Showing 108 items

matching iron foundry

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water Pump, Goulds Manufacturing Co, 1915-1925

Gould manufacturing company was founded in 1848 at Seneca Falls, New York when Seabury S. Gould purchased an interest in Downs, Mynderse & Co. and the firm became Downs & Co. Wooden pumps were produced at the time in an old cotton factory building. In 1869, the name of the company was changed from Downs & Company to Goulds Manufacturing Company. Seabury S. Gould was regarded as a man of unusual vision, and as the founder of Goulds Manufacturing Company he was keen to start producing cast iron pumps. An iron pump, he believed, would overcome all the disadvantages of a wooden pump. It would be strong and efficient and provide fresh flowing water for the pioneers. He ran the company until after the American Civil War and because Goulds Manufacturing had a foundry, they also produced all kinds of cast iron products such as corn shellers, bells, sad irons, sinks, tools, and a line of fire engines. From 1848 to 1964 a Gould family member had always been President of the company. However, the company ownership in 1964 was transferred from family-owned stock to public offerings and employee ownership of stock. The subject item called the "N e w Deluge" was an improved bilge pump for vessels having not more than 25 feet depth of hold. It was also used by contractors for pumping out excavations and was well adapted for irrigation use. This hand pump was designed to be used where a hand pump of large capacity was desired. Goulds made many different types of pumps to suit differing pumping situations such as. Well Pumps, Hydraulic Rams, Diaphragm Pumps, Tank Pumps, Sprayers and Small Capacity Power rumps. Goulds Triplex, Centrifugal, Rotary and Deep Well Power Pumps The subject item was first introduced to the market in the Goulds catalogue of 1915 and became a very popular pump used in Australia and the USA. It is manufactured by a company still trading today with offices in Australia and many other countries.Hand Pump cast iron with long reversable pumping lever and cylindrical casing there are 4 metal holes for fastening to floor surface. Painted black. Embossed "NEW DELUGE" "- - -" and "No 16" or "No 18".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pump, hand pump, goulds manufacturing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Carronade

