIONS FOR USE", "ROBERT HARPER AND COMPANY LIMITED", "INCORPORATED IN VICTORIA, AUSTRALIA", "NET WEIGHT 12 OUNCES", "LARGE BOX 12 OZS"domestic laundry essentials, cotton clothing preparations, household starch "crisp and neat appearances. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine Attachment - Buttonhole

... . "For Light Manufacturing and Home Use" on green 'cloud' on side...' on side of box. "For Light Manufacturing and Home Use" on green ...This sewing machine was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's grandmother used it in 1942 to make button holes.Historical: Type of machine used by S.E.C.V. wives living in Mt Beauty in the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and chook fetes e.g.. children's clothes and dolls clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Green & white box containing black & silver metal with 4 parts for attaching to Singer sewing machine for sewing button holes."Singer Buttonhole Attachment" on green 'cloud' top of box. "The Singer manufacturing Company" on green 'cloud' on side of box. "For Light Manufacturing and Home Use" on green 'cloud' on side of box. "Made in Great Britain" on white top half of end of box & teen 'cloud' below end of box is "Singer / Buttonhole Attachment / No. 86662 / For Singer Lock Stitch/ Family Sewing Machines.singer manufacturing co.. clothes. fetes. domestic. sewing. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine

... Valley. singer manufacturing co.. sewing. fetes. home duties ...This sewing machine would have been used by some ladies to mend and make clothes for the family as shops were some distance away and to sew items for Church and School fetes.Used in the Kiewa Valley.Black metal Singer sewing machine with gold decoration and writing on its body and platform. It sits on a wooden tray which is hollow under the body with a separate space on the right hand side. The body of the machine can be lifted by hinges attached at the back. This would enable items to be stored in the hollow part of the box. Similarly the hollow section on the right hand side, which hasn't got a lid. The body has the needle and cotton attachments on the left and a handle for working the machine on the right. There is a metal rod at the top for the cotton reel. The body is attached to the platform at each side forming an arch. The top of the box has metal along its perimeter. At each end of the top of the box there is a plate with a small hollow rectangle in the middle enabling an attachment such as a board to be inserted for an extended bench.Front & back of body: "Singer". and at front on an oval brass plate: "The Singer Manfc. Co." Inside of body on left: "This machine contains / some substitute / parts and accessories" On metal platform on right: "Y3071189" Along top of body: "The Singer Manufacturing Co." On Wood right hand side: "Godfreys Ltd / 57 Gawler Place / Phone 460261 / No. 7063 singer manufacturing co.. sewing. fetes. home duties. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDress

made locally circa 1910. Due to relative long distance to haberdashery stores majority of children's garments were hand made by a local talented seamstress or mother/relativeHistorical significant to the period circa 1900 to circa 1950 when fashion was dictated by long lasting durability, local manufacture, earthy colours and ease of mobility. Photos in the KVHS collection show girls from Tawonga Primary School in a dress that could be this dress which is dated 1910. Dress brown cotton with long sleeves. Dress top and sleeves lined. Back of dress is open with metal hooks for fastening. Hand stitched eyelets and decorative strip down centre front bodice and around hips. Gathered skirt is joined at hip. One pocket on left side 6cm from waist band.Decorative strip at bottom of dress with a pleated hand and machine stitched frill.no inscriptions or markings suggesting locally made.dress, clothing, girl's dress, home made -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySkittles wooden, Circa 1980

Indoor children's toy. Historically these gained greater popularity when professional ten pin bowling had its major impact in Australian sport and recreation. This item was gifted by one who had played skittles as a child with her brother on carpeted passage in her home. Skittles was an indoor game.This item clearly represent a period in rural Australian development when entertainment and sporting facilities were broadcast but local access to professional facilities not readily availableThis is an incomplete set of toy wooden skittles. There are three green, two yellow, one red and one brown pin. The bottom and top have manufacturing markings from a wood turning machine. Full set is nine pinschildren, wooden, toy, skittles -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

Colour photograph of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkKitchen boiler, Copper Kitchen boiler, Approx 1900

