Showing 86 items

matching machine belts

-

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchWeapon - Bayonet & Scabbard

The Pattern 1907 bayonet, officially called the Sword bayonet, pattern 1907 (Mark I), was a British bayonet designed to be used with the Short Magazine Lee Enfield (SMLE) rifle. The Pattern 1907 bayonet was used by the British and Commonwealth forces throughout both the First and Second World Wars. The Pattern 1907 bayonet consisted of a one-piece steel blade and tang, with a cross guard and pommel made from wrought iron or mild steel, and a grip usually of walnut secured to the tang by two screws. The entire bayonet was 21+3⁄4 inches (550 mm) long and weighed 16+1⁄2 ounces (470 g), although the weight of production models varied from 16 to 18 ounces (450 to 510 g). The Pattern 1907 bayonet's blade was 17 inches (430 mm) long. A shallow fuller was machined into both sides of the blade, 12 inches (300 mm) long and extending to within 3 inches (76 mm) of the tip, with variations due to the judgement of individual machinists.[2][3] The Pattern 1907 bayonet was supplied with a simple leather scabbard flitted with a steel top-mount and chape, and usually carried from the belt by a simple frog. The Pattern 1907 bayonet attached to the SMLE by a boss located below the barrel on the nose of the rifle and a mortise groove on the pommel of the bayonet.[2][4] The combined length of the SMLE and Pattern 1907 bayonet was 5 feet 2 inches (1.57 GR 1907 6.......'17 Wilkinson Stamped on right side of base of blade with various symbols on the left side. Hand carved on RHS Bakelite part of handle K ? (EFX) on LHS - MB -

Southern Sherbrooke Historical Society Inc.

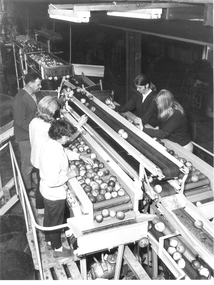

Southern Sherbrooke Historical Society Inc.Photograph - Packing apples at Montague Orchards, Narre Warren North

B&W photo showing staff packing apples at Montague Orchards, Narre Warren North. Four women and a man stand either side of a machine with rollers and a central belt. Crates of apples are in the background. -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchMachine Gun Belt

... Machine Gun Belt... Machine Gun Belt ...Belt with used shells, linked ). 30/06 Calammunition, korea, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchBelt

... Ammunition Korea Army Linked Ammunition for Machine Gun Belt ...Linked Ammunition for Machine Gunammunition, korea, army -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Uniform - GSSC School Dress

... . At centre back is a decorative half belt with diagonal check.... At centre back is a decorative half belt with diagonal check ...Golden Square High School in the city of Bendigo, was established in temporary accommodation at Camp Hill Primary School in central Bendigo in 1960. With the completion of the new school's buildings, it moved to Golden Square in 1962, providing for Forms 1 to 6, now known as years 7 to 12. In 1978 it became a 7–10 school and was one of the original feeder schools to Bendigo Senior High School. In 1986, a Hearing Impaired Unit was established and in 1990 it underwent a name change to become Golden Square Secondary College. The Golden Square Secondary College campus closed on 28 November 2008. It merged with Kangaroo Flat and Flora Hill secondary colleges as part of the implementation of the Bendigo Education Plan. Its buildings were demolished. (Wikipedia https://en.wikipedia.org/wiki/Golden_Square_Secondary_College) This uniform collection belonged to Anna Matthews, daughter of the donor, who attended GSSC as part of the last group enrolled before the school closed in 2008. Golden Square Secondary College school dress made from green and white cotton and polyester check fabric. There is a thin yellow line at edges of check pattern. Short set in sleeves with a cuff edged with piping. White flat collar. The dress has a front placket opening to the waist fastened with four dark green buttons. Bust darts on both sides. Front and back below the waist have two inverted pleats. On the right hand side there is an internal pocket with a zip fastener. At centre back is a decorative half belt with diagonal check. Machine hemmed.Tag below collar. Front. "PREFECT Value Based Apparel. NAME _ _ _ _ _ _ _ " Reverse "65% Polyester 35% Cotton. Washing Instructions."gssc, golden square secondary college, uniform, bendigo education plan., school dress -

Kew Historical Society Inc

Kew Historical Society IncClothing - Red Lace Evening Dress, & Matching Red Velvet Jacket, 1930s

The Fashion & Design collection of the Kew Historical Society includes examples of women’s, men’s, children’s and infants’ clothing from the 18th, 19th and 20th centuries. Items in the collection were largely produced for, or purchased by women in Melbourne, and includes examples of outerwear, protective wear, nightwear, underwear and costume accessories.This 1930s dress and jacket is one of a number of items donated to the Fashion Collection by Teresa Mayer.Long burgundy machine-made lace evening dress with a separate red underslip. The dress is currently paired with a red velvet jacket and belt which it is believed was part of the original donation by Teresa Mayer.evening dresses, australian fashion - 1930s, women's clothing, evening wear, evening ensembles -

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionUniform - Fyffe uniform & hat, 1945 circa

VX 42774 Captain Robert (Bob) Fyffe, a grazier from Tocumwal, NSW, served with the Tocumwal troop of the 20th Light Horse prior to WWII (1939-46). He enlisted at the outbreak of war and served with the 9th Division Cavalry Regiment in North Africa. During the attack on Trig 22 on 17 July 1942 Captain Fyffe commanding a composite squadron manoeuvred his tanks to knock out machine guns and anti-tank guns enabling 2/32 Battalion to capture the objective. Captain Fyffe was awarded the Military Cross for his leadership and courage in the action. This was 9th Division Cavalry's first tank action of the war.Fine example of a uniform worn by a well known grazier and citizen soldier of the Tocumwal district, southern NSW, in both peace and war.Khaki wool serge officer's tunic with leather Sam Browne belt and revolver holster, and slouch hat with emu plumes and 20th Light Horse hat badge against red backing. Tunic has 20th Light Horse colour patches. overseas service chevrons and ribbon bar for Military Cross, 39-45 Star, Africa Star, Defence medal, British War Medal and Australian Service Medal 1939-45; metal Australia shoulder titles captain's rank stars and Rising Sun collar badges. Uniform worn by Captain Robert Fyffe MC, 20th Light Horse and 6th Division Cavalry Regiment AIF.. uniform, fyffe robert captain mc, 20th light horse, 9th division cavalry regiment, military cross -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSewing Machine, 1883 - 1885

Treadle sewing machine with metal base, wooden table and leather drive belt. The base plate is decorated with a rural scene featuring a 3 storey house, male & female figures in Victorian dress, horse and buggy painted in colour.Name printed on arm of machine, hard to decipher - appears to be "New Home Treadle Serial No 404879"dometsic items sewing machinery -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPulley Stand

Flat belt pulley stand with multiple pulleys. Set up for driving multiple machines. Present power source is an electric motor. In working order, unpainted.trades, carpentry, metal working -

Brighton Historical Society

Brighton Historical SocietySuit, 1980s

Pink taffeta suit comprising jacket, skirt and belt. Fitted jacket with peplum. Machine-quilted shawl collar and separate belt. Calf-length pencil skirt with V-shaped pleated insert centre back. .1 - jacket .2 - skirt .3 - beltLabel, woven silver on cream acetate, centre back jacket and skirt: Prue Acton woman's suit, 1980s, prue acton -

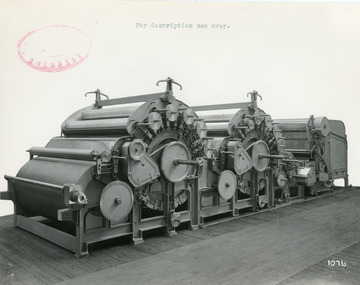

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

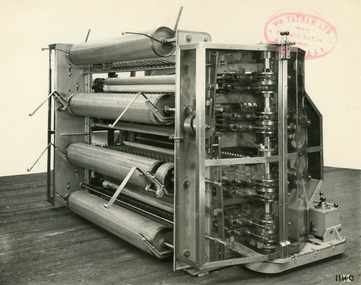

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Singer Treadle Sewing Machine, The Singer Manufacturing Company, c1890

