Showing 696 items

matching wool manufacturing

-

National Wool Museum

National Wool MuseumCurrency - One Pound Note, John Ash, 1938 - 1948

John Ash succeeded Thomas Harrison as the Australian Note Printer in 1927 and oversaw the printing of a new series of banknotes, known as the Ash Series. First issued between 1933 and 1934, the new banknotes sought to improve the currency's resistance to counterfeiting. A special watermark was created to increase the security of the new series. Shaped as a medallion, the watermark showed the profile of Edward, the Prince of Wales. A new portrait of the King was also introduced, depicting him frontally rather than in profile as he had appeared in the prior banknotes of the Harrison Series (1923-1925). The back of each denomination contained an individual vignette that reflected a sector of the country's economy. The wool and agricultural industries were represented, as they had been in the first series of the nation's banknotes (1913-1914), and they were joined by manufacturing and commerce. The prominent British sculptor, Paul Montford, contributed to the design of the new series. Recognised for his sculptural works on the exterior of Melbourne's Shrine of Remembrance, Montford was commissioned to produce relief sculptures that formed the basis of the banknotes' vignettes. His sculptures were translated into wash drawings by Frank Manley, the artist and engraver for the Commonwealth Bank's Note Printing Branch. Manley accentuated the sculpture's three-dimensional qualities with deep shadows and touches of illusionism. A sheep in Montford's pastoral scene, for example, stands forward from the frame as if entering the viewer's space to escape branding and Manley preserves this visual conceit in his drawing. Whereas the printing of the previous series of Australian banknotes had been criticised for its poor definition, the sculptural basis of the Ash Series clarified the banknotes' imagery. During a period of record unemployment, the scenes emphasised the strength of the human figure in gestures of labour, evoking classical, heroic qualities in their poses. The sculptural forms suggested stability in the turbulence of the Great Depression and imparted a sense of solidity to paper currency. - museum.rba.gov.auCommonwealth of Australia paper one pound note in green and white tones depicting graphics and text. The obverse has a framed design with a blank portal to the left and King George VI in the right portal. The centre shows the Australian Coat of Arms, serial number, and detail over one pound symbol on a mosaic background, with signatories below. The reverse features a framed pastoral scene with farmers tending sheep, with a blank portal to the right.Obverse: ONE / 1 / 1 / ONE / COMMONWEALTH OF AUSTRALIA / K / 58 / 790230 / K / 58 / 790230 / This Note is legal tender for / ONE POUND / in the Commonwealth and in all / Territories under the control of the / Commonwealth. / [signature] / GOVERNOR / COMMONWEALTH BANK ON AUSTRALIA / [signature] / SECRETARY TO THE TREASURY Reverse: 1 /1 / 1 / 1 / PASTORALcurrency, money, pound note, pastoral scene, industry, commonwealth of australia, paul montford, king george vi, frank manly, john ash -

National Wool Museum

National Wool MuseumUniform - Tie, Wendy Powitt, 1992 Barcelona Olympic Games Official Occasions Male Tie, c1992

About the 1992 Barcelona Olympic Games donator Doug Pleasance wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technichian, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. The 1992 Barcelona Olympic Games saw an evolutionary change in designer selection. A Declaration of Interest Form was communicated to over forty potential designers. The task and especially tight timelines that were involved deterred many aspirants, however, there remained eight designers with the potential we were seeking. These eight designers were paid $3,000 per submission and the winning designer, Wendy Powitt, was paid $15,000. For the first time the judging panel included two athletes, one male swimmer and one female basketballer, their influence was pivotal. The ensemble consisted of three elements- 1. The Official Uniform which was used for travel and all official functions. This included: a tailored blazer and trouser/skirt (all water repellent) by Fletcher Jones, pure wool olive-green faille fabric by Foster Valley, cotton PE formal shirt by Pelaco, pure wool knitwear by Spangaro, printed wool tie by TD Noone, wool nylon socks by Holeproof and footwear by Hush Puppy. 2. Opening Ceremony Uniform a lightweight wool fabric printed with floral designs that had been inspired by the work of Australian artist Margaret Preston. This included: Lightweight W/PE shorts by Fletcher Jones in Foster Valley Fabric, socks by Holeproof and footwear by Hush Puppy. 3. Village Clothing was designed to be highly visible garments to make it easy to ‘spot the Aussie’ and helped to contribute to good team spirit. This included: A pure wool shirt featuring blocks of contrasting colours, and a newly developed stretch 50:50 wool/cotton fabric by Bradmill was made into shorts and jeans by Fletcher Jones.Floral tie with cream, red, green native flower design.On label - Woven & manufactured in Australia by "Tee-Dee" exclusively for the Australian Wool Corporation1992 barcelona olympics, uniform, tie, australian wool corporation -