This deck cannon is believed to be a replica Carronade as it has no foundry mark, year of manufacture, proof marks or weight of carronade on it. However, its design matches the design of Carronades used in the early to mid 19th century. History: The carronade was designed as a short-range naval weapon with a low muzzle velocity for merchant ships, but it also found a niche role on warships. It was produced by the Carron iron works and was at first sold as a complete system with the gun, mounting, and shot altogether. Carronades initially became popular on British merchant ships during the American Revolutionary War. A lightweight gun that needed only a small gun crew and was devastating at short range was well suited to defending merchant ships against French and American privateers. Its invention is variously attributed to Lieutenant General Robert Melville in 1759, or to Charles Gascoigne, manager of the Carron Company from 1769 to 1779. In its early years, the weapon was sometimes called a "mellvinade" or a "gasconade". The carronade can be seen as the culmination of a development of naval guns reducing the barrel length and thereby the gunpowder charge. The Carron Company was already selling a "new light-constructed" gun, two-thirds of the weight of the standard naval gun and charged with one-sixth of the weight of the ball in powder before it introduced the carronade, which further halved the gunpowder charge. The theory of its design was to use less powder and had other advantages that were advertised in the company's sales pamphlet of the time, state. The smaller gunpowder charge reduced the barrel heating in action, also reduced the recoil. The mounting, attached to the side of the ship on a pivot, took the recoil on a slider, without altering the alignment of the gun. The pamphlet advocated the use of woolen cartridges, which eliminated the need for wadding and worming, although they were more expensive. Carronades also simplified gunnery for comparatively untrained merchant seamen in both aiming and reloading that was part of the rationale for adopting the gun. Other advantages promoted by the company were. The replacement of trunnions by a bolt underneath, to connect the gun to the mounting, reduced the width of the carriage that enhanced the wide angle of fire. A merchant ship would almost always be running away from an enemy, so a wide-angle of fire was much more important than on a warship. A carronade weighed a quarter as much as a standard cannon and used a quarter to a third of the gunpowder charge. This reduced charge allowed Carronades to have a shorter length and much lighter weight than long guns. Increasing the size of the bore and ball reduces the required length of the barrel. The force acting on the ball is proportional to the square of the diameter, while the mass of the ball rises by the cube, so acceleration is slower; thus, the barrel can be shorter and therefore lighter. Long guns were also much heavier than Carronades because they were over-specified to be capable of being double-shotted,(to load cannons with twice the shot, for increased damage at the expense of range). Whereas it was dangerous to do this in a carronade. A ship could carry more carronades, or carronades of a larger caliber, than long guns, and carronades could be mounted on the upper decks, where heavy long guns could cause the ship to be top-heavy and unstable. Carronades also required a smaller gun crew, which was very important for merchant ships, and they were faster to reload. Additional notes: Cannon cast in England, Wales and Scotland had their imperial weight chiselled or engraved in the format of 4-2-0 on the bottom of the cascabel, indicating the weight of the cannon as 4 hundredweight, 2 quarters and 0 pounds. Since a hundredweight equals 112 pounds and a quarter weight is 28 pounds the total weight is 504 pounds or about 228 kilograms. The small bore replica carronade and carriage is part of a collection of nineteenth Century Flagstaff Hill Guns and cannons, and is a representation of carronades used from the early 18th up to the 1850s on merchant and military ships particularly the British Royal Navy until 1850. This example is not significant in the historic sense but demonstrates the type of artillery used aboard vessels of the time for protection & offensive military actions. Cannon, cast iron, small smooth bore cannon on the stepped wooden carriage with wooden wheels. It appears to fire a 12-pound cannonball. The Cannon barrel can have its elevation adjusted via a sliding sloped block at the rear of the cannon. Gun carriage has loops for locating and holding the carriage in position with the use of ropes. It is believed this carronade is a replica of a mid-to-late 19th-century Carronade cannon.Cast into metal; [Royal emblem of Queen Victoria (VR "Victoria Regina")]warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannon, naval cannon, cannon on carriage, 19th century cannon, fortifications, smooth bore cannon, 12 pounder, carronade, artillery, replica, deck cannon, cannon in carriage, ship cannon -

Federation University Historical Collection

Federation University Historical CollectionPhotograph (colour), Lisa Gervasoni, Cowley's Eureka Ironworks name plate, 2007

... Cowley's cowley's eureka iron works eureka ironworks foundry Colour ...Colour photograph of a Cowley's Eureka Ironworks name plate.cowley's, cowley's eureka iron works, eureka ironworks, foundry -

Federation University Historical Collection

Federation University Historical CollectionPhotograph Album, Ballarat College of Advanced Education Faculty of Science Photo Album, c1987

Maroon photograph album with photographs thought to be Ballarat College of Advanced Education Science students and staff. Includes a photograph of the Lal Lal Ironworks kiln in the early 1970s.ballarat college of advanced education t-shirt, bbq, ray martin, brian sunter, laboratory, mineral industry laboratory, mount helen, bill vermeend, frank hurley, jim thyer, barry shearer, lyn robert, frank martin, colin kline, alan ballard, roger johnson, david james, ian mckee, robert pyke, bushnell, judy dixon, dennis else, john murray, peter dahlhaus, kim dowling, richard macewan, aziz albazazz, susanne hynes, stafford mcknight, bob smith, paul bennett, athol shelton, peter richards, geoff brooks, computers, snow, snowman, bruce cameron, iron monarch, mining, lal lal iron mine, ginny goff, ausimm scholarship, diane haddon, david martin, glenn kreelman, sunter's, clarendon, anne beggs sunter, foundry, stawell, brian sunter's farewell, jack harvey, microscope, metallurgy -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Set of Oval iron boilers, Cauldron, T & C Clark Co

Oval iron boiler with lid and handle, capacity four gallons (15 litres). Made by T. & C. Clark & Co., Wolverhampton, England. T. & C. Clark & Company Limited was founded in 1795 by Thomas and Charles Clark. Based at Shakespeare Foundry, Wolverhampton, it became one of the largest foundries in the area.These cooking pots were used by the local pioneers to cook their meals over an open fire. The flames from the fire turned the pots black.Oval iron boilers with lid and handle of various capacity : 2½ gallon, 3 gallon, 5 gallon and 6 gallon. Made by T. & C. Clark & Co., Wolverhampton, England. T. & C. Clark & Company Limited was founded in 1795 by Thomas and Charles Clark. Based at Shakespeare Foundry, Wolverhampton, it became one of the largest foundries in the area.T. and C. Clark with their makers markcooking, iron pots, moorabbin pioneers, cast iron, t & c clark & company -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Furphy Water Cart, J. Furphy & Sons, c. 1942

This horse-drawn, two-wheeled cart with a tank, is known as a Furphy Farm Water Cart that was made in Shepparton, northern Victoria, c. 1942. John Furphy (1842-1920) was born in Moonee Ponds, in 1842 to Irish immigrant parents and subsequently raised in the Yarra Valley before the family moved to Kyneton in central Victoria, where he completed an apprenticeship with the firm Hutcheson and Walker. Murphy began operations of his own at a site on Piper Street in Kyneton in 1864. He relocated for a business opportunity and founded the first blacksmiths and wheelwrights shop in the newly surveyed town of Shepparton in 1873. Furphy invented many farming tools and machines including a patented grain-stripper, and won awards at the 1888-89 Melbourne International Exhibition. His most famous invention is the Furphy Farm Water Cart, designed in the 1880s, at a time when water for most households and farms was carted on wagons in wooden barrels. The Furphy’s water cart is a single item that combines a water metal tank and a cart. The design of the cart was simple yet effective, and became popular very quickly and established itself as a vital piece of farming equipment. The water cart has had a number of words cast into its ends over many years. References to the foundry’s location in Shepparton, as well as advertising of other products also manufactured by J. Furphy & Sons were present on the ends. However, the most significant set of words to feature on the tank, was a poem encouraging continual improvement: ‘Good Better Best, Never Let it Rest, Until your Good is Better, And your Better Best’. During The Great War (1914-1918), the water cart was used by the Australian militarily at a large AIF (Australian Imperial Force) camp in Broadmeadows (Melbourne) where thousands of men were camped for months, before being transported aboard. Furphy Water Carts provided water to the troops, and were usually placed near the camp latrines, which was one of the few places the troops could share gossip and tall tales away from the prying eyes and ears of their officers. The water cart drivers were also notorious sources of information, despite most of their news being hearsay, or totally unreliable. By the time the men of the AIF were in engaged in combat on the Gallipoli Peninsula and the Western Front, the carts used for water supply had no markings and became simply referred to as Furphys. This owed as much to the coining of the term ‘Furphy’, Australian slang for suspect information or rumour. After a number of decades as principally a soldier’s word, 'Furphy' entered the broader Australian vernacular and was used mainly by the political class until recently when the term was taken up by a Australian brewer as a beer brand. This Furphy Water Cart was purchased by Friends of Flagstaff Hill in 2014. The support of local individuals, organisations and businesses enabled its restoration and later its installation alongside the existing late-19th century water pipe stand and 1940s hand pump The Furphy Farm Water Cart is of historical significance as it represents a famous Australian time-saving and energy-saving invention of the 1880s, replacing the labour intensive activity of collecting and dispensing water from barrels and casks on the back of carts. The water cart’s connection with manufacturing companies J. Furphy & Sons and Furphy Foundry are significant for being early Australian businesses that are still in operation today. Furphy carts are of military significance for the role they played during The Great War (1914-1918) in Australian army camps, and theatres of war in Europe and the Middle East, to supply the AIF troops with fresh water. A wooden framed, two-wheeled, horse-drawn cart, fitted with a horizontally mounted, cylindrical metal tank. The tank is made of rolled, sheet steel with a riveted seam, and cast iron ends with cast iron ends. The spoked metal wheels have fitted flat iron tyres and metal hubs. A metal pipe is joined to the outlet. The tank is silver coloured, the ends, wheels and trims are crimson, and the script lettering on tank sides is black. There are inscriptions on the tank, ends, and hubs. The water tank was made in 1942 in Shepparton, Australia, by J. Furphy & Sons and has a capacity of 180 gallons (848 litres). Hub perimeter, embossed “J. FURPHY & SONS” “KEEP THE / BOLTS TIGHT” Hub centre embossed [indecipherable] Tank, each side, painted “J. FURPHY & SONS / Makers / SHEPPARTON” Tank ends, embossed – “FURPHY’S FARM WATER CART” “BORN ABOUT 1880 – STILL ‘GOING STRONG’ 1942” “j. FURPHY & SONS / MAKERS / SHEPPARTON - VIC “ “S - - - - - L MANUFACTURERS” [SPECIAL] “SPIKE ROLLERS” “SINGLE TREES” “PLOUGH WHEELS” “IRON CASTINGS” “LAND GRADERS” “STEEL DELVERS” “CAST IRON PIG” “CHAIN YOKES” “GOOD – BETTER – BEST / NEVER LET IT REST / TILL YOUR GOOD IS BETTER / AND YOUR BETTER – BEST” Image [Stork carrying a baby] above shorthand, transcribed "Produce and populate or perish" Image [Furphy Pig Feeder] beside ‘Cast Iron Pig’ Shorthand, transcribed “"Water is the gift of God but beer and whiskey are concoctions of the Devil, come and have a drink of water"warrnambool, flagstaff hill maritime museum, water cart, furphy cart, furphy tank, furphy farm water cart, furphy, john furphy, john furphy & sons, furphy foundry, kyneton, shepparton, mobile water tank, jinker, hutchinson & walker, blacksmith, farm equipment, implement maker, tool maker, horse drawn, stork and baby, good, better, best, barrel, tank, first world war, wwi, eastern front, gallipoli, j furphy & sons -

Bendigo Historical Society Inc.

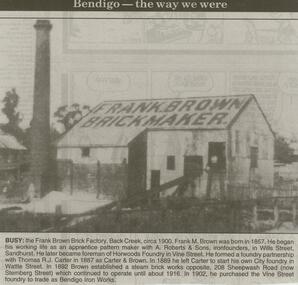

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: BUSY

Bendigo Advertiser '' The way we were'' from 2000. Busy: the Frank Brown Brick factory, Back Creek, circa 1900. Frank M. Brown was born in 1857. He began his working life as an apprentice pattern maker with A. Roberts & Sons, iron founders, in Wills Street, Sandhurst. He later became foreman of Horwoods Foundry in Vine Street. He formed a foundry partnership with Thomas R.J. Carter in 1887 as Carter & Brown. In 1889 he left Carter to start his own City foundry in Wattle Street. In 1892 Brown established a steam brick works opposite 208 Sheepwash Road (now Sternberg Street) which continued to operate until about 1916. In 1902 he purchased the Vine Street foundry to trade as Bendigo Iron Works. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HORSE AND CART PROCESSION

Sepia image mounted on board: image shows large procession of horse drawn vehicles, line of jinkers, carriages, etc. disappears into background, with bicycle riders alongside. Men are mostly wearing three piece suits, hats, and women wearing long dresses, seated in carriage. Procession is lined up outside buildings. Timber buildings with iron roof. Written on sign ' Roberts & Sons. Indistinct, behind trees' Roberts & Sons operated a foundry in Wills Street, Bendigo. Roberts & Sons, picnic, 1896. (Source: Bendigo Trust Collection)'Robevent, recreation, picnic, bendigo, procession, roberts & sons, foundry, wills street. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CONSERVATORY, c.1910

Sepia photograph of Conservatory Building and Gardens with statues, Pall Mall Bendigo. Written on back in pencil 'Conservatory Pall Mall Bendigo'. Inscriptions: on front, below image printed 'Conservatory, Bendigo'. History of object : James Lerk, 2000 'Conservatory gardens, Pall Mall. Venus in the foreground has now been moved to the northern end of the Conservatory building. The cast iron frame of the Conservatory was cast at Brown's Foundry. The building was opened in 1898. Photo c.1910' Photograph Bendigo Advertiser 11.1.2001.buildings, conservatory -

Bendigo Historical Society Inc.

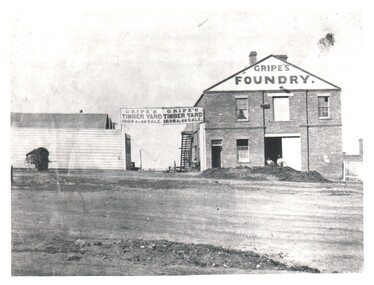

Bendigo Historical Society Inc.Photograph - GRIPES FOUNDRY, 1861

... . In image ' Gripes Foundry' 'Gripes Timber yard, iron & c on sale'..., iron & c on sale' Photograph GRIPES FOUNDRY ...black and white photo: 2 storey brick building on right. Large central double door ground floor. Door in first storey with beam for raising materials. 2 windows first storey, one on each side of door. Small door and small window on lhs ground floor. Gripes Foundry on gable steps on side to top storey. Entrance gate centre of photo. Double inscription ' Gripes Timber Yard Iron & on sale over gate. Single storey building on left. 2 males in front. Batchelder cart left hand side. In image ' Gripes Foundry' 'Gripes Timber yard, iron & c on sale'batchelderorganization, business, gripes foundry -

Bendigo Historical Society Inc.

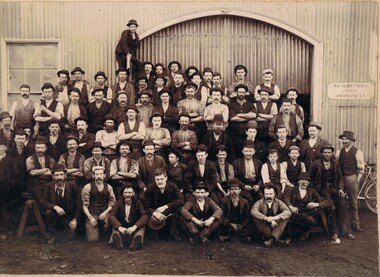

Bendigo Historical Society Inc.Photograph - GROUP OF SIXTY FOUR MEN (FOUNDRY WORKERS?)

Black and white photograph, mounted on brown board. Group of sixty four men in six rows, with one young man standing, straddled over a post, above the rest of the group. One Aborigine? On the RH side of picture. They are a work group of blue collar workers. All have hats or caps of various kinds. Standing in front of an iron wall with a doorway and one window. Eight have pipes, most are mature men but there are some young boys (apprentices?). Inscriptions: in image - sign of RH side of doorway 'no admittance except on business'. On back - stamp 'WH Robinson, Photographer, Bendigo. Handwritten 'cannot identify', '?foundry staff?'.WH Robinsonperson, group, male group of workers -

Bendigo Historical Society Inc.

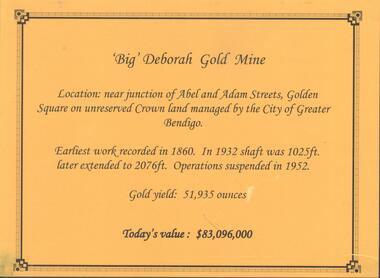

Bendigo Historical Society Inc.Photograph - DEBORAH GOLD MINE, GOLDEN SQUARE

Information display card regarding the 'Big' Deborah Gold Mine, located near the junction of Abel and Adam Street, Golden Square. Earliest work recorded 1860. Shaft 2076 feet. Operations suspended in 1952. Gold yield 51,935 ounces. Battery shed still on site containing a 5 head stamper which was originally a 20 head stamper. The battery was manufactured by Horwood's Foundry, Bendigo. Photos of mine site taken in 2012: a.Engine room concrete footings, iron work visible. Pepper corn trees in background. Pampas grass in foreground. Steel mesh fence on RH side, enclosing the poppet head site. b. Concrete footings, peppercorn tree in background. c. Corrugated iron shed constructed over the stampers. Steel mesh front. d. Steel poppet head, no winding wheel at top. Pampas grass in foreground. e.. Stamper shed and steel poppet legs in background enclosing dilapidated wooden poppet head legs. f. Close up image of weights in stamper room g.Winding wheel on stampers h.Looking upwards to top of stampersbendigo, mining, deborah gold mine -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - VICTORIAS IRON LACEWORK PART B