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s.| This sewing machine belonged to Isla Ilma Margaret Ernestine neeTasker, mother of Alfred Haeusler. Singer was first established as I. M. Singer & Co. in 1851 by Isaac Merritt Singer with New York lawyer Edward C. Clark. Best known for its sewing machines, it was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. The Singer company began to market its machines internationally in 1855 and won first prize at the Paris world's fair that year. They had offices established in both Sydney and Melbourne by the mid-1960s. The company demonstrated the first workable electric sewing machine in 1910. Singer was also a marketing innovator and a pioneer in promoting the use of instalment payment plans, making their machines more affordable for many people. This item is from the Hauseler Collection which documents social life of early settlers in the Wodonga community.Singer "Coffin top" treadle sewing machine with extension table. The machine is mainly black and silver metal but is extensively decorated with coloured decals. The decorations on this machine features a pheasant design which also helps to date the machine as it was only used from 1890 to 1915. The sewing machine is set into a wooden table with and extension leaf and 6 drawers, 3 on either side. The frame and treadle mechanism are iron with a thin leather belt to drive the mechanism. The "coffin" shaped top sits over the machine to protect it when not in use and is easily removed. The extension leaf provides a larger working surface and folds down when not in use. The Singer logo attached to the front of the machine features a needle, shuttle and thread.On metal base plate: "PATENTED /DEC 5 -1882/ MARCH 20 - 1883/ AUG - 21 1888. Model no: L6485622 Along top of machine: "The Singer Manufacturing Co." Front right: Singer Company Logohaeusler family, wodonga pioneers, sewing machines, singer sewing macnine -

Woodend RSL

Woodend RSLHorse Saddle Girth, James Robb, Belt attachments presumably made prior to 1917

James Robb (born 1940) was an importer and manufacturer of all kinds of saddlery. References: Centre for Australian Art, 2020 http://www.printsandprintmaking.gov.au/impressions/31305/ Faded, mustard coloured woven strap with buckles on either end. Centre of strap has a thin leather belt loop attached. Buckles are attached with brown, rectangular leather strips which appear to be hand-sewn to strap in white thread. Two holes which appear to be for a buckle prong, are visible on one side above the leather buckle attachment. A row of machine stitched holes on this side suggests a rectangular, arrow headed strap was once attached.J. ROBB MAKER HOBARTTOWN stamped into brown leather buckle attachments. -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRaindance Aerial Incendiary Machine R2

Alan McArthur from the CSIRO began his experimental burning program in the late 1950s near Canberra and published his landmark paper in 1962, “Controlled burning in eucalypt forests”. Leaflet No. 80, as it was known, proved a turning point for forest and fire managers across Australia. It led to the McArthur Forest Fire Danger Meter (FFDM) which first appeared in operational use in 1967 as the Mk 4. The CSIRO had developed its semi-automatic aerial incendiary machine dropping small capsules, with the first trial from a fixed-wing Cessna 337 at Manjimup in December 1965. Many technological and safety improvements followed including the Raindance machineAerial Incendiary Machine developed in Western Australia Rather than "ping pong balls" it uses a belt of incendiary "caplets" which are injected inside the machine before being ejected Raindance Systems R2forests commission victoria (fcv), planned burning, bushfire aviation, bushfire -

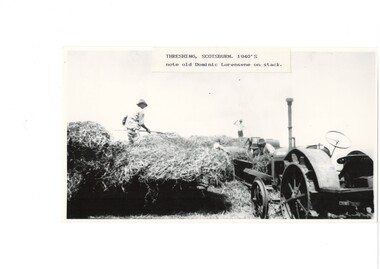

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Copy of B/W photograph, Threshing machine at Scotsburn in 1940's, Not known

... Scene showing farm machinery in use. Threshing machine.... Threshing machine vdriven by belt from stationary tractor. Several ...Photograph shows early farming method and illustrates some of the machines used at this timeThreshing machine in operation at Scotsburn in the 1940's. 3 workers and tractor visbleThreshing machine. 1940's. Note old Dominic Lorensene on stack.scene showing farm machinery in use. threshing machine vdriven by belt from stationary tractor., several man are working on the equipment, l -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Photograph, Gibbons, Denis, M60 Number 2

Denis Gibbons (1937 – 2011) Trained with the Australian Army, before travelling to Vietnam in January 1966, Denis stayed with the 1st Australian Task Force in Nui Dat working as a photographer. For almost five years Gibbons toured with nine Australian infantry battalions, posting compelling war images from within many combat zones before being flown out in late November 1970 after sustaining injuries. The images held within the National Vietnam Veterans Museum make up the Gibbons Collection. A black and white photograph of a Seven Platoon, Charlie Company, 4th Battalion/New Sealand (ANZAC), Royal Australian Regiment, number two on the M60 machine gun, patrols through close country on Operation Federal. the bullet belts for the m60 are twined about his body to distribute the weight.photograph, long binh, operation federal, 7 platoon, c coy, 4rar nz, gibbons collection catalogue, m60 machine gun, charlie company, anzac, royal australian regiment, denis gibbons -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumLathe (Model)

"This is a rough model of the woodturning lathe Kurt Beilharz built from scrap as a 17 year old in Camp 3, Tatura. The drive wheel was a hollow redgum block from the firewood supply. The shaft was a 1/2" water pipe, the bearings of the spindle were 3/4" water pipe with tooth paste tubes melted into and honed out for the spindle. They had holes for oiling. The drive belt came from my Mother's sewing machine. I used screws in the model, but in reality bolts were used, which were bought as well as the framing timber"Wooden model of a lathe made and used at Camp 3. Triangular upright frame with a hollow drive wheel, driven by a piece of wire with a handle on one end. Drive belt is a piece of fine cord.lathe, model, beilharz, k, camp 3, tatura, ww2 camp 3, handcrafts, models -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Photograph, Gibbons, Denis, Heliborn Assault 2

Denis Gibbons (1937 – 2011) Trained with the Australian Army, before travelling to Vietnam in January 1966, Denis stayed with the 1st Australian Task Force in Nui Dat working as a photographer. For almost five years Gibbons toured with nine Australian infantry battalions, posting compelling war images from within many combat zones before being flown out in late November 1970 after sustaining injuries. The images held within the National Vietnam Veterans Museum make up the Gibbons Collection.A black and white photograph of RAAF Huey 'slick' Helicopters transporting Diggers from the 1st Australian Task Force Base, Nui Dat, Phuoc Tuy Province, to their drop zone to commence operations. The machine gun depicted in the forefront of the photograph is a 7.62mm belt-fed weapon.photograph, huey helicopter, raaf, 1 atf, nui dat, phuoc tuy province, m 60 machine gun 7.62, gibbons collection catalogue, denis gibbons, photographer, vietnam war, diggers -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Digital Image, Melbourne & Metropolitan Tramways Board (MMTB), machine shop at Preston Workshops c1943, 1943

Digital Image of the machine shop at Preston Workshops c1943. Shows the nature of the work positions, the belt drives and some of the equipment provided. Image made from a published print.trams, tramways, preston workshops, tramcar construction -

Bendigo Military Museum

Bendigo Military MuseumUniform - SLACKS, SERVICE DRESS, ARMY, Australian Government Clothing Factory, 1980

Slacks - garment is part of a Women's Service Dress uniform. Possibly issued to "BALAAM", Service No. "F380519" Refer also Cat No. 9616.1. Slacks - dark green colour wool and polyester, full length slacks with belt loops. Front nylon zipper fly, brown colour plastic button at waist - no pockets. Manufacturers labels - two, inside back of waistband, exterior back of waistband - (to be removed when worn). White colour polyester fabric. 2. Belt - fabric as above with keeper and metal press stud closer.Manufacturers label - black ink print. Inside back "A.G.C.F. VICTORIA 1980 ^/ 8410-66-096-5182 size 10, AVE HGT/ FULL HIP/ WAIST 60 CM HIP 90 CM" Garment care instructions under headings "HAND WASH, MACHINE WASH IRONING", Followed by "NAME/ Service No.". Outside back "THE TAG IS FOR IDENTIFICATION ONLY/ PLEASE REMOVE BEFORE WEARING" with printed and handwritten information.uniform, womens trousers, army, balaam, passchendaele barracks trust -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - NEW MOON MINE - COPIES OF NEGATIVES OF THE NEW MOON MINE

Four copies of negatives, three showing mining machinery and the fourth, a table. (a) shows machinery driven by a large flywheel. A man is operating the machine. (b) shows the crushing machine and tables. They are driven by long belts being driven by a long overhead shaft. Two men are at the machine. A tub is in the foreground. (c - shows a view of the fitting shop at crushing machine. Picture is not very clear. There are four men in the picture. (d) shows a reverse image table of gross total of tons, gold, dividends and calls to June 30th, 1906. photo, new moon mine, copies of negatives of the new moon mine, mine machinery, crushing works, a richardson -

National Vietnam Veterans Museum (NVVM)

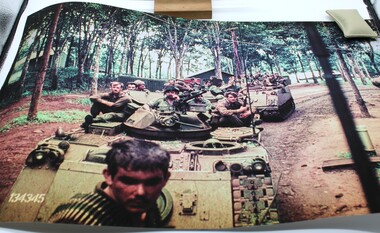

National Vietnam Veterans Museum (NVVM)Photograph - Photo poster

This items commemorates the war in Vietnam (1962-1972)Coloured photo of B Coy 4RAR/NZ returning back to base on 3 APC's. Photo depicts soldiers sitting atop an APC with machine guns and various weapons. Base camp with tents, trees and tanks in the background. soldier in the foreground with an ammunition belt over his right shoulder. 134345 on front of first APC.soldiers, apc's, franz bernhardtt, minolta camera, 4rar, new zealand, b coy -

Bendigo Historical Society Inc.

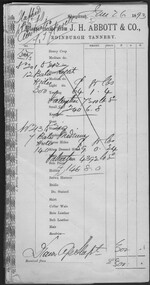

Bendigo Historical Society Inc.Administrative record - Abbott Collection: July to Dec 1898: records and receipts for purchases by J.H. Abbott & Co

various 1898 company letterhead receipts which J.H. Abbott used to access supplies2403.86 (A to G) Abbott Collection: Jan to Jun 1893: records and receipts for purchases by J.H. Abbott & Co. from a wide range of generally Melbourne based companies 2403.87A: J.H. Abbott's issued 46 invoices for their Edinburgh Tannery 1 July - 24 December 1898 2403.87B: 18 invoices Thomas P. Power, Saddler Ironmonger & Manufacturer; 5 July - 28 December 1898 2403.87C: 12 (blue) invoices Thomas McPherson & Son, Machinery & Iron Merchants; 9 July - 17 December 1898 2403.87D: 23 invoices The India Rubber Gutta Percha & Telegraph Works Co. 11 August - 29 September 1898 2403.87E: 30 invoices & 5 credit notes Edward Keep & Co, Wholesale Ironmongers & Importers of Carriage Materials; 6 July - 23 December 1898 2403.87F: 16 invoices Ullathorne & Co, materials; 12 July - 28 December 1898 2403.87G: 5 invoices Tuck & Co. Limited, manufacturers of asbestos goods for every description; 28 July - 27 October 1898 2403.87H: 3 invoices Banks & Company, importers and wholesalers; 6 July - 11 November 1898 2403.87I: 2 invoices John Danks & Son, Sheet Lead, Lead, Compo. & Tin Plate; 18 August - 22 August 1898 2403.87J: 6 invoices M. Donahy & Sons, Manufacturers of Steam-Laid flat & Round Ropes. 14 September - 10 November 1898 2403.87K: 17 invoices Reid Brothers & Russel, importers of Mines and Engineering Furnishings, 15 September - 22 December 1898 2403.87L: 2 invoices A. Spooner & Co., manufacturers of a wide range of goods; 30 August - 22 October 1898 2403.87M: 5 invoices Charles Aitkins & Co., manufacturers, refiners and importers of Lubricating Oils, Antifriction Grease, Machine Belting, Engine Packings etc.; 17 August - 31 December 1898 2403.87N: 2 invoices E. L. Yencken & Co. Oil Color and Glass Merchants; 14 August - 23 December 1898 2403.87O: 3 invoices Morris & Meeks, Wholesalers Ironmongers & Machinery Merchants; 24 November - 6 December 1898 2403.87P: 8 invoices Felton Grimwade Co.: 22August - 16 December 1898 2403.87Q: 12 invoices N. Gutheridge & Co., Wholesale Saddlers, Saddlers, Ironmongers & Importers; 6 July - 21 December 1898 2403.87R: 2 invoices John Perry., Timber Merchant, Coach Builders, Ironmongery & Wheelwrights' Materials; 19 & 30 November 1898 2403.87S: 34 invoices Frank Vial & Co., Universal Leather Belt Factory; 7 July - 23 December 1898trade company purchases 1893