Showing 222 items

matching razor

-

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Razor

Man's cutthroat razor with black curved handle which folds down to cover blade.Crown Imperial Special Hollow Ground|Made in Germanypersonal effects-toilet requisites, shaving -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchSafety razor with metal container, Approximately 1914

Possibly WWI historical significance.American model safety razor. Made in Germany possibly from 1914 with metal container.Safety Razor, Warranted, Made in Germany. Safety razor printed on metal container -

Mont De Lancey

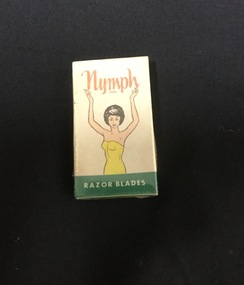

Mont De LanceyRazor

Ladies "Nymph" razor blades (x 6) ground in England from Swedish steel. In cardboard box.shaving equipment, razor blades -

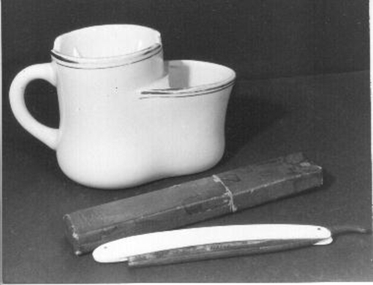

Mont De Lancey

Mont De LanceyRazor, Carman & Sons

3 x Cut-throat razors. 1. Ivory handle with crown and sword carving. 2. Bakelite handle.1. Made in Germany ERN 1166. 2. Dr. Peres Solingencut-throat razors, shaving equipment -

Mont De Lancey

Mont De LanceyRazor, T.R. Cadman and Sons

Metal Bengal Razor blade with brown handle. Blade folds back into the handle. Has brown leather case.cut-throat razors, shaving equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Razor

Used by Daryl Cook of Rotherwood Ave, Mitcham and 14 McDowall Street, Mitcham.Cut-throat folding style razor with black ebony handle. Faded black clothe covered cardboard box with lid.Hollow Ground|Joseph Allen & Sons, Sheffield, England.|NON XLLpersonal effects-toilet requisites, shaving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRazor

Cut-throat razor, White bone handle, "Magnetic Platypus Extra Hollow Ground", Made in Germany by Oswald- Solingen. With Boxflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cut-throat razor, oswald- solingen, magnetic platypus extra hollow ground -

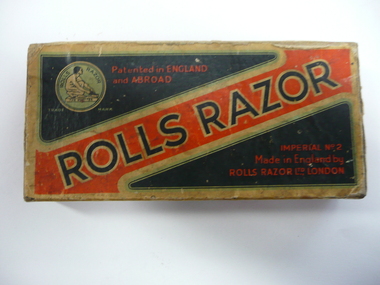

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - ROLLS RAZOR

A Rolls Razor in box with instructions on bottom, nickel plated case with key hole pattern containing razor and inbuilt strop. Cardboard box in red, green & black labelled Imperial number 2 Rolls Razor nickel plated.Rolls Razor made in England patented in England and abroad English patent numbers 457383 284428 242718 242717 and pending Rolls Razor Pat no's 224578 242718personal effects, shaving -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumRazor Blade Sharpener

Razor blade sharpener was brought to Australia by Otto Lobert, a POW in Camp 3Mottled grey cardboard box containing a razor blade sharpener. (black rectangle base and stainless steel parts), 5 razor blades, 3 paper razor blade packets, 1 razor blade box, 1 folder of instructions (Allegro), 1 maroon rectangle pocket, 1 razor blade holder (Part of the sharpener), 3 "Star" razor blades, 1 "7 o'clock" razor blade, 1 "thin Gillette blade" razor blade.Allegrorazor blade sharpener, lobert o, camp 3, tatura, ww2 camp 3, toilet, requisites, shaving -

Mont De Lancey

Mont De LanceyRazor, 1925

Durham Duplex cream and steel razor with plastic handle. Has three interchangeable blades in cardboard box. Patented July 4 1911. Plus blue plastic case with red top. cut-throat razors, shaving equipment -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Functional Object, 1965

White and fawn metal and plastic cordless razorPhilishaverazor, philishave -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Safety Razor, Razor

Minute gold coated lady's safety razor in box with red lid. Instructions in box. Fully enclosed in a green cardboard boxThe Laurel Ladies' Boudoir Safety Razor.personal effects-toilet requisites, shaving -

Hume City Civic Collection

Hume City Civic CollectionRupertswood Battery Collection

This cut throat razor was found in the original Battery shed at Rupertswood.Black handle cut throat razor."Bengall"rupertswood battery collection, rupertswood, personal items, menhennitt, tony, george evans collection -

Bendigo Military Museum

Bendigo Military MuseumEquipment - RAZOR & POUCH, 1914-1918

Item belonged to Edwin James Jones No 3511 AIF. Refer 1367.5 for his service history..1) Brown leather pouch, folds out to fit safety razor. Has compartments to fit disassembled razor. .2) Safety razor, disassembles into 4 pieces.toilet requisites - shaving, razor, accessory, jones -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, mens' 'Gillette' safety razor, c1950

A safety razor is a shaving implement with a protective device positioned between the edge of the blade and the skin. The initial purpose of these protective devices was to reduce the level of skill needed for injury-free shaving, thereby reducing the reliance on professional barbers for providing that service and raising grooming standards. The term was first used in a patent issued in 1880, for a razor in the basic contemporary configuration with a handle attached at right angles to a head in which a removable blade is placed (although this form predated the patent). 1847 William S. Henson. patented a "comb tooth guard or protector" which could be attached both to the hoe form and to a conventional straight razor. May 1880 by Fredrik and Otto Kampfe of Brooklyn, New York, improved the 'safety razor' and it differed from the Henson design in distancing the blade from the handle by interposing,, "a hollow metallic blade-holder having a preferably removable handle and a flat plate in front, to which the blade is attached by clips and a pivoted catch. 1900 King C. Gillette had the revolutionary idea of disposable blades so thin and so strong they were deemed impossible to forge by MIT-trained scientists. By 1901, he’d proven them wrong with his breakthrough innovation. The success of Gillette's invention was largely a result of his having been awarded a contract to supply the American troops in World War I with double-edge safety razors as part of their standard field kits (delivering a total of 3.5 million razors and 32 million blades for them). The returning soldiers were permitted to keep that part of their equipment and therefore easily retained their new shaving habits. The subsequent consumer demand for replacement blades put the shaving industry on course toward its present form with Gillette as a dominant force. Plastic disposable razors and razors with replaceable disposable blade attachments, often with one to three cutting edges (but sometimes with four and as of recently, five cutting edges), are in common use today. A steel 'Gillette' safety razor gillette co ltd, cheltenham, moorabbin, maynard dennis, sfety razors, safety razor blades -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, safety razor blade 'King Gillette'', 20thc

King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. Gillette's safety razor retailed for a substantial $5 half the average working man's weekly pay — yet sold by the millions. The most difficult part of development was engineering the blades, as thin, cheap steel was difficult to work and sharpen. This accounts for the delay between the initial idea and the product's introduction. To sell the product, Gillette founded the American Safety Razor Company on September 28, 1901 (changing the company's name to Gillette Safety Razor Company in July 1902). Gillette obtained a trademark registration (0056921) for his portrait and signature on the packaging. Production began in 1903, when he sold a total of 51 razors and 168 blades. The following year, he sold 90,884 razors and 123,648 blades, thanks in part to Gillette's low prices, automated manufacturing techniques and good advertising. By 1908, the corporation had established manufacturing facilities in the United States, Canada, England, France and Germany. Razor sales reached 450,000 units and blade sales exceeded 70 million units in 1915. In 1918, when the U.S. entered World War I, the company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. The company continues in the present day as the Gillette brand of Procter & Gamble, USA. Throughout the 20thC most men used this type of safety razor with disposable stainless steel razor blades to shave their beards prior to the introduction of affordable electric razors in 1960'sA blue packet of unused 'King Gillette' safety razor blades.on top of packet; Press with thumb / and snap end open / GILLETTE QUALITY THE / SAME THE WORLD OVER / FACTORIES IN / USA / CANADA , GREAT BRITAIN / MEXICO , FRANCE / COLUMBIA, GERMANY / BRAZIL, SPAIN / ARGENTINA, AUSTRALIA / GILLETTE TRADE MARK / KING C GILLETTE / RED. TRADE MARKS / GILLETTE (AUST.) PTY. LIMITED / MELBOURNE / DE 2023 / MADE IN AUSTRALIA / shaving equipment, safety razors, gillette king, proctor & gamble, moorabbin, bentleigh, cheltenham, -

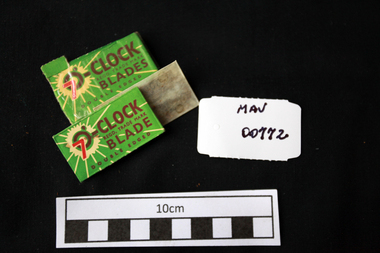

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, man's razor blade in box, 20thC

Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor. Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. In 1918, when the U.S. entered World War I, the Gillette company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. An unused, wrapped, man's razor blade in a box. 7 O'clock brand '7 O'CLOCK / REGD. TRADE MARK / BLADES / DOUBLE EDGED shaving equipment. razorblades, safety razors, cheltenham, moorabbin, bentleigh, pioneers, early settlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, Gillette Razor and Box, c1940

After the Gillette Pty Ltd made the stainless steel Safety Razor it was very popular world wide . The stainless steel box is lined with velvet and contains a stainless steel lift up protector for the razor blades.George Reed was a resident of City of MoorabbinThe Gillette Pty Ltd made the stainless steel Safety Razor c1940 and it was used by men world wide . This portable compact easy clean stainless steel kit was a practical part of men's toiletries George Reed was resident of City of Moorabbin A Gillette Pty Ltd stainless steel Safety Razor with a stainless steel box, lined with velvet and containing a stainless steel lift up protector for the razor blades Inside lid of box ; TRADE Gillette MARK / MADE IN ENGLAND gillette pty ltd. safety razor, stainless steel, razor blades, post world war 11 housing estates, moorabbin, bentleigh, mckinnon, ormond, toiletries, men's fashion, menswear,, reed george, reed gladys, -

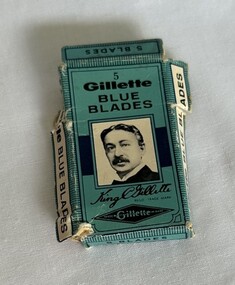

Greensborough Historical Society

Greensborough Historical SocietyFunctional object - Razor blades, Gillette, Gillette Blue Blades, 1960s

Small replacement blades for a man's razor.Small blue cardboard packet containing 4 wrapped razor blades."Gillette Blue Blades. Made in Australia."razors, safety razors -

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncDomestic object - Razor Strap

Item used to sharpen cut throat razor bladesDouble layered razor Strap . Leather joined at one end to form a handle and at the other to house a hanging attachment. Top layer is green and black leather and the bottom layer is natural. The item was used to sharpen cut throat razor blades.The words 'SPECIAL' and 'Soft Finish' are in gold lettering on the front straprazor strap, razor sharpener -

Upper Yarra Museum

Upper Yarra MuseumRazor, Cut throat

Sharped Edged instrument used for cleaning hair from the skin. http://en.wikipedia.org/wiki/Straight_razor A straight razor is a razor with a blade that can fold into its handle.[1] They are also called open razors and cut-throat razors. HISTORY The first modern straight razor complete with decorated handles and hollow ground blades was constructed in Sheffield, England, by Benjamin Huntsman in 1740. Huntsman's process was adopted by the French sometime later. The English manufacturers were even more reluctant than the French to adopt the process and only did so after they saw its success in France.[5] Straight razors were the most common form of shaving before the 20th century and remained that common in many countries until the 1950s. TODAY Straight razors are still manufactured. DOVO, of Solingen, Germany, and Thiers Issard of France are two of the most well-known European manufacturers. Feather Safety Razor Co. Ltd. of Osaka, Japan makes a razor with the same form as a traditional straight, but featuring a disposable blade that can be installed through an injector-type system. Modern straight razor users are known to favor them for a variety of reasons. Some are attracted to the nostalgia of using old and traditional methods of shaving. It is a masculine ritual comparable to pipe smoking. Others profess an interest in reducing the waste of disposable blades.[11][22] Still others agree that straight razors provide a superior shave through a larger blade and greater control of the blade including the blade angle. Straight razors cover a much greater area per shaving stroke because their cutting edge is much longer than any of the multiblade razors. Ivory cut throat razor, with cream case 00121.3.Known as a straight razor.Razor with square point, full hollow ground 5/8” blade and double transverse stabiliser. The centre pin adds stability and rigidity to the handle---I think this is it ROM Parts The narrow end of the blade pivots on a pin, between 2 pieces of ivory forms the handle. LONG EXTRACT FROM WIKI _ SHORTEN to describe 00121 The parts of a straight razor and their function are described as follows: The narrow end of the blade rotates on a pin called the pivot, between two protective pieces called the scales or handle. The upward curved metal end of the narrow part of the blade beyond the pivot is called the tang and acts as a lever to help raise the blade from the handle. One or two fingers resting on the tang also help stabilize the blade while shaving. The narrow support piece between the tang and the main blade is called the shank, but this reference is often avoided because it can be confusing. The shank sometimes features decorations and the stamp of the country of origin. The top side and the underside of the shank can sometimes exhibit indentations known as fluting, or jimps for a more secure grip.[8] The curved lower part of the main blade from the shank to the cutting edge is called the shoulder.[9] The point where the shoulder joins the cutting edge is called the heel. A thick strip of metal running transversely at the junction where the main blade attaches to the shank is called the stabiliser. The stabiliser can be double,[10] single or can be absent in some razor models. The first stabiliser is usually very narrow and thicker and runs at the shank to blade junction, covering the shank and just spilling over to the shoulder. The second stabiliser can be distinguished since it is considerably wider and narrower, appearing after the first stabiliser and running lower into the shoulder. The non-cutting top of the blade is called the back or the spine while the cutting part of the blade opposite the back is called the cutting edge.[11] Finally the other free end of the blade, at the opposite end of the tang, is called the point and, sometimes, the head or the nose.[9][12] There are two to three pins in any handle. The middle pin, if present, is plastic coated and is called the plug.[13] Its function is to stabilise the sides of the handle so that they cannot be squeezed in the middle. When folded into the scales, the blade is protected from accidental damage, and the user is protected from accidental injury. During folding, the back of the blade, being thick and normally with a curved cross-section, acts as a natural stopper and prevents further rotation of the blade out of the handle from the other side shaving, lever, handle, blade, pivot, razor, tang -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Razor and case, E.M. Dickinson, 1895-1930

E M Dickinson was a cutlery company in Sheffield that made all types of cutlery knives of all types and patterns, razors domestic electroplated cutlery etc. Edwin Murray Dickinson started recruiting workers for his new cutlery firm at 11 Cambridge Street Sheffield England in 1870. The original premises consisting of warehouse, offices, cutlers shops fitted with the latest steam-powered equipment however this premises was offered for let in November 1887, and new premises were secured at 51 Division Street and were occupied by Dickinson's in early 1888. By October 1890 Dickinson was advertising the Division Street premises to let and moved the company into other new works (still called Murray Works) at 122 Rockingham Street. On 12th October 1901, Dickinson gave notice that the firm was to be converted to a limited company and by March 1908 the Rockingham Street works had been advertised for sale. In 1909 the deeds for other new premises at 203 Arundel Street Sheffield were deposited to secure a £3,000 loan from the Sheffield Banking Company. Then on Christmas Eve 1926 several hundred pounds worth of damage was caused by a fire at the Arundel Street works. The founder, Edwin Dickinson died on 21st October 1930 aged 81 at his home at 449 Crookesmoor Road and on the 23rd May 1939 the firm went into voluntary liquidation.An item made by a company that made many different types and patterns of cutlery for domestic use and export.Straight razor with black celluloid handle and it’s boxBlade has marking, INVICTA" with decorative engraved design, on the other side engraved "E M DICKINSON SHEFFIELD ENGLAND"flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, razor, e m dickinson ltd, e m dickinson ltd sheffield england., cut throat razor, cutlery -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Accessory - CUT THROAT RAZOR

Wilhelm Weber Gold Medal cut throat razor with bone handle and case.Wilhelm Weber Hamburg 8 Goldene Medaillepersonal effects, shaving, razor -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Accessory - Razors in a Box

Wooden box lined with blue satin and velvet containing three white handled razors.Made expressly for W. Jno. Baker, Sydney.|W.Jno Baker, 3 Hunter St, Sydney - inscribed on each razor.personal effects-toilet requisites, shaving -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Haeusler Collection Men's Cut Throat Razor c. early 20th-century, Kaufmann Imperial

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. This item has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. An open cut throat razor with black plastic handle. On one side of blade near handle, "1st GERMAN MANUFACTURE". On other side of blade near handle, "KAUFMANN/IMPERIAL"haeusler, haeusler collection, wodonga, razor, cut throat razor -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects. 'Philips" electric Shaver, c1977

Established in 1891 in Eindhoven, the Netherlands, Philips & Co. was founded to meet the growing demand for light bulbs following the commercialization of electricity. Science and technology underwent tremendous development in the 1940s and 1950s, with Philips Research inventing the rotary heads that led to the development of the Philishave electric shaver, and laying down the basis for later ground-breaking work in transistors and integrated circuits.Philishave was the brand name for the electric shavers manufactured by the Philips Domestic Appliances and Personal Care unit of Philips They used the Philishave brand name for their shavers from 1939 to 2006. The Philishave shaver was invented by Philips engineer Alexandre Horowitz, who used rotating cutters instead of the reciprocating cutters that had been used in previous electric shavers. The shaver was introduced in 1939, though initial production was limited due to the outbreak of World War II. A more ergonomic egg-shaped single-head model was introduced in 1948 and was designed by US industrial designer Raymond Loewy. Global sales increased markedly after a double-head model was introduced in 1951. As a spin off from the light bulb and research is the dynamo-powered bicycle lamp. Its rotating power system inspires the Philishave triple head electric razor. A triple-head model was test marketed in Australia and New Zealand in 1956, but would not be introduced globally until 1966. The brand name Philishave was phased out in 2006 so shavers now bear only the Philips name. Mr Alfred William ( Bill ) Roper, 1913 - 1996 grew up in Ripponlea, ( East St Kilda ) Victoria. As a child he went with his father Arthur Leopold Roper to purchase vegetables from the Moorabbin Chinese market gardeners at the Hotham St. / Nepean Highway corner. c1920 . Bill served in WW2 in New Guinea and post war was Army Auditor, Victoria Barracks, St Kilda Road Melbourne. His staff presented this 'Philishave upon his retirement and he used it until his death1996. He lived in Carlton, Belgrave, Ascot Vale, South Yarra, East St Kilda and moved to Bentleigh in 1987.A ‘Philishave’ triple head electric razor , with cord, head protector and cleaning brush in a hinged plastic case The case has compartments, for Razor and cord, that are lined with a mustard coloured, soft, synthetic material .Case top PHILIPS ; inside EXCLUSIVE PHILISHAVE Razor Handle front PHILIPS / PHILISHAVE; back Type HP 1121/ 110-130V/ 220-240 V / PHILIPS Shield / ? Shield / BS 3456 / V 75255 / MADE IN HOLLAND Nameplate Presented to / BILL ROPER / On the occasion of his retirement / BY THE STAFF OF / DEFENCE AUDIT BRANCH / May 1977 philishave, royal philips electric company, razors, electric razors, bentleigh, moorabbin, market gardeners, st kilda markets, world war 2 1939-1945, department of defence melbourne, melbourne, roper alfred william, roper arthur leopold, ripponlea, chinese market gardeners -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, Cut-throat razor ‘Sinfonie’, c1900 -1930

Gebrüder Stoll, Central-Stahlwarenfabrik Founded in 1889 . Solingen-Foche in 1900- 1930. Names: ‘Gallop’, ‘Pedecor’ (Dedecor?), ‘Sinfonie’, ‘Stoll’, ‘Stoll Brothers’. The parts of a straight razor and their function are described as follows: The narrow end of the blade rotates on a pin called the pivot, between two protective pieces called the scales or handle. The upward curved metal end of the narrow part of the blade beyond the pivot is called the tang and acts as a lever to help raise the blade from the handle. One or two fingers resting on the tang also help stabilize the blade while shaving. The narrow support piece between the tang and the main blade is called the shank, but this reference is often avoided because it can be confusing. The shank sometimes features decorations and the stamp of the country of origin. The top side and the underside of the shank can sometimes exhibit indentations known as fluting, or jimps for a more secure grip. The curved lower part of the main blade from the shank to the cutting edge is called the shoulder. The point where the shoulder joins the cutting edge is called the heel. A thick strip of metal running transversely at the junction where the main blade attaches to the shank is called the stabiliser. Although straight razors were once the principal method of manual shaving, they have been largely overshadowed by the safety razor, which incorporates a disposable blade. Electric razors of various types have also been an available alternative, especially since the 1950s. Straight razors require considerable skill to hone and strop, and require more care during shaving A man's cut-throat razor that folds to protect blade inside handle. with a caseon blade 'SINFONIE' on case; Stahlwaron / Fabrikcut-throat razors, straight razors, shaving equipment, steel blades, stoll gebruder ltd., solingen germany, cutlers, steel manufacturers, ‘sinfonie’ trade mark, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, -

Numurkah & District Historical Society

Numurkah & District Historical SocietyFunctional object - Razor - cut throat & case

Cut throat razor, "Cuckoo' Brand, with a black tortoise shell handle, contained in a brown tortoise shell case Cuckoo Brand, Made in Germany (see photo)personal care, shaving, razor -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory