Showing 110 items

matching machine maker

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Surgeon's Gown, early to mid 20th century

This surgeon's gown was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. White, heavy duty cotton surgeon's gown, part of the W.R. Angus Collection. Gown hasshoulder button fastening. Both cuffs are well worn and fraying, also 'L' shaped tear on front right has been machine repaired. Remnants of label on inside collar with name "ANGUS". Also Maker's label, "PUKKA", made in Melbourne.Remnants of ‘ANGUS” on inside collar. Maker’s label “It’s a PUKKA” and “PUKKA DRILLS / TAILORED BY PERO MELBOURNE / UNSHRINKABLE” Label has "SIZE 42" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, surgeon's gown, surgical clothing, pukka, pukka drills, tailored by pero melbourne, melbourne taylor -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

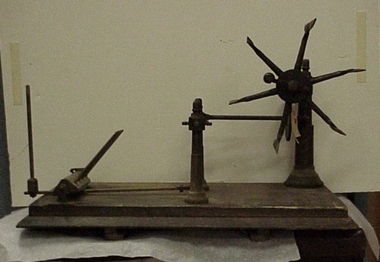

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing machine, Wilcox & Gibbs, c1870

... dressmaking mateial machine makers wrought iron work telford england ...Willcox and Gibbs: Serial No. 158679. The Willcox & Gibbs Sewing Machine Company was founded in 1857 by James E. A. Gibbs and James Willcox and opened its London Office in 1859 at 135 Regent Street . By 1871 the Company's Chief Office for Europe was at 150 Cheapside, London, this office was later moved (post 1885) to 94 - 96 Wigmore Street, then 37 & 39 Moorgate Street (by 1891 to post 1907) and later 20 Fore Street, London . Right from the initial production the manufacturing of the Company's single thread, chain stitch machine was undertaken by Brown & Sharpe, Rhode Island and this continued up until 1948. A special hand crank mechanism was produced in England for the European market, but the general design of the Willcox & Gibbs remained essentially the same throughout its production. The only major improvement was in 1875 when the glass tension discs were replaced with an automatic tension device which ensured the machine could not get out of adjustment. In addition to the domestic hand and treadle machines the company produced a wide range of industrial models. The Company finally closed in 1973. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America in the late 1860's but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The cloth plate has various American patent dates, four dating between 1857 & 1860 relating to J. E. A. Gibbs, three dating between 1860 & 1864 relating to Chas H. Willcox (son of James Willcox), the machine was also licensed under five other patents including the infamous Elias Howe patent of 1846. There are only two English patents one for J. E. A Gibbs and the other for James Willcox. In 1887 a W & G Sewing Machine sold in England for 6 pounds , with its box and bits, at a time when the average wage was less than 10/- shillings per week. The early settlers of Moorabbin Shire had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. The women were skilled dressmakers and craft workers.Willcox and Gibbs: Serial No. 158679. A single thread, chain stitch Sewing Machine with a special hand crank mechanism produced in England for the European market, and the glass tension discs which were used on domestic models until 1875. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America c1870 but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The Willcox & Gibbs badge is located on the rear of the base castingsewing machines, early settlers, pioneers, moorabbin, brighton, gibbs james, willcox james, willcox henry, new york, america, dressmaking, mateial, machine makers, wrought iron work, telford england -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Jewellery, 2 lady's hat pins mauve, c1900

A hat pin is a decorative pin for holding a hat to the head, usually by the hair that was styled in a Chignon or French Roll style and usually worn in a pair. They are typically around 20 cm in length, with the pinhead being the most decorated part. The hatpin was invented to hold veils in place, and was handmade. Birmingham, England was the centre of production when demand eventually outgrew the number that could be supplied by hand-making and they also began to be imported from France. In 1832, an American machine was invented to manufacture the pins, and they became much more affordable. During the 1880s, bonnets gave way to hats, some of which were very large and the popularity of hatpins soared. In the Victorian era, when appearance was everything, it just wouldn't do for a fashionable lady's hat to blow off in the wind. They remained a standard women's' accessory through the 1910s and were produced in a vast range of materials and types. Hat pin holder boxes were also produced. One of the most well-known makers of hatpins is silversmith Charles Horner, of Halifax, whose turn of the century jewellery company became a leader in the market by creating a series of mass-produced pins that were still of exceptional quality. As a result, thousands of Horner's pins are still on the market and on display in museums worldwide. Women of the 1920’s used hat pins as decoration on their Cloche hats that fitted snugly to their heads. The women of the pioneer families liked to dress up in their best hand made dresses and fashionable hats for Church gatherings and special occasions as a relief from the daily chores of hand washing, ironing with flat irons and cooking over open fires.2 lady's long steel hat pins with sequents in a flower design on mauve material bonnets, hats, veils, scarves, moorabbin, bentleigh, brighton, cheltenham, early settlers, pioneers, clasps, hairdressing, combs, steel pins, jewellery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing machine in cabinet, Ward Brothers (G & S Ward), ca. 1933

The donor inherited this Wardana machine from her mother, who bought it in about 1933 and used it to sew garments for her sister's dressmaking business in Frankston, Victoria. The donor often used this machine until she purchased an updated model. There were originally three Ward Brothers who owned the North Melbourne sewing machine business but they had a falling out. This machine's decals on the map of Australia only include the two remaining brothers. The Ward Brothers, G & S Ward, established their sewing machine business in North Melbourne in 1888. The cabinets and ironwork of the machines were made in Australia and the Ward Bros. imported their machines from overseas manufacturers in England, America and Germany. The assembled machines were sold under brand names that included Ward, A.N.A. the patriotic-sounding Australian Sewing Machine Company. The "Wardana" was one of their brands.This sewing machine was fabricated in Australia from imported parts from England, giving a snapshot into the early manufacturing industries that were operating at the time just after Federation.Sewing machine in a wooden cabinet with iron foot-operated cast iron treadle mechanism. The hinged cabinet top opens out to form a worktop. The sewing machine lifts out of the cabinet to sit level with the worktop, resting on two supports within the cabinet. The lockable cabinet door opens from right to left revealing fitted shelves and spikes for spools and bobbins. The gold-painted maker's name is cast into the black treadle. The machine has its original instruction book, oil can, and eighteen accessories in an enclosed cardboard box. The round shallow oil bottle has a rubber dispensing tube. Colourful decals decorate the black body of the machine. Inscriptions include a Serial Number stamped on the bed of the machine. The Wardarna Central Bobbin machine was made in England for the Ward Brothers of North Melbourne.TREADLE: cast into metal ACROSS THE TOPE AND ON THE FOOTPLATE "WARD", "WARD" SERIAL NUMBER stamped into oval plate "28383" DECAL: (Map of Australia ) with images of [two brothers] , "WARDANA" above (logo of the rising sun) DECAL: (Decorative floral design with heraldic-like emblems) above "MADE IN ENGLAND" ARM: "WARDANA" PEDESTAL: "C.B." (representing Central Bobbin) "MADE IN ENGLAND" "MADE IN ENGLAND / FOR / WARD BROS / NORTH MELBOURNE" BOOK TITLE: "Instructions for Treadle Machine" ACCESSORIES: some have indecipherable embossed stamps OIL BOTTLE base: (image of log and short lines radiating from a central inscription (indecipherable)sewing machine, domestic, wardana, ward bros., central bobbin, made in england, north melbourne, c.b., flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, treadle sewing machine, home industry, clothing, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Voice Recorder, Thomas A. Edison, Edison Laboratory, 1916-1929

This Edison Ediphone voice recording electronic business machine is manufactured to suit a small office and is light enough to carry between work and home for use outside normal business hours. It is a dictation machine, also called by the competitor’s brand name ‘Dictaphone’, and is used for recording spoken words that would later be transcribed and typewritten. A wax cylinder would be installed onto the machine’s drum and the Reproducer on the machine would be lowered onto the cylinder. The user would speak a message into a microphone and the reproducer would then convert the sounds to scribed marks on the cylinder. Later, the cylinder could be played and the Reproducer would enable the sound to be amplified through an attached speaker. This machine is currently without its power cord, microphone and speaker horn. Thomas A. Edison extended the technology of the telegraph to his phonograph machine, invented in the late 19th century. It could record and play back sounds of music and voice on a manually operated mechanical machine that used wax cylinders to store the sound. He envisaged the way this technology could be an asset in the office, and he was right! However, most of his phonograph machines were used for entertainment, some for playing lessons, and some for-teaching languages. In 1916 Edison introduced the Ediphone, which grew in popularity after the First World War and into the late 1920s until flat round records replaced the wax cylinders. This Edison Ediphone is significant for improving the way business administration was carried out in the early 20th century, freeing up precious time for professionals and administrative personnel. It was the forerunner of audio tapes and digital technology. The Ediphone enabled letters to be dictated when the time and place suited and reduced the time professionals needed to spend with their secretaries. Secretaries were able to type the letters as they played the recording and they could replay the message if necessary.Voice recorder; a dictation machine; desktop model Edison Ediphone. The electronic machine is in a medal case with remnants of the original grey colour. It has a rectangular base with an A4-sized footprint and a domed hood that retracts halfway into the back of the base. The corners of the base have metal reinforcing, and a short metal bar is on the front centre edge of the lid and the base. A long metal drum is mounted inside the machine. A round device called a ‘reproducer’ is mounted above the drum. There is a folding handle on the left front of the machine and an angled stand with paper guides in front of the drum. A rear cover has the maker’s name stamped on it. An electrical socket with eight pins is recessed beside the cover. Made by Edison.In white letters; “EDISON”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, edison, ediphone, dictating machine, office equipment, voice recorder, usa, dictation, communication, office machine, dictaphone, speaking phonograph, thomas edison, ediphone voicewriter, voice writer -

Bendigo Historical Society Inc.

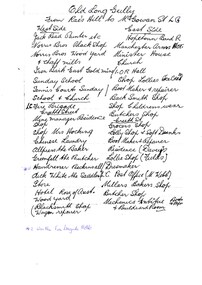

Bendigo Historical Society Inc.Document - LONG GULLY HISTORY GROUP COLLECTION: OLD LONG GULLY FROM RAE'S HILL TO MCGOWAN ST

Titled Old Long Gully From Rae's Hill to McGowan St. LG. West Side - Jack Read Painter etc, Norris Bros Black Shop, Norris Bros Wood Yard & Chaff Mills, Iron Bark East Gold Mine, Sunday School, Tennis Courts Sunday School & Church, LG Fire Brigade, Creeth Street, Mine Managers Residence, Shop, Shop Mrs Hocking, Chinese Laundry, Allpress the Baker, Greenfell the Butcher, Hairdresser Beckinsall was the Fire Brigade Hotel, Dick White the Saddler, Store, Hotel Rose of Australia, Woodyard, Blacksmith Shop Wagon Repairer, Hotel Kocks (Pioneer Hotel), 2 China Shops owned by Chinese, Hotel Silver mines Hotel, Police Station, Grocers Shop (per? Reef Mine Hotel) E Bryant, Mine Windmill, Church Residence, Minister. East Side - Hopetoun Band R, Manchester Arms Hotel, Minister House, Church, IOR Hall, Shop Lollies Icecream, Boot Maker & Repairer, Back Smith Shop, Shop Childrens Wear, Butchers Shop, Creeth Street, Grocers Shop, Lolly Shop & Soft Drinks, Boot Maker & Repairer, Residence (Davey's), Lollie Shop (Fields), Dressmaker, LG Post Office (M Webb), Millars Bakers Shop, Butcher Shop, Mechanics Institute Books & Paper & Billiard Room, Connell the Baker, Dr SElby, Pentreath Organ Builder & Tuner, Blacksmith Shop, Hexagon Toilet, Kocks Machine Shop, Kocks Mine Office, Kocks Material Shop, Police Station, Dyson's Dam Warm waer, Air Station, Mine Battery stone crusher 80 head approx, Kocks Mine, Needle Mine. Some notes written at the end - Norm Shotples used to have Barber Shop - he has gone to Queensland, Violet Street started off as the German School, Wells Street used to run through Victorian Consol ? the other side, Comet Hill would like a visit. Contact Helen Gorlay at Violet Street would line to some video. Alan has good info on the Long Gully School. Betty has book. Views of Bendigo. Frank Cusack - Bendigo Trust. Bendigo School Hisking? School, Violet Street. Older levels lo?ing at Architecture.bendigo, history, long gully history group, the long gully history group - old long gully from rae's hill to mcgowan st, jack read, norris bros, iron bark east gold mine, long gully fire brigade, mrs hicking, allpress, greenfell, beckinsall, dick white, rose of australia, hopetoun band r, manchester arms hotel, ior hall, davey's, fields, m webb, millars, mechanics institute & billiard room, kocks pioneer hoel, silver mines hotel, e bryant, windmill mine, pere? reef mine hotel, connell, dr selby, pentreath, kocks machine shop, kocks mine office, kocks material shop, dyson's dam, kocks mine, needle mine, norm shotples, german school, victoria consols, helen gorlay, long gully school, frank cusack, bendigo trust -

Coal Creek Community Park & Museum

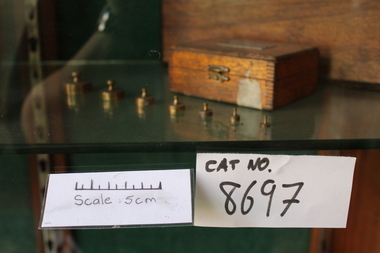

Coal Creek Community Park & MuseumWeights

8697.1 - Small wooden box with a metal latch used to house the small weights. 8697.2 - Brass weight. 8697.3 - Brass weight. 8697.4 - Brass weight. 8697.5 - Brass weight. 8697.6 - Brass weight. 8697.7 - Brass weight. 8697.8 - Brass weight.8697.1 - NAG BROWN MAKERS - Melbourne - Scientific instruments - Fine weighing machines -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumGritzner Sewing Machine, Gritzner

9050.1 Hand operated Gritzner Sewing Machine 9050.2 Bobbin 9050.3 Black handled screw driverGRITZNER R on machine in gold 2721541 on machine plate GRITZNER, DURLACH on metal maker's crest of spider in a web -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - LADIES STRIPED''SHIRT MAKER'' LONG SLEEVED DRESS, 1950's

Clothing. A ''shirt-maker'' styled ladies long-sleeved dress, with 4 mm, red/navy striped fabric. The ''straight-through'' dress has a tie-belt, 2cm wide if desired. Long 3/4 set-in sleeves are gathered into a ''turn-back'' cuff 6.5 cms wide, and fastened by two x 1.5 cm covered buttons,and two false stitched button holes. Five covered buttons and machine-stitched burtton holes in the front, from below the revere collar to below the waist.costume, female, ladies shirtmaker dress -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Vehicle - Centurion A41 Battle Tank, c.1948

A41 Centurion Main Battle Tank.This tank carried a crew of four - a Commander, Gunner, Loader and driver. It was powered by a Rolls Royce V12 Meteor petrol engine and it had a top speed of about 34 kph. It had a 5 speed crash box transmission and drum brakes. There was a twenty pounder main gun and two machine guns. This tank has been fitted with items that were used in Vietnam as well as the items carried by crews for their own comfort. These items cover the four tours by Centurion MBT in Vietnam - C Sqn, B Sqn, A Sqn & C Sqn, who served two tours. Most tanks also carried several stretchers, mainly for use of the infantry. Army registration number/ serial number: 169016, Unit marking 106, WIDOW MAKER on gun barrel. centurion tank, tank, transport -

Puffing Billy Railway

Puffing Billy RailwayMachine - Steam Hammer, G James, 1841

Steam hammers, invented by Englishman John Naysmith in 1841, made possible the forging of heavy iron bars and greatly reduced the physical labour required in forging. The hammers could vary in capacity (drop-force) from 400 pounds [lbs.] (181 kg) to 400 Tons (406.3 tonnes) and were once a part of most major engineering works. The Victorian Railways, from where the Museum exhibit came, used many hammers of varying sizes, their largest being at Newport Workshops measuring 30 feet (9.1 metres) high by 15 feet (4.6 metres) wide. Steam Hammers have made forging of heavy iron bars possible and has greatly reduced the physical labour required in forging. Historic - Victorian Railways - Industrial Steam Hammer Large metal mechanical steam hammer. made of iron & wrought ironC James Maker Melbournelarge, mechanical, steam, hammer -

Puffing Billy Railway

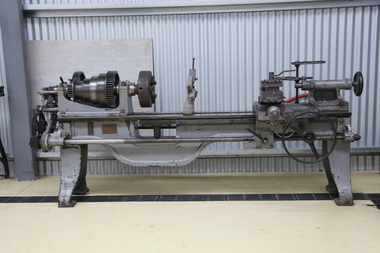

Puffing Billy RailwayLathe - Gap Bed, early 1900s

Possibly ex Victorian Railways Newport workshops Supplied by Bevan & Edwards Machinery Merchants, Melbourne Sebastian Lathes Described by its makers as the Utility School, Garage and Repair-shop Lathe, the machine immediately below, a Sebastian 15" (circa 1910 - 1926) was the Company's cheapest offering and, in its basic form, lacked a compound slide rest, the tailstock did not set over for taper turning and the bed lacked a gap. However, a friction-type countershaft unit was included in the price as well as a tool post, faceplate, drive plate, changewheels for screwcutting and a small tool kit. As with modern cars (especially BMW) everything worthwhile was on the options' list and by spending more it was possible to specify all those small but important extras. Although in its lowest-cost form this model was reduced to the fundamentals required for a useable, screwcutting centre (engine) lathe it was still reasonably specified and would certainly have fulfilled many requirements when installed in a school or training workshop. The true swing was 15.25", it was properly backgeared and screwcutting was through a conventional tumble-reverse mechanism that allowed both left and right-hand powered movement to the carriage by altering the position of just one lever. As standard it accepted 40" between centres, but any capacity could be ordered, in foot intervals, up to a maximum of 88" - when it is hoped that a central bed support might have been included …… The spindle, which ran in white-metal bearings, had a useful 15/8" hole and a No. 3 Morse taper centre. Some models appear to have had the leadscrew clasp-nut lever on the right-hand side of the apron, while on others it was positioned to the left.. Early Sebastian 13-inch lathe Typical of the Centre or "Engine" lathe made by many manufacturers from the late 1800s until the late 1930s, the basic flat-belt drive Sebastian, with separate countershaft, was eventually relegated to the economy end of the Company's range by the introduction of geared headstocks and self-contained motor-drive systems.Historic - Industrial Machinery - Gap Bed Lathe - Possibly ex Victorian Railways Newport workshops - Purchased and supplied from Bevan & Edwards Gap Bed Lathe - Grey with raw steel parts and a timber cupboard with gears and tools. Bevan & Edwards PTY,LTD Machinery Merchants Melbourne (possible government tag) 365bevan & edwards pty,ltd machinery merchants melbourne, puffing billy -

Puffing Billy Railway

Puffing Billy RailwayThe Quasi Arc Co Ltd Generator - Flat Belt Driven D.C, 1900s

QUASLARC Generator Built by the Quasi-Arc Co. Ltd. Victoria London SW.1, This generator is believed to have been used for welding purposes. The generator is driven by a belt from a nearby steam plant. The quasi-arc co ltd 6 kw. d.c generator 60/30 volts 0/200 amps 1200 rpm comp cont rating No 4696 Historic - Industrial Generator Large casting with a drive pulley on one end, cast aluminum covers, bronze makers plaque. The quasi-arc co ltd 15,grasyenor ????ens. Victoria,London,S.W.1 This machine is designed for use with ????? Arc electrodes 6 kw. d.c generator 60/30 volts 0/200 amps 1200 rpm comp cont rating No 4696puffing billy, generator, welding, quasi - arc -

Clunes Museum

Clunes MuseumDomestic object - LACE MAKER

Includes; .1 Lace Maker .2 3 x samples of lace .3.Bill of Sale dated 7 March 1916 payment received with thanks C.H Coombe .4 Price list of Torchon Lace Co.229 Collins Street, Melbourne, Victoria, Australia .5The Torchon Lace Making Booklet, 12th edition, copyright 1904 .6 Letter (undated) offering The complete lacemaking outfit .7 Document with customer reviews .8 Booklet "The Torchon Lace Maker (illustrated) Copy right 1904 All rights Reserved .9 30 x cardboard lace making patterns No. 20 Torchon Edging, Diamond Point Edging, Net Ground, 2 x Round Point Edging, Edging No. 11, Diamond Antique Edging, Jewel Insertion, Smyrna Edging, Rose Ground, Edging No. 24, Insertion No. 22, No.5 Twisted Hole Ground with "Spider". Spider insertion, Copenhagen Lace, Plain Hole Ground, Ornamental Ground Pin Check, Block Lace, Spider Lace, No. 18 Medici Lace, ZigZag Lace, Wide Antique Lace, Diamond Antique Edging, Block Lace, Jewel Insertion, Edging No. 24, Spider Lace, Zig-Zag Lace, Medici Lace, No. 21 Maltese Lace. .10 .35 x bobbins (8 with cotton) .11 2 x cream coloured lace doyleys with square linen damask machine sewn into the centre of the doyley. .12 Large wooden cotton reel with cream coloured lacemaking thread .1 White sticker, "63" printed in black placed on Lace Maker .12 Eagley imprinted into one end of the reellace making machine, christina mckenzie lawrence -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps Museumcream separator, Approx 1900

very old steel machine on solid stand. Vat (23 gallons per hour) is from a different machine (alfa laval). The separator is American with Australian agency. All parts are there but not put together. Two spouts,one for skim milk, one for cream. Run by hand with turning handle attached.Mc Cormick Deering U.S.A (maker) Chicago. International harvester company (Agent)dairy, cream, imported materials -

Anglesea and District Historical Society

Anglesea and District Historical SocietySewing Machine, Estimated 1890

... Anglesea great-ocean-road machine sewing hand operated Maker's ...Jones Lock-Stitch Sewing Machine made of black painted heavy metal with gold-leafed pattern on the fiddle-shaped base and along the upper arm. Four claw feet moulded on to base and handle attached to wheel - metal workings visible under hollow base.Maker's insignia on centre of base in gold and green circle reads "JONES MACHINE" around circumference and 'HAND" in central shield.machine, sewing, hand operated -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.F H Murgatroyd/20 Kensington Rd/ Leopold 3224weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumTextile - Quilt, Domestic Wagga, 1950s

Part of the Running Stitch collection, possibly made in BallaratDomestic wagga, unfilled, consisting of two machine sewn layers of woollen garment pieces both knitted and woven. The front pieces are predominantly red, blue and yellow, the back is mostly brown red and blue.WAGGA/ Maker unknown 154cm long X 90cm wide/ Made of parts of wool garments, knitted and woven.....handicrafts quilting quilting - history, running stitch collection, running stitch group, handicrafts, quilting, quilting - history -

National Wool Museum

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

National Wool Museum

National Wool MuseumFunctional object - Typewriter, Remington Typewriter Company, c.1925

This Remington No.12 typewriter is of the typebar, front-strike class. It was made by the Remington Typewriter Company of Ilion, New York, U.S.A. in about 1925. The Model No. 12 was introduced in 1922 and was one of the first 'visible writer' machines, in which the typed characters were visible to the operator. Previous models were of the upstrike class in which the characters were typed on the underside of the platen. To see what had been typed the operator had to raise the platen, meaning the typist was typing blind much of the time. This machine was used by Margaret Ganly née Burn in the 1930s. It was purchased for her by one of the sons of William Pride, a famous saddle maker in Geelong, William was Margaret’s grandfather. The typewriter was donated with original sales receipt and servicing tools. Margaret worked at Dennys for 7 years during the 1930s. The typewriter is accompanied with a story written by Margaret about her time working at the company. Margret married Jack Ganly, a fellow employee of Dennys. The Ganly name was well known within Dennys, with three generations of the Ganly family working at the company. WORKING CONDITIONS & OFFICE WORK DUTIES. Written by Margaret Burn in 2021. Worked at Dennys Lascelles in the 1930s. In the 1930s coming out of the Depression, jobs were hard to come by and had to be clung to by efficiency and subserviency. There was no union to protect workers – bosses could be tough and rough. Dennys Lascelles revolved around fortnightly wool sales in the “season” – September to May. Sale day was always a day of suppressed excitement. Preparation from a clerical point of view was complete and we now awaited the aftermath of the actual wool auction. The building teemed with people. There were country people down to see their wool sold, buyers of many nationalities, or from the big cities, who were coming in and out of the building all day. Their role was to inspect the acres of wool bales displayed on the show floors; however, caterers were present to feed clients, and there was plenty of social interactions on top of business. The office staff did not go home but waited until the first figures came back from the wool sales and the machines went in to action, both human and mechanical, preparing the invoices for the buyers’ firms. This comprised of lists of lot numbers, weights, prices per lb., and the total prices paid. A lot of this was done by old-school typewriters, making this work a big, heavy, tiring job. Before the finished lists could be dispatched, they were collated on an “abstract”. The lists had to balance with the catalogue from which the invoices had been prepared. This never happened automatically. All the paperwork had to be split up amongst pairs of workers and checked until discrepancies were found. This would happen until midnight but occasionally went until 2 or 3 am. Once complete, the invoices could then be rushed off to the buyers’ firms usually in Melbourne, and hire cars took the staff home. It was back on the job the next morning, usually around 8.30. The office hours varied according to the size of the sale and work involved. Some days started as early as 8 and could finish around 5.30. The second phase of work began with the account sales to be prepared for the sellers of the wool. These detailed all the weights, descriptions of wool, brands, and prices. One Sales account could have multitudes of lot numbers, all needing to be individually described. Various charges needed to be deducted such as finance for woolpacks, extra stock, or farmers who were given a loan to live on during the season. Details of how payment was to be made was also noted, whether the seller was to be paid by cheque, to a bank, or credited to their account with the company (which often left the seller still in debt). For a couple of months in the winter, things were quieter when staff took holidays and were sometimes given afternoons off. But there were still weekly skin sales and stock sales around the state. The annual end of June figures to be prepared for a big company like Dennys with branches all around the state also kept the staff busy. In good years there was sometimes a bonus. On sale days there was a bar open for the clients and wool buyers. This added to the excitement for the young girls, who were strictly barred from using it, but somehow managed to sneak a gin and tonic. This is how I had my first ever, before the evening meal. There was also the romantic notion in some minds, with all the influx of males, that some of us might end up on a wealthy station, or be noticed by an exotic buyer. To my knowledge, this never happened at Dennys Lascelles Limited. Group staff photo at Dennys Lascelles Limited. Margaret Burn. Age 18 or 19. Jack Ganly (Margaret’s future husband). 22.The typewriter has a black painted metal frame. The top section of the typewriter consists of a cylindrical platen on a carriage featuring plated metal fittings. A curved folding paper guide sits behind the platen and moves on the horizontal axis when the user types on the keyboard. A horizontal semicircular type basket with typebar links the top section to the lower keyboard. The ink ribbon is carried between two spools on a horizontal axis, one on each side of the type-basket. At the rear, a paper tray features gold lettering which reads ‘Remington’. At the front, a four-row QWERTY keyboard is found with 42-character keys total. 'SHIFT LOCK' and 'SHIFT KEY' are to the left of the keyboard, 'BACK SPACER' and 'SHIFT KEY' to the right. All keys are circular, white with black lettering. At the top of the keyboard are five circular red keys with the numbers 1-5 displayed behind their respective keys. A Spacebar is found along the front of the keyboard. The typewriter is accompanied by a cardboard box. This box contains the original sales receipt, on blue paper with grey lead handwriting. It also contains spare parts, a spare ribbon stretched between two spools, and cleaning tools such as brushes of differing sizes. Serial Number. Engraved. "LX45395" Gold lettering. Paper tray. “Remington” Gold Lettering. Behind keyboard. “Made in Ilion, New York, U.S.A. Gold Lettering. Mirrored both sides of type-basket. “12”remington, dennys lascelles ltd, worker conditions 1930s -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumMakers Plate

Makers plate (from a knitting machine) from the Grosser Knitting Machine Company, Leicester.THE / GROSSER KNITTING / MACHINE COMPANY / NICHOLS STREET WORKS / LEICESTERmachine knitting, grosser knitting machine company -

National Wool Museum

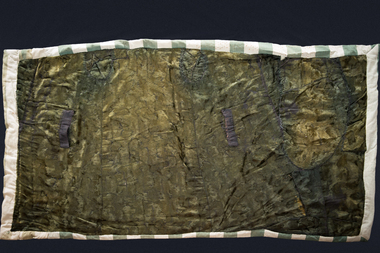

National Wool MuseumQuilt, Travelling rug

Part of the Wagga collection. Maker unknown, c. early 1940s. Possibly from South Australia. This 'travelling rug' was found in an opportunity shop in Campbell's Creek near Castlemaine in Victoria. Unfortunately, nothing is known about the maker but it could be surmised that the quilt had many uses. It is heavy and designed for warmth, lined with a woollen blanket and hessian. Its size suggests usage in an open buggy or car when travelling or as a picnic rug along the way. The sturdy canvas backing is of the type commonly used for awnings, chair coverings or tent cloth. The quality of the green velvet made it ideal for further use as a quilt after the original use as an overcoat or smoking jacket for either a man or a woman. Apart from the original machine stitched seams in the garment, it is sewn together by hand using herringbone stitch. It is not known if this quilt was designed to be used with a cover. However, the arrangement of pieces in the garment to create a shape with straight edges may suggest that this may have been a consideration.Travelling rug made of wool, cotton and green velvet.No. 27 "Travelling rug" Maker Unknown Running Stitch Collection...quilting history, handicrafts, running stitch group, blankets, running stitch collection, highlights of the national wool museum: from waggas to the wool quilt prize - exhibition (22/09/2001 - 02/12/2001), quilting - history -

National Wool Museum

National Wool MuseumBook, Textile Machines

This book provides a brief history and overview of English textile machinery, machinery makers and factories.SHIRE / ALBUM / 103 / Textile Machines / ANNA P. BENSONtextile machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Cigarette Maker

Nickel plated cigarette tin with the Crest of Jersey. Also contains a cigarette making machine. It has two rollers to take the cigarette papers and the tobacco to make a cigarette. Also included is a packet of Tally Ho cigarette papers and the direction for making cigarettes.EVANCON OD No.548003 Made in England.personal effects, smoking accessories