Joseph Fowler (1888-1972), businessman and municipal councillor, was born on 28 February 1888 at Bagworth, Leicestershire, England, one of thirteen children of John Fowler, groom, and his wife Mary, née Ash. With his brother Sydney, in the early 1900s Joseph worked in a fruit-preserving business run by an uncle at Maidstone, Kent, and continued with the firm after 1908 when it was relocated at Reading. At St Andrew's parish church, Leicester, on 7 September 1910 he married a nurse, Elizabeth Harris (d.1965); they emigrated in 1913 and settled at Camberwell, Melbourne. Encouraged by his commercial experience, and by the variety and quality of fruit in Australia, Fowler set up a fruit-bottling business in the rear of his small house in Burke Road. Trading as J. Fowler & Co., by 1915 the company had begun producing home-bottling kits which contained a sterilizer, bottles, lids, rings and a thermometer. To acquire the capital to establish a factory, Fowler travelled the district, selling his kits door-to-door from the back of a cart. In 1920 he bought a shop at the corner of Power Street and Burwood Road, Hawthorn, and registered his business as a private company. During the Depression his kits became a household name. In 1934 Fowlers Vacola Manufacturing Co. Ltd was registered as a public company. Housewives, nationwide, were urged to bottle their own fruits and jams by 'Mrs B Thrifty', the dainty cartoon character who graced the firm's advertisements. Numerous recipes and instruction books, such as From Orchard to Bottle the Fowlers Way, advertised the necessary preserving equipment, extending to jelly bags and juice extractors. Australian-made glass and imported steel and rubber were used in the production of Fowlers Vacola Bottling Outfits. Determined to put something back into the community which had supported him so well, in 1933-60 Fowler represented Yarra Ward on the Hawthorn City Council (mayor 1938-39 and 1945-46). He served as vice-president of Swinburne Technical College (1942) and of the Hawthorn branch of the Australian Defence League (1943); he was also a Rotarian, and a warden and vestryman of St John's Anglican Church, Camberwell. Changed demands in World War II encouraged Fowlers Vacola to diversify their product. Canned goods were manufactured for allied troops in the South Pacific. In 1953 new buildings and plant, including a giant pressure-cooker, were installed to increase productivity: from that time Fowlers Vacola sold canned and bottled food throughout Australia and abroad. By 1960 the factory occupied more than 122,000 sq. ft (11,330 m²) and further expansion was to occur when the firm moved to Nunawading. Fowler retired in 1961, but remained chairman of directors; his son Ronald succeeded him as managing director. Variously described as a generous, jovial man with a sense of humour, and as a strict and astute manager whose company was his life, Fowler was renowned for his straight business dealings and his 'no-nonsense' attitude. Survived by his son and daughter, he died on 24 April 1972 at Camberwell and was cremated. His estate was sworn for probate at $204,424. On Ronald Fowler's death in 1978, the company was bought out by the Sydney firm, Hooper Baillie Industries Ltd; it in turn sold to Sabco Ltd of South Australia; in 1994, when Sabco went into receivership, Australian Resource Recovery Technologies re-established Fowlers Vacola Australia Pty Ltd's headquarters in Melbourne. Copper boiling pot for home preserves, handles, lid and removable thermometer, also acc ompany instruction booklet. "Fowlers Method of Bottling Fruits and Vegetables"Fowler's "Vacola" Reg. No. 68081 Sterilizer -

Orbost & District Historical Society

Orbost & District Historical Societyraisin stoner, late 19th century

This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesA cast iron raisin stoner with a clamp. It has a wooden handle on a turning arm.On arm-PAT.APP. Aug 20.95 Oct 5-97 On one side- WET THE RAISINS On other side-ENTERPRISE M.F.C. PHILADELPHIA. P.A. U.S.A. On chute- No. 38raisin-stoner food-preparation -

Orbost & District Historical Society

Orbost & District Historical Societyhat stretcher, first half 20th century

Prior to the 1960s, hats were worn by all men. Aluminium hat stretchers were generally in use from the 1920’s. The hat was placed on the aluminium dome shaped piece. When the handle was turned, the dome section split vertically, one section moving away from the fixed half. A graduated scale along the side indicated the size. This item was possibly used in the hat factory in Orbost. Stuart Hats commenced manufacturing hats in about 1948 and closed their factory in Orbost around 1953 probably because of the high transport costs. The company's head factory was in Melbourne. The hats made in Orbost were sold all over Australia as well as in Melbourne at Myers and David Jones. The building became first a Dry Cleaners and then a private home.This item was possibly used by Stuart Hats which was a significant manufacturing business in Orbost in the 1950's employing nearly 20 local people.A hat stretcher consisting of an aluminium dome-shaped piece (on which the hat was placed) and a metal winder. It has been mounted onto a wooden baseOn wooden base : "Restored by John Mundy"millinery hats hat-stretcher -

Orbost & District Historical Society

Orbost & District Historical SocietyCoolgardie safe, first half 20th century

Without refrigeration, storage of meat was difficult. Flies were a problem, and it was important to keep meat cool and out of the way of pests. One way of doing this was to use a meat safe: a kind of cupboard designed to store meat and keep it fresh enough to eat. Meat safes are ventilated. They were sometimes made with sides of wire mesh or perforated metal, so that air could circulate around the meat while keeping flies and other animals out.The Coolgardie safe was invented in the late 1890s by Arthur Patrick McCormick, who used the same principle as explorers and travelers in the Outback used to cool their canvas water bags Originally they were handmade using materials to hand. In the early 20th century, Coolgardie Safes were manufactured commercially across Australia, and found their way into homes in both rural and urban areas. These safes incorporated shelving and a door, had metal or wooden frames and Hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (refs ABC-Home; Museum Victoria)The Coolgardie safe was an Australian invention used especially in country areas from the 1890s until the mid 20th century. It began to be replaced by ice chests from the turn of the twentieth century in cities and country towns which had ice works. This item is an example of a domestic appliance commonly used before electricity was widely available for domestic use.A cube-shaped metal Coolgardie safe painted blue. It has a triangular hook on the top for hanging or lifting. There are small feet at bottom . The sides are perforated in a Above the door; Inside a rhomboid shape "WILLOW"food-storage coolgardie-safe domestic -

Orbost & District Historical Society

Orbost & District Historical SocietyCoolgardie safe, first half 20th century

Without refrigeration, storage of meat was difficult. Flies were a problem, and it was important to keep meat cool and out of the way of pests. One way of doing this was to use a meat safe: a kind of cupboard designed to store meat and keep it fresh enough to eat. Meat safes are ventilated. They were sometimes made with sides of wire mesh or perforated metal, so that air could circulate around the meat while keeping flies and other animals out.The Coolgardie safe was invented in the late 1890's by Arthur Patrick McCormick, who used the same principle as explorers and travelers in the Outback used to cool their canvas water bags Originally they were handmade using materials to hand. In the early 20th century, Coolgardie Safes were manufactured commercially across Australia, and found their way into homes in both rural and urban areas. These safes incorporated shelving and a door, had metal or wooden frames and Hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (refs ABC-Home; Museum Victoria)This item is an example of a common domestic appliance used before the widespread connection of electricity to homes and refrigeration. The Coolgardie meat safe is an Australian invention used widely in rural areas from the 1890's until the mid 20th century.A metal meat safe, painted white. It has a shelf inside. The door has two perforated rectangular sections metal framed in solid metal. The base is flat.storage domestic coolgardie-safe -

Orbost & District Historical Society

Orbost & District Historical Societycruet set, 1913-1917

This cruet set reflects the style of tableware produced in Staffordshire, England, in the early 20th century. Staffordshire became the centre of pottery manufacture in England by 1730, and a century later it was established as an international centre, exporting its products around the world. Staffordshire pottery was widely used in homes and cafes throughout Australia.A cruet set on a silver plated stand. The jug and shaker are ceramic - violets on a cream background.The shaker has a silver-plated topBase of jug- S.F. & G. Stoke on Trent England ; a crown ; Crown Division Shaker - on lid -E.P.N.S. and on the base - S.F. & G. Stoke on Trent England ; a crown ; Crown Divisionporcelain pottery cruet-set fielding -

Cheese World Museum

Cheese World MuseumButter printer, J Bartram & Son, c1900

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This butter cutter is part of the collection of items given into the care of the Cheese World Museum. It was in the early 1900s for hand-use in home dairies or small factories. An example of an early butter packaging machine.Wooden Eureka brand butter printer and weigher with dovetailed corners on the bulk butter box, wooden rollers for moving butter along once cut and wire cutter.Eureka/J Bartram & Son/sole makers Uebergang No. U027butter cutters, uebergang, allansford, dairy manufacture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRangefinder, E R Watts & Sons, 1930-1945

E. R. Watts and Son, makers of theodolites and other surveying instruments, of 123 Camberwell Road, London. The company was established in 1856 by Edwin Watts at twenty-three he had saved £100 from his earnings to start the business with his staff consisting of one boy and later Alexander Clarkson as an apprentice with the workshop a small room over a Bemondsey stable. Watts' first order was from Negretti and Zambra for a mining dial Alexander Clarkson In the early days the firm worked mainly on marine compasses. Edwin Watts would go down to the Docks to adjust the compasses once they had been installed on the ships. In May 1873 the business moved to larger premises a house with a garden. The workshop was also the home of Mr and Mrs Watts and their five sons and three daughters. By now there were fifteen to twenty men employed by the firm. The company were commissioned to supply the Theodolites and Levels for the construction to the Canadian Pacific Railway in 1881. Towards the end of the century, the firm began to make heliographs continuing to produce them for the government until just before the Second World War when by agreement assigned their manufacture to another firm. 1904 The first dividing engine was completed by George William Watts. It was so remarkable an instrument at the time and for years afterwards, In 1907 Arthur Ames went to Canada and started an organisation in Winnipeg in 1909 this became a separate company called E. R. Watts and Son Ltd. of Ottawa. This firm developed considerably and was eventually with the co-operation of three other instrument companies (Cambridge Instrument Co, Ross, and Negretti and Zambra), were reconstituted as ”Instruments Ltd” of Ottawa and Toronto. During the next ten years, the firm expanded greatly to include glass grinding, leather work, dividing and engraving, testing, adjusting and packing. This expansion was continued during the First World War when workshops were completed and the machinery installed and running within eleven weeks from the start of construction. During the war, a Sergeant Coles, among the rats, lice and mud of the trenches, fitted various bits of scrap into his cocoa tin and made the first Flash Spotter for plotting the positions of enemy guns. Coles was rushed home to the firm's factory where he and George William Watts designed a spotter not made out of a cocoa tin and as a result, the Watts Vertical Force Variometer was developed during WWI. Other Watts instruments made in the First World War included the Light Mountain Theodolites which were taken on Mt Everest expeditions. In 1919 ER Watts and Sons was incorporated as a limited company and in 1939 G. A. Whipple joined the Board of Directors. Shortly afterwards, Frank Charles Watts died having been Chairman of the firm for over 37 years and seen it through the First World War with all its expansions and difficulties. He was succeeded by his brother George William Watts with the vacant post of Managing Director being filled by G. A. Whipple. During the Second World War, the company expanded further and the number of employees rose to well over 1,300. In 1946 Watts acquired 78% of Adam Hilger and the microscope maker James Swift and Son Who were Manufacturers of Theodolites, Levels, Alidades, Meteorological Instruments, Variometers, and many other types of scientific instruments Then in 1948 the company amalgamated with Adam Hilger as Hilger and Watts which was then incorporated as a public company.Naval Rangefinder with a vertical wooden handle, and an arrangement of optical lenses. Three reversible brass inserts calibrated on both sides in yards, correspond to various base heights, (20 and 25 feet, 30 and 35 feet and 40 and 50 feet). They are fitted along the axis of the instrument. When the scale for the appropriate base height is selected and inserted, the carriage can be slid for coincidence and the distance read at the index mark on the sliding carriage.inscribed "Rangefinder Cotton Type Mk II" Calibrated scale up to 5000 yds (50 ft), 5000 yds (35 ft), 4000 yds (25 ft) made by E. R. Watts & Son.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, rangefinder, cotton type, e r watts & sons, naval range finder, marine equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Landers, Frary & Clark , 1897-2000

Landers, Frary & Clark were a housewares company based in New Britain, Connecticut. It operated from 1865 until its assets were sold to the General Electric company in 1965. They manufactured a wide variety of products over the years, including stainless steel bull-nose rings and electric ranges, kitchen scales and vacuum bottles, window hardware and ice skates, mouse traps and percolators, can openers, corkscrews, cutlery, straight razors, aluminium cookware, and thousands of other products. Many of these items were marketed under the brand Universal. Some of the non-electric kitchenware assets were acquired from G.E. in 1984 by Universal Housewares, Inc./Universal Trading, Inc., who still market "Universal" meat grinders and coffee mills.An early domestic item its function was for use in the home kitchen that's the original patented design from 1897 is still being produced today under its brand name of Universal by Universal Trading Inc USA.Food mincer cast iron with wooden handle & thumbscrew for bench attachment.Marked "No. 2 Universal".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, mincer, food mincer, universal brand, kitchen appliance, food grinder, lander frary & clark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ornament, Early 20th Century

Staffordshire dog figurines are matching pairs of pottery spaniel dogs, standing guard, which were habitually placed on mantelpieces in 19th-century homes. Mainly produced by Staffordshire pottery factories, these earthenware figures were also made in other English counties and Scotland. They are also known as hearth spaniels or fireplace dogs as they were positioned on top of the mantelpiece. Many other breeds were produced, particularly the greyhound, though the spaniels were especially popular and this is attributed to royalty favouring the King Charles Spaniel breed. In Scotland, they have colloquially been termed 'Wally dugs.' and were manufactured in bulk at potteries in places such as Pollokshaws in Glasgow and Portobello near Edinburgh. Though the most popular, the dogs were only one of many types of Staffordshire figures; other animals and human figures of various kinds were also popular. Staffordshire dogs are nowadays collectors’ items and since the 1720s, spaniels had been produced by various pottery factories in Staffordshire. The quality of the modelling and painting of the Staffordshire dogs may differ from factory to factory. As the popularity of the figurines increased towards the end of the 19th century, the quality began to decline. Thousands were manufactured but originals in good condition and their correct pairs are now uncommon. These figures continued to be made until the 1920s and early models are of better quality. However, reproductions were still being manufactured in 2009.Early 19th century pair of Staffordshire dogs used as a mantle place display however given their damaged condition and being of a later provenance have little historic or monetary value. Ceramic white dog, figurine one of a pair, with painted face and collar. Both are nearly identical except one sits to the left while the other sits to the right.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ornament, ceramic ornament, dog ornament -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Beer Stein, Reinhold Merkelbach, 1945 to 1964

This mug was made by Reinhold Merkelbach. Reinhold Merkelbach was founded in 1845 by Wilhelm Merkelbach, a descendent of a long line of German potters, and the company eventually took the name of his son Wilhelm Reinhold Merkelbach, who left school early to get involved with the family business. The company became a major name in German ceramics, especially in the Jugendstil style. The company produced a large number of collectable beer steins in the late 18th and early 19th centuries, including a number of so-called “character steins.” In 1882, the firm began producing art pottery, which at that time was enjoying a revival and new appreciation in Europe in general and in Germany in particular. Reinhold Merkelbach produced ceramic objects both with and without pewter hardware but rarely altered its manufacturing techniques. Many of its products were destined for use at pubs, bars, or breweries as well as in the homes of Germany’s beer-drinking populace. It had a retail location in Munich and also sold products through its factory warehouse. In 1971, half of the company’s ownership was sold to W. Goebel KG and the firm’s name changed officially to Merkelbach Manufaktur GmbH & Co. KG. Goebel ultimately purchased the other half of the business before members of the Merkelbach family, along with a handful of collectors and former staff members, repurchased the factory in 1988. In 2007, Judith Merkelbach Engelmann decided to close the firm; demand for ceramics had been decreasing and the next generation of the family had no interest in maintaining the business. Luckily, Reinhold Merkelbach transferred its moulds to Töpferei Girmscheid Höhr-Grenzhausen to ensure that its best-known pieces of Jugendstil art pottery and steins would continue to be available to interested consumers and collectors.This beer stein was made around the mid-20th century by a popular German maker. It fits in with the context of maritime village life. At this current time, there is no particular connection with people, places and events. The German beer stein is made from ceramic ironstone. It has a bell-shaped hinged pewter lid with a leaf-shaped thumb lever. The lid has a pattern stamped on it. The design on the mug includes a woman in bright colours, a man holding a musket, and buildings in mountain settings. There are inscriptions on the mug. Marked "Made in Germany" "RM" "4070" (underside of mug) "05" to the side of mug flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, beer stein, ceramic beer stein, reinhold merkelbach, drinking vessel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, 1850-1890

In the industrialized world, as stoves replaced open fires and braziers as a source of more efficient and reliable heating, models were developed that could also be used for cooking, and these came to be known as kitchen stoves. The first manufactured cast-iron stove was produced at Lynn, Mass., in 1642. This stove had no grates and was little more than a cast-iron box. About 1740 Benjamin Franklin invented the “Pennsylvania fireplace,” which incorporated the basic principles of the heating stove. The Franklin stove burned wood on a grate and had sliding doors that could be used to control the draft (flow of air) through it. Because the stove was relatively small, it could be installed in a large fireplace or used free-standing in the middle of a room by connecting it to a flue. The Franklin stove warmed farmhouses, city dwellings, and frontier cabins throughout North America. Its design influenced the development of the pot-bellied stove, which was a familiar feature in some homes well into the 20th century. The first round cast-iron stoves with grates for cooking food on them were manufactured by Isaac Orr at Philadelphia, Pa., in 1800. The base-burning stove for burning anthracite coal was invented in 1833 by Jordan A. Mott. The subject item is a mid to late 19th century settlers stove probably of Canadian manufacture imported into Australia around this time. The stove gives us a social snapshot into what life must have been like for our early colonialists using this device for heating and cooking in their meagre homes. Cast iron stove with four-legs, 2 plates on top and a hinged front door. The door has been cast with a maple leaf design and the sides have a pattern cast into them.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, stove, domestic heating, domestic cooking, heater, cooking unit, pot belly stove, wood fired stove, wood stove -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor, John Clarke Ltd, 1930s

In 1848, 43-year-old John Clarke launched a cutlery business in Harvest Lane in Neepsend, Sheffield UK. Clarke entered the trade late in life he was indenture and apprenticed to Octavius Twigg, a razor maker. Clarke was granted his Freedom in 1856 and began using the trademark 'NEVA'. By the 1860s, Thomas Clarke's son by his wife Elizabeth had joined the firm. When John Clarke died at his home at Augusta Place, Rock Street, Sheffield on 25 July 1873 (aged 68), he only employed six workmen. By 1881, Thomas had expanded this number to twenty. He sold a wide range of cutlery and was also an ‘emigration agent’, the Sheffield Independent, of 7th September in 1886 had an article published stating Thomas helped to recruit personnel from England for cutlery centers in America. In 1893 Clarke’s showroom displayed miniature knives from '5/16ths-inch long to the most expensive sportsman's knives, that were gold and silver mounted. Table knives and carvers were also manufactured (or factored). Agencies were opened in London, New York, and Melbourne. Besides ‘NEVA, the ‘EXPRESS’ and ‘RING’ marks were used on razors; and Clarke’s marketed the American ‘GEM’ safety razor. By 1901, the firm had moved to Mowbray Street, where its Mowbray Works overlooked the River Don. Thomas Clarke died at Harrogate on 26 April 1902, aged 62, and was buried in the same Burngreave cemetery as his parents. Thomas’s sons, John Roome Clarke (1860-1925) and Thomas Edward Clarke, were directors, another son George William Clarke was a shareholder. John Roome Clarke died on 3 February 1925, aged 64 his son, John Clarke, of Crimicar Lane, remained as the senior partner. Clarke’s was one of the last producers of hand-made pocket knives and it also produced a large output of sheath knives for scouting associations. The firm was liquidated in 1964, but the company name was resurrected and Its last address after 1980 was at 65 Garden Street Sheffield. The company trademark passed on to Meteor Industries and then to Egginton Ltd. Weber & Co: The Clarke company purchased or (factored) many of its blades for razors and knives from Weber & Co of Solingen Germany. The full name of the firm originally was Jowika Stahlwarenfabrik Eugen Weber & Altenbach KG. It was founded in Solingen prior to 1928, under the name Johann & Wilhelm Kleinewefers GMBH, Messerfabrik. JWK for short, hence JoWiKa. The company was sold to Eugen Weber in the 1930s. Weber was married to a woman named Altenbach, from a family that manufactured innovative low-priced pocketknives, as well as other cutlery items. In 1960 Weber opened a branch factory in Listowel Ireland. It was sold to Albert M. Baer of Imperial Schrade in 1978. The Listowel factory was closed about a year and a half before the U.S. Schrade factory closed in 2004 and the Jowika factory in Solingen had closed in 1984.An item with an interesting manufacturing history from the 1930s showing how one man can grow a business into a successful concern that made quality products that stand the test of time.Razor metal folding blade with horn handle in its original cardboard box Inscription Made by John Clarke and Son England. "Champion" razor. On box " The Champion 10/6d" and "Weber Lohmann & Co SOLINGEN".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Cot, Late 19th to early 20th century

Iron beds made from metal or wrought iron have been around since the late 18th century when they were hand made by craftsmen and artisans. The iron castings were always hand poured and originated from sand cast molds, more ornate beds are associated with the Victorian period. Later in the Edwardian era cast iron beds and cots had much less decoration and were quite plain .An relatively early domestic piece of furniture used as a babies cot giving a snapshot into domestic life around the end of the 19th century and beginning of the 20th. The item is not associated with a significant event, person or place and would have been common place in most homes of the time made by many different manufactures.Cot, metal, with chrome knobs and removable sides. Has wheelsNoneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cot, metal cot, iron bed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, Enterprise Manufacturing Company, circa 1911

This particular food mincer was manufactured by Enterprise Manufacturing Company. Located in Philadelphia, this company specialized in making hardware products. The company was especially known for its cherry pitters, apple peelers, and coffee mills. The company was founded in 1864 and was located on the corner of Dauphin, 3rd, and American Streets. Enterprise Manufacturing Co. remained in business until 1956 when it was bought by Silex Co.A mass produced early domestic item made for home food preparation this item's first patent design was approved in 1897. Manufactured by a well known company in the USA the "Enterprise Manufacturing Company” up until 1956. They specialised in making kitchen appliances of various types for domestic use and for export. Food mincers of the subject items design are still being produced today under the brand name of "Universal" made by Universal Trading Inc USA.Food mincer, metal, clamp on bench style, with rotating wooden handle. Inscriptions stamped on metal.Marked "Enterprise tinned Meat Chopper" "No. 10" "Enterprise MF'G Co. PHILA. USA" "PAT. JAN.30.83" flagstaff hill, warrnambool, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mincer, food mincer, meat mincer, food preparation, kitchen utensil, domestic object, enterprise manufacturing company, kitchen appliance -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Music stand, Early 19th Century before 1860

Thomas Sheraton (1751-1806) appears to have been the first to record the written term “Canterbury” music or magazine stand. In his Cabinet Dictionary of 1803 he refers to “a small music stand” with divisions for holding loose sheet or bound volumes of music. The music stand designed to hold sheet music came into fashion in the late 18th Century in England and was often crafted from mahogany, rosewood or walnut. They were seen as status symbols since music was practiced exclusively by the upper classes of society. In a period when printed music was more widely available and disseminated due to more affordable printing techniques, modern sheet music was very popular and therefore storage for such favoured tunes became a luxury and an opportunity for innovative design by cabinet makers. The Classical period of music, from about 1750 to 1820 and the Romantic Period from around 1815-1910 was the golden age of classical music. And it was at this time that The Canterbury often accompanied the piano in the parlour with styles ranging from Georgian simplicity to Victorian exuberance. Social activities of colonial Victoria would have included evening gatherings of family and friends around the piano to enjoy performances or sing along together with from old and up-to-date music sheets. The Canterbury would also be an elegant and practical place to also store newspapers, magazines, posters and drawings from overseas. The news from ‘home’ would be enjoyed by all. THE INSCRIPTION “Jack Morse” Morse. In 2010 Mr Jack Morse was recognised as one of the “people who have contributed to the long term development of Flagstaff Hill Maritime Village”. He was a member of the Flagstaff hill Planning board and a Current Life Member and had been awarded a Certificate of Service and the provision of an Annual Family Membership for life by Flagstaff Hill. The Morse’s family business, Morse’s Engineering, closed in 2010. It was considered “One of Warrnambool’s longest operating businesses with roots dating to 1883 with the design and manufacture of coaches and buggies, progressing to automotive repairs and later specialising in under-vehicle work” The Canterbury appears to have been handmade prior to 1860 as the dovetails are handmade and there are no saw marks on the drawer sides or back as well the sides. Also the back has small nicks indicating a hand plane or drawer knife was used rather than a saw blade to size the material. Additional indications are that the spindles are slightly different in size meaning they were handmade individually not mass produced. From these indicators the writer believes that the item was made before 1860 as machinery was only used after this date to produce furniture. As yet no individual maker can be attributed to this item, however it is a significant piece historically and is quite valuable if a known maker can be associated with the Canterbury. The item highlights a time in our social history when music played an everyday part in people’s lives as the only entertainment families could enjoy together in their own homes. A Canterbury music stand, having three compartments consisting of twenty turned spindles supporting the slat dividers. A drawer, with two turned wooden handles, is fitted below. The music stand has turnip style turned feet. The drawer front and carcass of the stand are veneered rosewood over a mahogany carcass. The underlined words "Jack Morse" are handwritten underneath the drawer bottom.Hand written inscription on underneath the drawer bottom "Jack Morse".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canterbury, music rack, magazine rack, music stand, magazine stand, 19th century furniture, occasional furniture, frederick cornwallis, jack morse, morse’s undercar, music, thomas sheraton, regency furniture, music canterbury -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Medicine Bottle, J.C. Ayer & Co, 1868-1878

The glass medicine bottle is an example of an early 20th-century medicine bottle. Moulton glass was blown into a two-piece mould and a tool with an inscription was used to stamp the base. The mouth was added after the bottle was blown. The bottle has encrustations and residue on the surface of the glass. The cargo of the Falls of Halladale included medicine. It was made by Ayer & Co. and its shape and maker's mark matches one of Ayer's early style bottles that contained J.C. Ayer's Hair Vigor, which was made from about 1868 to 1915. James C. Ayer, born in Connecticut, US in 1818, was a medicine manufacturer. His first medicine was Cherry Pectoral, for pulmonary illness. His medicine was very popular in the 1850s. Ayer died in 1878. A section of his home town Groton Junction was nameed 'Ayer' in his honour. The FALLS of HALLADALE 1886 – 1908: - The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roof tiles, barbed wire, stoves, oil, benzene, and many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. The medicine bottle is an example of medicine containers in the late 19th to early 20th century. It is also significant for its association with the historic cargo ship Falls of Halladale, wrecked in local waters in the early 20th century. The ship is listed on the Victorian Heritage Register, No. S255. It was one of the last ships to sail the Trade Routes and one of the first vessels to have fore and aft lifting bridges. The ship is an example of the design, materials and fittings of a late-19th-century sailing vessel. Its cargo represents several aspects of Victoria’s shipping trade. The wreck is now protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act 1976.Clear glass bottle with a green tinge. The bottle has a rolled applied lip, narrow mouth, slim neck, rounded shoulders and straight rectangular body and an indented base. The body has side seams and irregular thicknesses of glass. Glass has imperfections and bubbles, and one shoulder is missing. An embossed inscription is on the base. The bottle was recovered from the wreck of the Falls of Halladale. "AYER"flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, falls of halladale, iron ship, four-masted ship, sailing ship, clipper ship, windjammer, shipwreck, peterborough, 1908 shipwreck, russell & co., fore and aft lifting bridges, medicine bottle, health care, ayer, j c ayer & co., james c ayer, hair vigor, men's hair care, personal care