National Wool Museum

National Wool MuseumEphemera - Physician Blanket Cardboard Advertisement, Collins Bros Mill Pty Ltd, c.1980s

... Mill Pty Ltd Manufacturing Geelong Wool Advertising sign ...Physician blankets were manufactured by Collins Bros Pty Ltd, established 1874.Advertisement card featuring text and colour photographic image of a blanket. The back has a fold out stand. Printed: AUSTRALIAN / PURE WOOLLEN BLANKETS / PURE NEW WOOL / PHYSICIAN / BLANKETS, ESTABLISHED 1874 / by COLLINS BROS. PTY. LTD.blankets, physician, collins bros mill pty ltd, manufacturing, geelong, wool, advertising, sign -

National Wool Museum

National Wool MuseumBooklet - The Care of a Physician Blanket, Collins Bros Mill Pty Ltd

... Mill Pty Ltd Manufacturing Geelong Wool Advertising Printed ...Physician blankets were manufactured by Collins Bros Pty Ltd, established 1874.Fourteen page booklet with blue printed text held with one staple at the binding. Front and back cover has blue, pink and yellow graphics and text, including a lamb wearing a stethoscope. There is a hole punched in the top left corner. Printed: THE CARE OF A / "Physician" / Chill Proof / BLANKET / YOURS, FOR LASTING SERVICE AND SATISFACTIONblankets, physician, collins bros mill pty ltd, manufacturing, geelong, wool, advertising -

National Wool Museum

National Wool MuseumDocument - Wool Register Card

... 1874. Collins Bros Mill Pty Ltd Manufacturing Geelong Wool ...Card used by Collins Bros Pty Ltd, established 1874.Cream card with black printed text. Printed: Factory No. / WOOL / REGISTER / Lbs. / Rates / Invoice Value / Charges / Stock Value / Invoice Date / Sale No / Broker / Brand / Lot No / Bale No / Description / Type / Date Issuedcollins bros mill pty ltd, manufacturing, geelong, wool -

National Wool Museum

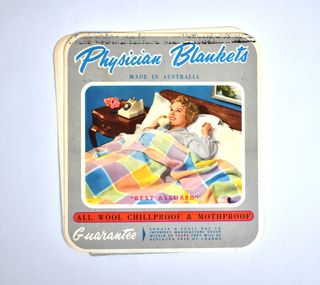

National Wool MuseumEphemera - Physician Blankets Label, Collins Bros Mill Pty Ltd

... Mill Pty Ltd Manufacturing Geelong Wool Advertising Printed ...Physician blankets were manufactured by Collins Bros Pty Ltd, established 1874.Folded paper label, grey with coloured text and graphics. Front is grey with blue, red and white text, showing central colour graphic of a woman lying in bed using a telephone under a blanket. Back is grey with white, blue and pink text with an outline graphic of a man lying in a single bed. Inside of label is white with blue text. Printed: Physician Blankets / MADE IN AUSTRALIA / "REST ASSURED" / ALL WOOL CHILLPROOF & MOTHPROOF / Guarantee / SHOULD A FAULT DUE TO / IMPERFECT MANUFACTURE OCCUR / WITH 20 YEARS THEY WILL BE / REPLACED FREE OF CHARGEblankets, physician, collins bros mill pty ltd, manufacturing, geelong, wool, advertising -

National Wool Museum

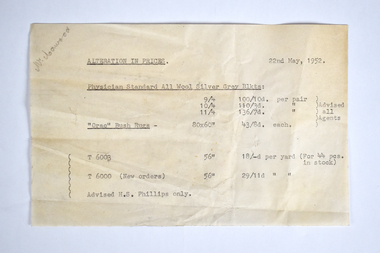

National Wool MuseumDocument - Memo – Physician Blankets, Collins Bros Mill Pty Ltd, 22 May 1952

... Mill Pty Ltd Manufacturing Geelong Wool Memo Printed ...Memo advising agents of alternation in prices for physician blankets. Physician blankets were manufactured by Collins Bros Pty Ltd, established 1874.Cream paper with black printed text and hand written pencil text. Printed: ALTERATION IN PRICES. / 22 May, 1952 ...blankets, physician, collins bros mill pty ltd, manufacturing, geelong, wool, memo -

National Wool Museum

National Wool MuseumCard - Packaging – The Look of Berber, c.1980s

... . Collins Bros Mill Pty Ltd Manufacturing Geelong Wool Berber ...Modern industrialized Berber carpets are distinguished by a loop pile construction type that gives a similar appearance to the distinct knot of traditionally woven Berber carpets. The modern carpets usually contain small flecks of dark colour on lighter shades of background colours resembling a natural undyed version of the traditional carpets. Berber is known for being one of the oldest and most durable kinds of carpet. Traditionally, Berber carpets are carpets hand-woven by the Berber people in North Africa and the Sahara. The carpets come in traditional and modern designs, which are distinguished by different knotting patterns, dyes and fabric textures. The origin of carpet weaving by the Berber populations dates back several millennia. The hand-spun cloth they created was named after the individual tribe, and they used natural fibres to create cloaks, rugs and other fabrics. Card showing printed text and graphic featuring an image of a sheep in tones of orange, brown and cream. Printed: PURE NEW WOOL / THE / LOOK OF / BERBERcollins bros mill pty ltd, manufacturing, geelong, wool, berber -

National Wool Museum

National Wool MuseumBooklet - How to Wash Physician Blankets, Collins Bros Mill Pty Ltd

... Mill Pty Ltd Manufacturing Geelong Wool Advertising Printed ...Booklet describing how to care for and wash physician blankets. Physician blankets were manufactured by Collins Bros Pty Ltd, established 1874.Four page folded card featuring black text and graphics. Front shows green, red, white and black image of a factory exterior with a car and people in the foreground.Printed: HOW TO WASH "PHYSICIAN" BLANKETS / from Collins Bros. Pty. Ltd. / .... to you / MANUFACTURERS OF / "PHYSICIAN" / BLANKETS AND FLANNELS / ALSO MANUFACTURERS OF THE FAMOUS / UNSHRINKABLE PHYSICIAN BABY SAXONY FLANNEL / AND CRIMEAN SHIRTING / LADIES' DYED DRESS MATERIALS / SLIPPER AND FURNISHING FELTSblankets, physician, collins bros mill pty ltd, manufacturing, geelong, wool, advertising -

National Wool Museum

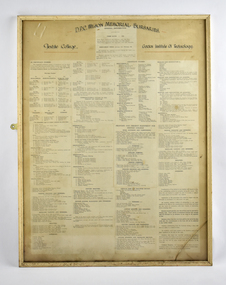

National Wool MuseumPhotograph - Framed Printed Coursework, Gordon Institute of Technology, Textile College, 1950

Framed papers outlining the courses and coursework for the Textile College at the Gordon Institute of Technology in 1950. The courses include Woolcombing, Worsted Spinning, Woollen Yarn Manufacture, Designing, Weaving and Turning and Finishing. A digital copy of this item was made for the National Wool Museum Collection, with the original remaining with the donor. Digital TIFF file, 100 MB, showing image of framed printed paper.D.P.C. WILSON MEMORIAL BURSARIES. / Textile College / Gordon Institute of Technology. / GENERAL INFORMATION / TERM DATES 1950 ...courses, gordon institute of technology, textile college, geelong, woolclassing, weaving, spinning, coursework, 1950 -

National Wool Museum

National Wool MuseumTextile - Blanket, Albany Woollen Mills, Albany Woollen Mills blanket, c 1950s

Note from collector: I love the generous size and thickness of Albany blankets and know someone who collects from this Mill only. The colour shades and combinations Albany used are still so gorgeous. From Western Australia. Note from collector - "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. " Checked blanket, blues and creamAlbany Woollen Mill/Blanket/All Pure Wool/Emblem: A, Albany blanket, blanket fever, wool, albany, albany woollen mills -

National Wool Museum

National Wool MuseumPhotograph - Women's Basketball Team, Albion Mill, 1941

Gwen Low, who donated this photograph, was the Captain of this 1941 Women's Basketball Team and worked at the Albion Mill.Black and white photograph showing an outdoor portrait of seven women, with four standing at the back and three kneeling in foreground. The woman in the centre front is holding a basketball. The women are wearing matching uniforms with heart motives. Trees and buildings are shown in the background.albion mill, geelong, wool, industry, sport, basketball, teams, women's sport, manufacturing -

National Wool Museum

National Wool MuseumPhotograph - Women's Basketball Team, Albion Mill, 1942

Gwen Low, who donated this photograph, was the Captain of this 1942 Women's Basketball Team and worked at the Albion Mill. The uniforms were made from fabric woven at the Albion Mill.Black and white photograph showing an outdoor portrait of seven women standing side on in a line. The woman in the front is holding a basketball. The women are wearing matching sports uniforms. albion mill, geelong, wool, industry, sport, basketball, teams, women's sport, manufacturing -

National Wool Museum

National Wool MuseumBook - Wool Pages: A Directory of the Sheep and Wool Industry, Eighth Edition, The Australian Wool Showcase Inc, 2004

... Manufacturing Tourism Wool Craft Wool Products Education front: [printed ...Contents include Education, Processing and Manufacturing, Rural Equipment, Services, Rural Tourism, Sheep, Trade / Commerce / Finance, Wool Craft, Wool Organisations / Associations, Wool Products. Eighty eight page booklet showing an image of sheep on the cover, with printed text.front: [printed] WOOL PAGES / Directory 2004 / Compiled by Australian Wool Showcase / australian wool / innovation / limitedwool, organisations, directory, rural equipment, manufacturing, tourism, wool craft, wool products, education -

National Wool Museum

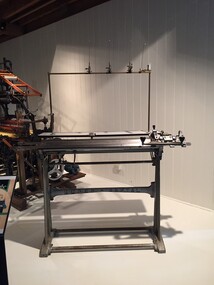

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

National Wool Museum

National Wool MuseumTaxidermy Sheep, Bilby Bill, c1980

Originating in New Zealand, the Drysdale, represented by Bilby Bill, was developed in the 1930s at Massey University (Canterbury) by crossing a coarse haired Romney and the hardy Cheviot breed. First imported to Australia in 1975, the Drysdale, due to a genetic abnormality, produces coarse, long staple fleece. This same gene also gives them their horns, something that generally does not occur in the parent breeds. Their fleece grows very fast, up to 25cm every six months; as such shearing is carried out twice a year. The coarse and hard wearing wool is mostly used for the manufacture of carpets. The Drysdale is a medium to large stocky sheep, weighing approximately 55kg and produces about 6 to 8kg of fleece per animal annually, which is 35 to 45 microns in diameter. The yarn used on the National Wool Museum’s Axminster Gripper Loom to make the Manor House Rug is spun from the wool of Drysdale sheep.Taxidermied male Drysdale sheep. Medium sized animal with white body coloration. Large horns protruding from the top of the skull. drysdale, sheep, new zealand -

National Wool Museum

National Wool MuseumStencil - HOLDENS BIB

... been farmed by or sent to that company for manufacture. wool ...This stencil was used as a organisation stamp for the transportation of wool bales. Wool bales marked HOLDENS BIB would have been farmed by or sent to that company for manufacture.Wool bale export stencil - HOLDENS BIBHOLDENS BIBwool - transportation, wool sales, wool class, wool classers -

National Wool Museum

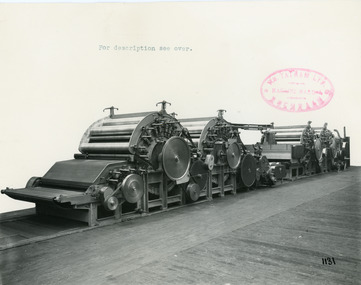

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

... wool manufacture... wool manufacture 8038.1 - Front - top margin: For description ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

... wool manufacture... countries around the world. textile machinery tatham wool ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

National Wool Museum

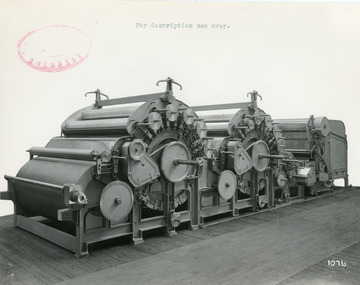

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

... wool manufacture... tatham wool manufacture scribbler carding Front - top margin ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

National Wool Museum

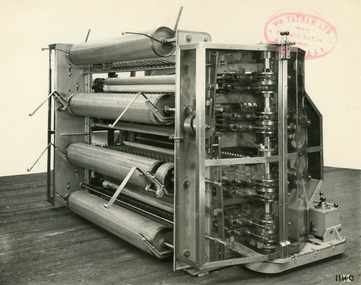

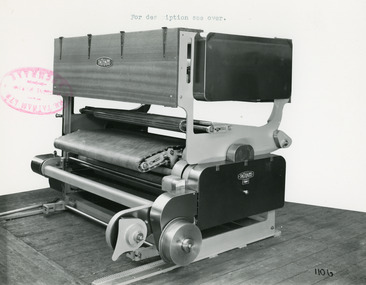

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

... wool manufacture... tatham wool manufacture carding Patent Parallel Fibre Feed ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

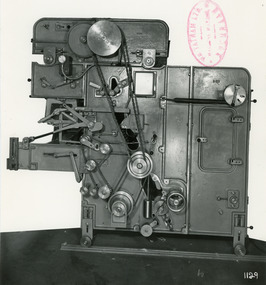

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

... wool manufacture... tatham wool manufacture carding automatic feeding machine wool ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

National Wool Museum

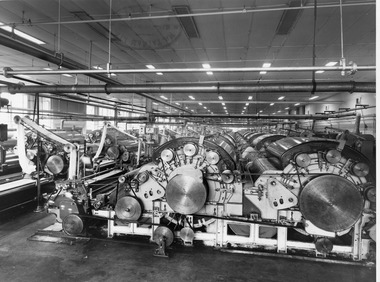

National Wool MuseumPhotograph - Carding Machines

... wool manufacture.... textile machinery wool manufacture carding wool Glasgow On rear ...Sales photograph for William Tatham Ltd. of Rochdale, to showcase new Carding Machines in a newly developed textile factory. The photograph was taken in Glasgow, Scotland.A black and white photo of a room filled with working Carding Machines in a portrait format. A man is working at the end of the closest machine.On rear - top margin - Showing Card Sets in new Card Room. Bottom right corner - Commercial Artists photographers and blockmakers Scottish Studios and Engravers LTD. 196 Clyde st. Glasgow. C C.P.D 6893 Dtextile machinery, wool manufacture, carding, wool, glasgow -

National Wool Museum

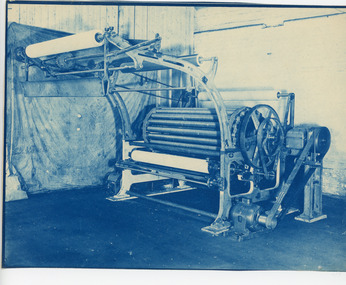

National Wool MuseumPhotograph, Q-VEE Machine, 29/06/1937

... wool manufacture... machinery wool manufacture wool scouring 8051.1 - rear - "Q-VEE ...Photographs were most likely used for promotional purposes. The Q-VEE machine is a scouring machine. When fabric is removed from the loom it is often stiff, rough or uneven. Scouring removes the oils and dirt picked up from manufacture, leaving the fabric soft and fluffy. The photographed machine was made by J. Stone & Co, a British marine and railway engineering company based in Deptford in south east London.Four black and white, blue tinged photos of a Scouring Machine from different angles. Black writing on the rear, typed with a typewriter and stamped with the company stamp.8051.1 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 849 8051.2 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 856 8051.3 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 851 8051.4 - front on machine - FIY Chain Gear J.Stone & Co Ltd London rear - P.I.V. Dial Control Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 853textile machinery, wool manufacture, wool, scouring -

National Wool Museum

National Wool MuseumPhotograph, Loom, Unknown

... wool manufacture...-1895) of Holmfirth. textile machinery wool manufacture wool ...Photograph of a Hutchinson, Hollingworth and Co. Limited Loom gears and mechanisms. Hutchinson, Hollingworth and Co. was an Oldham-based loom manufacturer estalished in 1860 by Messrs. John Hutchinson (c.1816-1888) of Cawthorne and James Hollingworth(c.1834-1895) of Holmfirth.Three black and white photographs in portrait format of a looms gear mechanisms.8052.1 - front on machine mid left quadrant - Hutchinson, Hollingworth and Co 8052.2 - front on machine mid left quadrant - Hutchinson, Hollingworth and Cotextile machinery, wool manufacture, wool, loom -

National Wool Museum

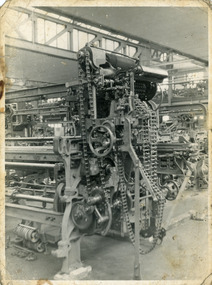

National Wool MuseumPhotograph, Yarn Spinning Machine, Unknown

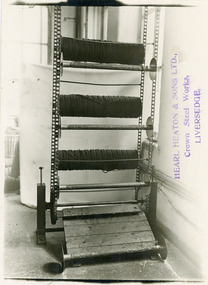

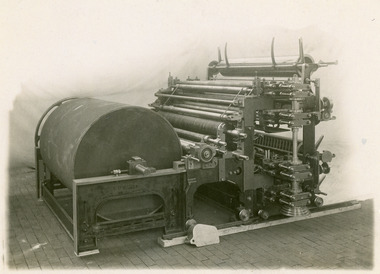

... wool manufacture... manufacture wool spinning 8053.1 - Front right edge - Hearl Heaton ...Photographs most likely used for promotional purposes. The photographs are of a yarn spinning machine used to place yarn onto bobbins. The machine was made by Hearl Heaton and Sons Ltd, founded in 1809. The company played an important part in Britain’s Industrial Revolution, providing bobbins to the textile mills across the North of England.Four black and white photographs of a yarn spinning machine. The first two photos show the machine in the lower floor of the building and the last two are on the upper floor. The are connected by the two chains working the machine.8053.1 - Front right edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.2 - Rear middle - No.1 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.3 - Front top edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.4 - No. 2 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge.textile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumPhotograph, Carding Machine, Unknown

... wool manufacture... established in 1899. textile machinery wool manufacture wool spinning ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Two black and white photographs of a carding machine. The first photo is of the rear of the machine, the second the front.8054.1 - rear handwritten top edge - Chadwicks left edge - unknown 8054.2 - a calculation of numberstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumBook - Textile Industry Award 1974, Australian Textile Workers’ Union, 1974

Forty seven page book with metal binding and black and white printed text. A piece of paper is stapled to the inside cover page. Cover is grey, with printed black text. front: [printed] TEXTILE INDUSTRY AWARD / Printed privately by / CHAMBER OF MANUFACTURES INDUSTRIAL SERVICE unions, textile workers union, award, legal document, textile industry, woollen, worsted -

National Wool Museum

National Wool MuseumSign - Metal Sign, J Dyson & Sons Pty Ltd

J. Dyson & Co was a company manufacturing scouring and dyeing vats during the first half of the twentieth century. The company continued to operate into the 1980s. J. Dyson & Sons company relates to Scouring Bowl W468 and Skin Press W1993 in NWM Collection.Metal sign with embossed lettering and four screw holes. J. DYSON & SONS. PTY. LTD. / GEELONG / VICTORIA . AUSTscouring, dyeing, j dyson & co, skin press, wool, industry, geelong