Showing 111 items

matching machinery operation

-

National Wool Museum

National Wool MuseumBook, The Development of the Tentering Machine

"The Development of the Tentering Machine and the Last Word in Modern Methods of Cloth Drying" - Arthur Heaton & Co. Ltd, England, c.1928. Provides an overview of machine cloth drying and tentering, and examines the operation of the Krantz Tentering Machine.Book: "The Development of the Tentering Machine and the last word in modern methods of cloth drying" - Arthur Heaton & Co. Ltd, c.1928.textile machinery, arthur heaton and co. ltd, tentering -

National Wool Museum

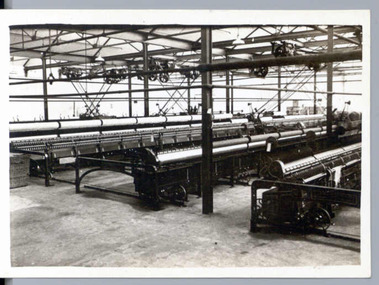

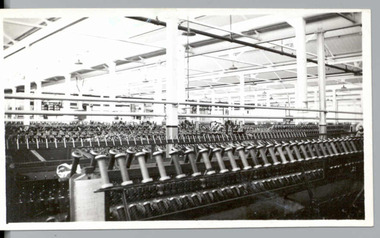

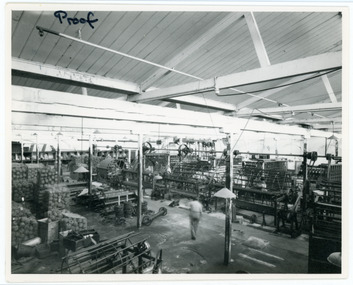

National Wool MuseumPhotograph

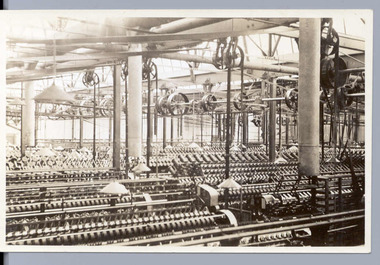

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning mule for woollen threads. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - woollen -

National Wool Museum

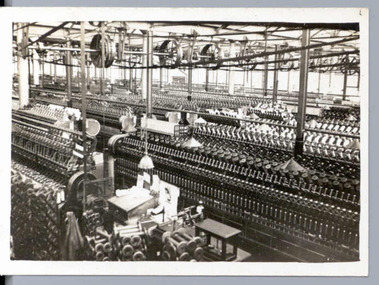

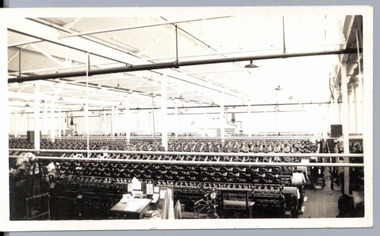

National Wool MuseumPhotograph

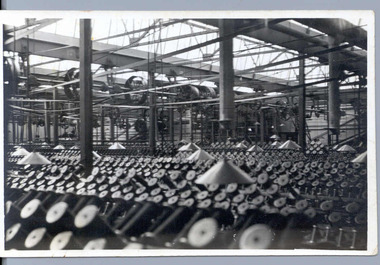

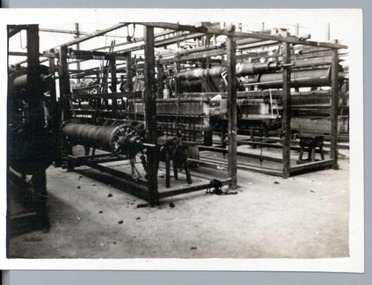

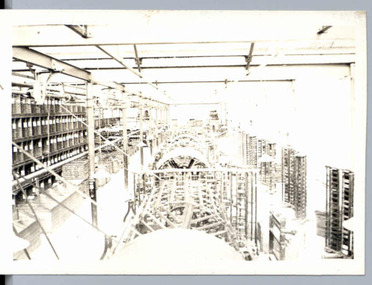

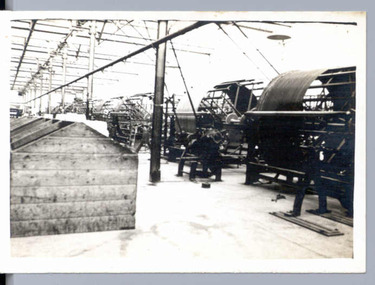

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

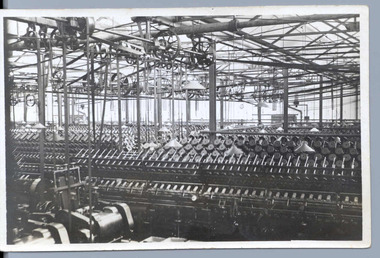

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

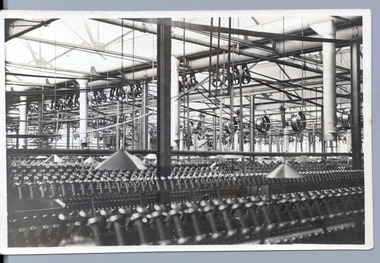

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

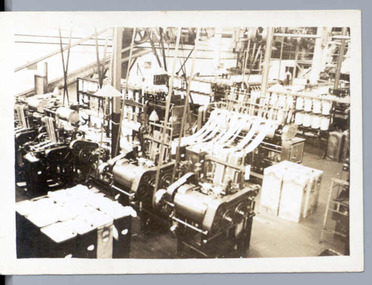

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

National Wool MuseumPhotograph

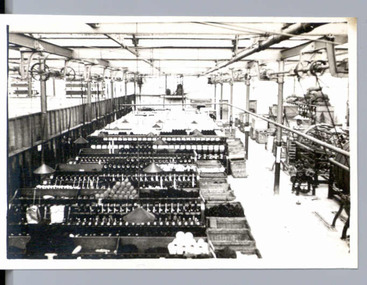

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the winding of the warp. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, winding, winding machinery -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows warping. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, warping, warping machinery -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows warping. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, warping, warping machinery -

National Wool Museum

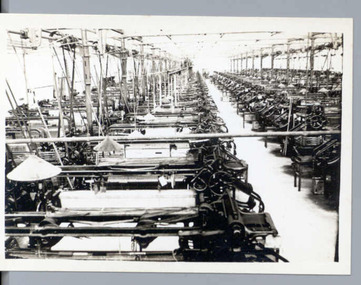

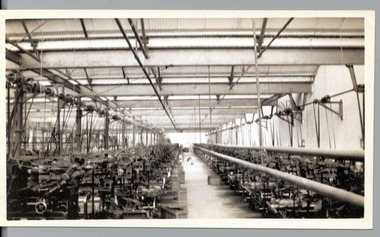

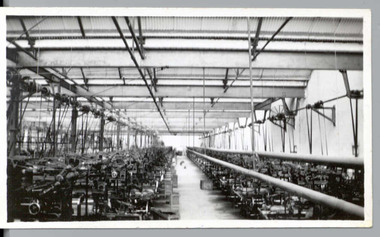

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows rows of weaving looms. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, weaving looms, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

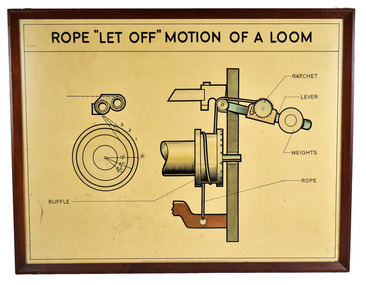

National Wool MuseumPhotograph - Loom Diagrams

Six framed diagrams of loom operation. The original framed works were deaccessioned, with digital images remaining in the collection.Six digital TIFF files, depicting four framed and two unframed diagrams of loom mechanics and operation, each showing a different process:textile mills, textile machinery, diagram, loom, gordon institute of tafe -

National Wool Museum

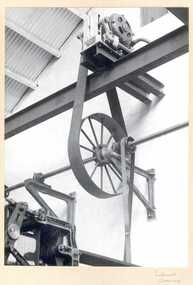

National Wool MuseumPhotograph, Foster Valley Mill

... the machinery. Textile Mills - operation Valley Worsted Mill T. Lockwood ...Interior view of showing machinery at Foster Valley Mill. Shows a wall mounted drive shaft which runs the machinery.Drive shaft for textile machinery within the Valley Mill.T. Lockwood Lockwood / GEELONGtextile mills - operation, valley worsted mill -

National Wool Museum

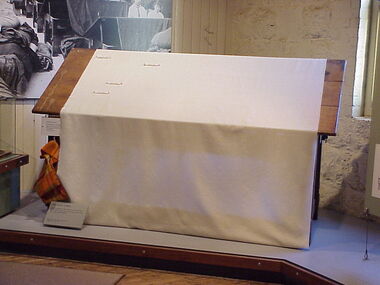

National Wool MuseumFunctional object - Mending Table, c1930

Any faults in the final product can be repaired by mending. Prior to more advanced machinery, fabric was draped over a mending table and carefully inspected for faults. Quick eyes and nimble fingers were needed. Repairing faults was a highly skilled manual operation. Any knot or thickness had to be removed without affecting the quality of the fabric and mending had to be invisible. In the 1930s to make the day pass faster, popular records were played to the factory workers in the mending room. The top of the table is propped up to make it a well-lit surface over which bolts of fabric were unrolled to check for faults. Menders repaired them with invisible hand stitching. Each weaver stitched a coloured thread in the selvage to show the start of their shift, therefore if mistakes were found the company could easily find who was responsible. This table was used by Gail Morris in teh 1960s. Large wooden table with tilted top. mending table, wool processing, fabric, textile industry -

National Wool Museum

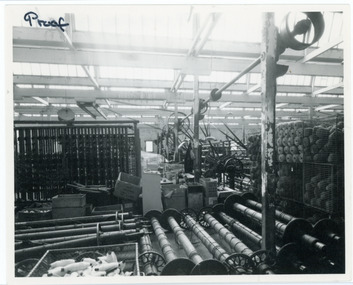

National Wool MuseumPhotograph

Depicts the warping operations from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, warping, warping machinery -

National Wool Museum

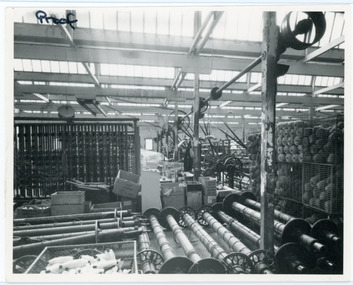

National Wool MuseumPhotograph

Depicts the warping operations from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, warping, warping machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the warping operations from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, warping, warping machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the warping operations from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, warping, warping machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the warping operations from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, warping, warping machinery -

National Wool Museum

National Wool MuseumPhotograph

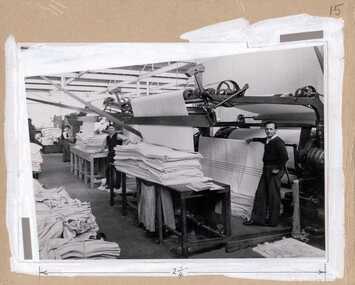

... for publication. Textile Mills - operation Drying Drying Machinery ...Depicts the drying operations within a mill, c.1950s. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, drying, drying machinery -

National Wool Museum

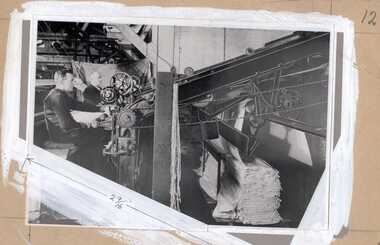

National Wool MuseumPhotograph

... for publication. Textile Mills - operation Folding Machinery Photograph ...Depicts the folding operations within a mill, c.1950s. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, folding machinery -

Ballarat Tramway Museum

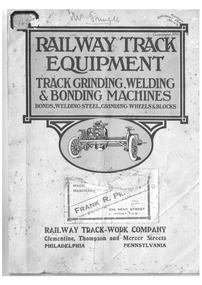

Ballarat Tramway MuseumDocument - Folder with papers, Railway Track-work Company and Clementine and Thompson and Mercer Sts and Philadelphia and Pennsylvania USA. and Perrot and Adams Ltd, "Railway Track Equipment - Track Grinding Machines, Welding and Bonding Machines - Bonds, Welding Steel, Grinding Wheels and Blocks", 1920's?

Yields information about the type and presentation of books or information folders that were sent to the Electric Supply Company of Victoria about tramway products available on the market and the company the produced them.Folder with 24 pages of advertising pamphlets bound into it with two metal clip binders advertising products available from the Railway Track-Work Company and titled ""Railway Track Equipment - Track Grinding Machines, Welding and Bonding Machines - Bonds, Welding Steel, Grinding Wheels and Blocks". Has brochures or pamphlets for: . The Universal Rotary Track Grinder . Reciprocating Track Grinder . The Atlas Rail Grinder . The Ajax Electric Arc welders .Vertical Rail Lifter . The Jackson Electric Tie Tamper. Generally the lead page of each pamphlet has been imaged. Provides a description of each item, along with method of operation and parts listing generally. The folder has on a number of pages and the back cover, a sticker from Frank R. Perrot (Now Perrot and Adams Ltd), Machinery Merchant of 394 Kent St Sydney. Railway Track-work Company , Clementine, Thompson and Mercer Sts, Philadelphia, Pennsylvania USA. For a full scan of the document see the hi res file.Numerous: Front cover sticky label "1620" in top left hand corner, "Mr Pringle" on front cover and stamp with words "Ballarat Tramway Preservation Society Catalogue No. 10" in ink on front cover. Inside front cover has a pencil note, behind the crease in the bottom right hand corner. On the first pamphlet "Ballarat Tramway Preservation Society Catalogue No. 10" in ink on top right hand corner. On parts page for the Reciprocating Track Grinder has the "Perrot and Adam Ltd" company stamp.trams, tramways, trackwork, equipment, rails