Showing 525 items

matching use of machinery

-

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c.1870

... . This heavy machinery was not used until after 1853. The Three Mile... discovered and removed. This heavy machinery was not used until after ...This photograph was taken in approximately 1870 and depicts four male miners standing in mining sluice at the Three Mile Goldfields. These men are wearing typical attire for 1870s gold miners. They wear white shirts, tan coloured pants with water proof shoes and most of the men are wearing an apron to prevent their clothing from becoming too dirty from the mud. Each man is wearing a wide brim hat and hold large wooden tools used for sorting through the sluice. Three of the four men have full beards. The photograph was donated to the Burke Museum by R. Ziegenbein before 2001 but the photographer and the individuals captured in the photo are unknown. The image depicts the landscape of the Three Mile Goldfields during a period when open cut sluicing was undertaken to reach gold. Open cut sluicing is a method used to extract gold and other precious metals from beneath the surface of the earth. This technique involved the use of high-powered hoses which broke down the soil enabling miners to come along and search this soil for gold. After the gold rush of the early 1850s, diggers had to enlist the assistance of heavy machinery and techniques like hydraulic sluicing in order to reach gold because the surface alluvial gold had already been discovered and removed. This heavy machinery was not used until after 1853. The Three Mile Goldfields was a site of rich alluvial gold deposits located about 5 km south of Beechworth in Victoria. Today, the location of this gold deposit is called Baarmutha. It was a popular area for gold mining in the 1850s but became largely abandoned by the following decade. In 1865, a man named John Pund recognized that the area could be potentially rich if a better water supply could be obtained. He secured a 15 year license with three other miners. Within the next five years, these men had constructed 19 km of water race going from Upper Nine Mile Creek to Three Mile Creek. By 1881, these four men had delivered 950,000 gallons to the Three Mile Sluicing area which is depicted in this photograph. Pund was later go into partnership with John Alston Wallace who would become owner of the Star Hotel in Beechworth. The Three Mile sluicing location continued to be operational until 1950. Sluice box workers were a vital part of gold mining regardless of how inefficient they were in the recovery of gold. After using hydraulic sluicing to cut away the earth, miners would use the big wooden boxes depicted in the image to catch the earth which would then be sifted for gold. However, accidents would occur often which would result in the gold washing away and unable to be recovered. It was not a very efficient system because the gold, which was alluvial and thus very fine, would often pass through the sluice box undetected.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray an open cut sluicing site can reveal important information for society and technology for the date when the photograph was taken. This image is of important historical significance for its ability to convey information about sluicing and the methods used to find gold in the late 1800s and early 1900s. It also shows a location where sluicing was undertook which provides insight into the impact of sluicing on the environment at a time when it was done. Images, like this one, of Australian gold rush history can reveal important information about the social and environmental impact of this period. This image depicts diggers standing in a mining location and therefore, this image has the capacity to reveal or support significant information for researchers studying the fashion and social status of diggers in Australia in approximately 1870. It can also provide information on the landscape of Australia in this period and the impact of mining for gold on both society and the Australian landscape. The Burke Museum is home to a substantial collection of Australian mining photographs which can be used to gain a deeper understanding into life on the gold fields, technology used in mining, the miners themselves and the impact of the gold digging on the environment.Sepia toned rectangular photograph printed on matte photographic paper and mounted on board.[illegible] about 1870 / 97 2514.1 / 2594 30three mile goldfields, goldfields, 1870, 1870 gold, australia, australian landscape, miners, gold miners, diggers, gold diggers, beechworth, victoria, sluice box workers, sluicing, sluice, mining -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph - Photograph - Reproduction

... of machinery was used in mining to place holes in the walls of a mine... of machinery was used in mining to place holes in the walls of a mine ...This photo depicts a man standing next to a large piece of mining equipment identified as a hydraulic chisel (alternative name: drifter dill or power rock drill). This piece of machinery was used in mining to place holes in the walls of a mine which were then filled with dynamite or other explosives for rock blasting or to make holes for plug and feather quarrying. The additional tools to the right of the photograph and in front of the machinery can be identified as either picks or as feather and wedges, the latter of which were used to split stone drilled by the hydraulic or power chisel. Depending on the date of the photograph, which is not provided, this chisel was either powered by electricity or by hydraulics. The following is written on the drill "R.C. FORD'S PATENT No91 / MELBOURNE VICTORIA 1879". The man depicted in this photograph wears a wide brim hat, a loose fitting white shirt and loose pants. He wears boots and has a medium sized dark beard. This attire, along with his locality in the mine and proficiency with the mining equipment, identifies this man as a miner working in this particular, but unidentified, mine. It depicts an instance of hydraulic chiseling which makes this photograph valuable for the study of mining techniques from a date c1880.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray the types of machinery used in mining can reveal important information for technology and highlight the methods used to break apart the earth in order to obtain access to gold and other precious materials during the period this photograph was captured. Further research into RC Ford can potentially reveal even further information pertaining to this photograph. This image is of important historical significance for its ability to convey information about the methods and machinery used to access gold or mine more in general. It also highlights the size of machinery at the time and allows us to compare this to the size of the person standing besides the machinery to better understand the manpower which would have been required to use and set-up this macinery.A black and white rectangular reproduced photograph printed on matte photographic paper.Reverse: 7816/ copy 1/3gold, sluicing, gold sluicing, hydraulic sluicing, gold and tin mine, mining, gold mining, beechworth, burke museum, melbourne, victoria, hat, mining machinery, machinery, r. c. ford -

The Beechworth Burke Museum

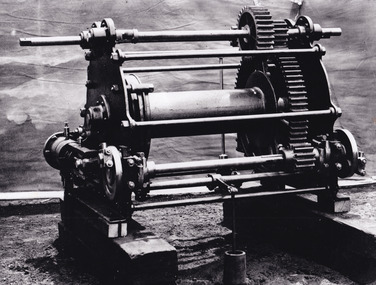

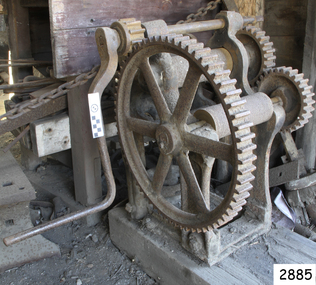

The Beechworth Burke MuseumPhotograph - Photograph - Reproduction, c.1870s

This photograph shows a piece of gold mining equipment identified as a mine winch, possibly an air winch cylinder of 1870s RG Ford's Patent design. Throughout the history of mining for gold and other precious materials, the windlass or winch (pictured) was used to bring up buckets full of soil from the bottom of a mine. This soil was then searched for gold/metals before being relocated to a different area. Due to the size and complexity of this particular piece of equipment, this winch may have been used to raise and lower mine carts to the entrance of the mine (often used in coal mining) and could have been used in raising cages up and down (acting as elevators) containing miners if the mine was particularly deep. The actual use of this particular item in the Beechworth locality is undocumented but these are some possibilities based on the use of these pieces of equipment in other mining locations. Mining can have a largely detrimental impact to the environment and therefore, the study of machinery like the one depicted in this photograph can help researches to reconstruct the methods and technologies used in the late 1800s and early 1900s. This particular item appears to have been removed from it's original site where it would have been used to assist with mining. It is possible that this photograph has been taken for recording purposes or as part of a machinery exhibition. Prior documentation records that this piece of equipment had connections to the Rocky Mountains Mining Company. Today, the Rocky Mountains Gold Mining company is famous in Beechworth for having been instrumental in the creation of the Rocky Mountain tunnel. Construction for this tunnel began in 1859 when a group of 12 men blasted a 400ft long tailrace though the rock beneath the town of Beechworth. Today, the 800ft tunnel, completed in 1871, is a popular tourist attraction but during the decades of gold mining, the purpose of this tunnel was to divert water away from the main sluicing operations so miners could better access gold and precious materials. The tunnel was used for this purpose for many years, later becoming useful for the Zwar Brother's tannery and currently as an outfall drain for Lake Sambell. This area continued to be mined until the early 1900s. The period when this item was in use is unclear but it is estimated to have been in the 1870s based on the design and appearance of the image. The gold works at the Rocky Mountain Tunnel closed in the early 1920s but the impact of mining remains in Beechworth today and therefore the study of photographs like this one which contain mining equipment can further understanding of mining in this region.This photograph has historic and research potential for study on the gold mining of the Beechworth region and types of equipment used to locate gold after the initial gold rush of 1853-1854 which resulted in the discovery of the surface gold and required miners to dig deeper to access precious metals. The clarity of the photo, and its good preserved condition, means it can continue to be used for research. This photo is part of a collection of six photos all within the Burke Museum Collection which depict mining equipment.Square black and white photograph on card.7793.1beechworth, mining, goldmining, goldmining equipment, beechworth burke museum -

The Beechworth Burke Museum

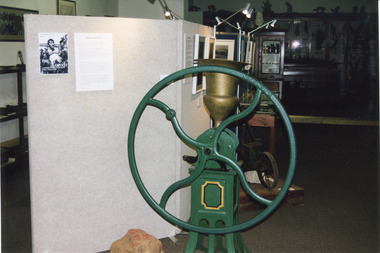

The Beechworth Burke MuseumPhotograph, Estimate 1999

This photograph was taken in 1999 at 'The Harvest' exhibition at the Burke Museum for members of Baking Industry Victoria. The grain mill, manufactured by B.M. Purshouse in Wolverhampton, England, was of special interest.This photograph is of primary social significance to the Beechworth community because it depicts a 19th-century grain mill, manufactured by B.M. Purshouse in Wolverhampton, England, which was probably used at flour mills in the Ovens District, such as that at Tarrawingee, which opened in 1866. The purchase of agricultural machinery such as the grain mill accompanied the expansion of agriculture, including grain growing, in the Ovens District following the gold mining prosperity of the 1850s. This photograph may be of interest to researchers who wish to observe an image of the Purshouse grain mill.Colour rectangular photograph printed on matte AGFA photographic paper.Obverse: THE HARVEST / THE HARVEST Reverse: 2854beechworth, burke museum, promoting settlement, living in country towns, making regional centres, preserving traditions and commemorating, farming and agriculture, exhibitions, burke museum exhibitions, building local economies, transforming land, victorian agricultural history, marketing and promoting agricultural products, the harvest exhibition, harvests, victorian gold rush towns, grain mill, bm purshouse, crops and grain, baking industry victoria -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1999

Taken in 1999, the photograph depicts a section of “The Harvest” exhibition held at the Burke Museum between May 1st and June 20th 1999 as part of the Baking Industry Victoria. In the foreground is believed to be an old seed distributor. The grain mill made by B. M. Purshouse in Wolverhampton, United Kingdom, was of special interest during the exhibition. This photograph is of historical and research significance, connecting with various themes such as farming, adapting to diverse environments, and the promotion of settlement in Victoria. The photograph is an example of an exhibition held at the Burke Museum in 1999, demonstrating the communal interest of Beechworth in their farming history. The photograph contains a strong interpretive capacity as it demonstrates the importance of farming to Beechworth and Beechworth's history, revealing the enduring connection between the local community and the surrounding land. The historical and research value of the photograph is further enhanced by the depiction of historical farming machinery, providing a means for future generations to view historical machines used in farming. Colour rectangular photograph printed on photographic paper.Reverse: 2857burke museum, the harvest, exhibition, baking industry, grain mill, b. m. purshouse, beechworth, baking industry victoria, seed, seed distributor -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1999

Taken in 1999, the photograph depicts a section of “The Harvest” exhibition held at the Burke Museum between May 1st and June 20th 1999 as part of the Baking Industry Victoria. In the foreground is depicted a seed distributor. The grain mill, which can be seen in the background, was made by B. M. Purshouse in Wolverhampton, United Kingdom, and was of special interest during the exhibition. This photograph is of historical and research significance, connecting with various themes such as farming, adapting to diverse environments, and the promotion of settlement in Victoria. The photograph is an example of an exhibition held at the Burke Museum in 1999, demonstrating the communal interest of Beechworth in their farming history. The photograph contains a strong interpretive capacity as it demonstrates the importance of farming to Beechworth and Beechworth's history, revealing the enduring connection between the local community and the surrounding land. The historical and research value of the photograph is further enhanced by the depiction of historical farming machinery, providing a means for future generations to view historical machines used in farming.Colour rectangular photograph printed on photographic paper.Reverse: 2855burke museum, the harvest, baking industry, baking industry victoria, seed distributor, grain mill, b. m. purshouse, beechworth, exhibition -

Orbost & District Historical Society

Orbost & District Historical Societyharness

Horses were a vital part of the agricultural industry in Orbost before the mechanisation of farm machinery. This item is associated with that time.A leather spider harness with chains. It has a wooden pole for display purposes. It was used for a large working horse.equestrian agriculture farming harness -

Orbost & District Historical Society

Orbost & District Historical Societyjack, 1908

... ten shillings. This item is an example of the machinery used ...Used by Ettore Alessandri who came to Australia in 1930's. He had land at Marlo and used this jack to clear the property of trees and stumps in 1940's and 1950's. The Trewhella Monkey jack was invented by the Trewhella brothers to help land clearance in Australia during the 1880's. Two jacks were made a 5 ton and a 10 ton. This item is a 10 ton model having two extension bars. The longer spear is used for larger tree work and the smaller spear for general work and small trees. Both models had two lifting claws at different heights. Th lower claw was useful for roots. The top claw was intended for going under loads and the bottom claw used for rolling timber. In 1929 the cost of the 10 ton model was thirteen pounds ten shillings.This item is an example of the machinery used by the early settlers to clear land. A 10 ton monkey jack. It has two extensions (spears) and two lifting claws. It has a detachable handle. 2033.1 is the main jack. 2033.2 is the handle. 2033.3 is the shorter extension and 2033.4 is the longer extension.On extension - BRITISH STEEL On main section - 10 TON MONKEY JACK PATENTED 1411-50 AUGUST 04 1412-50 AUGUST -05 ?????? JUL -06 12104-20 JUL-08 Trewalla Bros Trentham Vicrural monkey-jack trewhella agriculture machinery -

Orbost & District Historical Society

Orbost & District Historical Societypress, late 19th century - early 20th century

This item was probably used in leather work for horse harnesses.A hand-operated heavy cast iron press. It has a detachable handle at the top for twisting the screw.THE J.D. RANDALL COpress machinery leather-harness -

Orbost & District Historical Society

Orbost & District Historical Societyiron chain, First half 20th century

This was probably used on a farming property and would have been attached to various horse-drawn farm implements and machinery.Horses were a vital part of the agricultural industry in Orbost before the mechanisation of farm machinery. This item is associated with that time.A heavy iron chain for attaching to a horse drawn implement. It has a strong hook at one end and a large ring at the other. It has several ring attachments and straps which have been added with wiring.chain farming -

Orbost & District Historical Society

Orbost & District Historical Societywagon wheel rim, mid 19th century -mid 20th century

... machinery used in the Orb ost district. iron wheel-rim agricultural ...Could have been from a hay rake and used on a local farming property.This item is an example of early farming machinery used in the Orb ost district.Rim of an iron wheel. Possibly from agricultural machinery. The 13 spokes have been cut off.iron wheel-rim agricultural-machinery -

Orbost & District Historical Society

Orbost & District Historical Societyfarm implement

This is a very common 'farm' style of old swinglebar. Blacksmiths and agricultural machinery suppliers made them by the thousands. They were used most commonly on heavy vehicles pulled by horses. This one would have been used on a farming property on the Orbost district.This item is an example of an early farming implement used in the Orbost district. It also demonstrates the improvisation skills of the agricultural community.Four pieces of wood connected by iron fittings. Two pieces have iron loops at both ends. The two straight pieces appear to be newer. There are two swingle trees. It appears to be a 2-horse set of swinglebars with a double-bar. which has been added to and repaired.agricultural-implement horses farming swinglebar -

Orbost & District Historical Society

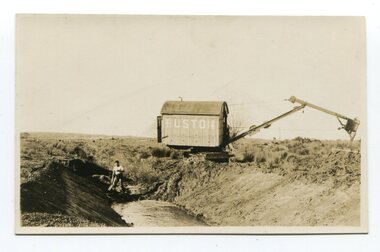

Orbost & District Historical Societyblack and white photograph, first half 20th century

Ruston & Hornsby, later known as Ruston, was an industrial equipment manufacturer in Lincoln, England, the company's history going back to 1840. The company is best known as a manufacturer of narrow and standard gauge diesel locomotives and steam shovels. This machine is probably a drag line excavator.This photograph records early an early type of excavator used to construct drainage channels in rural Victoria.A black / white photograph / postcard of a man digging in a very large trench, probably a drainage channel, with an earth mover in the background. The machine has the name "RUSTON" on it.drainage-channel earth-moving-machinery -

Orbost & District Historical Society

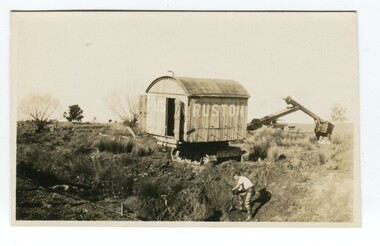

Orbost & District Historical Societyblack and white photograph, first half 20th century

Ruston & Hornsby, later known as Ruston, was an industrial equipment manufacturer in Lincoln, England, the company's history going back to 1840. The company is best known as a manufacturer of narrow and standard gauge diesel locomotives and steam shovels. This photograph records early an early type of excavator used to construct drainage channels in rural Victoria.A black / white photograph / postcard of a man digging in a very large trench, probably a drainage channel, with an earth mover in the background. The machine has the name "RUSTON" on it.drainage-channel earth-moving-machinery -

Orbost & District Historical Society

Orbost & District Historical Societyblack and white photograph, first half 20th century

Ruston & Hornsby, later known as Ruston, was an industrial equipment manufacturer in Lincoln, England, the company's history going back to 1840. The company is best known as a manufacturer of narrow and standard gauge diesel locomotives and steam shovels. This photograph records early an early type of excavator used to construct drainage channels in rural Victoria.A black / white photograph / postcard of a man digging in a very large trench, probably a drainage channel, with an earth mover in the background. The machine has the name "RUSTON" on it. In the foreground is a man, dressed in a long dark coat, watching.agricultural-machinery drainage-channels ruston -

Orbost & District Historical Society

Orbost & District Historical Societypair of hames, late 19th - early 20th century

Hames are attached to a horse collar used to distribute the load around a horse's neck and shoulders when pulling a wagon or plough. The collar often supports and pads a pair of curved metal or wood pieces, called hames, to which the traces, which attach to the wagon or plough, of the harness are attached. The collar allows the horse to use its full strength when pulling. This pair of hames would have been used on a farm in the Orbost district.Horses were a vital part of the agricultural industry in Orbost before the mechanisation of farm machinery. This item is associated with that time.A pair of hames, joined together by a metal chain. Iron has been cased over wood to form the hames. Each has a hook attached and a ring.WARRANTED picture of bull's head FORGEDsaddlery equestrian agriculture horses hames -

Orbost & District Historical Society

Orbost & District Historical Societyhorse hames, late 19th -early 20th century

Hames are attached to a horse collar used to distribute the load around a horse's neck and shoulders when pulling a wagon or plough. The collar often supports and pads a pair of curved metal or wood pieces, called hames, to which the traces, which attach to the wagon or plough, of the harness are attached. The collar allows the horse to use its full strength when pulling. This pair of hames would have been used on a farm in the Orbost district. Horses played a vital role of the agricultural industry in Orbost before the mechanisation of farm machinery. This item is associated with that time.A pair of hames, iron shaped over a wooden frame. They are linked together by a metal chain. Each has a hook attached and a metal ring at the end.WARRANTED PLOUGHMANBRAND FORGEDequestrian saddlery rural agriculture horses hames -

Orbost & District Historical Society

Orbost & District Historical Societypair of horse hames, late 19th -early 20th century

Hames are attached to a horse collar used to distribute the load around a horse's neck and shoulders when pulling a wagon or plough. The collar often supports and pads a pair of curved metal or wood pieces, called hames, to which the traces, which attach to the wagon or plough, of the harness are attached. The collar allows the horse to use its full strength when pulling. This pair of hames would have been used on a farm in the Orbost district. Horses were a vital part of the agricultural industry in Orbost before the mechanisation of farm machinery. This item is associated with that time.A pair of horse hames, iron shaped over a wood frame and linked together by a metal chain and hook. Each has a hook attached and a ring at the end held by string,WARRANTED SWAN BRAND FORGEDsaddlery horses hames agriculture rural equestrian -

Orbost & District Historical Society

Orbost & District Historical Societypair of horse hames

Hames are attached to a horse collar used to distribute the load around a horse's neck and shoulders when pulling a wagon or plough. The collar often supports and pads a pair of curved metal or wood pieces, called hames, to which the traces, which attach to the wagon or plough, of the harness are attached. The collar allows the horse to use its full strength when pulling. This pair of hames would have been used on a farm in the Orbost district. Horses were a vital part of the agricultural industry in Orbost before the mechanisation of farm machinery. This item is associated with that time.A pair of all metal horse hames, flat and angular shape. They are held together by a metal chain. Each has a hook attached and a metal ring at the end. One of the chain links has been repaired with wire.DOWNEE ALL STEELequestrian saddlery horses agriculture rural hames -

Orbost & District Historical Society

Orbost & District Historical Societyhames and traces, late 19th century - first half 20th century

Hames are attached to a horse collar used to distribute the load around a horse's neck and shoulders when pulling a wagon or plough. The collar often supports and pads a pair of curved metal or wood pieces, called hames, to which the traces, which attach to the wagon or plough, of the harness are attached. The collar allows the horse to use its full strength when pulling. This pair of hames would have been used on a farm in the Orbost district for pulling ploughs or other farm implements.Horses were a vital part of the agricultural industry in Orbost before the mechanisation of farm machinery. This item is associated with that time.Wooden hames with leather traces which have chains and springs (to absorb shock) on each end.equestrian rural farming harness traces -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph - Photograph - Reproduction, Unknown

This image is a reproduction of an 1899 original depicting the 'Williams Good Luck Mine' on the Mopoke Reef (also called 'Morepork Gully') in the Dingle Ranges, approximately three miles from Beechworth. The foreground of the image is littered with piles of smashed rock and detritus, known as ‘mullock’, beside a reinforced mine shaft, a vertical access passageway allowing miners to enter the mine and haul ore out using lifting technology such as a poppet heads, whims or windlasses. A group of miners and a dog appear close to an open-sided miner’s hut. Following the discovery of gold at Beechworth in 1852, rushes quickly followed at surrounding creeks and gullies in the district. In the late nineteenth and early twentieth centuries, small syndicates of miners continued to work old or abandoned quartz reefs, often persisting without the assistance of heavy machinery to remove the large amounts of rock, in order to obtain yields at ever greater depths. The group of miners in this photograph are Mr. Roger Williams and Sons, who revived operations at the ‘Old Good Luck’ mine on the Mopoke Reef in the Dingle Range near Beechworth around 1892, working the site for more than two decades. An emigrant from Cornwall with experience in the tin mining industry, 19 year old Roger Williams senior sailed to New Zealand in 1840, then to Australia where he spent time in the Bendigo Gold Fields before settling in Beechworth in the early 1860s. Mr Williams senior worked on various mining activities in the district, including the Rocky Mountain Tunnel project. Conversant with the character of gold-bearing reefs in the area, the syndicate dug an eight hundred foot tunnel, digging down as far down as two hundred feet with little capital save their labour, to connect and provide better working access to the mass of reefs and veins in the vicinity. Progress was hampered by poor air quality charged with fumes from dynamite and large quantities of rock had to be crushed to obtain payable yields. The Victorian Goldfields are filled with ruins and remnants of the area's rich mining history, ranging from small alluvial diggings to the remains of huge mining companies. Site names often changed several times throughout the nineteenth and twentieth centuries. Some sites were abandoned and forgotten, others were worked continuously over many decades. The names of mines were often repeated at different locations throughout the Victorian Goldfields. For example, there is a Mopoke Gully heritage mine near Fryers Creek, Victoria. 'Mopoke' is a common onomatopoeic name for Morepork and Australian Boobook owls. This image has historical, social and research significance for patterns of emigration during of the Victorian Gold Rush, and the historical, social and environmental impacts of mining at Beechworth at the turn of the nineteenth and twentieth centuries. As gold became scarce and government support and large company investment waned, poor hard-working miners laboured intensively to make a living through periods of high unemployment. This image can be compared and studied alongside other historical mining photographs and objects in the Burke Museum Collection. It has potential to improve our understanding of miners working conditions and the shifting character of mining in the Beechworth district. Black and white rectangular reproduction photograph printed on matte photographic paper.Obverse: Williams Good Luck Mine Beechworth / Roger! / Reverse: 6858 / burke museum, beechworth museum, beechworth, gold fields, gold rush, victorian gold rush, gold ming history, colonial australia, australian gold rushes, mining technology, beechworth historic district, indigo gold trail, migration, indigo shire, good luck gold mine, victorian goldfields, mining syndicates, gold fever, quartz-mining, small-scale mining, old good luck mine, mopoke gully, quartz reefs beechworth -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1900

... the machinery used and attire worn by men and women during the gold rush ...A black and white photograph depicting seven men and four women surrounded by tunnel boring machinery. A tunnel boring machine (TBM), also known as a "mole", is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata. They may also be used for microtunneling. They can be designed to bore through anything from hard rock to sand. Tunnel boring machines are used as an alternative to drilling and blasting (D&B) methods in rock and conventional "hand mining" in soil. TBMs have the advantages of limiting the disturbance to the surrounding ground and producing a smooth tunnel wall. This significantly reduces the cost of lining the tunnel, and makes them suitable to use in heavily urbanised areas. The major disadvantage is the upfront cost. TBMs are expensive to construct, and can be difficult to transport. The longer the tunnel, the less the relative cost of tunnel boring machines versus drill and blast methods. This is because tunneling with TBMs is much more efficient and results in shortened completion times, assuming they operate successfully. Drilling and blasting however remains the preferred method when working through heavily fractured and sheared rock layers.This photograph is significant as it shows the machinery used and attire worn by men and women during the gold rush era. Black and white rectangular photograph printed on photographic paperburke museum, mining, beechworth, boring machinery, excavate, gold, gold fields, gold rush, miners -

The Beechworth Burke Museum

The Beechworth Burke MuseumPostcard, George Symons, c.1990

... . These periods did not require the use of heavy machinery or the digging ...The photograph printed on this postcard comes from the collection of the Mitchell Library in Sydney. It is sepia in tone and depicts seven men standing and sitting around a mine shaft in the Beechworth region. The photograph has been dated to approximately 1872. This period in history post-dates the Victorian gold rushes which occurred 1852-1853 in Ballarat, Bendigo and Beechworth. During this period, in the 1870s, the surface alluvial gold had been discovered and removed from location. Therefore, in order to reach the deeper and less accessible alluvial gold, diggers began to dig shafts into the earth. These shafts sunk below the ground level by 20 to 30 feet and required timber structures around the entrance and winches to bring the paydirt to the top. The top of this wooden structure is visible behind the man standing in the upper right of the image. This type of mining was highly dangerous as mines often caved in which injured the minors and often resulted in death. Thus, following this period, in the early 1900s, miners opted instead for hydrolic slucing which cut away the earth without the devastating consequences of a mine cave in. This particular group of miners appear to have been unable to afford a horse (then worth around 50 pounds) which were generally used at mines like this to help pull buckets attached to ropes up and down the mine. Instead, this group brought the buckets up and down by windlass. The windlass was a wooden structure mounted over the mining shaft and fitted with a hand-cranked winch which enabled the bucket attached to the rope to be brought up and down.Gold was first discovered in Beechworth in Spring and Reid's Creek in the summer of 1852-1853. At its popularity, this region had approximately 8000 people on the gold fields searching for gold on the banks of these creeks. These periods did not require the use of heavy machinery or the digging of deep mining shafts like the one depicted in this image. Therefore, this image has important connotations for the technologies associated with mining during the approximated 1870s when gold was harder to access. This is a later period in gold history which does not fit into the "gold rush" period. Instead, it occurred after the surface gold had disappeared and therefore, is essential for researchers who are investigating the mining techniques and structures used to reach the alluvial gold which was located deeper under ground in the 1870s. This period predates the use of big heavy machinery used to mine in the 1900s which include dredges. Images such as this one can also impart essential information as to the wardrobe and fashion of men during this period. It also imparts knowledge about the landscape of Beechworth which is useful for people researching the environment and impact of gold mining in the north-east region of Victoria. In addition, since this image is a postcard reproduction of an early Australian image which may date to approximately 1990 it can impart knowledge as to the interests of people during this time period when there may have been an increase into Australian history.A sepia tone facsimile of an early Australian photograph (circa 1872) printed as a postcard.Obverse: BEECHWORTH / Victoria, Australia / Reverse: GM 2 3275 / CORRESPONDENCE / AUSTRALIAN / YESTERYEAR / CARDS / ADDRESS / Published by George Symons (057) 65 3240 / THE MINEHEAD C. 1872 / The easily gleaned gold of the early fields did / not last very long. In order to reach less / accessible alluvial gold diggers began sinking shafts as much as twenty to thirty feet down / and the mines required timbering and winches / to bring the paydirt to the top. / This syndicate has been unable to afford the / luxury of a horse (about 50 pounds) and so everything / must go up and down by windlass and rawhide / bucket. / Photo: Mitchell Library, Sydney / A sepia tone facsimile of / an early Australian photographmining album, gold mine, beechworth, burke museum, mine shaft, postcard, australian yesteryear cards, george symons, the minehead, gold fields, alluvial gold, early australia, c.1872, 1872, gold diggers, north east victoria -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTyre Bender, 1884

A tyre bender is used to bend and shape metal rims for wooden wagon wheels. This tyre bender’s model first appeared in the Day Bros catalogue in 1884 as the “Giant” model. The catalogue of 1883 only showed a lighter duty model called the “Lion”. It can be assumed that this later “Giant” model was a heavy duty improvement over the 1883 "Lion" and other smaller models which were still being advertised for sale in 1884. The Day Bros foundry, makers of this tyre bender, was operating as the manufacture of wheel right and blacksmith tools and general machinery in the 19th century in the USA and successfully exported their goods all over the world. Wagon tyre benders would have been very common circa 1850-1920, so there were probably many makers over the years. Early on, it would have become clear to the blacksmiths about which designs worked best so, eventually, the various makers would have made similar products to each other. This tyre bender was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The tyre bender is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The machine or tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Steel tyre bender mounted on timber base, used for wagon wheel steel rims. Made from cast iron and steel, double geared with four cogs to unite the upper and lower steel rollers. There are adjustable guide collars to keep the iron in line while it is being bent. It can also be used with two cranks for heavy duty work utilising the use to two operators. It is the Giant model, made in 1884 by Day Bros. of Philadelphia. This tyre bender once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria. “DAY BROS. PHILAP. PA” cast into the side of machineflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, machinery, wagon wheel, wheelwrights, blacksmith, steel rim wheels, tyre bender, tire bender, the giant tyre bender, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, wagon tyre bender, day bros. philadelphia pennsylvania, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVice, 1800s

A wheelwright’s spoke vice was used to hold the wheel hub firmly while the spokes were hammered into the wheel hub, then the spokes would be joined to the wooden wheel felloe before finally the metal flat tyre, or later the rubber tyre, would be attached to the felloe. A wheelwright’s spoke vice would have been very necessary for blacksmiths circa 1800s-1920s as it would have been used in the manufacture and repair of carts, wagons, coaches and other horse-drawn vehicles. This wheelwright’s spoke vice was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The wheelwright’s spoke vice is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Vice; wheelwright’s wheel spoke vice. Manufactured in 1800s. This was once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, machinery, wagon wheel, steel rim wheels, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, wheel hub, wheel spoke, wheel felloe, wheel tyre, wheel tire -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Hand-cranked separating maching, made in Sweden for Melbourne Crown Separator Co. Pty Ltd. Machine is used for separating cream from milk, with the machine speed being 70 revs per minute.Separator machine. Hand-crank operated milk separator, small, painted red, Crown Separator Co Pty Ltd. Base and spinning mechanism only (mechanism spins very rettly). Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, cream separator, dairy machinery, farming machinery, crown separator co pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ships' Telegraph section, Milne Brothers, Copper and Brass Works, Early-to mid-20th century

This Engine Room section of a ship's telegraph system was part of the equipment of the Ports and Harbour ship the SS Rip. The vessel serviced and maintained the lights and buoys at Port Phillip Bay and Queenscliffe. The SS Rip was possibly the former gunboat "Albert". The ship’s communication system that was used from the late 19th century to early-to-mid-20th-century is called an Engine Order Telegraph (E.O.T.) or ship’s telegraph. The system has two parts, the Bridge Section and the Engine Room Section. The Bridge Section is usually mounted on top of a pedestal, and the Engine Room Section is often attached to a vertical surface. The standard commands printed or stamped onto the dial are the directions of AHEAD and ASTERN, and the speeds of STOP, FULL, EASY, STD. BY. and FIN. ENG. The ship’s pilot on the Bridge of a vessel sends his Orders for speed and direction to the to the Engine Room with the E.O.T. He moves the lever or levers, depending on the number of engines the ship has, to change the indicator on the Bridge Section’s dial to point in the new direction and speed of travel. This change causes the Orders to be duplicated on the Engine Room Section’s dial and a bell to signal the change simultaneously. The engineer then adjusts the ship’s engines and steering equipment to follow the pilot’s Order. The manufacturer, Mulne Bros., was a copper and brass works at 166 Sussex Street Sydney, in December 1892, and previously from 1870 at 128 to 130 Sussex Street. The company made and sold a wide range of equipment including machinery and gauges for the Railways.The Engine Room section is significant for being part of the communications system on the ship SS Rip, owned by Melbourne's Ports & Harbours department and used to service and maintain the navigation signals of Port Phillip Bay and at Queenscliffe in the mid-20th century. The dial is an example of marine equipment made in Australia and used for the safety of Victorian vessels. It is also significant for being made by an early Australian manufacturer, Milne Brothers of Sydney.Engine Room Section of a ship’s telegraph or Engine Order Telegraph (E.O.T.). The round metal dial has inscriptions stamped around the edges. The inscriptions are nautical terms for direction and speed and include the maker’s details. The dial was made by Milne Bros. of Sydney. It was part of the equipment on the "SS Rip" in Victoria.Black paint around dial: "MILNE BROS. / MAKERS / SYDNEY" "FULL EASY STD. BY " "FIN ENG. EASY FULL" ""ASTERN" "STOP" "AHEAD"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, marine technology, marine communications, engine order telegraph, e.o.t., ship’s telegraph, bridge section, engine room section, ship’s engine telegraph section, marine telegraph, milne bros., milne brothers, sydney, copper and brass works, ports & harbours ship, ss rip, gunboat albert, service ship, maintenance ship -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageShip Log, 1900-1920

Thomas Walker & Son was internationally renowned in the manufacturing of ships logs. Founding father Thomas Walker (1805–1871), an engineer in Birmingham, patented a mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kick starting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ships log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (British-based organisation promoting ties and trade with the British Caribbean) and the most common log in use for two generations. It took till 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By the time of his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log and the Walker factory was one of the first to introduce the 48 hour work week for employees. This ship log was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades. Ship Log, three analogue dials calibrated in increments of Miles, the Rocket Log is a nautical instrument for measuring a vessel’s speed and distance traveled. The floating log was drawn behind the ship over a fixed time period in order to measure the distance traveled. The counter could measure enough miles to cover the maximum distance traveled by a ship in one day. The log has two distinct parts; a brass register, made by Walker, showing the distance recorded and the rotator made by Reynolds, that spins in the water driving the counter. both parts are connected by a linked chain. The register has a cylindrical brass body approx 4.5 cm diameter containing registering mechanism with hardened steel bearings. Distance is indicated by the three pointers on enamel plate as follows: graduated every 10 miles from 0-100; every mile from 1-10; every 1/4 mile from 1/4 -1. A brass sling and eye secured to the body enables it to be attached to the taffrail. The original rotator would have had a cylindrical tapered wooden body, approx 4.5 cm in diameter with three metal alloy fins or could be all made from brass. A towing eye is fitted to the tapered end. The two pieces of apparatus are connected by a length of linked chain, length 22.9 cm."Walkers Rocket Ship-Log Birmingham (Patented)" printed on face-plate. "Made by Thomas Walker".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ship log, rocket log, mechanical ship log, measuring instrument, marine instrument, nautical instrument, speed recording instrument, ship log register, walker ship log, walkers rocket ship-log, thomas walker, thomas walker & son, thomas ferdinand walker, walker log business, reynolds ship log rotor, taffrail log, taff rail log, west india association -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageShip Log, 1900-1920

The Excelsior IV Log is a nautical instrument for measuring a vessel’s speed and distance travelled. When navigating a ship it is essential to be able to estimate the boat’s speed and distance travelled to determine its position at sea. In times past the only way to measure a ship’s speed was to throw a wood log into the water and observe how fast it moved away from the ship. In the 16th century, the log was fastened to a rope knotted at set intervals. The log was thrown over the stern (back) of the vessel and a crew member counted the number of knots that were paid out in a set time. From this, they could estimate the speed of the vessel through the water. This was known as streaming the log and is also the derivation of the knot as a measurement of nautical speed. The Walker’s Excelsior Mark IV instrument was designed for smaller vessels, such as yachts, launches and fishing vessels. Historical: Thomas Walker & Son was internationally renowned in the manufacturing of ships logs, founding father , Thomas Walker (1805–1871), an engineer in Birmingham, patented a mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kick starting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ship’s log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (British-based organisation promoting ties and trade with the British Caribbean), being the most common log in use for two generations. It took until 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By the time of his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log and the Walker factory was one of the first to introduce the 48 hour work week for employees. The ship log was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades.Ship's Taff Rail Log, rope attached. Walker's Excelsior IV Log model. Nautical miles dials: units and 10's. "Walker's Excelsior IV Log", "Made in England by Thomas Walker, Birmingham"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, log register, taff rail log, taffrail log, marine navigation, a1 harpoon log, cherub’ log, walker’s excelsior mark iv log, ship’s log instrument, mechanical ship’s log, measure ship’s speed, nautical instrument, navigation instrument, massey & sons, thomas walker, blue brick walker, thomas walker & son, thomas ferdinand walker, 48 hour work week -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Ship Taffrail Log Flywheel, 1930+

The flywheel possibly belongs to a Walker's Cherub Mark III Ship-log taffrail, how the flywheel operates is a metal loop of the recording log would have been connected to the flywheel, so you could see if it was spinning properly. After the flywheel, is the rotor that was towed behind the ship and the revolutions of the rotor would register on the indicator, thus measuring the distance the vessel had travelled. Thomas Ferdinand Walker (1837–1921) first patented the Cherub log in 1878. It was one of the first logs in which the recorder was placed onboard a ship rather than being incorporated as part of the rotor. The Cherub Mark III series was produced from 1930 it came in two versions a thousand-mile which is quite rare and a five hundred-mile version.This ship log flywheel was invented and made by a significant marine instrument maker and innovator of machinery Thomas Walker. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades to measure the distance travelled at sea updated versions are in use today by mariners.Log Governor (or Fly-wheel) from a Ships Taffrail Log, metal wheel with 6 spokes, hub has rope attached for connecting to ships log. Boss the other side for attachment to the spinner.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, log governor