Showing 139 items

matching wool selling

-

Warrnambool Art Gallery

Warrnambool Art GalleryAfrican thumb piano, mid to late 1800s

... selling wool and on his travels. Later in life Dallimore enlisted... received from selling wool and on his travels. Later in life ...This item was donated to the museum by Joseph Dallimore. Dallimore was brought up at Lake Gillear, and as a young man he left Australia to travel overseas both to help his parent's business in the wool trade and for pleasure. He wrote many letters to his parents keeping them updated with the prices he received from selling wool and on his travels. Later in life Dallimore enlisted in the Australian Army and went on to have a distinguished career during the Boer War. He would have collected this piano whilst on service in South Africa.South African thumb piano from the Zulu culture. It is a wooden panel board with 15 iron finger keys in it. They are stuck onto the wood at one end with some sort of glue and also held in place by an iron rod passing over the top of them. At the bottom of the board is a metal panel and attached to that is a small circular cymbal. There is a string tying the metal panel to the wooden board.There are no original markings on this although the original museum label is still stuck to the bottom which says, ' Native piano ( Mashona)' on it in script.south africa, joseph dallimore. war, boer war, zulu, finger piano, music -

National Wool Museum

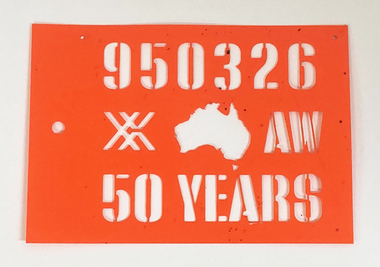

National Wool MuseumTool - Stencil, c.2018

... micron wool was selling for prices between 4 to 5,000 cents per... industry. 15 micron wool was selling for prices between 4 to 5,000 ...The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. Thin sheet of orange plastic with letters and numbers moulded to produce a consistent pattern for the surface below through the application of ink. This wool classing stencil once belonged to Denis Hucker. The top number is Denis’ Wool Classing Stencil Number. On the next line is the emblem of the Australian Wool Exchange, followed by an image of Australia, and finally the letters AW. The final line reads 50 years, indicating Denis’ experience in the profession of wool classing. This stencil is reserved for wool classers who have held their stencil and been actively classing wool in Australia for more than 50 years. Wool classers sort, classify, and grade wool into various lines so that it can be sold at best market price. They also manage and supervise wool-handling teams. The stencil is used in the final step of preparing a bale of wool for sale. It is branded across the front of a wool bale to indicate the quality of the wool, with the classers number used as a seal of approval. Accompanying the stencil are two sheets of white A4 paper with printing in gold and black ink. The first sheet was presented by the Australian Council of Wool Exporters & Processors to Denis Hucker for achieving 50 years of wool classing. Surrounded by a thin gold boarder, the page is made up of black text with gold headings. In the top right corner, an image of a sheep with an outline of Australia is found. The second piece of paper was presented by the Australian Wool Exchange to Denis Hucker for achieving 50 years of wool classing. Two thirds of the page is made up of a gold stencil which reads “50 years”. Accompanying the stencil is black text. Moulded letters, numbers, emblem, and imagery. “950326 / (emblem AWEX) (Image Australia) AW / 50 Years” A4 Paper. Printed. See Multimedia A4 Paper. Printed See Multimedia wool classing, stencil, 90 years wool classing between father & son -

National Wool Museum

National Wool MuseumTool - Stencil, 1983

... micron wool was selling for prices between 4 to 5,000 cents per... industry. 15 micron wool was selling for prices between 4 to 5,000 ...The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. Thin sheet of metal with letters and numbers cut to produce a consistent pattern for the surface below through the application of ink. In small text on the top edge of the stencil two separate phrases are engraved.” A.W.C. PROPERTY NOT TRANSFERABLE” and “PROFESSIONAL“. This wool classing stencil belonged to Stanley Hucker. It was his last Wool Classing Stencil. Dated to 1983, it is 45 years older than his first stencil. The role of a Wool Classer is to sort, classify, and grade wool into various ‘lines’ so that it can be sold for best market price. Wool Classers are typically also tasked with the managing and supervising of wool-handling teams. The stencil is used in the final step of preparing a bale of wool for sale. It is branded across the front of a wool bale to indicate the quality of the wool, with the classers number used as a seal of guarantee.Engraved letters. “A.W.C. PROPERTY / NOT TRANSFERABLE” Engraved letters. “PROFESSIONAL“. Cut imagery. Sheep’s head Cut letters, numbers, and imagery. “83 (Image Australia) P I / 50922”wool classing, stencil, 90 years wool classing between father & son -

National Wool Museum

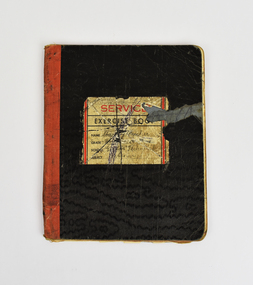

National Wool MuseumBook - Wool Classing Exercise Book, 1936-38

... micron wool was selling for prices between 4 to 5,000 cents per... industry. 15 micron wool was selling for prices between 4 to 5,000 ...The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. This is the first in a series of 5 wool classing exercise books. They were written by Stanley Hucker in his time at the Gordon Technical College from 1936-1938. This book begins in a cover of black vinyl with a strip of red tape on the spine to give added support. Some of the vinyl has been removed on the cover, revealing blue card beneath. A sticker label is also found on the front cover. It has been damaged. Part of the sticker has been removed, while blue ink can also be found obscuring the text below. Internally, the book is handwritten on yellowed pages with blue lines for the assistance in clarity of handwriting. The pages are also surrounded by a margin of red pen. The exercise book’s content is about veterinary studies relating to the diseases, injuries, and treatment of sheep. It is handwritten and accompanied by an occasional hand drawn diagram. A selection of pages have been photographed to give an impression of the information taught in classes, 90 years ago. This includes information about a sheep’s heart, hind limbs, and reproduction system in ewes. Front Cover. Wording, printed and handwritten “SERVICE / EXERCISE BOOK / NAME Stanley Hucker / GRADE wool classing / SCHOOL Gordon Technical / SUBJECT Veterinary”gordon institute geelong, wool classing, 1930s sheep farming, 90 years wool classing between father & son -

National Wool Museum

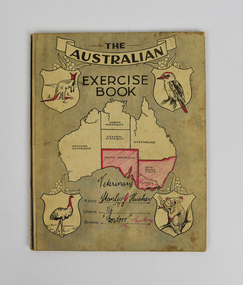

National Wool MuseumBook - Wool Classing Exercise Book, 1936-38

... micron wool was selling for prices between 4 to 5,000 cents per... industry. 15 micron wool was selling for prices between 4 to 5,000 ...The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. This is the third in a series of 5 wool classing exercise books. They were written by Stanley Hucker in his time at the Gordon Technical College from 1936-1938. This book begins in a white cover with black ink illustrations and writing. These illustrations have been added to with Pink ink. Internally, the book is handwritten on yellowed pages with blue lines for the assistance in clarity of handwriting. The pages are also surrounded by a margin of red pen. The exercise book’s content is about veterinary studies relating to the diseases, injuries, and treatment of sheep. It is handwritten. A selection of pages have been photographed to give an impression of the information taught in classes, 90 years ago. This includes information about blow fly and bacterial diseases.Front Cover. Wording, printed and handwritten “THE / AUSTRALIAN / EXERCISE / BOOK / Veterinary / NAME Stanley J Hucker / GRADE III / School “Gordon” Geelong” Front Cover. Illustrations, printed. Kangaroo, kookaburra / Map of Australia with state names / Emu, Koalagordon institute geelong, wool classing, 1930s sheep farming, 90 years wool classing between father & son -

National Wool Museum

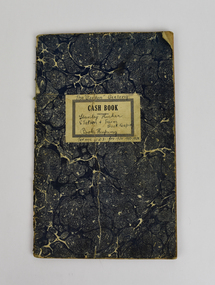

National Wool MuseumBook - Wool Classing Exercise Book, 1936-38

... micron wool was selling for prices between 4 to 5,000 cents per... industry. 15 micron wool was selling for prices between 4 to 5,000 ...The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. This is the fifth in a series of 5 wool classing exercise books. They were written by Stanley Hucker in his time at the Gordon Technical College from 1936-1938. This book begins in a white cover with blue ink swirls covering its entirety. It has a central sticker label. Internally, the book is handwritten on yellowed pages with blue lines for the assistance in clarity of handwriting. The pages are also surrounded by a margin of red pen. The exercise book’s content is about recording and tracking the financial transactions of Sheep Stations and Wool Classers. It is handwritten. A selection of pages have been photographed to give an impression of the information taught in classes, 90 years ago. This includes information about: - General bookkeeping terms and definitions - Practise invoices - Larger multiple page definition of bookkeeping - Assets liabilities - Practise bale bookFront Cover. Wording, printed and handwritten. “The “Gordon Geelong / CASH BOOK / Stanley Hucker / Station + Farm / Bookkeeping / Bookkeeping / Terms 1.2.3 for 1936. 1937. 1938”gordon institute geelong, wool classing, 1930s sheep farming, 90 years wool classing between father & son -

National Wool Museum

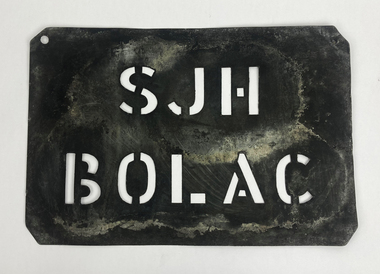

National Wool MuseumTool - Stencil, 1938

... micron wool was selling for prices between 4 to 5,000 cents per... industry. 15 micron wool was selling for prices between 4 to 5,000 ...The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. Thin sheet of metal with letters cut to produce a consistent pattern for the surface below through the application of ink. This wool classing stencil belonged to Stanley Hucker. It was his first Wool Classing Stencil. It was used on Stanley’s property named “Yohhatnbu” in Willaura. Stanley gained the property as part of the Returned Soldiers Settlement Scheme for his service in World War 2. The role of a Wool Classer is to sort, classify, and grade wool into various ‘lines’ so that it can be sold for best market price. Wool Classers are typically also tasked with the managing and supervising of wool-handling teams. The stencil is used in the final step of preparing a bale of wool for sale. It is branded across the front of a wool bale to indicate the quality of the wool, with the classers number used as a seal of guarantee.Cut letters. “SJH / BOLAC ”wool classing, stencil, 90 years wool classing between father & son -

National Wool Museum

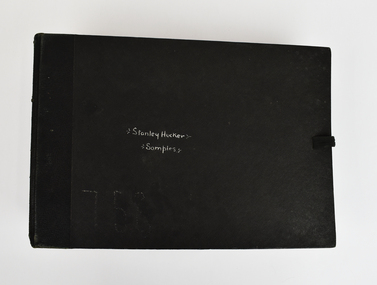

National Wool MuseumBook, Wool Sample, 1936-8

... micron wool was selling for prices between 4 to 5,000 cents per... industry. 15 micron wool was selling for prices between 4 to 5,000 ...The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo.Large black bound book with ribbon for fastening containing 12 double-sided blue pages. Pages have several samples of shorn wool mounted and annotated to include information such as specific breeding, shearing faults, and geographical area. The book concludes with four pages without wool samples. Two of these pages relate to plans for a shearing shed and other industry related structures. The final two-pages relate to the anatomy of a sheep. Wool sample books were constructed by Wool Classing students at the Gordon Technical School as examples of what to look for when classing wool. The students were tasked with constructing these books with samples they retrieved themselves from several different farms and animals. The book would serve as a reference point for the wool classers throughout their years in the field, it was always on hand to refresh knowledge. This book was constructed by Stanley Hucker over his schooling at the Gordon between 1936 and 1938Front Cover. Handwritten, White Ink "Stanley Hucker / Samples"90 years wool classing between father & son, wool classing, gordon technical school -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, spirit-fuelled sad iron, c1920

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Late in the 19thC designers experimented with heat retaining fillings for these irons. William Coleman began selling Kerosene lanterns in 1900 in Kingfisher, Oklahoma, USA. He moved to Wichita, Kansas in 1902 and the company became world wide. The company also produced a range of cooking stoves and domestic irons. This spirit- fuelled flat iron was very popular in 1920s - 30s These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin ShireA) spirit- fuelled, sad iron with chrome plated sole c1920, and metal trivet The iron is blue enamel with a white speckled body, with a hemispherical tank for the Coleman 'Lighting Petrol' that provided the heat for smoothing the material B) Coleman Fuel measuring can and funnellMetal Trivet/stand " COLEMAN" ; Petrol can " COLEMAN" / MEASURING CAN / for INSTANT LIGHTING IRON/ with printed instructionssad iron, kitchen equipment, coleman william, kansas, oklahoma, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, petrol fuelled irons, spirit flat irons, coleman lamp stove co. ltd. -

Bendigo Historical Society Inc.

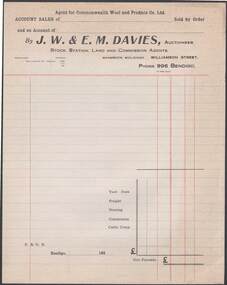

Bendigo Historical Society Inc.Document - CAMBRIDGE PRESS COLLECTION: ACCOUNT - J. W. AND E. M. DAVIES

Three different size account pages for the sale of livestock by J. W. & E. M. Davies, Auctioneer. Two have space to take Yard Dues, Freight, Droving, Commission and Cattle Compensation from the selling price of the livestock. The third has space to take Commission, Droving, Cattle Comp., Swine Comp and Freight from the selling price. One has a yellow backing paper. Two have a date line ending in 193- and the other it ends 19- -.business, printers, cambridge press, cambridge press collection, commonwealth wool and produce co ltd, j w & e m davies, shamrock buildings -

Ithacan Historical Society

Ithacan Historical SocietyPhotograph, Embroidered Blouse

The blouse was made in Greece about 1945. The method used to create this fine embroidery was to copy a design from a cross stitch embroidery book guided by fine white tapestry threads tacked onto the yolk; when the design was finished, the embroiderer would pull out each fine white tapestry thread until only the embroidery remained around the yolk of the blouse.Throughout the centuries and up until the 1970s-80s, the women of Ithaca spun, wove, embroidered and knitted. Mothers prepared their daughters' 'glory boxes' trousseau (prikia), weaving bedspreads, rag mats (koureloudes) for everyday use, finer wool rugs for formal use, as well as linen sheets, pillowcases, blankets, towels and tablecloths. Linen was also woven to make the mattress that the young brides would take to their future homes. Mothers also wove and embroidered the fabric for their daughters' underwear and petticoats, nightgowns, etc. Sewing of the garments was also done by hand. The girls embroidered handicrafts using various stitches, they crocheted lace, netted pillows and even linen carpets. The handicrafts were usually embroidered by hand in cross-stitch using linen and cotton fabric. At the time there were merchants who travelled to the villages to sell machine made goods for the trousseaus, but most of the dowries consisted of the beautifully crafted work of the women. In the 30's the SINGER Company came to Ithaca and taught the girls sewing on the machine. A handwoven silk blouse. Colour - ecru. Hand embroidered, hand sewn, very fine white tapestry was tacked round the yolk; a gusset was sewn under each short puff sleeve at the armpit; two-tone hand made silk thread cords were passed through the hollow border of the sleeves and neckline. -

Myrtleford and District Historical Society

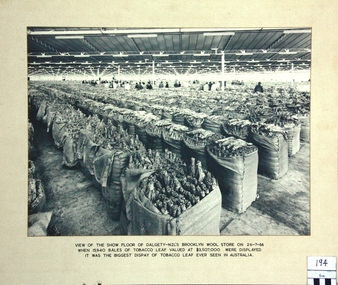

Myrtleford and District Historical SocietyTobacco Sales Photograph

The photograph depicts the magnitude of the tobacco industry in the late 1960s to 1970s era when many Myrtleford district growers contributed to the annual tobacco harvest. The impact of post-war migration from southern Europe was playing an important role in reaching harvest records.The photograph reflects the "golden years" of tobacco growing in the district, which continued into the 1970s, prior to later deregulation in the 1980s and 90s and the ceasing of production altogether in 2006. This sales floor attracted local farming families to observe activities off-season in Melbourne, before the sales were conducted at a complex in Myrtleford. A monochrome photograph displaying a large tobacco selling floorInscription: "VIEW OF THE SHOW FLOOR OF DALGETY-NZL's BROOKLYN WOOL STORE ON 27-6-1966 WHEN 15,940 BALES OF TOBACCO LEAF VALUED AT $3,507,000 WERE DISPLAYED. IT WAS THE BIGGEST DISPLAY OF TOBACCO LEAF EVER SEEN IN AUSTRALIA" tobacco industry, myrtleford tobacco selling floor -

National Wool Museum

National Wool MuseumCloth sample, 1816-1821

Cloth sample from an opera cloak made in England c. 1820 from wool clipped from Macarthur's merino sheep in 1816. The cloak was passed down through the family to Harold Lethbridge with whom the main part of the cloak resides, in Narrandera. The fragment was passed to Lethbridge's niece who gave it to the donor's mother who passed it onto him and then it was donated to the National Wool Museum. The cloth fragment was tested by Gordon Institute of Technology in 1974 showing the wool to be very fine (15-16 microns) which is consistent with the pure lineage of Macarthur's sheep. The cloth fragment was framed in 1952 and remains in the original frame to this day. Cloth sample form an opera cloak made in England c. 1820. Wool for the cloak was clipped from John Macarthur’s merino sheep in 1816. Macarthur is recognised as the pioneer of the wool industry that was to boom in Australia in the early 19th century and become a trademark of the nation. Macarthur was responsible for the first bale of Australian wool to be exported. The British woollen mills were desperate for wool at the time because of the Napoleonic blockade, and the Australian bale sold for a record price. Australia needed a product to sell in European markets which did not perish during long sea-voyages and which offered high value per unit of weight. Wool also had a ready market in England because the Napoleonic Wars had increased demand and cut English cloth-makers off from their traditional source of quality wool, Spain. Australia's first $2 banknote featured John Macarthur thanks largely to his establishment of wool as the backbone of the early Australian economy. Red fabric sample folded in half and mounted in the centre of a brown metal frame.'ARCO' MADE IN ENGLANDmacarthur, wool industry, australian economy -

National Wool Museum

National Wool MuseumFunctional object - Spinning Wheel, Philip Elford, 1976-7

Jackie Kerin's (donor's) story. In 1973, I was in my late teens and while I’d moved to Sydney from Melbourne, to begin my first year of drama studies at the National Institute of Dramatic Art. My parents had moved to Lake Bunga, a few kilometers north of Lakes Entrance (Victoria). On my first holiday visit to Bunga, I called into the Jolly Jumbuck Country Craft Centre in Bairnsdale http://jumbukwool.com.au/history. I was entranced by the place and spent the following weeks learning to spin lumpy wool on an Ashford Wheel. By the end of the holidays, I had my own Ashford and it travelled with me back to Sydney. After graduation, I returned to Melbourne and the hippy “back to nature” movement was in full swing; there were many shops and galleries selling handmade woollen items and pottery etc. So I found an outlet for my pieces. Sometime in 1976-77, I met a spinner and weaver of Swiss origin (I think) – her name was Ingeborg Guber (not sure of the spelling). She had a small gallery/shop at Brighton Beach where she worked, with her pet duck for company. Ingeborg had an upright Philip Elford wheel; an Australian wheel crafted from Acacia melanoxylon (blackwood). I was smitten and ordered one. I have a memory of Philip driving to Hampton from Ballarat to make the delivery. I used this wheel for years but as time and enthusiasm for spinning waned, the wheel became a decorative item in the house. Then in the 90s, and with my drama training, I set myself up travelling to schools and festivals, museums and galleries as a storyteller. The spinning wheel had a new life accompanying me on my adventures. For many children, familiar with references to spinning in fairy tales, seeing the little Philip Elford upright was magical. The wheel was donated to the National Wool Museum in 2021.Vertical tripod leg spinning wheel. 6 spoke wheel with three bobbins. Inscription “Philip Elford Ballart” can be read in gold text stamped to the base of the wheel. Wording, stamped, gold. Philip / Elford / Ballartspinning wheel, textile production, hobby textiles, aciacia melanoxylon (blackwood) -

National Wool Museum

National Wool MuseumAlbum - Photo Album, Grazcos, c.1999

Photo album detailing the process involved in the Jumbo Wool Auction Service. This process was developed by Grazcos, a company who advanced innovations for shearers and wool farmers before amalgamating with Dalgety in the early 1990s. Grazcos was a well-known name to source a competent shearing team, or as a destination for wool in need of bulk classing. The Jumbo Wool Auction service was designed to process wool more efficiently through volume. 63 traditionally dumped farm bales of wool would fill a typical shipping container. The Jumbo Wool Auction Service enabled 108 farm bales to fit into the same container. This brought reductions in the costs of handling, selling, storing, and shipping of wool. This photo album details this process; from classing to shipping. This photo album was a draft copy produced for review before the production of mass-produced advertising flyers. 12-page hard cover photo album. Internally colour images and printed text have been stuck behind a protective plastic onto paper. The backing paper has many distinctive orange and grey horizontal lines. Printed text is in black ink. Colour images are 2 x 3 inches with rounded corners. Images and text are numbered 1 to 16 detailing the process of the Jumbo Wool Auction Service developed by Grazcos.wool auction, wool processing, grazcos -

National Wool Museum

National Wool MuseumTool - Knitting Pins, 1960-69

The donor (Lynn Fitzpatrick) purchased these knitting needles 20 years ago from an opportunity shop. Aero Knitting Pins are a discontinued brand that were popular in the 1960s, 70s and 80s. They are made of smooth, aircraft-quality anodized aluminium. To this day, they are a popular and sort after knitting needle. Being a long-lasting product, they are often given as heirlooms. Abel Morrall was a major needle manufacturer from Studley, a town near Redditch. In 1785, Michael Morrall who was taught the art of needle making by a maternal uncle, moved to Studley. He founded the Abel Morrall company with his brother Abel, and another unnamed brother-in-law. Within five years the company was producing 40% of the 2.5 million needles that were made each week in the Redditch area. In 1811 the company introduced the concept of creating the eyes by using a stamping press. Additional machines were invented by them throughout the 19th century leading to major improvements in the way needles were produced. Abel Morrall demonstrated their needle making machinery at the Great Exhibition of 1851 and Queen Victoria personally inspected it. The company selected the demi-griffin for its trademark in 1861, which can be seen on older products produced by the company. Set of four knitting needles stored within paper packaging. Packaging features black, red, and white ink, detailing the selling points of the Aero Knitting Pins. The packaging folds with 3 main sections, each providing different insights into the knitting needles. Examples of this are " CANNOT SOIL LIGHT WOOL", "...SPECIALLY TAPERED POINTS WHICH WILL NOT INJURE THE FINGERS" and "RUSTLESS-NON-GLITTER FINISH". As the packaging unfolds, the grey knitting needles become visible. The needles can be removed from the packaging by sliding them through small bands of paper that hold the needles secure while in transportation. The four knitting needles are a “NEUTRAL” grey colour finished in a double point style.Printed. Orange, White and Black Ink Numerous, see multimediaabel morrall, knitting needles, knitting pins, 1960s home knitting -

National Wool Museum

National Wool MuseumSpinning Wheel, Carrington wheel

Part of the Zakrzewski Collection of spinning wheels donated to the National Wool Museum by Mr Wlodzimierz Zakrzewski. For many years, Mr Zakrzewski collected, researched and repaired spinning wheels from all over the world. This wheel is known as a Carrington wheel. It was designed and built by Mr Zakrzewski who made 400 similar wheels of three different designs over a 30 year period. The design was named for his wife, Sonya Carrington who was a Polish artist and teacher who became a well known tapestry weaver. She married Mr Zakrzewski in 1956 and continued to exhibit under her own name. As it was difficult in the 1950s to obtain tapestry wools she decided to spin and dye her own. She didn't have a spinning wheel, so Mr Zakrzewski, whose training was in engineering, offered to make her one. They became very popular and he continued to make and sell them.Part of the Zakrzewski Spinning Wheel collection.handicrafts - history, spinning wheels, carrington wheel, highlights of the national wool museum: the zakrzewski spinning wheel collection - exhibition (28/07/2001 - 02/12/2001), zakrzewski, mr wlodzimierz carrington-zakrzewska, mrs sonya -

National Wool Museum

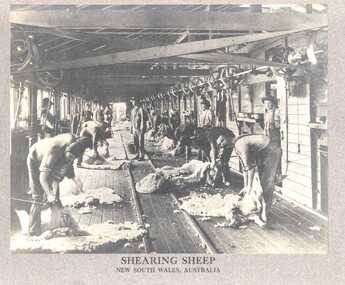

National Wool MuseumPhotograph, Shearing Sheep, New South Wales, Australia

Photo depicts the interior of a shearing shed with shearing taking place. The shed is located in New South Wales and this photo would appear to date from the turn of the century. Presumably the Philadelphia Museum inscription on the front indicates that either this photo is from their collection (unlikely) or that it was commissioned by them for selling / distribution.Photograph, 'Shearing Sheep', 1900-10 (Philadelphia Museum). Caption on reverse of photograph - 'Shearing Sheep', (Philadelphia Museum) c.1900-10.SHEARING SHEEP / NEW SOUTH WALES, AUSTRALIA / THE PHILADELPHIA MUSEUMshearing shearing sheds, philadelphia museum, shearing, shearing sheds -

National Wool Museum

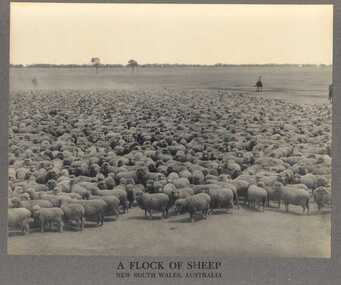

National Wool MuseumPhotograph, A Flock of Sheep, New South Wales, Australia

Photo depicts a flock of sheep being mustered in New South Wales. This photo would appear to date from the turn of the century, like the other, similar photo of sheep shearing. Presumably the Philadelphia Museum inscription on the front indicates that either this photo is from their collection (unlikely) or that it was commissioned by them for selling / distribution.Photograph of a flock of sheep, NSW, c.1900-10 (Philadelphia Museum). Caption on reverse of photograph - A Flock of Sheep (Philadelphia Museum), 1900-10.A FLOCK OF SHEEP / NEW SOUTH WALES, AUSTRALIA / THE PHILADELPHIA MUSEUMsheep - australian, philadelphia museum -

National Wool Museum

National Wool MuseumSample, dyed wool

This sample is one of five donated by Mrs Walker who dyes her own yarns to knit into hats which she felts herself (in a washing machine) and sells to craft shops. She runs workshops and also teaches home dyeing. She uses a Landscape and Earth Pallette and also uses food colourings and jelly and cake decorating colours.Sample of hand dyed wool produced by Mrs Robin Walker, 1999.handicrafts, walker, mrs robin -

National Wool Museum

National Wool MuseumSample, dyed wool

This sample is one of five donated by Mrs Walker who dyes her own yarns to knit into hats which she felts herself (in a washing machine) and sells to craft shops. She runs workshops and also teaches home dyeing. She uses a Landscape and Earth Pallette and also uses food colourings and jelly and cake decorating colours.Sample of hand dyed wool produced by Mrs Robin Walker, 1999.handicrafts, walker, mrs robin -

National Wool Museum

National Wool MuseumSample, dyed wool

This sample is one of five donated by Mrs Walker who dyes her own yarns to knit into hats which she felts herself (in a washing machine) and sells to craft shops. She runs workshops and also teaches home dyeing. She uses a Landscape and Earth Pallette and also uses food colourings and jelly and cake decorating colours.Sample of hand dyed wool produced by by Mrs Robin Walker, 1999.handicrafts, walker, mrs robin -

National Wool Museum

National Wool MuseumSample, dyed wool

This sample is one of five donated by Mrs Walker who dyes her own yarns to knit into hats which she felts herself (in a washing machine) and sells to craft shops. She runs workshops and also teaches home dyeing. She uses a Landscape and Earth Pallette and also uses food colourings and jelly and cake decorating colours.Sample of home dyed wool produced by Mrs Robin Walker, 1999.handicrafts, walker, mrs robin -

National Wool Museum

National Wool MuseumSample, dyed wool

This sample is one of five donated by Mrs Walker who dyes her own yarns to knit into hats which she felts herself (in a washing machine) and sells to craft shops. She runs workshops and also teaches home dyeing. She uses a Landscape and Earth Pallette and also uses food colourings and jelly and cake decorating colours.Sample of home dyed wool produced by Mrs Robin Walker, 1999.handicrafts, walker, mrs robin -

National Wool Museum

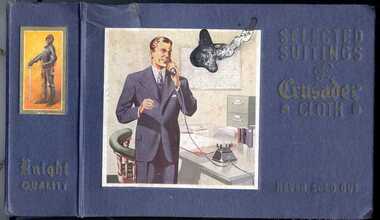

National Wool MuseumSample Book, "Selected Suitings of Crusader Cloth" sample book

This book dates from the 1940s and was part of the Running Stitch collection of quilts, probably because it was common for women to acquire these books from travelling salesmen. This sample book is an example of the type made by textile mills and given to tailors to sell fabric for made to measure suits. With little money to spare during the austere years of the war, women often acquired these books from tailors when the fabrics were no longer available. They made use of the fabric sample pieces to make quilts. The Australian Woollen Mills was an example of a woollen mill which went into worsted production making good quality English-type suiting. They were very successful until the 1960's when the oversupply of worsted fabrics from Europe and Asia led to the decline of the industry in this country. This book was displayed in the Running Stitch exhibition "Wool Quilts Old and New" of 1985 where it was catalogue entry number 40.Australian Woollen Mills Crusader fabric sample book, c.1940sKnight / QUALITY SELECTED / SUITINGS / of / Crusader / CLOTH / NEVER SOLD OUT Crusader / CLOTH / Makes the best suits "Crusader" / WORSTEDaustralian woollen mills pty ltd running stitch group, cloth - worsted, running stitch collection -

National Wool Museum

National Wool MuseumDecorative object - Knitted nativity scene, Christine Ballard, 2002

Made by Christine Ballard in 2002 who was a visitor to the Museum in late 2001. The Christmas Crib is from a Jean Greenhowe pattern. Christine originally made 4 sets of Mary, Joseph and Baby Jesus to sell at her church fete. They were so successful she received 7 orders.Knitted nativity sceneknitting christmas, christmas, hand knitting, jerusalem, knitting -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

National Wool Museum

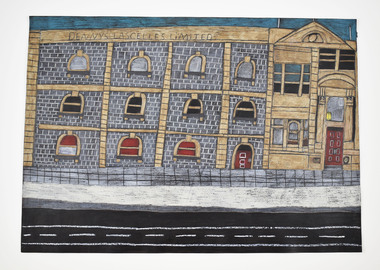

National Wool MuseumDrawing, Christian Den Besten, National Wool Museum, 2019

Christian Den Besten was Born 1972. Through art Christian interprets his community - the current affairs, infrastructure, and people that affect his everyday life. He is a prolific artist and often works with an accumulation of small components in creating his artworks. Christian is an artist living with an intellectual disability. He takes pleasure in drawing the beautiful buildings that dot Geelong’s cityscape. He exhibits and sells his work regularly.Denny’s Lascelles building Geelong by Christian Den Besten, 2019. -

National Wool Museum

National Wool MuseumPhotograph - Transporting Wool, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a man standing in front of a truck loaded with wool bales. The bales are being transported from Boorowa to Sydney.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W40. Seventy bales of Wool going by motor vehicle from Boorowa to / Sydney.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumPhotograph - Loading Wool Bales, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing two men loading wool bales onto a motor transport vehicle.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W68 / W68. Loading wool bales on to / a motor transport.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool