Showing 1575 items matching "johnson"

-

Bendigo Military Museum

Bendigo Military MuseumPhotograph - Johnson Ground Elevation Meter (JGEM) Survey Vehicle - Army Survey Regiment, Fortuna, Bendigo, c1960s

This is a set of 16 photograph of the Royal Australian Survey Corps’ Johnson Ground Elevation Meter (JGEM) Survey Vehicle taken at the Army Survey Regiment, Fortuna, Bendigo. The JGEM vehicle was extensively used by RA Svy within Australia from the late 1960s. A limited number of Ground Elevation Meter (GEM) station wagon type vehicles were manufactured by General Motors Corporation (GMC) in the USA for the United States Geological Survey, Canada’s mapping agencies, RA Svy and National Mapping (Natmap). The GEM was a four-wheel drive, four-wheel steer vehicle. Four-wheel steering was necessary to avoid systematic errors caused by non-tracking of front and rear wheels on conventionally steered vehicles. The manufacturer substituted the rear axle with a front axle and connected them to form the four-wheel steering mechanism. The two Australian GEM vehicles, referred to as Johnson GEMs (JGEMs) were converted into right-hand drive. After delivery in 1964, acceptance Natmap and RA Svy testing and operator training was undertaken at the Army's School of Military Survey located at Balcombe, Victoria. A small fifth wheel was mounted on a cantilever arm suspension midway between the front and rear wheels on the right side of the vehicle. It was lowered to and raised from its operating position by use of a constant pressure air cylinder. A telescopic bar, suspended between the front and rear axles, provided the reference datum for the angle measurement. The wheel provided the velocity or distance signal through a pulse generator system. A sensitive pendulum mounted on this bar provided the angle measurement for each minute distance traversed. The JGEM contained electromechanical instruments used to determine relative elevations, by trigonometric principles, along a traversed path. These relative elevations were obtained through apparatus which measures the instantaneous angle of inclination of the road and the instantaneous velocity of the meter along such a path. Road routes over which the JGEM operated were planned so that each started and ended as near as practicable to an existing point of known elevation (formally referred to as a level traverse bench mark). The difference in height from the bench mark and the road surface alongside the JGEM’s fifth wheel was measured with a level and staff. Along each route, mapping control photo reference points where new elevation values were required were identified on aerial photographs. Under favourable conditions it was possible to survey as much as 160km in an ordinary working day. The first of RA Svy’s JGEM operations was undertaken in 1:250,000 scale map areas of Queensland. CPL John Hook was the JGEM’s main operator in the early 1970s undertaking operations covering 1:250,000 scale map blocks over northern Victoria and central NSW, each requiring 36 points (9 runs of photography and 4 points across. SPR Lyn Thompson and SPR Bob McDonagh teamed with CPL Hook on some of these JGEM operations. When RA Svy was integrated into the Royal Australian Engineers in 1996, the JGEM vehicle with the Survey Corps collection was donated to its museum. It is believed to be the last of the original manufactured fleet in existence. The JGEM has undergone extensive refurbishment to achieve roadworthiness and is currently housed at The Australian Army Museum of Military Engineering, Hoslworthy Barracks, NSW. It can be viewed by making an appointment with the museum’s curator.This is a set of 16 photograph of the Royal Australian Survey Corps’ Johnson Ground Elevation Meter (JGEM) Survey Vehicle taken at the Army Survey Regiment, Fortuna, Bendigo. The photographs were on 35mm slide film and were scanned at 96 dpi. They are part of the Army Survey Regiment’s Collection. .1) - Photo, colour, c1960s, Johnson Ground Elevation Meter (JGEM) Survey Vehicle .2) - Photo, colour, c1960s, JGEM instrumentation, on-board computer. .3) - Photo, colour, c1960s, JGEM instrumentation. .4) - Photo, colour, c1960s, JGEM instrumentation, on-board computer. .5) - Photo, colour, c1960s, JGEM tyre pressure controller .6) - Photo, colour, c1960s, JGEM rear doors, SGT Geoff Briggs. .7) - Photo, colour, c1960s, JGEM 5th wheel distance/angle measurement device in lowered position, SGT Geoff Briggs. .8) - Photo, colour, c1960s, JGEM 5th wheel distance/angle measurement device in lowered position. .9) & .10) - Photo, colour, c1960s, JGEM tyre pressure system, SGT Geoff Briggs. .11) - Photo, colour, c1960s, JGEM tyre pressure system. SGT Geoff Briggs. .12) - Photo, colour, c1960s, JGEM levelling scope, levelling staff, unidentified technicians. .13) & .14) - Photo, colour, c1960s, JGEM levelling scope, unidentified technician. .15) & .16) - Photo, colour, c1960s, probably survey operation adjusted height plotted on block base sheet. .1P to .16P - Some of the equipment is annotated on the frame of the 35mm slides.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, surveying -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Johnson family boys with Dexter, Dave, James, Mr Humble, Leslie & Edwin

Group of men. The Johnson Boys taken in Perth WA 1965. L/R Dexter. Dave. James. Mr Humble. Leslie and Edwin.stawell -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Letter, Ballarat Junior Technical School: Application for Leave - Ben Alexander Johnson, 1961

An application for leave submitted by Ben Johnson, teacher at BJTS, to attend the Tenth Annual Conference of the Australian Science Teachers' Association to be held in Adelaide over five days.1 page, typed.ballarat junior technical school, 1961, ben alexander johnson, application for leave, annual conference, australian science teachers, adelaide -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Letter, Ballarat Junior Technical School: Report on progress of Michael Johnson, 1952

School Report on student Michael Johnson. Settled well from England in 1951. Coping with Form 2 work. Promotion to Form 3 probable. Good character.Cream paper, typed ballarat junior technical school, head master, l garner, michael johnson, moved from england, form 2, adjusted to new school -

Narre Warren and District Family History Group

Narre Warren and District Family History GroupBook, Keith Lynden Brown, Seeds of time. The John and Stephen Johnson families in Victoria : an introduction to John and Sarah Johnson and Stephen and Mary Ann Johnson and their descendants / Book 1, 1997

This family history is an introduction to William and Hannah Johnson and to the Huntingdonshire in which they and their children lived; to their children, John and Stephen Johnson, their fortunes in Victoria, and their immediate descendants.non-fictionThis family history is an introduction to William and Hannah Johnson and to the Huntingdonshire in which they and their children lived; to their children, John and Stephen Johnson, their fortunes in Victoria, and their immediate descendants.john johnson, stephen johnson, huntingdonshire -

Orbost & District Historical Society

Orbost & District Historical Societybook, Johnson, Brenda, The Orbost Story 1959 to 1966, after 2000

This story was written by Brenda Johnson and details her time in Orbost from 1959 -1966 settling on land at Lake Road in Newmerella.This book is a useful and interesting reference tool on life in Newmerella in the mid 20th century.A thin stapled paperback book of 31 pp. It is titled "The Orbost Story 1959 to 1966 Lake Road Newmerella Victoria". The cover is shiny silver with black print. In the centre is a black/white photograph of the block with numbers ( 2 3 ?) carved into a tree. There is a Land Rover in the background.Stapled inside back cover - "Bob Johnson" with telephone details and email address.newmerella-history johnson-brenda rural farming -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

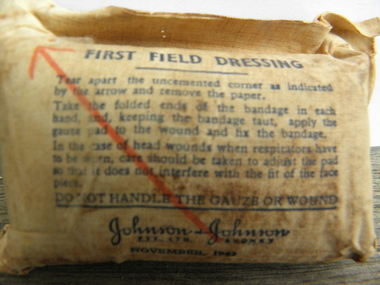

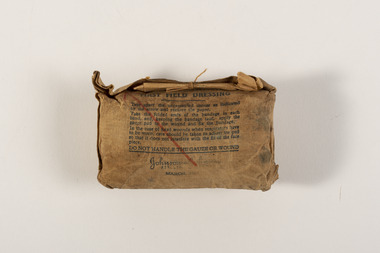

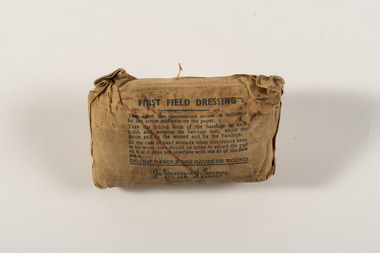

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomFirst Field Dressing, October 1942

Used by the thousands in World War 2. And, on issue long after the war.Cotton outer cover, secured by a thread. 2 x inner water proof covers each containing a dressing. Dressings consist of gauze pad stitched to a bandage, and a safety pin Johnson & Johnson Pty Ltd Sydney October 1942 Instructions for usefield dressing -

Geelong RSL Sub Branch

Geelong RSL Sub BranchFirst Field Dressing, Johnson & Johnson Pty Ltd, 1942

This First Field Bandage is dated 1942 and is thought to have been carried by a member of the Military Forces during WW2.This First Field Dressing is Original it appears to have been carried by a member of the Military during WW2.An oblong shaped gauze bandage in a cotton cover (First Field Dressing), the outer cover is well worn buff colour.The Dressing was made by Johnson and Johnson Pty Ltd Sydney November 1942.first field dressing, ww2, 1942 -

St Kilda Historical Society

St Kilda Historical SocietyPhotograph, Peter Johnson

Peter Johnson was President of St Kilda Historical Society 2010-2015. The photograph was taken during a survey of St Kilda Park Primary School Tower, Fitzroy Street, St Kilda on 27/11/2001Colour photograph, unmountedst kilda park primary school, peter johnson, schools, st kilda historical society, skhs -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumTalc powder container, 1990's

Plastic square container with round lid. The lid twists and has holes to dispense the talc powder. Contains 100g net. On the back is printed a barcode with directions for use, caution alerts and ingredients. Customer service free call, information. Trademark J&J 1993Johnsons Baby (clinically proven mildness) powder, Johnson and Johnson 100g net. J&J on lid. On base ACI 316 1 Recycle symbol 2. -

Ithacan Historical Society

Ithacan Historical SocietyPhotograph, Nakis Raftopoulos in the fruit shop, 1937

In the photograph a young Nakis Raftopoulos is arranging the fruit display in his father's (Spiro Raftopoulos) shop which was at 250 Johnson Street in Abbotsford. Many Ithacan Greeks who settled in Melbourne opened businesses as it was difficult for non-British immigrants to secure employment in the early years when Ithacans first started arrive. The business were mostly associated with food vending, either cafes, restaurants, oyster bars and sea food shops, or fruit shops, stalls or barrows. They ventured into the food vending business because it was an area the had skills in. Also some of these business didn't require enormous initial capital outlay and provided a springboard for entrepreneurial Ithacans to progress to larger scale businesses. The ownership of businesses by Ithacans assisted the development of chain migration with Ithacan business owners providing employment to relatives who wished to emigrate to Melbourne. A black and white photograph of a young man in a fruit shop. he is arranging apples in a display behind a counter. The photograph has been reproduced and is mounted on board. -

Vision Australia

Vision AustraliaAward - Object, Alex Johnson Memorial medal awarded to Hugh Jeffrey, 1972

This is a coin shaped gold coloured medal sitting upright on top of a small plastic pedestal. On the front the coin contains representations of leaves, and a white cane across the top. Around the sides is an inscription: ' Alex Johnson Memorial Medal for devoted service to the blind' and across the bottom 'Blind Workers Union of Victoria'. On the back is inscribed in signature style ' Hugh H Jeffrey' 1972' inside a circle of leaves. 1 coin shaped medal on pedestalawards, hugh jeffrey -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - G. Awburn Caterer Wodonga Plate

Mr George Awburn Jr. arrived in Wodonga West with his parents by bullock dray when he was aged six years old. As a young man he went to Melbourne where he worked with the Melbourne Tramway and Omnibus Company. He drove the first through tram from Abbotsford to Balaclava. On he return to Wodonga, Mr. Awburn opened a bakery and grocery business in Sydney St., Wodonga which he conducted up till the time of his death in 1946. He was active in community affairs in roles including being a foundation member of the Library Committee, a committeeman of the Town Band and football club, a member of the Hibernian Lodge and an ardent worker for the Roman Catholic Church. Johnson Bros. was founded by two brothers named Alfred and Frederick who purchased a pottery factory in Hanley, England, in 1883. They were grandsons of a renowned English potter, Alfred Meakin. They were later joined in the business by their brothers Henry and Robert. Their business grew rapidly, as they were one of the world's largest pottery factories by the turn of the 20th century. By 1970, Johnson Bros. obtained the Royal Charter to become the official provider of china for Her Majesty Queen Elizabeth II. More than 1,300 patterns have been created throughout Johnson Brothers' history. Due to their growing success, manufacturing plants were established overseas including the establishment of a tableware factory, Johnson Brothers Australia in 1957 in Croydon, Victoria operated through a company known as Sovereign Pottery Ltd. Due to rising competition, Johnson Brothers became part of the Wedgewood Group in 1968. In 2015, following the acquisition of Wedgewood by Finnish company Fiskars, the Johnson Brothers branding was discontinued. The trademark on this bowl was used by Johnson Brothers between 1913 and 1942.This item originates from a well-known and respected Wodonga business.A round china plate imprinted with business name of G. Awburn Wodonga and Johnson Brothers on the back of the plate.On front: G. Awburn Caterer Wodonga On back: Hotelware / Johnson Bros/ Englandawburn family, wodonga businesses -

National Vietnam Veterans Museum (NVVM)

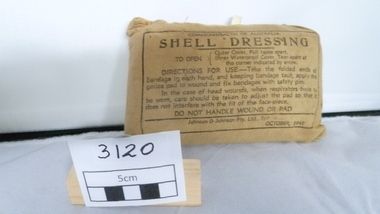

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Field Dressing, 1941

Tan coloured cotton package containing dressing. Instructions for use written on outside.Commonwealth of Australia Shell Dressing. Extensive directions for use. Johnson & Johnson P/L Syd October 1941field dressing, shell dressing, sas -

Inverloch Historical Society

Inverloch Historical Society000405 - Photograph - Inverloch - outside Johnson and MacKieson's cafe - koala on pole - Gwen Evans - Gladys Jacobson - Gert Martyn - Geoff Johnson - from Noelle Green

-

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Digital photographs, L.J. Gervasoni, Samuel Johnson at Connie Johnson Memorial Service at St Paul's Cathedral, 2017

st paul's cathedral, st paul's, memorial service, connie, constance johnson, connie johnson, love your sister, village, villagers, cancer, charity, samuel johnson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ribbon Gauze & Box, Johnson & Johnson Pty Ltd

Most surgical wounds are closed primarily, but some are allowed to heal by secondary intention. This usually involves repeated packing and dressing of the raw wound surfaces. Although the long-term care of such wounds has devolved to the care of nurses in the community or out-patient setting, the initial wound dressing or cavity packing is done by the surgeon in the operating theatre. Many surgeons are unaware of the growth of the discipline of wound care, and still use traditional soaked gauze for dressing and packing open surgical wounds and cavities. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1963638/The control of bleeding and wound management is vitally important for the survival of the patient.Gauze bandage and cardboard box.Two boxes. One box in better condition. Red Chain Bandage. Johnson and Johnson Pty Ltd Sydney. 3 inches, 6 yards. Sterilized neat edge.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, "red chain bandage", gauze, bandage, johnson & johnson -

South West Healthcare

South West HealthcareCorn Plaster Set, 20th century

1 box 12 corn plasters;1 metal stand with glass lamp with 1 wick.Box labelled "Johnson & Johnson" , "MADE IN ENGLAND" "THICK" "CORN P". Distributers label - "SAMBELL'S Cnr. Pharmacy/ WARRNAMBOOL"medicine, corn plaster -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchEquipment - First Field Dressing, March 1943

field dressing carried by a soldier as part of their field kit to enable immediate first aid in battleItem was part of first aid equipment that all soldier carried when on active war like duties in WWII. First Field Dressing unpacked from original container. Bandage in waterproof package with safety pin in waterproof wrapping attached by cotton thread. Red arrow diagonally across package indicating where to open. Printed on waterproof wrapping. FIRST FIELD DRESSING/ Tear apart the uncemented corner as indicated / by the arrow and remove the paper. / take the folded ends of the bandage in each / hand and keeping the bandage taut, apply the / gauze pad to the wound and fix the bandage. In the case of head wounds when respirators have / to be worn, care should be taken to adjust the pad / so that it does not interfere with the fit of the face / piece. / DO NOT HANDLE THE GAUZE OR WOUND/ Johnson & Johnson / Pty. Ltd Sydney/ October 1942 / a red arrow drawn diagonally over top of printed instructed pointing to where to open the bandage. On the reverse is hand written "Lent by Lance Flynn" bandage, guaze, waterproof paper -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchFirst Field Dressing, March 1943

Item is an essential item of kit that is carried by a soldier to provide immediate first aid to a personal injury sustained in battle of to render first aid to a fellow combatant Item was part of first aid equipment that all soldier carried when on active war like duties in WWII. First Field Dressing unpacked from original container. Bandage in waterproof package with safety pin in waterproof wrapping attached by cotton thread. Red arrow diagonally across package indicating where to open. Missing safety pin. Printed on waterproof wrapping. FIRST FIELD DRESSING/ Tear apart the uncemented corner as indicated / by the arrow and remove the paper. / take the folded ends of the bandage in each / hand and keeping the bandage taut, apply the / gauze pad to the wound and fix the bandage. In the case of head wounds when respirators have / to be worn, care should be taken to adjust the pad / so that it does not interfere with the fit of the face / piece. / DO NOT HANDLE THE GAUZE OR WOUND/ Johnson & Johnson / Pty. Ltd Sydney/ October 1942 / a red arrow drawn diagonally over top of printed instructed pointing to where to open the bandage. On the reverse is hand written "Lent by Lance Flynn" bandage, guaze, waterproof paper, cotton -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

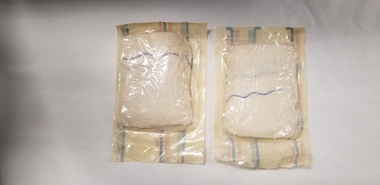

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Two packets of packing gauze, Johnson & Johnson

Two sealed packets of packing gauze. Printed stamp on each package reads 'NUFOLD RAYTEC packing gauze/ONE ROLL/100mm x 2m'. Each package is also stamped with the number '054U'. Packing is printed with a blue and red design noting the contents as sterile and being manufactured by Johnson & Johnson.surgery -

Bendigo Military Museum

Bendigo Military MuseumAward - MEDAL SET WW2, post 1945

Medals awarded to Cyril John JOHNSON VX36298 died as a POW. Refer Cat No 3144 for his service history.Set of (5) WWII Medals court mounted re C.J. JOHNSON. 1. 1939 - 1945 Star 2. Pacific Star 3. Defence Medal 4. War Medal1939 - 1945 5. Australian Service Medal 1939 - 1945Engraved “VX36298 . C .J. JOHNSON”medals, military, history -

Bendigo Military Museum

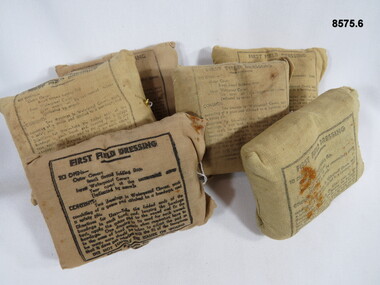

Bendigo Military MuseumEquipment - FIRST FIELD DRESSING, Johnson & Johnson PTY LTD, 1941-1944

Medium size First Field dressing bandages designed to be carried on the person and to be used in the first instance of a wound. There are basic instructions on the field dressings on how to place the dressings on a wound. Each packet has the identical markings except for the Manufacturers date. 1. February 1942. 2. October 1941. 3. January 1942. 4. June 1944. 5. June 1944. 6. November 1944. FIRST FIELD DRESSING. "See attachment for Treatment conditions". DO NOT HANDLE THE GAUZE OR WOUND. Johnson & Johnson Pty Ltd. SYDNEY February 1942.passchendaele barracks trust, first field dressings -

Bendigo Military Museum

Bendigo Military MuseumEquipment - FIRST FIELD DRESSINGS, Johnson & Johnson, 1942-1944

Small First Field dressing bandages designed to be carried on the person and to be used in the first instance. There are basic instructions on how to place the dressings onto or over a wound. All packets have identical markings except for the Masnufacturers date. 1. November 1942. 2. November 1942. 3. March 1943. 4. June 1944. 5. June 1944. “FIRST FIELD DRESSING” "See attachment for treatment conditions". “DO NOT HANDLE THE GAUZE OR WOUND. Johnson & Johnson Pty Ltd, SYDNEY November 1942”passchendaele barracks trust, first field dressings -

Learmonth and District Historical Society Inc.

Learmonth and District Historical Society Inc.Boxed Gold Scissors, "Circa 1937"

Presented to Mrs. H.J.Wheeler with the compliments of the State Electricity Commission of Victoria, Electricity Supply Department, Ballarat Branch, on the occasion of the "Switching On" of the Electricity Supply to Learmonth,19th March,1938.A pair of scissors that were used to "switch on" the electricity supply to Learmonth on the 19th March 1938. Gold Scissors in black box, with blue and white lining.Johns and Johnsonlearmonth, boxed gold scissors, electricity -

Orbost & District Historical Society

Orbost & District Historical Societyteapot

Round china teapot with yellow/orange background colour. Blue,pink and purple rose on front and back.bottom-............pottery, Johnson.....(unreadable)teapot domestic-items food-drink-consumption johnson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

This semi-porcelain wash basin would have been used in a Victorian household for bathing and personal hygiene. It was made by the well-known firm Johnson Bros. in England. The wash bowl or basin is a typical example of a Victorian era household's bathing item. It is significant for its association with renowned potters Johnson Bros. of EnglandBowl or wash basin, white with pink and green floral decoration. Inscription on base; stamped in brown paint. Royal semi-porcelain material, made by Johnson Bros, England"ROYAL / SEMI-PORCELAIN / JOHNSON BROS. / ENGLAND" Symbol [Crown above a ribbon with maker's name.]flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wash bowl, wash basin, bathing, personal hygiene, johnson bros, pottery, percelain, semi-porcelain -

Bendigo Military Museum

Bendigo Military MuseumAward - MEDAL SET WW1, Post 1919

Noel Johnson, No 650, 21st Battalian AIF embarked for overseas on 8.5.1915. He was later hospitalised and invalided home on 3.3.1916. He re enlisted as No 5948 in the 23rd Batt AIF and returned overseas on 16.11.1916. He was hospitalised twice more and then was discharged medically unfit on 29.8.1918.Medal set, court mounted, set of (3) re N Johnson. 1. 1914-15 Star, replica not engraved. 2. War Medal 1914-18 replica not engraved. 3. Victory medal 1914 - 19"650 PTE. N. JOHNSON. 21 BN AIF."medals, military, history, campaign. -

Orbost & District Historical Society

Orbost & District Historical SocietyFirst Field Dressings, World War 2, Johnson & Johnson Pty Ltd, 1942, 1943

These packs were Australian army issue to service men and women during World War 2.Many Orbost men served in World War 2. Three field dressing packs made from cloth or waterproof covering and with a black printed label on one side of each pack. The words FIRST FIELD DRESSING and instructions TO OPEN and CONTENTS are printed on each pack. On the bottom of the print area are JOHNSON & JOHNSON PTY LTD, SYDNEY. One pack has the date May 1942, and the other two are December 1943. australian-army first-field-dressings world-war-two