Showing 157 items

matching machine parts

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing machine in cabinet, Ward Brothers (G & S Ward), ca. 1933

The donor inherited this Wardana machine from her mother, who bought it in about 1933 and used it to sew garments for her sister's dressmaking business in Frankston, Victoria. The donor often used this machine until she purchased an updated model. There were originally three Ward Brothers who owned the North Melbourne sewing machine business but they had a falling out. This machine's decals on the map of Australia only include the two remaining brothers. The Ward Brothers, G & S Ward, established their sewing machine business in North Melbourne in 1888. The cabinets and ironwork of the machines were made in Australia and the Ward Bros. imported their machines from overseas manufacturers in England, America and Germany. The assembled machines were sold under brand names that included Ward, A.N.A. the patriotic-sounding Australian Sewing Machine Company. The "Wardana" was one of their brands.This sewing machine was fabricated in Australia from imported parts from England, giving a snapshot into the early manufacturing industries that were operating at the time just after Federation.Sewing machine in a wooden cabinet with iron foot-operated cast iron treadle mechanism. The hinged cabinet top opens out to form a worktop. The sewing machine lifts out of the cabinet to sit level with the worktop, resting on two supports within the cabinet. The lockable cabinet door opens from right to left revealing fitted shelves and spikes for spools and bobbins. The gold-painted maker's name is cast into the black treadle. The machine has its original instruction book, oil can, and eighteen accessories in an enclosed cardboard box. The round shallow oil bottle has a rubber dispensing tube. Colourful decals decorate the black body of the machine. Inscriptions include a Serial Number stamped on the bed of the machine. The Wardarna Central Bobbin machine was made in England for the Ward Brothers of North Melbourne.TREADLE: cast into metal ACROSS THE TOPE AND ON THE FOOTPLATE "WARD", "WARD" SERIAL NUMBER stamped into oval plate "28383" DECAL: (Map of Australia ) with images of [two brothers] , "WARDANA" above (logo of the rising sun) DECAL: (Decorative floral design with heraldic-like emblems) above "MADE IN ENGLAND" ARM: "WARDANA" PEDESTAL: "C.B." (representing Central Bobbin) "MADE IN ENGLAND" "MADE IN ENGLAND / FOR / WARD BROS / NORTH MELBOURNE" BOOK TITLE: "Instructions for Treadle Machine" ACCESSORIES: some have indecipherable embossed stamps OIL BOTTLE base: (image of log and short lines radiating from a central inscription (indecipherable)sewing machine, domestic, wardana, ward bros., central bobbin, made in england, north melbourne, c.b., flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, treadle sewing machine, home industry, clothing, dressmaking, clothing manufacturer -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - COACH BUILDING WORKS

Black and white photograph of a coach building business. Note the number of workers involved in the manufacture of the different styles required by customers. To the right of photo there are a number of workers using machines to manufacture the different body parts that are required. One cart to left of photo appears to be the finished product. Centre top there is a cantilever structure with bodywork stacked on top and a number of wheels, large and small, hanging from the side. There are also a number of wheels hanging from posts of the building framework. Note the differing clothing styles of the workers from shirt, trousers and apron, to hats shirts, waistcoats, trousers. Differing stages of construction have bodies on tables, wooden frameworks, boxes and wooden horses.industries -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1940

The “Coogee” is an intermediate single seat sailplane designed and built by Tom Proctor in 1940. Only one was built. It was first flown at Stuart Hill near Bendigo Victoria in January 1941 and was maintained in flying condition until 1967. The aircraft was flown extensively by the Victorian Motorless Flight Group (now the Melbourne Gliding Club) and Geelong Gliding Club and several subsequent owners. This exhibit is a "one off" Australian designed and built glider similar in some respects to the Hutter H17. Its usage is relevant to the history of gliding in Victoria in the post war years. Also the aircraft provides an insight into gliding technology in Australia in the 1940s. Wood and fabric single seat glider sailplane with strutted wings and strutted tailplane – features metal framed perspex canopy, central fuselage skid and wheel, small tail skid, instruments include airspeed, turn and bank indicator; variometer and altimeter. Metal parts include struts and fairing covering wing joint. All surfaces are pink doped – awaiting painting.australian gliding, glider, sailplane, coogee, tom proctor, victorian motorless flight group, geelong gliding club -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1948

The Schweizer SGS 2-12 or TG-3A as officially certificated is a glider that was designed in 1941-1942 and produced in United States of America from 1942 for training of military glider pilots. It is understood that over 100 TG-As were supplied to the USA military and at the end of the war many were sold off as surplus. Fred Hoinville imported the Museum’s TG-3A into Australia in August 1950. It is understood that it had been built in 1948 and given construction number G15. On arrival in Australia it was assembled at Bankstown aerodrome and delivered by aero-tow behind a DH Tiger Moth to Camden where Hoinville’s club, the Hinkler Soaring Club, was based. Hoinville’s TG-3A performed well at the Hinkler club in 1950-1951. Several altitude records (including a solo flight to 8000 feet by Grace Roberts – a national women’s record) were set and many soaring flight made over Camden. However, it was badly damaged in a crash landing on 15 April 1951. The glider was repaired after the crash at Camden. It is likely that modifications were made to the cockpit canopy at this time. There were three configuration tried at various times: the original dual cockpit canopy as was standard for TG3As; an unusual dual bubble canopy set up; and a single canopy over the forward seating position (in effect converting the glider to a single seater). When the glider was flown by Hoinville at the 1958 Australian Gliding Championships at Benalla, Victoria in January 1959 (refer The Age Newspaper, January 10, 1959 p.21) it had a single canopy. Records show that the glider was entered on the Australian register as VH-GDI on 6 May 1957. And the Logbook commencing in 1959 shows that ownership passed to the Port Augusta Gliding Club in South Australia on 16 August 1959. Inspections were carried out at that club and airworthiness certificates renewed in 1965. The logbook record indicates that VH-GDI had 1191 flights with an aggregate time in the air of 197 hours at the Wilmington Road Airstrip used by the Port Augusta Club. The glider was transferred to the Cooma Gliding Club, New South Wales. Flying at Cooma began in November 1966 and continued until August 1969: the glider was in the air a further 108 hours from 1067 flights. The last recorded technical inspection of the glider was conducted on 28 September 1968. The glider then passed on to Bill Riley on 20 March 1980 who stored the glider until March 2004 when it was collected by the Australian Gliding Museum. It is not clear whether the current poor state of the airframe is due to accident damage or the conditions under which it has been stored over many years or a combination of factors. Although in poor condition, this exhibit is the sole example of a TG3A ex-US military aircraft in Australia. Further the connection with the story of well-known power and glider pilot Fred Hoinville adds to its historical significance. Tubular metal framed fuselage (without covering and fittings), wooden rudder (no covering) and in damaged condition, wooden fuselage component (formers for fuselage top), Parts of control mechanism, Wooden stringers, Wooden wings without fabric covering and in damaged condition, Ailerons, Tailplane /Elevator without fabric covering, Perspex bubble canopies.australian gliding, glider, sailplane, schweizer, tg 3a, hoinville, roberts, hinkler soaring club, port augusta gliding club, cooma gliding club, riley -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumStandard Capacitor Nalder Bros & Co

No. of pieces: one object recessed into wooden box with detachable parts. Handmade wooden box enclosing a machine molded solid metal object. Plastic machine molded attachment. Gold electroplated metal, wax-matte hand polished wooden box, plastic has either been polished or had a varnish polish added to the surface. Detachable brass elliptical stopper, two brass butterfly screws, two hook latches attached to outside of box to secure object for transport. Polished wood surface, possibly wax coated. Brass metal coated with gold patina/electroplating. Plastic component either polished or coated with gloss varnish. Inscribed on top of the object, in the wooden box: “MICROFARAD/NALDER BROS & CO/WESTMINSTER/No 1509” Paint dot approx. 1.0cm in diameter on top face of wooden box, back edge, towards the right. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MCCOLL, RANKIN AND STANISTREET COLLECTION: CENTRAL NAPOLEON GOLD MINING CO. N.L, 1934-1950

Pink Manilla Folder containing: General Correspondance Letters to and from suppliers of machinery and parts e.g. Electricity Supply Departments, Fred Milne & Son (Engineers), Thompsons Engineering & Pipe Co.Ltd, Miller & Co Machinery Pty Ltd, Alfred J Jorgenson, Bingle Machinery Co, The Richardson Gears Pty Ltd, Buckell & Jeffrey Pty Ltd, Commercial Union Assuarance Company Limited, Bendigo Machinery & Trading Co Pty Ltd, Ronaldson Bros & Tippett Pty Ltd (including a picture of a drawlift pump), J.G. Bloomfield, Ronaldson - Tippett list of 4583 Machines in Victoria & addfor crude oil engine, A.H McDonald & Co Pty Ltd & ad for crude oil engine, E Treliving letter & list of second hand materials for sale, J. Edwards-Retallack Machinery Manufacturers Representative, Hume & Iser Pty Ltd Timber & Hardware Merchants, Bendigo Timber Co Timber & Hardware Merchants, markings read 'Cent. Napoleon G.M.Co N.L Machinery', Correspondance dating from 16 July 1934 - 26 October 1950.organization, business, industrial - mining, mccoll rankin & stanistreet, mining, gold mining, central napoleon -

Monbulk RSL Sub Branch

Monbulk RSL Sub BranchBook, Harper Collins, Hell's heroes, 2009

Hell′s Heroes is the story of the POW camp that never was − so dubbed by one old soldier because the atrocities that occurred there went largely unreported at the time. For while the Burma−Thai railway‚ the Bataan death march and events at Changi and in many other parts of Asia became synonymous with Japanese brutality‚ most of the camps which were set up to provide slave labour for the enemy military machine at home were slowly forgotten in the aftermath of World War II.Ill, maps, p.359.non-fictionHell′s Heroes is the story of the POW camp that never was − so dubbed by one old soldier because the atrocities that occurred there went largely unreported at the time. For while the Burma−Thai railway‚ the Bataan death march and events at Changi and in many other parts of Asia became synonymous with Japanese brutality‚ most of the camps which were set up to provide slave labour for the enemy military machine at home were slowly forgotten in the aftermath of World War II.world war 1939 – 1945 - prisons and prisoners - japanese, atrocities - japan -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Sabre F-86E Methods of tooling and fabricating machined parts - NAA

... machined parts - NAA Manual Sabre F-86E Methods of tooling ... -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncAircraft, B-24 Liberator, Consolidated Aircraft Corporation, c. 1940

This particular aircraft was modified with a search radar in the lower fuselage to help locate and track targets and was then redesignated as a B-24R model. The RAAF took A72-176 on charge in late 1944 and this saw it issued to 7 OTU (Operational Training Unit) based at Tocumwal, south west NSW. The training saw bomber crews learn how to fly the bomber, operate as a team and work with fighters. Towards the end of the war there were up to 50 aircraft located at Tocumwal along with 5000 personnel. A72-176 was noted as flown on training missions by various aircrew.This aircraft is one of the only remaining B-24 bombers in the southern hemisphere and 1 of only 8 remaining B-24 airframes still existing in the world, out of the nearly 19,000 which were originally built. The restoration honours the contribution of one of the RAAF’s main bombers of the WWII era. This restored Liberator aircraft was assembled from parts salvaged from B-24M models, manufactured during the 1940s in the USA. Made from aluminium, the plane is 68 feet long, with a wingspan of 110 feet, and is metallic silver with a distinctive blue and white target design on each side. The aircraft is powered by four wing-mounted engines, and is fitted with 10 heavy machine guns.Registration number on side of fuselage at rear of plane: 'A72-176' Inscription on side of fuselage at front of plane: 'ROYAL AUSTRALIAN AIR FORCE / US ARMY B24-10 CO / AIR FORCES SERIAL NUMBER 44-41956' aircraft, liberator, bomber, wwii -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps Museumcream separator, Approx 1900

very old steel machine on solid stand. Vat (23 gallons per hour) is from a different machine (alfa laval). The separator is American with Australian agency. All parts are there but not put together. Two spouts,one for skim milk, one for cream. Run by hand with turning handle attached.Mc Cormick Deering U.S.A (maker) Chicago. International harvester company (Agent)dairy, cream, imported materials -

Uniting Church Archives - Synod of Victoria

Uniting Church Archives - Synod of VictoriaPhotograph, C. 1950s

Extract from The Spectator of June 12, 1946: "From the Queensland 'Methodist Times'. Dreams do come true. At any rate, that is what the Rev. Cliff Lanham believes, who after the lapse of several years finds that his early dream of a Flying Patrol for the Inland is now an actuality. The Methodist Inland Mission Board has purchased from the Disposals Commission of the R.A.A.F. a De Haviland Fox Moth Biplane. Indeed, two machines have been bought, but one will be broken up for spare parts. This 'new angel of the air' is fitted with a 130 h.p. engine and possesses a cruising speed of 100 miles per hour. The petrol consumption is only that of a big six-cylinder car—18 miles per gallon. In addition to the pilot there is room for three passengers, and a stretcher is installed whereby urgent cases of sickness or accident can be flown to the nearest hospital. In this machine, Mr Lanham proposes to cover the whole of S. W. Queensland and a portion of the Northern Territory from his headquarters at Mt Isa. It takes little imagination to realise what a boon the 'flying parson' will be to those of the great outback." …. "Before [Mr Lanham] inaugurated the scheme [the idea of a flying parson] he spent his first furlough from inland mission work (and incidentally £60) learning to fly. 'In a month,' he says whimsically, 'I was a pilot of sorts.' Mr Lanham is a son of the Church. His parents were staunch Methodists, and their home offered generous hospitality to mininsters and preachers. His brother, the Rev. Percy Lanham, M.A., died in Libya when on active service as a chaplain. His widowed mother must be proud of her tall, stalwart son, whom the Church now sends forth on his flying mission for the Lord. May he ever be wafted through inland skies on two wings and a prayer." It is of interest to note that although Cliff Lanham's brother, Percy, is listed in the Methodist Church of Australasia's Ministerial Index (9th Edition, Revised to 1961) Cliff Lanham himself is not listed as either active or deceased.Three B&W identical photographs of Lanham standing next to a Methodist Inland Mission bi-plane. Lanham and an unidentified man are holding a stretcher between them with a boy of about 10-11 on it. They seem to be exiting the plane. The original photograph F69-1 is a 110x65 mm Kodak print; the other two are 195x145 mm enlargements. Lanham is wearing a white shirt and grey trousers, the other person is wearing a safari helmet.All three photos identify "Rev. Cliff Lanham" on the back. They seem to have been originally used or intended for use by The Spectator.lanham, cliff, queensland, methodist inland mission, flying parson -

National Wool Museum

National Wool MuseumMachine - Sliding Box Plate Camera, 1866-1882

Made by Cox, F J 1845-1882 (1891), optical & mathematical instrument maker, optician, camera manufacturer, London.Sliding box camera, about 1855. This type of camera was in use before bellows became common. The camera belonged to Hugh Strachan who passed it on to an employee, Charlie Lugg. The Strachan family is distinguished in the Geelong wool industry. James Ford Strachan, born in Scotland, established a very successful wool broking business and his sons carried on his work.Wooden case with brass handle lined with green felt containing one sliding box camera, with a brass fitting for a lense, a removable glass focussing screen, which conseals the removable lense inside the camera. Also two small wooden frames for developping the photographs. Also a linen cape and a leather pouch containing metal filters with gradients. Booklet about the life of Charles Lugg who owned the camera before it was passed to his nephew who then donated it to the NWM. Booklet details Lugg's military service, working life in Stachan's wool stores and life in Geelong and Moriac. Measurements of parts (in centimeters): 27 26 41.5 Carry Case 24.5 36.5 21.2 Sliding box Camera 15.4 .5 17.6 slide frame 11 14.5 9.5 lens 152 71 cape 9 1.5 6.5 pouch 8.5 .1 6.5 5.5 Filter Lense 8.5 .1 6.5 4.5 Filter Lense 8.5 .1 6.5 3.5 Filter Lense 8.5 .1 6.5 1.2 Filter Lense F.J. Cox/ 26/Ludgate Hill/ London (Plaque on top of box) Fred J Cox/26 Ludgate Hill/London (Engraved on side of Lens)charles lugg, fred j cox, james ford strachan -

National Wool Museum

National Wool MuseumGriswold stocking knitting machine, c1890 - 1900

... Griswold stocking knitter machine. Black steel manual... detached parts of the machine include a bobbin holder and yarn ...The machine was most recently used by donor's father c2008 to knit socks, but had been used for many years earlier. According to family history, it is believed that the machine came to Australia with donor's grandparents in the early 20th century, and was created c1890-1900. It is still in working order and a demonstration was given by the donor during the acquisition process.Griswold stocking knitter machine. Black steel manual machine which clamps on to the edge of a table and is operated by turning a handle. Centre of machine is a cylinder which can be lined with pins to create the sock/stocking. Two detached parts of the machine include a bobbin holder and yarn feeder. Accompanying items include: 3 examples of incomplete attempted socks made by donor. 4 envelops containing instructions, pattersn, notes and advice on using the machine, created by donor's father and grandfather. 1 bobbin with grey yarn. 2 metal machinery pieces. 2 tins containing pins for the machine. 1 metal yarn feeder cone. 10 weights plus two weight stands. Stocking knitter machine has an identifier plate with patent numbers on the side. -

National Wool Museum

National Wool MuseumKnitting Machine Part, Sock

A tobacco tin containing 2 needles and 3 parts for the "Beehive" sock knitting machine.A tobacco tin containing 2 needles and 3 parts for the "Beehive" sock knitting machine.LUCKY HIT TOBACCO/READY RUBBEDknitting textile machinery machine knitting textile mills textile mills, hosiery, knitting, textile machinery, machine knitting, textile mills -

National Wool Museum

National Wool MuseumTextile - Quilt, Domestic Wagga, 1950s

Part of the Running Stitch collection, possibly made in BallaratDomestic wagga, unfilled, consisting of two machine sewn layers of woollen garment pieces both knitted and woven. The front pieces are predominantly red, blue and yellow, the back is mostly brown red and blue.WAGGA/ Maker unknown 154cm long X 90cm wide/ Made of parts of wool garments, knitted and woven.....handicrafts quilting quilting - history, running stitch collection, running stitch group, handicrafts, quilting, quilting - history -

National Wool Museum

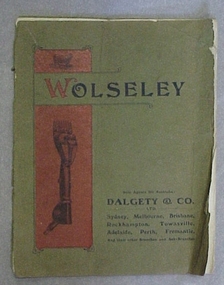

National Wool MuseumBooklet, Wolseley

Specification manual outlining all parts for a complete Wolseley set of shearing machinery, in text and images.Specification manual outlining all parts for a complete Wolseley set of shearing machinery.shearing, wolseley sheep shearing machine co. ltd -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine Treadle

Treadle home sewwing machine. pre-electric - rusted missing parts rusted gold leafBlack pre-elctric Treadle sewing machine with silver coloured rim on fly wheel.Gold leaf floral design on machine. Shield of gold leaf. fastened to wooden table -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine

... Inlayed case has box snibbed shut with parts for sewing... Machine on wooden base with wooden cover. rusted missing parts ...Inlayed case has box snibbed shut with parts for sewing machine. base also inlayed home sewing machine pre electric "treadle"Black Machine on wooden base with wooden cover. rusted missing parts. On to of the machine the remains of name "THE". Light wood case lid has inlayed wood around the top of the lid. -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine - Treadle type

... with handle. Tool box has more parts in it. Sewing Machine - Treadle ...Home sewing machine - pre electric.Black Metal - Remains of gold leaf. Cotton reels attached Inlayed case with handle. Tool box has more parts in it."RThe" -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Singer Sewing machine Treadle type

Home Sewing machineBlack - Floral Design - crackled. Wooden curved top case. Case with handle metal turned wood - keyhole. key on black wool no box for tools and parts. Empty bobbin in slot. Foot Pedal'Singer" Trade mark Stamp " The Singer Maine co" fastened to the machine "Y8089019" "Simarco 193017" -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumInformation pamphlet, The Alfa-Laval Homestead Milker

Used in preference to slower hand milking practice after electricity was connected to the farmPaper pamphlet describing parts of the vacuum pump milker. Recommended for herds of ten cows or lessSee photosmilking machine, dairying -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumInstruction Manual, Alfa Laval, The Alfa Daisy Milker

The first centrifugal separator was invented in1878 by Dr. de Laval. This recognized the need for a mechanical milker for which patents were granted in 1894. Alfa Laval were leading world producers of mechanical milking machines. The manual was used in Tungamah during the 1940's and 1950'sPaper booklet describing the operation, parts and installation of the Alfa Daisy Milker. Inside front cover is listed the companies that distribute the milker. Australian capital cities. Illustration includes 12 pagesSee photos -

National Wool Museum

National Wool MuseumBooklet, Dubied Reserve Parts Type MR Catalogue N198

Catalogue of reserve parts for the Dubied Type MR hand knitting machine, which also forms part of the collection.machine knitting, sartori, mrs genitilia -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Image - Black and White, Macaroni Factory, Hepburn Springs, 1900, 1900

"MACARONI MANUFACTORY. On the pretty road to the Hepburn Mineral Springs, and not far from where the health-laden waters gush plentifully from the earth, is a two-storied brick it is that Messrs Lucini and Co, carry building, dedicated to the manufacture of macaroni, vermicelli, and the Italians' own especial delight— spaghetti. Here on operations, and Mr Lucini himself was good enough to show the writer around and explain the various proces ses of a manufacture which is little known to Australians. The finest wheat and the mineral waters fresh from the springs are utilised, and by means of a most ingenious machine, the hollow rods of macaroni are turned out in large numbers. Finally, they are packed in boxes and cases, and sent off to the prin cipal agent in Daylesford, Mr J. W. King, who in turn forwards them to all parts of the country. Mr Blackett, thv Govrnment Analyst, writes in most lau datory manner of the productions of the factory, and says that on testing them he found the various sam ples were of excellent quality, and quite equal to any of Italian manufacture. Visitors to the springs should not fail to call in at Messrs Lucini's, which is one of the show places of the district, and will well repay an inspection.A number of women, members of the Lucini family, make macroni and the macaroni factory in Hepburn Springs. lucini, macaroni factory, hepburn springs, spaghetti, macaroni -

Moorabbin Air Museum

Moorabbin Air MuseumBook (Item) - Includes machined parts details and schematic diagrams, Aircraft Blueprint reading

... Includes machined parts details and schematic diagrams ... -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates how tram tickets could be punched and the manufacture of ticket punches.Brass cast, chrome plated, machined, device or ticket punch, used to cancel or punch paper tickets when purchased. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. . Chrome plate has been partly worn off. Secured by three screws. For another example see Reg Item 7468 with large screws. There are no manufacturer markings or numbers on the punch. Punch is very heavy in construction compared to other punches in the collection.trams, tramways, ticket punch, tickets, fares