Showing 1097 items

matching metal tools

-

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

There are several different designs of drench guns within the NWM Collection that show the change in their development over time. This drench gun has a large diameter curvature suggesting this gun was typically used for dosing ewes as opposed to lambs. The attached spring-loaded hose is the only example in our collection how this mechanism works. The hose will be screwed into the liquid which is used to drench the sheep. This liquid is typically located on the back of the operator who will wear a large container in a backpack. This gun also has a adjustable dosing mechanism located on the right side of the gun.Silver metal with black finishing drench gun. Large curvature tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney”. Behind this body is silver cylinder featuring attachment point for the tubing which would have carried the liquid drench into the gun. The attached tubing has a yellow/orange appearance from remanence of drench which would have been this colour.Left rotated lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

There are several different designs of drench guns within the NWM Collection that show the change in their development over time. On the left side of this gun white paint indicates the adjustable dose lever. It is a sliding scale from 10 to 0 cubic centimetres of liquid (now typical measure in millilitres). It also has a small and straight tip suggesting this gun was typically used for dosing Lambs as opposed to ewes. The manual adjuster helped to minimise cases of overdosing which can be fatal for livestock while the additional curvature helped to ensure the liquid reached the desired location within the sheep’s mouth. This desired location is on the left rear of the sheep’s tongue (from the sheep’s point of view) as this is where the oesophagus is located. The main risks are that drench may be delivered into the lungs via the trachea or “windpipe”, which can also prove fatal. The opening to the trachea which leads to the lungs is in the middle of the back of the throat. Another risk is the throat can also be damaged due to rough handling.Silver metal with black finishing drench gun. Straight tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards has silver cylinder on top of the handle where tubing carrying the liquid drench into the gun attaches. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.sheep drenching, veterinary instruments -

National Wool Museum

National Wool MuseumTool - Metal Files, c. 1920

... inscription on lid of box. Tool Metal Files ...Selection of metal files used for cutting wool bale stencils with an accompanying box. Not all files belong to this box as some are too long to fit within. Used in Denny’s Lascelles Bow Truss building by Maurice Dalton who was the foreman of the building for 34 years. Files are ‘Cup Brand’ – ‘Best refined steel files’ and were manufactured by the no longer trading Moss & Gamble Brothers LTD at the Franklin works in Sheffield, England.12 steel files of varying length, thickness and shape. The longest and thickets are in a flat half circle with some files being fully flat, others complete cylinders, one is a complete square and others are in the shape of a triangle. Cardboard box is brown with black inscription on lid of box.stencils, denny’s lascelles bow truss building -

National Wool Museum

National Wool MuseumTool - Sickle, Pre. 1988

Feed for sheep farming is crucially important. Whether growing a sheep for breeding, wool or meat, it is vital to ensure that all sheep at whatever stage of life are maintaining or growing in weight. Sheep are often pictured grazing in paddocks; however, the grass available in a paddock is often not enough to maintain a sheep’s weight. In addition, if a sheep eats grass too low in a paddock then corrosion can affect the soil preventing any grass from growing in this location. For these reasons, supplementary feed is introduced to sheep’s diets. In most occasions’ food high in protein such as Lupins is sought. In times such as drought or to makeup a sheep’s roughage; feed such as silage, hay and straw may be required in the feeding of sheep. This is where the sickle is introduced to sheep farming. Although modern-day machines are used to harvest cereals, in times past the sickle was used for harvesting these crops. Once harvested, these crops can be fed to sheep freshly cut or dried. This sickle has been on display for 30 years at the National Wool Museum. It was at the entrance to Gallery One in the “A New Europe” wood hut display case. It was taken off display in 2021 with the “On the Land” redevelopment of this gallery space.Curved Metal serrated blade extending from carved dark wooden handletools of the trade, sheep feed, sheep farming -

National Wool Museum

National Wool MuseumTool - Stamp, 1940s

... and metal stamp Tool Stamp ...Note from collector- "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from." Wood and metal stampBlanketsblankets, blanket fever, stamp -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

National Wool Museum

National Wool MuseumTool - Drench Gun, 1940-1950

There are several different designs of drench guns within the NWM Collection that show the change in their development over time. On the left side of this gun white paint indicates the adjustable dose lever. It is a sliding scale from 10 to 0 cubic centimetres of liquid (now typical measure in millilitres). It also has a large diameter curvature suggesting this gun was typically used for dosing ewes as opposed to lambs. The manual adjuster helped to minimise cases of overdosing which can be fatal for livestock while the additional curvature helped to ensure the liquid reached the desired location within the sheep’s mouth. This desired location is on the left rear of the sheep’s tongue (from the sheep’s point of view) as this is where the oesophagus is located. The main risks are that drench may be delivered into the lungs via the trachea or “windpipe”, which can also prove fatal. The opening to the trachea which leads to the lungs is in the middle of the back of the throat. Another risk is the throat can also be damaged due to rough handling.Silver metal with black finishing drench gun. Large curvature tip on gun protrudes from the body which feature a thin squeezable trigger to the front of the body. The main bulk, which the trigger is squeezed towards, has badge which reads “Manufactured and designed by N.J. Phillips Pty Ltd, Sydney”. Behind this body is silver tubing featuring attachment point for the tubing which would have carried the liquid drench into the gun. The small section of tubing still attached has a yellow/orange appearance from remanence of drench which would have been this colour.Left lettering: 10CC 5CC 0/ 7.5 2.5/ Left rotated lettering: MANUFACTURED/ & DESIGNED BY/ N.J.PHILLIPS PTY. LTD./ SYDNEY . AUSTRALIA/sheep drenching, veterinary instruments -

Whitehorse Historical Society Inc.

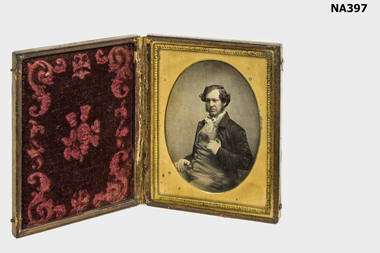

Whitehorse Historical Society Inc.Functional object - Photo and Frame, c1990

Tooled leather folding frame with brass clips. Leather strip covers hinge. Embossed burgundy velvet protects metal and glass frame. Photo of gentleman unknown. Photographic method known as 'daguerreotype'.domestic items, ornaments / decorative, photography, photographs / slides / film -

Whitehorse Historical Society Inc.

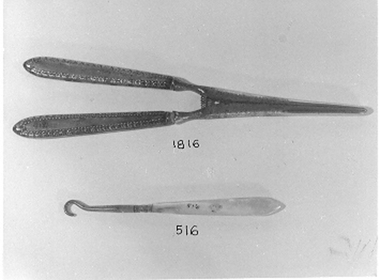

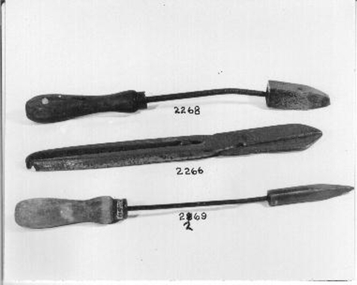

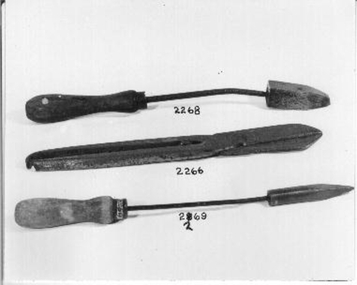

Whitehorse Historical Society Inc.Accessory - Pipe cleaning tools

... Small metal ring with three pipe tools attached there is a hook ...Donated by Box Hill Historical SocietySmall metal ring with three pipe tools attached there is a hook attached to the ring to attach tools to belt. etc. Tamper used to push the tobacco down into the bowl of the pipe, this has a round disc on end of stem which is hinged. A knife like tool which is used to clean out the bowl of the pipe. A tweezer like tool possibly used to take the tobacco out of the pouchHallmarks on tamper and knifelike toolpersonal effects, smoking accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - T Tap wrench

Engineers T tap wrench of metal, with 1/4 inch thread tap. Incised on tap, '1/4 20 WHIT Made in England', and on wrench, a triangular design containing the letters GTD, and below, KOn tap, '1/4 20 WHIT Made in England|On wrench, 'GTD' AND 'K'trades, mechanics, tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Instrument - Divider

... Mitcham melbourne trades mechanics tools A pair of metal compass ...A pair of metal compass divider with a knurled nut on threadtrades, mechanics, tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Scales

A metal hanging scales with ring on one end and hook for weighing with spring scale measured down frontPocket balance (MP) productdomestic items, weighing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Needle nose pliers

... and metal clasp Tool Needle nose pliers ...Used by W.R. Cruickshank from 1920 -1970 in Albury, while at Nicholson & Smith, Watchmakers and JewellersSix small needle nose pliers. Precision tools as used in watchmaking. Steel pliers held in brass sleeve, bakelite handle. Stored in leather case with purple cloth lining and metal clasphorology, tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Secateurs

Heavy metal secateurs with finger hooks. Brass tension insert instead of a spring. Bevelled curved blade. Hook at base of handles secures blades closed.Seymour Smith and Smith.rural industry, horticulture, domestic items, gardening -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Brace - Carpenter's

... by a bolt to tighten split end. Metal breast plate. Tool Brace ...Hand brace - 'U' shaped with split end to take a tapered end drill. Drill is secured by a bolt to tighten split end. Metal breast plate.trades, carpentry, tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Centre bits

Part of collection of Carpenters' tools used on sailing ships from England to Australia7 metal centre bits of various sizes for drilling in wood.NA987.1 Arthur NA987.2 Marples and Sons 11/16 NA987.3 Larnshaw BRC Sheffield NA987.4 JOHN WILSON Sheffield NA987.5 1 1/4 NA987.6 W.Marples + Sons NA987.7 R.Sorby Casteeltrades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Screwdriver

Tools used by Mrs Duncan's grandfather, when he was a carpenter on the clipper ship of the 1870's between England and Australia.Metal chisel London' pattern with wooden handletrades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - File

Part of carpenters' tools used on sailing ships from England to AustraliaMetal file with pointed endtrades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - File

Part of collection of carpenters' tools used on sailing ships from England to AustraliaMetal file with pointed endtrades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - File

Part of collection of carpenters' tools used on sailing ships from England to AustraliaMetal file with pointed endtrades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Midwifery Kit, 1925

Midwifery set - Brown leather case with metal clasp enclosing nine Instruments, 2 keys included (in pouch)Metal Plaque - the William Barnes Prize , Presented to Elinor Mary Patterson, March 28th, 1925,medicine, nursing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Tracing Wheel

From the Betty McPhee sewing collectionSmall, spiked metal wheel on metal arm attached to a wooden handle. Silver coloured metal arm has a brass ring where it joins to the wooden handle. book binding tool.S Osborne & Co 6handcrafts, equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Button Hook

From the Betty McPhee sewing collectionHooked metal arm attached to a wooden handle for hooking wool through canvas or hessian to make a rug.handcrafts, equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Metal Stiletto

... activities. Tool Metal Stiletto ...From the Betty McPhee sewing collectionMetal stiletto or seamstress eyelet-pricker, with a wooden handle. Handle is secured to stiletto with a metal ferrule. Used to form a hole in embroidery and other dressmakers activities.handcrafts, equipment -

Whitehorse Historical Society Inc.

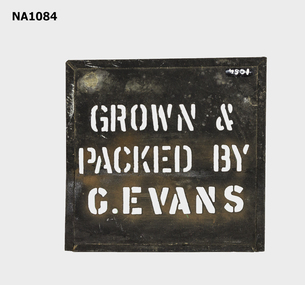

Whitehorse Historical Society Inc.Tool - Stencil

Would have been used by orchardists to mark fruit boxesMetal stencil - cut out 'Grown and Packed by C. Evans'commerce, labels -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Knife Cleaner

Wooden round container on metal legs with a metal handle to turn it with. It has a number of holes in which to place cutlery. It is filled with a carborundum and appears to have leather straps to distribute the carborundum which cleans the cutlery.On an enamelled plate on the side ' Warren's Rotary Knife Cleaner- Sole manufacturer'domestic items, cutlery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Glove Stretcher

Metal glove stretcher with two prongs and decorated handles. Operated by spring devices.costume accessories, glove accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Soldering Iron

Belonged to donor's father and used by him. Later used by donor until the advent of electric soldering irons.Long wooden handle with metal bar attached to shaped Copper piece.trades, plumbing, tinsmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Soldering iron

Belonged to father of donor. Used by father and later by son until the advent of the electric soldering iron.Long wooden handle with metal bar attached top shaped copper piecetrades, plumbing, tinsmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Blow Torch

Used by donor for soldering spouting and downpipes on his home in McDowall Street Mitcham.Round metal cylinder with handle. Smaller cylinder attached to top.trades, plumbing