... -Decoration-Foundries Robin Vowels Victorias Iron Lacework Part B ...Victorias Iron Lacework Part B ''The Founders'' includes historical information about the foundries and founders who left us with the great legacy of decorative ironwork. Illustrations of the designs registered in Victoria, and some unregistered designs, are included. 408 pages enclosed in a hard cover with black and white & some coloured photographs. Limited edition of 100 copies, copy number 40.Robin Vowelsbuildings, fittings & materials, iron lace, history-buildings-decoration-foundries -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - VICTORIAS IRON LACEWORK

Victoria's Iron Lacework, includes historical information about the foundries and founders who left us with the great legacy of decorative ironwork. Illustrations of the designs registered in Victoria, and some unregistered designs, are included. 320 pages enclosed in a hard cover with black and white & some coloured photographs. Limited edition of 100 copies. Copy number 40.Robin A Vowelsbuildings, fittings & materials, iron lace, history-buildings-decoration-foundries -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Bay Street, Sandridge, 1870s

Photographed in 1872 by William PATERSON as one of a series for the Melbourne Exhibition of 1873; original mount hanging in Engineering Department at Port Melbourne Town Hall at 19-9-1994 but now in Port Phillip,City Collection. This set of original prints belonged to Town Clerk Syd ANDERSON, then to his daughter-in-law Phyllis ANDERSON (donor). Accompanied by list of captions, both hand written and typed (the latter a partial listing).View southeast in Bay Street from roof of building on north west corner of Bay and Liardet Streets c1871. Includes hotel identified in caption as "Foundry" on opposite corner (if captions were written in the 1920s the Port Theatre had already been constructed at this site, but there once was a 'Foundry' Hotel on that corner*); ginger beer/lemonade factory (Dawborns?) and pawnbroker; Graham Family Hotel can be seen in the distance at far left; also Holy Trinity (iron, with tower), Victorian Sugar Works, Post Office/Mail Exchange. Pre 1873 * '...try Hotel' visible?"P. Anderson" ink, on back:"11" in ballpoint on upper left face of photoindustry - manufacturing, business and traders - pawnbrokers, sydney sims anderson, town clerks, bay street, liardet street, foundry hotel, business and traders - hotels -

Bendigo Historical Society Inc.

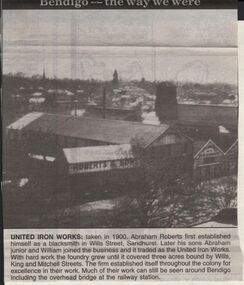

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: UNITED IRON WORKS

Bendigo Advertiser "The way we were" from 1999. United iron works: taken in 1900. Abraham Roberts first established himself as a blacksmith in Wills Street, Sandhurst. Later his sons Abraham junior and William joined the business and it traded as the United Iron Works. With hard work the foundry grew until it covered three acres bound by Wills , King and Mitchell Streets. The firm established itself throughout the colony for excellence in their work. Much of their work can still be seen around Bendigo including the overhead bridge at the railway station.newspaper, bendigo advertiser, the way we were -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - WES HARRY COLLECTION: GRIPES FOUNDRY, 1860's

Photograph of a two storied brick factory with the words ' Gripes Foundry' painted below the gable. To the left of this building is a wide gateway and a single story wooden building with an iron roof. Above the gateway there is a large sign with ' Gripes Timber yard Iron &c on sale ' painted twice. There are two workmen standing in the doorway of the foundry and a large pile of earth in front of them. A picket fence can be seen running off to the right of the foundry Building.Batchelderbuildings, commercial, gripes foundry, gripes foundry, gripes timber yard, batchelder -

Bendigo Historical Society Inc.

