Showing 239 items matching "machine factory"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, cigarette papers 'Boomerang', c1946

Cigarette or Rolling papers are small sheets, rolls, or leaves of pre-cut paper made from wood pulp, hemp, flax, or rice straw which are sold for rolling cigarettes either by hand or with a rolling machine. When rolling a cigarette, one fills the rolling paper with tobacco. PROV - The West Richmond heritage overlay - The smaller former Australian Automatic Cigarette Paper Company factory at no.103-05 Hoddle Street Richmond, also retains original Moderne detailing, which includes 'Boomerang' in Art Deco script set vertically within the piers at either end of the building. 'Boomerang' was the brand of the cigarette papers manufactured by the company until 1948. A packet of 'Boomerang' precut cigarette papers Top: 60 LEAVES / BOOMERANG/ RICE / STAINLESS CIGARETTE PAPER/ Back:: 1/3 / 60 LEAVES / BOOMERANG / RICE / AUTOMATIC GUMMED / MADE IN AUSTRALIA . Inside packet: AUSTRALIAN AUTOMATIC CIGARETTE / PAPER CO. PTY. LTD. / MELBOURNEmelbourne, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, cigarette papers, tobacco, boomerang papers, australian automatic cigarette paper co. pty.ltd. -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

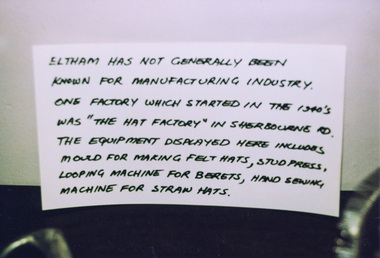

Two Colour photographs of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

Colour photograph of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Cheese World Museum

Cheese World MuseumVacuum recorder, E.M.P. Engineers Ltd, c1960

Used by first Warrnambool Cheese and Butter Factory Company Ltd Field Officer, Bruce McLaren, for on-farm testing in the Allansford area to check the amount of suction in milking machines.Phillips Rurakura Vacuum Recorder in a wooden box with lid, metal hinges and fastening clip, screw adjustment and name plate on outside. Inside has a clockwork-operated recorder with pen device to roll of paper.Internal: Trade mark Empel E.M.P. Engineers Ltd PO Box 5125, Hamilton, NZ Aust. Pat. 209 510. NZ Pat. 112 486. External: Empel Phillips Ruakura Type Vacuum recorder, Makers E.M.R. Engineers Ltd. PO Box 5125, Hamilton NZ -

Cheese World Museum

Cheese World MuseumButter printer, J Bartram & Son, c1900

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This butter cutter is part of the collection of items given into the care of the Cheese World Museum. It was in the early 1900s for hand-use in home dairies or small factories. An example of an early butter packaging machine.Wooden Eureka brand butter printer and weigher with dovetailed corners on the bulk butter box, wooden rollers for moving butter along once cut and wire cutter.Eureka/J Bartram & Son/sole makers Uebergang No. U027butter cutters, uebergang, allansford, dairy manufacture -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Cheese World Museum

Cheese World MuseumExercise Book, A Carroll Exercise Book

This exercise book was donated by Donna Daly, who found it among her parents belongings. Her parents were Josie and Tich Kelly and she was unsure of the connection with A Carroll.This document is significant as it indicates records kept on-farm by some farmers. It records prices received for milk, calves, pigs and the amount of the government subsidy during this period which covers the time of World War II. It provides an interesting comparison with the Taylor milk passbook from 1895 and associated milk slips which are also held by Warrnambool Cheese & Butter Factory.Fawn coloured exercise book with pictures of old sewing machines on the front cover and Arithmetic tables on the back in blue printing. The contents include farm records from 1935 to 1945 documenting income from dairy, calves and pigs.A Carroll (front cover) A Carroll, Mepunga West (back cover) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Balance Scale, 1850s

A Large Rare mid 19th Century Balance Scale (also called a Beam Scale) Made in England by W&T Avery a British manufacturer of weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into a specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs.Then from 1931 to 1973 the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail scales and industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. Item made and used possibly around the 1850s by Victorian colonial government to check weights of goods being sold by early shop keepers on the gold fields item is very rare.James McEwan & Co were the retailers of W & T Avery scales in Victoria from 1852. A very rare item used probably to check weights used by merchants during colonial times by government inspectors in Victoria. A similar example exist in a NSW museum, the item is believed to have been made before W & T Avery expansion to the Soho foundry in Birmingham in 1885 and after 1818.Beam balance scale suspended from a wooden tripod, with metal trays suspended by three chain lengths. embossed on the balance beam W T Avery, Birmingham,flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, scale, avery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Knife Sharpener, Johann Friedrich Dick, 1873 to 1900

Johann Friedrich Dick founded the company in 1778 to manufacture files, the company continued in the manufacture of files as its main product line until 1873, when Paul Friedrich Dick took over the company and began the production of sharpening steels, with the logo of “F Dick” on their products. One hundred years after the founding of the company, a factory in Esslingen began construction. At that time the company had 20 employees. In 1881, company commissioned Germany's first file production machine. In 1889, Friedrich Dick built a new factory in Kollwitz/Fleischmannstrasse in Esslingen, employing 100 people and expanding the product line to include knives for butchers and chefs, cleavers and other specialized tools. Files manufactured ranged from the smallest watchmaker's file to the largest (over 45 cm in length) square file. In 1997, the F Dick company moved to a new headquarters in Deizisau, Germany. The old factory in Esslingen is now a class listed monument and the town's landmark.An item made by a world class manufacture of cutlery for chefs, the subject item is significant as its manufacture was probably early in the firms beginnings when Friedrich Dick took over in1873 when he specialised in making sharpening steels. The company is still producing these items today as well as other specialised knives for professionals. Early manufactured steels such as the subject item are sought after today by collectors and quite rare. Sharpening Steel or Knife sharpener with bone handle with ribbed pattern, brass knobs and ring at end of handleMarked F Dick Esslingenflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, sharpening steel, knife sharpener, kitchen tool, carving, kitchen utensil, cooking, f dick -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

... the principal products of the original factory were washing machines... the principal products of the original factory were washing machines ...Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Petticoat, late 19th century to early 20th century

... developed in St Gallen. Factories used embroidery machines... developed in St Gallen. Factories used embroidery machines ...This petticoat was one of several items donated from the estate of Susan Henry OAM nee Vedmore (1944 - 2021). It is in very good condition and appears to be from the Edwardian era - early 20th century. A petticoat is a lady's undergarment - worn under a skirt or dress. They provided warmth, modesty and shape to the dress. In the middle of the 19th century, petticoats were worn over hoops, bustles or in layers. Petticoats varied according to the style of the outside skirt or dress. Plain petticoats tended to be worn with everyday wear whilst better dresses (party dresses or silk gowns) were worn with petticoats that often had more trim and embellishments. Edwardian petticoats had less volume than Victorian era petticoats and they had a "dust ruffle" or lining under a lace flounce. The "dust ruffle" protected the lace flounce and gave the petticoat more flare at the bottom, greater freedom when walking as well as saving the flounce (which was often made of finer material) from everyday wear and tear. Tucks are another feature of Edwardian petticoats - when the lace at the bottom became worn, it could be cut off and the tucks released. This extended the life of the petticoat. This petticoat features an intricate trim of broderie anglaise. Although broderie anglaise was a lace that could be made by hand, it was very time consuming to make. St Gallen was a city in Switzerland that had become known for producing quality textiles. At the beginning of the 19th century, the first embroidery machines were developed in St Gallen. Factories used embroidery machines but people also had them in their homes. They were able to produce broderie anglaise for export. By the early 20th century, machine made lace, fabric, ribbons etc. were being sold in drapers shops all over England and Wales to women who were making clothes and furnishings for their families. It is highly likely that the lady who made this petticoat brought the lengths of broderie anglaise already made to embellish and personalise her petticoat. Susan's family (Harold and Gladys Vedmore) immigrated to Australia from Wales in 1955 and settled in Warrnambool. Susan was well known in the Warrnambool community for her work supporting children and families across the district - particular those with disabilities, or those who were homeless, unemployed or isolated. Susan was the founding trustee of the "Vedmore Foundation" - a Warrnambool philanthropic trust set up in 2010 to support a range of charitable and not-for-profit causes by providing grant assistance. In 2021, she was awarded a Medal of the Order of Australia for services to the community.This item is an example of the needlework skills of women in the late 19th century - creating pintucks and adding lace to personalise and embellish a practical item of clothing. It is also significant as an example of a practical solution to the difficulties that women of this era faced with regard to the washing of clothes and household linens.A white lawn petticoat with a 22.5 cm opening that fastens with 2 small buttons and a drawstring tie. It is decorated with two wide pintucks followed by two gathered frills (or flounces) - one decorated with three rows of narrow pintucks and a single row of broderie anglaise and the bottom frilled hem finished with 3 rows of broderie anglaise in a flower design. The two bottom frills are lined with plain white cotton fabric.flagstaff hill maritime museum and village, great ocean road, petticoat, lady's petticoat, undergarment, lady's undergarment, lingerie, edwardian petticoat, broderie anglaise, lace, machine made lace, hand sewn, machine sewn, draper's shop, susan henry oam, vedmore foundation -

Flagstaff Hill Maritime Museum and Village

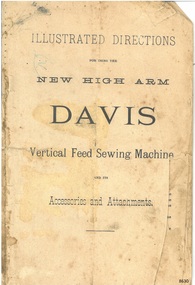

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWood Sample, about 1871

This piece of timber from the ship Eric the Red has been eaten through by the marine animals called Teredo Worms, sometimes called sea worms or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by using coatings of tar, wax, lead or pitch. In the 18th and 19th centuries the outside of their ships were sheathed in copper or a combination of copper and zinc (called Muntz metal) and would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. The American ship Eric the Red was a wooden, three masted clipper ship. She had 1,580 tons register and was the largest full-rigged ship built at Bath, Maine, USA in 1871. She was built and registered by Arthur Sewall, later to become the partnership E. & A. Sewall, the 51st ship built by this company. The annually-published List of Merchant Vessels of the U.S. shows Bath was still the home port of Eric the Red in 1880. The vessel was named after the Viking discoverer, Eric ‘the Red-haired’ Thorvaldsson , who was the first European to reach the shores of North America (in 980AD). The ship Eric the Red at first traded in coal between America and Britain, and later traded in guano nitrates from South America. In 1879 she was re-metalled and was in first class condition. On 10th June 1880 (some records say 12th June) Eric the Red departed New York for Melbourne and then Sydney. She had been commissioned by American trade representatives to carry a special cargo of 500 exhibits (1400 tons) – about a quarter to a third of America’s total exhibits - for the U.S.A. pavilion at Melbourne’s first International Exhibition. The exhibits included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, samples of corn and the choicest of leaf tobacco. Other general cargo included merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The Eric the Red left New York under the command of Captain Zaccheus Allen (or some records say Captain Jacques Allen) and 24 other crew including the owner’s son third mate Ned Sewall. There were also 2 saloon passengers on board. The ship had been sailing for an uneventful 85 days and the voyage was almost at its end. As Eric the Red approached Cape Otway there was a moderate north-west wind and hazy and overcast atmosphere. On 4th September 1880 at about 1:30am Captain Allen sighted the Cape Otway light and was keeping the ship 5-6 miles offshore to stay clear of the hazardous Otway Reef. However he had badly misjudged his position. The ship hit the Otway Reef about 2 miles out to sea, south west of the Cape Otway light station. Captain Allen ordered the wheel to be put ‘hard up’ thinking that she might float off the reef. The sea knocked the helmsman away from the wheel, broke the wheel ropes and carried away the rudder. The lifeboats were swamped, the mizzenmast fell, with all of its rigging, then the mainmast also fell and the ship broke in two. Some said that the passenger Vaughan, who was travelling for his health and not very strong, was washed overboard and never seen again. The ship started breaking up. The forward house came adrift with three of the crew on it as well as a longboat, which the men succeeded in launching and keeping afloat by continually bailing with their sea boots. The captain, the third mate (the owner’s son) and others clung to the mizzenmast in the sea. Then the owner’s son was washed away off the mast. Within 10 minutes the rest of the ship was in pieces, completely wrecked, with cargo and wreckage floating in the sea. The captain encouraged the second mate to swim with him to the deckhouse where there were other crew but the second mate wouldn’t go with him. Eventually the Captain made it to the deckhouse and the men pulled him up. At about 4:30am the group of men on the deckhouse saw the lights of a steamer and called for help. At the same time they noticed the second mate and the other man had drifted nearby, still on the spur, and pulled them both onto the wreck. The coastal steamer SS Dawn was returning to Warrnambool from Melbourne, its sailing time different to its usual schedule. She was built in 1876 and bought by the Portland and Belfast Steam Navigation Co. in 1877. At the time of this journey she was commanded by Captain Jones, and was sailing between Melbourne and Portland via Warrnambool. The provedore of the Dawn, Benjamin Lear, heard cries of distress coming through the portholes of the saloon. He gave the alarm and the engines were stopped. Cries could be heard clearly, coming from the land. Captain Jones sent out crew in two boats, and fired off rockets and blue lights to illuminate the area. They picked up the three survivors who were in the long boat from Eric the Red. Two men were picked up out of the water, one being the owner’s son who was clinging to floating kerosene boxes. At daylight the Dawn then rescued the 18 men from the floating portion of the deckhouse, which had drifted about 4 miles from where they’d struck the reef. Shortly after the rescue the deckhouse drifted onto breakers and was thrown onto rocks at Point Franklin, about 2 miles east of Cape Otway. Captain Jones had signalled to Cape Otway lighthouse the number of the Eric the Red and later signalled that there was a wreck at Otway Reef but there was no response from the lighthouse. The captain and crew of the Dawn spent several more hours searching unsuccessfully for more survivors, even going back as far as Apollo Bay. On board the Dawn the exhausted men received care and attention to their needs and wants, including much needed clothing. Captain Allen was amongst the 23 battered and injured men who were rescued and later taken to Warrnambool for care. Warrnambool’s mayor and town clerk offered them all hospitality, the three badly injured men going to the hospital for care and others to the Olive Branch Hotel, then on to Melbourne. Captain Allen’s leg injury prevented him from going ashore so he and three other men travelled on the Dawn to Portland. They were met by the mayor who also treated them all with great kindness. Captain Allen took the train back to Melbourne then returned to America. Those saved were Captain Zaccheus Allen (or Jacques Allen), J. Darcy chief mate, James F. Lawrence second mate, Ned Sewall third mate and owner’s son, John French the cook, C. Nelson sail maker, Clarence W. New passenger, and the able seamen Dickenson, J. Black, Denis White, C. Herbert, C. Thompson, A. Brooks, D. Wilson, J. Ellis, Q. Thompson, C. Newman, W. Paul, J. Davis, M. Horenleng, J. Ogduff, T. W. Drew, R. Richardson. Four men had lost their lives; three of them were crew (Gus Dahlgreen ship’s carpenter, H. Ackman steward, who drowned in his cabin, and George Silver seaman) and one a passenger (J. B. Vaughan). The body of one of them had been found washed up at Cape Otway and was later buried in the lighthouse cemetery; another body was seen on an inaccessible ledge. Twelve months later the second mate James F. Lawrence, from Nova Scotia, passed away in the Warrnambool district; an obituary was displayed in the local paper. Neither the ship, nor its cargo, was insured. The ship was worth about £15,000 and the cargo was reportedly worth £40,000; only about £2,000 worth had been recovered. Cargo and wreckage washed up at Apollo Bay, Peterborough, Port Campbell, Western Port and according to some reports, even as far away as the beaches of New Zealand. The day after the wreck the government steam ship Pharos was sent from Queenscliff to clear the shipping lanes of debris that could be a danger to ships. The large midship deckhouse of the ship was found floating in a calm sea near Henty Reef. Items such as an American chair, a ladder and a nest of boxes were all on top of the deckhouse. As it was so large and could cause danger to passing ships, Captain Payne had the deckhouse towed towards the shore just beyond Apollo Bay. Between Apollo Bay and Blanket Bay the captain and crew of Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag-board bearing the words “Eric the Red” was found on the deckhouse; finally those on board the Pharos had the name of the wrecked vessel. During this operation Pharos came across the government steamer Victoria and also a steamer S.S. Otway, both of which were picking up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated on to Point Franklin. Some of the vessels yards and portions of her masts were on shore. The pieces of canvas attached to the yards and masts confirmed that the vessel had been under sail. The beach there was piled with debris several feet high. There were many cases of Diamond Oil kerosene, labelled R. W. Cameron and Company, New York. There were also many large planks of red pine, portions of a small white boat and a large, well-used oar. Other items found ashore included sewing machines (some consigned to ‘Long and Co.”) and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire (some branded “T.S” and Co, Melbourne”), kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts, croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a fly wheel, a cooking stove, timber, boxes, pianos, organs and a ladder. (Wooden clothes pegs drifted in for many years). There seemed to be no personal luggage or clothing. The Pharos encountered a long line, about one and a half miles, of floating wreckage about 10 miles off land, south east of Cape Otway, and in some places about 40 feet wide. It seemed that more than half of it was from Eric the Red. The ship’s crew rescued 3 cases that were for the Melbourne Exhibition and other items from amongst the debris. There were also chairs, doors, musical instruments, washing boards, nests of trunks and fly catchers floating in the sea. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. (There is a photograph of a life belt on the verandah of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. This is rather a mystery as the ship was registered in Bath, Maine, USA.) Parts of the ship are on display at Bimbi Park Caravan Park and at Apollo Bay Museum. Flagstaff Hill Maritime Village also has part of the helm (steering wheel), a carved wooden sword (said to be the only remaining portion of the ship’s figurehead; further research is currently being carried out), a door, a metal rod, several samples of wood and a medal for bravery, awarded to Nelson Johnson, a crew member of the S.S. Dawn by the U.S. President, for the rescue of the crew. Much of the wreckage was recovered by the local residents before police and other authorities arrived at the scene. Looters went to great effort to salvage goods, being lowered down the high cliff faces to areas with little or no beach to collect items from the wreckage, their mates above watching out for dangerous waves. A Tasmanian newspaper reports on a court case in Stawell, Victoria, noting a man who was caught 2 months later selling tobacco from the wreckage of Eric the Red. Some of the silverware is still treasured by descendants of Mr Mackenzie who was given these items by officials for his help in securing the cargo. The gifts included silver coffee and tea pots, half a dozen silver serviette rings and two sewing machines. A Mr G.W. Black has in his possession a medal and a purse that were awarded to his father, another Dawn crew member who was part of the rescue team. The medal is inscribed and named “To John Black ….” (from “Shipwrecks” by Margaret E. Mackenzie, 3rd edition, published 1964). The wreck and cargo were sold to a Melbourne man who salvaged a quantity of high quality tobacco and dental and surgical instruments. Timbers from the ship were salvaged and used in the construction of houses and sheds around Apollo Bay, including a guest house, Milford House (since burnt down in bushfires), which had furniture, fittings and timber on the dining room floor from the ship. A 39.7 foot long trading ketch, the Apollo, was also built from its timbers by Mr Burgess in 1883 and subsequently used in Tasmanian waters. It was the first attempt at ship building in Apollo bay. In 1881 a red light was installed about 300 feet above sea level at the base of the Cape Otway lighthouse to warn ships when they were too close to shore; It would not be visible unless a ship came within 3 miles from it. This has proved to be an effective warning. Nelson Johnson, recipient of the medal for bravery, married Elizabeth Howard in 1881 and they had 10 children. They lived in South Melbourne, Victoria. Nelson died in 1922 in Fitzroy Victoria, age 66. In 1895 the owners of the S.S. Dawn, the Portland and Belfast Steam Navigation Co., wound up and sold out to the Belfast Company who took over the Dawn for one year before selling her to Howard Smith. She was condemned and sunk in Suva in 1928. The State Library of Victoria has a lithograph in its collection depicting the steamer Dawn and the shipwrecked men, titled. "Wreck of the ship Eric the Red, Cape Otway: rescue of the crew by the Dawn".The wood (timber) sample is listed on the Collections Australia Database, Heritage Victoria, number 239 00010 A “The Eric the Red is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA) Wood sample from the wreck of the ship Eric the Red. Triangular shaped, full of sea worm (Teredo worm) holes. The wood is dark in colour and is very light in weight.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwreck-artefact, eric-the-red, zaccheus-allen, sewall, 1880, melbourne-exhibition, cape-otway, otway-reef, wood-sample, s.s.-dawn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWood Sample, About 1871

This piece of timber from the ship Eric the Red has been eaten through by the marine animals called Teredo Worms, sometimes called sea worms or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by using coatings of tar, wax, lead or pitch. In the 18th and 19th centuries the outside of their ships were sheathed in copper or a combination of copper and zinc (called Muntz metal) and would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. The American ship Eric the Red was a wooden, three masted clipper ship. She had 1,580 tons register and was the largest full-rigged ship built at Bath, Maine, USA in 1871. She was built and registered by Arthur Sewall, later to become the partnership E. & A. Sewall, the 51st ship built by this company. The annually-published List of Merchant Vessels of the U.S. shows Bath was still the home port of Eric the Red in 1880. The vessel was named after the Viking discoverer, Eric ‘the Red-haired’ Thorvaldsson , who was the first European to reach the shores of North America (in 980AD). The ship Eric the Red at first traded in coal between America and Britain, and later traded in guano nitrates from South America. In 1879 she was re-metalled and was in first class condition. On 10th June 1880 (some records say 12th June) Eric the Red departed New York for Melbourne and then Sydney. She had been commissioned by American trade representatives to carry a special cargo of 500 exhibits (1400 tons) – about a quarter to a third of America’s total exhibits - for the U.S.A. pavilion at Melbourne’s first International Exhibition. The exhibits included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, samples of corn and the choicest of leaf tobacco. Other general cargo included merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The Eric the Red left New York under the command of Captain Zaccheus Allen (or some records say Captain Jacques Allen) and 24 other crew including the owner’s son third mate Ned Sewall. There were also 2 saloon passengers on board. The ship had been sailing for an uneventful 85 days and the voyage was almost at its end. As Eric the Red approached Cape Otway there was a moderate north-west wind and hazy and overcast atmosphere. On 4th September 1880 at about 1:30am Captain Allen sighted the Cape Otway light and was keeping the ship 5-6 miles offshore to stay clear of the hazardous Otway Reef. However he had badly misjudged his position. The ship hit the Otway Reef about 2 miles out to sea, south west of the Cape Otway light station. Captain Allen ordered the wheel to be put ‘hard up’ thinking that she might float off the reef. The sea knocked the helmsman away from the wheel, broke the wheel ropes and carried away the rudder. The lifeboats were swamped, the mizzenmast fell, with all of its rigging, then the mainmast also fell and the ship broke in two. Some said that the passenger Vaughan, who was travelling for his health and not very strong, was washed overboard and never seen again. The ship started breaking up. The forward house came adrift with three of the crew on it as well as a longboat, which the men succeeded in launching and keeping afloat by continually bailing with their sea boots. The captain, the third mate (the owner’s son) and others clung to the mizzenmast in the sea. Then the owner’s son was washed away off the mast. Within 10 minutes the rest of the ship was in pieces, completely wrecked, with cargo and wreckage floating in the sea. The captain encouraged the second mate to swim with him to the deckhouse where there were other crew but the second mate wouldn’t go with him. Eventually the Captain made it to the deckhouse and the men pulled him up. At about 4:30am the group of men on the deckhouse saw the lights of a steamer and called for help. At the same time they noticed the second mate and the other man had drifted nearby, still on the spur, and pulled them both onto the wreck. The coastal steamer SS Dawn was returning to Warrnambool from Melbourne, its sailing time different to its usual schedule. She was built in 1876 and bought by the Portland and Belfast Steam Navigation Co. in 1877. At the time of this journey she was commanded by Captain Jones, and was sailing between Melbourne and Portland via Warrnambool. The provedore of the Dawn, Benjamin Lear, heard cries of distress coming through the portholes of the saloon. He gave the alarm and the engines were stopped. Cries could be heard clearly, coming from the land. Captain Jones sent out crew in two boats, and fired off rockets and blue lights to illuminate the area. They picked up the three survivors who were in the long boat from Eric the Red. Two men were picked up out of the water, one being the owner’s son who was clinging to floating kerosene boxes. At daylight the Dawn then rescued the 18 men from the floating portion of the deckhouse, which had drifted about 4 miles from where they’d struck the reef. Shortly after the rescue the deckhouse drifted onto breakers and was thrown onto rocks at Point Franklin, about 2 miles east of Cape Otway. Captain Jones had signalled to Cape Otway lighthouse the number of the Eric the Red and later signalled that there was a wreck at Otway Reef but there was no response from the lighthouse. The captain and crew of the Dawn spent several more hours searching unsuccessfully for more survivors, even going back as far as Apollo Bay. On board the Dawn the exhausted men received care and attention to their needs and wants, including much needed clothing. Captain Allen was amongst the 23 battered and injured men who were rescued and later taken to Warrnambool for care. Warrnambool’s mayor and town clerk offered them all hospitality, the three badly injured men going to the hospital for care and others to the Olive Branch Hotel, then on to Melbourne. Captain Allen’s leg injury prevented him from going ashore so he and three other men travelled on the Dawn to Portland. They were met by the mayor who also treated them all with great kindness. Captain Allen took the train back to Melbourne then returned to America. Those saved were Captain Zaccheus Allen (or Jacques Allen), J. Darcy chief mate, James F. Lawrence second mate, Ned Sewall third mate and owner’s son, John French the cook, C. Nelson sail maker, Clarence W. New passenger, and the able seamen Dickenson, J. Black, Denis White, C. Herbert, C. Thompson, A. Brooks, D. Wilson, J. Ellis, Q. Thompson, C. Newman, W. Paul, J. Davis, M. Horenleng, J. Ogduff, T. W. Drew, R. Richardson. Four men had lost their lives; three of them were crew (Gus Dahlgreen ship’s carpenter, H. Ackman steward, who drowned in his cabin, and George Silver seaman) and one a passenger (J. B. Vaughan). The body of one of them had been found washed up at Cape Otway and was later buried in the lighthouse cemetery; another body was seen on an inaccessible ledge. Twelve months later the second mate James F. Lawrence, from Nova Scotia, passed away in the Warrnambool district; an obituary was displayed in the local paper. Neither the ship, nor its cargo, was insured. The ship was worth about £15,000 and the cargo was reportedly worth £40,000; only about £2,000 worth had been recovered. Cargo and wreckage washed up at Apollo Bay, Peterborough, Port Campbell, Western Port and according to some reports, even as far away as the beaches of New Zealand. The day after the wreck the government steam ship Pharos was sent from Queenscliff to clear the shipping lanes of debris that could be a danger to ships. The large midship deckhouse of the ship was found floating in a calm sea near Henty Reef. Items such as an American chair, a ladder and a nest of boxes were all on top of the deckhouse. As it was so large and could cause danger to passing ships, Captain Payne had the deckhouse towed towards the shore just beyond Apollo Bay. Between Apollo Bay and Blanket Bay the captain and crew of Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag-board bearing the words “Eric the Red” was found on the deckhouse; finally those on board the Pharos had the name of the wrecked vessel. During this operation Pharos came across the government steamer Victoria and also a steamer S.S. Otway, both of which were picking up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated on to Point Franklin. Some of the vessels yards and portions of her masts were on shore. The pieces of canvas attached to the yards and masts confirmed that the vessel had been under sail. The beach there was piled with debris several feet high. There were many cases of Diamond Oil kerosene, labelled R. W. Cameron and Company, New York. There were also many large planks of red pine, portions of a small white boat and a large, well-used oar. Other items found ashore included sewing machines (some consigned to ‘Long and Co.”) and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire (some branded “T.S” and Co, Melbourne”), kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts, croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a fly wheel, a cooking stove, timber, boxes, pianos, organs and a ladder. (Wooden clothes pegs drifted in for many years). There seemed to be no personal luggage or clothing. The Pharos encountered a long line, about one and a half miles, of floating wreckage about 10 miles off land, south east of Cape Otway, and in some places about 40 feet wide. It seemed that more than half of it was from Eric the Red. The ship’s crew rescued 3 cases that were for the Melbourne Exhibition and other items from amongst the debris. There were also chairs, doors, musical instruments, washing boards, nests of trunks and fly catchers floating in the sea. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. (There is a photograph of a life belt on the verandah of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. This is rather a mystery as the ship was registered in Bath, Maine, USA.) Parts of the ship are on display at Bimbi Park Caravan Park and at Apollo Bay Museum. Flagstaff Hill Maritime Village also has part of the helm (steering wheel), a carved wooden sword (said to be the only remaining portion of the ship’s figurehead; further research is currently being carried out), a door, a metal rod, several samples of wood and a medal for bravery, awarded to Nelson Johnson, a crew member of the S.S. Dawn by the U.S. President, for the rescue of the crew. Much of the wreckage was recovered by the local residents before police and other authorities arrived at the scene. Looters went to great effort to salvage goods, being lowered down the high cliff faces to areas with little or no beach to collect items from the wreckage, their mates above watching out for dangerous waves. A Tasmanian newspaper reports on a court case in Stawell, Victoria, noting a man who was caught 2 months later selling tobacco from the wreckage of Eric the Red. Some of the silverware is still treasured by descendants of Mr Mackenzie who was given these items by officials for his help in securing the cargo. The gifts included silver coffee and tea pots, half a dozen silver serviette rings and two sewing machines. A Mr G.W. Black has in his possession a medal and a purse that were awarded to his father, another Dawn crew member who was part of the rescue team. The medal is inscribed and named “To John Black ….” (from “Shipwrecks” by Margaret E. Mackenzie, 3rd edition, published 1964). The wreck and cargo were sold to a Melbourne man who salvaged a quantity of high quality tobacco and dental and surgical instruments. Timbers from the ship were salvaged and used in the construction of houses and sheds around Apollo Bay, including a guest house, Milford House (since burnt down in bushfires), which had furniture, fittings and timber on the dining room floor from the ship. A 39.7 foot long trading ketch, the Apollo, was also built from its timbers by Mr Burgess in 1883 and subsequently used in Tasmanian waters. It was the first attempt at ship building in Apollo bay. In 1881 a red light was installed about 300 feet above sea level at the base of the Cape Otway lighthouse to warn ships when they were too close to shore; It would not be visible unless a ship came within 3 miles from it. This has proved to be an effective warning. Nelson Johnson, recipient of the medal for bravery, married Elizabeth Howard in 1881 and they had 10 children. They lived in South Melbourne, Victoria. Nelson died in 1922 in Fitzroy Victoria, age 66. In 1895 the owners of the S.S. Dawn, the Portland and Belfast Steam Navigation Co., wound up and sold out to the Belfast Company who took over the Dawn for one year before selling her to Howard Smith. She was condemned and sunk in Suva in 1928. The State Library of Victoria has a lithograph in its collection depicting the steamer Dawn and the shipwrecked men, titled. "Wreck of the ship Eric the Red, Cape Otway: rescue of the crew by the Dawn".The wood (timber) sample is listed on the Collections Australia Database, Heritage Victoria, number 239 00010 A “The Eric the Red is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA) Wood sample from the wreck of the ship Eric the Red. Oblong shaped, full of sea worm (Teredo worm) holes. The wood is dark in colour and is very light in weight. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwreck-artefact, eric-the-red, zaccheus-allen, sewall, 1880, melbourne-exhibition, cape-otway, otway-reef, wood-sample, s.s.-dawn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Rod, Approx. 1871

This rod was salvaged from the American three-masted wooden clipper ship, Eric the Red, named after the Viking discoverer, Eric the Red. The ship first traded in coal between America and Britain and later traded in guano nitrates from South America. In 1879 its hull was re-metalled and the vessel was in first class condition. On 10th June 1880 Eric the Red departed New York under the command of Captain Z Allen, with 24 crew plus two passengers. It was heading for Melbourne and then Sydney. The ship was commissioned by American trade representatives to carry a special cargo of 500 American exhibits for the U.S.A. pavilion at Melbourne’s first International Exhibition. The items included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, and samples of corn and the choicest of leaf tobacco. Also on board was general merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The ship had been at sea for 85 days when, on 4th September 1880, it hit the Otway Reef on the southwest coast of Victoria and was quickly wrecked. Captain and crew ended up on floating parts, or in the long boat or the sea. He was amongst the 23 battered and injured men who were rescued by the steamer Dawn and later taken to Warrnambool, where they received great hospitality and care. Four men lost their lives; three crew and one passenger. Captain Allen took the train back to Melbourne and then returned to America. The captain and crew of the Dawn were recognised by the United States Government in July 1881 for their humane efforts, being thanked and presented with substantial monetary rewards, medals and gifts. The salvaging ship Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag board bearing the words “Eric the Red” was found on the deckhouse; finally, those on board the Pharos had found the name of the wrecked vessel. The government steamer Victoria and a steamer S.S. Otway picked up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated onto Point Franklin. Some of the vessel's yards and portions of its masts were on shore with pieces of canvas attached, confirming that the vessel had been under sail. On shore were many cases of Diamond Oil kerosene labelled R. W. Cameron and Company, New York. large planks of red pine, portions of a small white boat and a large, well-used oar. There were sewing machines, some consigned to ‘Long and Co.”, and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire, some branded “T.S” and Co, Melbourne”, and kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts. Other cargo remains included croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a flywheel, a cooking stove, timber, boxes, pianos, organs, wooden clothes pegs and a ladder. There were three cases of goods meant for the Exhibition Other items salvaged from amongst the debris floating in the sea were chairs, doors, musical instruments, washing boards, nests of trunks and flycatchers. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with a chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. A life belt was once on the veranda of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. Parts of the ship are on display at Bimbi Park Caravan Park and Apollo Bay Museum. Flagstaff Hill Maritime Village also has several artefacts from the wreck. There seemed to be no personal luggage or clothing. “The Eric the Red is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA)Iron rod with flat lugged washer. The rod is made of a heavy metal with encrustations and signs of rusting on the surface. It is stepped down in diameter mid-shaft and is slightly bowed on the narrower end. The narrow end flares out slightly in the last few centimetres with a burred foot and has a circular head on the wider end. The washer on the narrower end cannot move past the centre or the narrow end of the rod. The washer is a different metal from the rod and has a small lug jutting out along the circumference in one position. The rod was recovered from the wreck of the ship the Eric the Red.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rod, iron-rod, eric the red, steamer dawn, cape otway reef, 1880, captain allen, usa pavillion, melbourne exhibition, melbourne international exhibition, captain jones, medal, united states government, pharos, a. james, flag board, steamer victoria, steamer otway, diamond oil, r w cameron and company, long and co., t s and co melbourne, a. field and son, taunton, massachusetts, ketch apollo, ship nail -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wash trough, Melvin Newton Lovell, Mangle was Patented June 10, 1898 by Lovell Trough is possibly of later manufacture by a local unknown cabinet maker between 1900-1920

... the principal products of the original factory were washing machines... the principal products of the original factory were washing machines ...Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers). This item is now sought by collectors and is even rarer due to it's combination with a Lovell clothes wringer. Wooden wash trough with 2 troughs & attached a Lovell wringer (or mangle Anchor Brand) Hard to make out as worn off with useflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, wash trough, wringer, mangle, laundry, cleaning, washing, housework, domestic, melvin newton lovell, wooden was trough -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Standard avoirdupois weights, Avery Ltd, 1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weights, metal, silver electroplated, 1 x 2lb, 2 x 4lb, 1 x 7lb. (4) all government stamped, made by Avery Ltd.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, imperial weight, imperial standard weights and measures, imperial standard weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Weight Avoirdupois, Avery Ltd, 1940-1950s

A weight made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. An item used used by grocers and merchants to weigh store bought goods around the 1950s. This item gives an insight into social history of the time.Weight, brass, Stamped F27, 2lb.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, weight, brass weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century