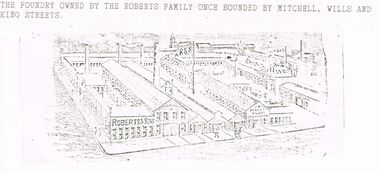

Bendigo Historical Society Inc.Document - CORNISH COLLECTION: DOCUMENTS RELATED TO VARIOUS CORNISH ENTERPRISES IN BENDIGO

Documents and copies of photos related to various Cornish enterprises in Bendigo: a. Line drawing (faint) of foundry owned by the Roberts family (Mitchell, Wills and King streets); b. copy of article from unknown source re United Iron Works with details of the firm and Roberts principals - William Roberts, Abraham Roberts and Arthur Roberts - with copies of photographic portraits (Bartlett Bros.) - bad copy with LH side of text partly illegible; c. copy of article titled 'Goyne's Battery Gratings re John Goyne and history of the business (submitted by person living at ''Rosemundy'', Goynes Road, Epsom - Goyne's home then on 20 acres); d. Photograph of old Robinson photo of Bendigo Stamper Grating Factory, Epsom and five men posed in front of large timber building (badly cut photo with LH edge missing. original photo (9 x 13) of ''Former Bendigo Cornish Fuse Factory'' (handwritten inscription on reverse) taken in recent times (hint - car in driveway); f. copy from un-named book of J Nankervis's Ham and Bacon Curing Factory, Golden Square - drawing of the establishment and a photos of winning display of small goods at the Bendigo Show (no date); g. copy from un-named book of photo of premises of A J Williams, Lily and McKenzie Streets - wooden structure with sign indicating Hardware Merchants and ??Mines Furnisher?? , showing three horse-driven small wagons (delivery?); h. copy of photo of Cornish store(1880s) at White Hills - mention of Frederick Stuckenschmidt (married Miss Mary Smith), William Mathews (original owner?) - corner brick building with family posed outside alongside horse and light cart;. reproduction of exhibit in Bendigo Spring Show, 1915 , the ''Made in Bendigo Exhibition'' - first prize awarded to Messrs H M Legg & Co. Progress Jams, preserves, tomato sauce, tomatoes products, candied peels etc. (folded and small tear).bendigo, buildings, early bendigo businesses, bendigo stamper grating factory. epsom. j. nankervic ham and bacon curing establishment. golden square. bendigo cornish fuse factory. cornish stores. messrs h. m. leggo and co. abraham roberts. arthur roberts. william roberts. goyne's battery gratings. -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Clunes Museum

Clunes MuseumTool - BLACKSMITH TOOL

CAST IRON BLACKSMITH TONGS USED IN FOUNDRY FOR HOLDING ITEMS BEING MADEblacksmith tool, blacksmith tongs, cast iron -

Stawell Historical Society Inc

Stawell Historical Society IncRealia, T Barker, Oven Doors, c. 1920

Thomas Barker was a large Ironmonger in Stawell Upper Main Street. up to the 1960'sCast Iron Oven Doors branded T Baker Stawell / Leader made of HeavyCast Iron with cast Hand on the HandlesT Barker Stawell / Leadermanufacture, business, foundry, hardware -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Colour, Umbrella Stand by Phoenix Foundry in the Ballarat Town Hall, 2017, 15/09/2017

... Office goldfields ballarat town hall phoenix foundry cast iron ...Photograph of a cast iron umbrella stand made by the Phoenix Foundry.ballarat town hall, phoenix foundry, cast iron, umbrella stand -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph, Redesdale Bridge, 2016, 18/01/2016

The Redesdale Bridge is a wrought iron and timber structure with bluestone abutments which was installed over the Campaspe River in January 1868, although the bridge actually bears the date 1867. In 1859, the "Herald of the Morning", a ship carrying a cargo including 350 tons of ironwork for the Hawthorn bridge, caught fire and was scuttled a quarter of a mile off the jetty at Sandridge. A Melbourne salvaging firm raised the ironwork from the bottom of the bay, but after details of an arranged sale to the government caused a scandal in Parliament, the material was sold privately to the Melbourne foundry Langlands & Co. Two hundred tons of it was sold to the goldfields shires of McIvor and Metcalfe for only £1000. The bridge was designed by engineer T.B. Muntz and built by a contractor named Doran, and was completed late and considerably over budget at £6274. The bridge spans 45.7m across the river and has two roadways which are carried between three metal lattice girders in a through truss configuration. The design for the Hawthorn bridge had the deck supported over the trusses, and to stiffen the through truss configuration three sets of distinctive paired arches connect the trusses above the roadways. The roadway decking is constructed of longitudinally placed timbers on timber cross girders which rest on the lower chords of the trusses. (Heritage Victoria) A number of colour photographs showing the historic bridge at Metcalfe.metcalfe, shire of metcalfe, bridge, municipal boundary, shire of mcivor, redesdale bridge, campaspe river, t.b. muntz, doran -

Hume City Civic Collection

Hume City Civic CollectionPhotograph, St. Andrews Uniting Church gates, 8th September 2001

These are the original wrought iron gates which served as the entrance to St. Andrews Uniting Church, formerly St.Andrews Presbyterian Church. They were erected there in 1922 and were made at H.V.McKay's Sunshine Harvester foundry, at Sunshine. H.V McKay was a member of the Presbyterian Church in Sunbury. Originally the gates opened onto Stawell Street, which ran at an angle between O'Shanassy and Barkly Streets. Apart from a small area leading to the Memorial Hall the rest of Stawell Street has been incorporated in the Village Green in Sunbury.The gates were restored and erected on their original site in 2000. A scanned coloured photograph of white painted wrought iron double gates with two smaller gates on either side and supported by stone pillars. A church building is just beyond a grassed area.st. andrews church, st. andrew's uniting church, wrought iron gates -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Golden City Implements Foundry, Ironbark, Bendigo, 1960-1980s

This foundry had been a landmark in Mt Korong Road for many years. It began with an Osborne and Mitchell. After 1914 when mining declined, it became the Golden City Implement boundary and the name can still be seen painted on on the façade which faces the intersection of Marong Road (Calder highway) and Eaglehawk Road. The interior is a mass of used and un-used machinery scattered amongst modern lathes and more modern apparatus. The yard was a fascinating graveyard of past times, with old mining and agricultural scrap everywhere mixed up with coke and slag from the smelting sheds at the rear. A feature of the foundry was the manufacturer of cast iron lace. National Trust Survey Data Sheet and article from the Bendigo Advertiser November 4th 1981. Osbornes Ironbark Foundryhistory, national trust bendigo collection, bendigo, foundary, iron bark bendigo -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - 247 View St, Bendigo

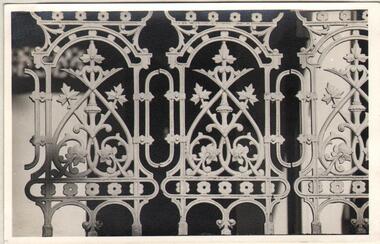

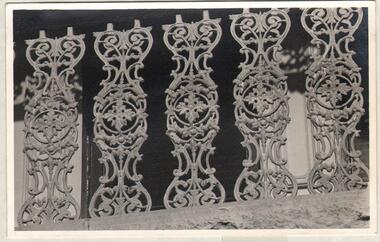

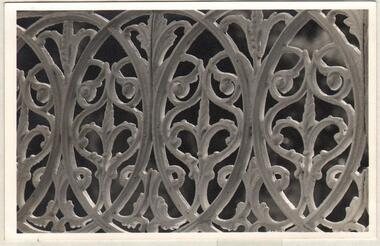

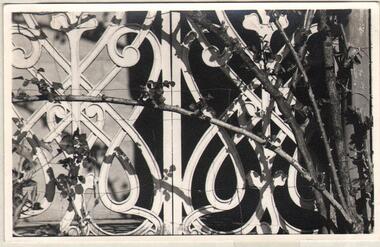

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore was melted in a blast furnace, mixed with alloys and then poured into molds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of the building at 247 View St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - 257 View St, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of the building at 257 View St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - 22 Valentine St, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into molds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of the building at 22 Valentine St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - 288 View St, Bendigo

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron",iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon. A black and white photograph by Alan Doney of 288 View St in Bendigo. The photo shows detail of the wrought iron on the fence. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - 159 Forest St, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of 159 Forest St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron