Showing 16955 items matching "metal"

-

The Beechworth Burke Museum

The Beechworth Burke MuseumAnimal specimen - Diurnal Owl / Ural Owl

Little owls (also known as the owl of Athena or owl of Minerva) usually prefer the warmer parts of Europe, North Africa and Asia, enjoying open country and agricultural land with high trees to swoop down upon their prey from. Their diet includes amphibians, small mammals, reptiles and insects that they also hunt from small holes in the ground. Little owls are monogamous and while they're usually solitary creatures, pairs who breed together will often stay together past breeding season. An Athene Noctua would usually be slightly smaller than this specimen. The colouring of browns and whites speckling the feathers is an accurate representation however the posture of a typical little owl would be more crouched, not so thin and tall. This specimen is part of a collection of almost 200 animal specimens that were originally acquired as skins from various institutions across Australia, including the Australian Museum in Sydney and the National Museum of Victoria (known as Museums Victoria since 1983), as well as individuals such as amateur anthropologist Reynell Eveleigh Johns between 1860-1880. These skins were then mounted by members of the Burke Museum Committee and put-on display in the formal space of the Museum’s original exhibition hall where they continue to be on display. This display of taxidermy mounts initially served to instruct visitors to the Burke Museum of the natural world around them, today it serves as an insight into the collecting habits of the 19th century.This specimen is part of a significant and rare taxidermy mount collection in the Burke Museum. This collection is scientifically and culturally important for reminding us of how science continues to shape our understanding of the modern world. They demonstrate a capacity to hold evidence of how Australia’s fauna history existed in the past and are potentially important for future environmental research. This collection continues to be on display in the Museum and has become a key part to interpreting the collecting habits of the 19th century.This Athene Nuctua (The Little Owl) is dark to medium brown with white specks all over the feathers. Large white spots are located on their wings/back. This specimen has some inconsistencies with how it has been styalised by the taxidermist. The tail curls in under itself where it should be straight and flat. There are several feathers which appear disheveled on the chest, shoulder and wing. The specimen is mounted on a wooden stand with paper and metal tags attached to the legs. Swing tag: 41. / Allied to / Diurnal Owl / Catalogue page 53 / Other tag: 31 / Strix Noctua / Holland Metal tag: 4061 /taxidermy mount, taxidermy, animalia, burke museum, beechworth, australian museum, skin, bird, owl, little owl, athene noctua -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesClothing - Blazers, Gayval - Schoolwear, Burnley College Black Wool Blazers with badges (2), 1967-1970

Black pure wool blazer worn by students of Burnley College 1967-1970. Blazer 1 - Edges bound in black braid. Woven badge of college on left breast pocket, also metal enamel Burnley College badge pinned on Left lapel. Made by Gayval - schoolwear of "The Doctor" flannel. Australian Wool Bureau gold medal winner - all pure wool - mothproofed. Blazer 2 - Different manufacturer , no braid. Woven badge of college on left breast pocket only. Blazer 1 - Black pure wool blazer with edges bound in black braid. Size S. Blazer 2 - Black pure wool blazer, no braid on edges. Size LBlazer 1 - Burnley College woven badge on left breast pocket. Burnley College Metal badge pinned on left lapel. Blazer 2 - Burnley College woven badge on left breast pocket identical to Blazer 1.blazer, burnley college uniform, student, burnley badge, badge, wool blazer -

Orbost & District Historical Society

Orbost & District Historical Societyhammer, 1920's

A ball-peen ) hammer, also known as a machinist's hammer, is a type of peening hammer used in metal-working. Its steel head is harder than that of a claw hammer, so is less likely to chip on impact. Ball peen hammers are commonly used to drive cold chisels, set rivets, and bend and shape metal. Before the advent of pneumatic rivet guns, ball peen hammers were commonly used for riveting. First the flat head drove the nail through, then the round ball was used to "peen over" the other side of the rivet. Before the advent of pneumatic rivet guns, ball peen hammers were commonly used for riveting. First the flat head drove the nail through, then the round ball was used to "peen over" the other side of the rivet. These hammers were made to last.Wooden handled ball peen pein) hammer. The handle has been nailed in and may not be the original. The metal head has one end shaped into a sphere and the other flat.hammer-ball-peen tool metal-work -

Victorian Maritime Centre

Victorian Maritime CentreEgg Cup - Metal

The souvenir metal Egg Cup was purchased sometime during a cruise by an unknown person. It is part of a cruise liner collection by D. Benson and Family over a period of years. D. Benson sold part of the collection to the V.M.C who purchased the remaining part. It is a great source of information to visitors to the V.M.C. At the time of ocean liner holiday cruising, many people purchased these souvenirs to keep or give away as gifts.A metal egg cup with 3 handles on the sides. Emblem on the side says S.S Anchises & Alfred Holt Line House flag.Emblem S.S Anchises & Flag Alfred Holt Linemerchant souvenir, s.s anchises, egg cup -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyHames - 2 pairs, Horse Equipment

Horse harness that connects a horse to a horse drawn vehicle 2 types 1. breast collar or breast strap 2. full collar or collar-and-hames. On either side of the collar are wooden or metal bars called hames.Used by farmers in the Kiewa ValleyShort knob top, forged hook, nut and bolt joint, loose rein ring, chain bottom, steel cased. They go on the collar and are made of two metal strips which take the full force of the pull padded by the collar.horse equipment, hames, horse collar -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Railway Signal Lamp, c. late 1800s - early 1900s

Metal and glass railway signalling lamps were used for communication, safety and lighting by train guards, shunters and signalmen, as well as station staff in the late 1880s to the early 1900s. They were hand operated and used fuel such as kerosene.The railway signal lamp has local significance as part of a set of three lamps donated by a resident of Wodonga who worked for the Victorian Railways. It also has national significance as an example of communication and safety equipment used by the railways in Australia in the late 19th century and early 20th century.Exterior casing of a black painted metal railway signal lamp with circular blue and red glass filters and a turning mechanism on the top under a circular handle. Small copper plate with the letters "A y" stamped on it, on one side of the lamp. "A y"railway lamps, signalling lamp, train signal lamps -

Clunes Museum

Clunes MuseumFunctional object - SCALES

USED IN CLUNES POST OFFICE, VICTORIA, AUSTALIASET OF WEIGHING SCALES INCLUDES: 0.1 SIX SIDED METAL WEIGHT 0.2 SIX SIDED METAL WEIGHT 0.3 SIX SIDED METAL WEIGHT 0.4 FIVE SIDED METAL WEIGHT 0.5 FIVE SIDED METAL WEIGHT 0.6 FIVE SIDED METAL WEIGHT 0.7 FIVE SIDED METAL WEIGHT 0.8 FIVE SIDED METAL WEIGHT 0.9 ROUND BRASS WEIGHT 0.10 ROUND BRASS WEIGHT 0.11 ROUND BRASS WEIGHT 0.12 ROUND BRASS WEIGHT 0.13 ROUND BRASS WEIGHT 0.14 METAL SCALE ASSEMBLY WITH TAN COLOURED COATING ON THE BASE AND ONE ARM, POLISHED METAL ON THE OTHER ARM .1 STAMPED: 2 kg .2 STAMPED: 2 kg .3 STAMPED: 1 kg .4 STAMPED: 500g .5 STAMPED: 500g .6 STAMPED: 200g .7 STAMPED: 200g .8 STAMPED: 100g .9 STAMPED: ON TOP OF WEIGHT 50g STAMPED ON BOTTOM: OK 89 C3 .10 STAMPED: ON TOP OF WEIGHT 20g STAMPED ON BOTTOM: K 89 D3 .11 STAMPED: ON TOP OF WEIGHT 20g STAMPED ON BOTTOM: OK 89 D3 .12 STAMPED: ON TOP OF WEIGHT 10g STAMPED ON BOTTOM: OK 89 D3 .13 STAMPED: ON TOP OF WEIGHT 5g STAMPED ON BOTTOM: A90 .14 STAMPED INTO TOP OF BASE: MERCURY STAMPED INTO METAL AFFIXED TO THE BASE: VICTORIA WEIGHTS AND MEASURES ACT 1958 LABEL AFFIXED TO BASE: MERCURY SCALE CO. LTD SCALE MANUFACTURERS THEBARTON SA NO. 9034 CAP 28LB australian postal system, operational object -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

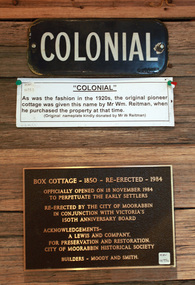

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Furnishings, 'Colonial' metal name plate c1917, c1917

c1917 it became fashionable to give residences a 'name' . Mr August Reitman attached this metal nameplate to the Cottage.when he began leasing the property. The Reitman family purchased the property in 1935 and resided there until 1953 . The property was sold to Lewis Timber Co . c1970. William Reitman, the son of August, donated the sign to the CMHS c1984 during the reconstruction of the pioneer cottage in Joyce Park ,Ormond.An unknown pioneer built the Cottage c1840 then William Box purchased it 1868 and his family resided there until it was leased to August Reitman in 1917. August placed this nameplate on the Cottage c1917. William Reitman, the son of August donated the sign to CMHS in 1984 when the Cottage was reconstructed in Joyce Park Jasper Road OrmondThe original metal name plate attached to Box Cottage c1917 by August Reitman when he and his wife began renting the property. 'COLONIALbox william, box elizabeth, reitman august, moorabbin, bentleigh, brighton, ormond, dendy's special survey 1841, market gardeners, sculptors, reitman william, lewis timber co ltd, box cottage museum -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing, Child yellow nylon dress & silk petticoat, c1960

This pretty yellow, Nylon dress with jap silk petticoat was made by Mrs Sharp c1962 for her daughter. Machine embossed white flowers decorate the dress that has long waist ties, a boat collar and puff short sleeves. A metal zipper is inserted. Nylon became a very popular easy care material c 1960 so that women in City of Moorabbin, who were accomplished dressmakers, made very pretty clothes for their families. Child's yellow nylon dress with jap silk petticoat Machine embossed white flowers decorate the dress that has long waist ties, a boat collar and puff short sleeves. A metal zipper is inserted. clothing, baby, nylon, machine pressed designs, layette, knitting,craftwork, wool, early settlers, city of moorabbin, bentleigh, ormond, moorabbin, post war settlers, world war 11 1939-40 sharp valma, -

Kiewa Valley Historical Society

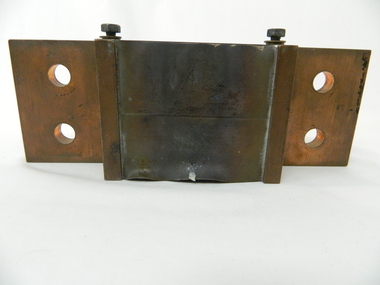

Kiewa Valley Historical SocietyElectric Current Shunt

This shunt is a type of resistor built of copper and designed to carry a current. It was part of the Hydro generator control metering system. It reduces the large current to a small voltage.Historical: This equipment represents a major construction and ongoing operational industry dealing with the supply of hydro electricity to Victoria.Made of copper the shunt has a middle cube with 12 sheets of copper, 5mm apart formed like shelves. On either side of the cube are two shelves coming out from the middle. Both have 2 hollow circles 17.5mm in diameter 25 mm apart in the middle. At the Join of the 'shelves' and cube is a screw on each side.Screwed in metal plaque: Deriv. 1662691 / OHM 0.0000833 / AMP 1200 on the side of the cube above a shelf and on the opposite shelf: ALTO ----> (also a metal plaque screwed on). kiewa hydro electric scheme. secv. hydro generator. victorian electricity grid, power station. electricity., resistor -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Lab Photograph, Small and Large Photograph of Neophot 2 Microscope, 1950s

This Microscope was the property of Ballarat College of Advanced Education which is a predecessor of Federation University .1 Small Photograph in Black and White with microscope and a student working in the Background .2 Large Photograph in Black and White with microscope and a student working in the Background Label on large photograph that reads: Metallurgy - The Electron Microscope enables studies (x 25000) of metal crystal structure by observation of carbon film replica of the metal surface.electron microscope, microscope, ballarat college of advanced education, neophot 2, metallurgy -

Clunes Museum

Clunes MuseumDomestic object - SEWING MACHINE, Wertheim

Black treadle sewing machine with gold markings, on wooden base which has inlaid wood patter and inlaid ruler 2ft marked in inches, on black iron stand with wheel and treadleOn machine; Wertheim Metal plate; Wertheim Frankfurt Metal tension plate; S 524559 Stand; One plate either side of the stand with "Wertheim Frankfurt Trademark"sewing, domestic item, home sewing -

The Beechworth Burke Museum

The Beechworth Burke MuseumAnimal specimen - Powerful Owl, Trustees of the Australian Museum, 1860- 1880

The Powerful owl is native to south-eastern and eastern Australia and is the largest owl on the continent. It is found in coastal areas and in the Great Dividing Range rarely more than 200 km (120 mi) inland. An apex predator in its narrow distribution, the Powerful owl is often an opportunist like most predators, but generally hunts arboreal mammals, in particular small to medium-sized marsupials. It is a typically territorial raptorial bird that maintains a large home range and has long intervals between egg-laying and hatching of clutches. Unlike most raptorial birds, male Powerful owls are larger and stronger than females and so the male takes the dominant position in the mating pair, which extends to food distribution. This example of a Powerful Owl show lighter brown coloured feathers and slight discolouration. The Powerful Owl has darker colourings and whiter feathers in real life. This example also show discolouration in the feet and they are brighter yellow in colour in real life. This specimen is part of a collection of almost 200 animal specimens that were originally acquired as skins from various institutions across Australia, including the Australian Museum in Sydney and the National Museum of Victoria (known as Museums Victoria since 1983), as well as individuals such as amateur anthropologist Reynell Eveleigh Johns between 1860-1880. These skins were then mounted by members of the Burke Museum Committee and put-on display in the formal space of the Museum’s original exhibition hall where they continue to be on display. This display of taxidermy mounts initially served to instruct visitors to the Burke Museum of the natural world around them, today it serves as an insight into the collecting habits of the 19th century.This specimen is part of a significant and rare taxidermy mount collection in the Burke Museum. This collection is scientifically and culturally important for reminding us of how science continues to shape our understanding of the modern world. They demonstrate a capacity to hold evidence of how Australia’s fauna history existed in the past and are potentially important for future environmental research. This collection continues to be on display in the Museum and has become a key part to interpreting the collecting habits of the 19th centuryThis Powerful Owl has medium brown to dark grey-brown above, with white barring, and off-white front. The glass eyes are yellow, set in a dark grey/brown facial mask. The legs are feathered with yellow feet and talons. The specimen stands upon a wooden platform and has no identification tags attached. Swing-tag: n/a Metal tag: n/a Mount: no markings taxidermy mount, taxidermy, animalia, burke museum, beechworth, australian museum, skin, reynell eveleigh johns, bird, owl, powerful owl -

Bendigo Military Museum

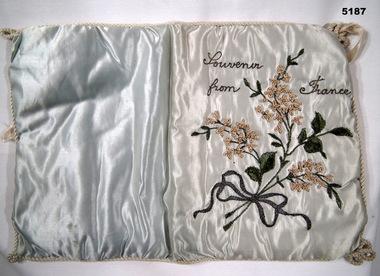

Bendigo Military MuseumSouvenir - SOUVENIR - Embroidered silk handkerchief holder, 1914-1918

Item sent home to "Dorrie" Elizabeth Dorothy Irene wood by her father, Private John Edward Wood 5239, 6th Battalion. Embarked 1/4/1916, killed in action 20/9/1917. No known grave. Name on the Menin Gate Panel 7, AWM Panel 49, Bendigo RSL Museum Roll of Honour. Headstone Eaglehawk Cemetery erected by his wife Ethel Irene Wood.Gold and green embroidered flowers on a blue silk fabric. Silk rope binding around its edges with knot on each corner. Cream silk on back and item is padded."Souvenir from France" embroidered in black/gold metal thread.souvenir, craft, textile, handkerchief holder -

Bendigo Military Museum

Bendigo Military MuseumSouvenir - SOUVENIR, FRAMED SILK LACE CLOTH

St Omer Church was built from 13th to 16th century in Omer, France. Omer airfield is not far from Ypres and was an airfield used by the RFC and RAF.Square multi coloured embroidered cloth. Flower, flower buds, leaves, stems on cream silk. Cotton lace border on all sides. Blue nylon ribbon bows attached at each corner. Centre - black lead sketch of St Omer Church. The item is framed in a dark wooden frame and has a dark green mounting board behind the silk." St Omer" embroidered in metal thread under the picture of the church.souvenir, embroidery, textile, ww1 -

Federation University Historical Collection

Federation University Historical CollectionScientific Instrument, Optics: Nipkow Disc

When glass disc spins the line visible through the front slit shows the movement of waves - sound , lightWooden frame - solid front with window slit. Open back with wooden cross bar. Spinning glass disc with a continuous black circular line - varying widths. One red line in one section. Metal plate on front " MADE SPECIALLY FOR H.B.SILBERBERG & CO MELBOURNE"optics, nipkow disc, glass disc, wave movement, scientific instrument -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchPhotograph - Framed photographs with shoulder patches and Service Medals

Very historical significance. Robert was part of a group of 500 Servicemen captured as P.O.Ws.at Padang Sumatra. The POWs were accommodated in 6 long barracks buildings that ran side by side. They were behind an 8 foot high wall containing a parade ground, sports ground, Japanese Officers and guards quarters. The POWs were put to work on the infamous Sumatra Railway. Part of that group were: Richard Winston Annear WX13468. Alfred John Burgess WX15756. Clifford Dudley Squance WX16885. Arthur Melville Magill WX16886. Harold Mervyn Smith WX17448. Robin Roy Semple WX7532. Edward Mason Hopson WX9241. Cecil George Quinn WX9285.Large grey framed photographs with shoulder patches, service stripes and Service Medals. Photographs are of Robert Frederick Nelson VX8212 2/29th A.I.F and Betty Emily Louise Collins A.C.W 110082 W.A.A.F. Service Medals for Robert are The Pacific Star, 1939 - 45 Star, 1939 - 1945 War Medal and 1939 - 1945 Service Medal. Service Medals for Betty are 1939 - 1945 War Medal and 1939 - 1945 Service Medal. Engraved metal nameplates with names and Service numbers at top and bottom. -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Drill brace

A hand tool used with a bit to drill holes, usually in wood. Pressure is applied to the top and the tool is rotated with a U-shaped grip. This example has two wooden handles.On the metal pipe says "Stanley". On other side is No,144 10in.carpentry, tool -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchUniform - Army Jacket, 1942

Army Jacket Rank Lieut. WW1 type colour patches to Artillery Unit. With well worn ribband bar for WW1 trio.WW1 Artillery Colour Patches. Metal rank pips of Lieutenant. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Lamb Fetus

This lamb fetus has been placed in preserving fluid. This can be formaldehyde, isopropyl or ethanol. It is important that glass jars are used, as plastic will be affected by the chemicals over time in the preserving fluid. Note the glass lid and the rubber seal; also the plastic covered metal clasp that has no contact with the contents. It is not known how long the lamb has been in this jar, but it is remarkably well preserved with just a little film of scum on parts on the top of the interior of the jar.The use of such preserved specimens is widespread in teaching students of all ages, veterinary operatives and museums of the composition of certain animals, insects and birds. Any information about an animal — be it photographs, blood, feathers or fur samples — is better than no information at all. But specimens are vital to ground-truth.Large glass jar containing a lamb fetus in preserving fluid. Glass lid is secured with rubber seal and metal fastening. flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, lamb, fetus, lamb fetus, animal specimen, biological specimen -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Anchor, Early to mid 20th century

Anchors are used to stop boats from moving and today are usually made of metal, and they are made to catch the ocean floor (the seabed). There are two main types of anchors: temporary and permanent. A permanent anchor is called a mooring block and is not easily moved. A temporary anchor can be moved and is carried on the boat. When people talk about anchors, they are usually thinking about temporary anchors. An anchor works by either weight (mass) or shape. Shape is more important to temporary anchors, and design is very important. Anchors must resist wind and tide, and also the up-and-down movement of waves. The subject item is a foundry produced item made specifically for marine use, at present there is no history or manufacturing provenance currently available as the item is unmarked.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item is believed to have been produced in the first half of the 20th century by an unknown manufacture and its design is known as the "Kedge Admirality" pattern.Anchor, Kedge Admirality design galvanised metal with shackle and rope hole at top of anchor Halibut is missing (bar at top) and two curved flat pointed metal hooks at the base of the anchor.Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ships anchor, marine eqipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Souvenir - Aircraft parts, 1914-1918

Collected by Charles Honybun during WW1.Aircraft parts reputed to be part of the aircraft used by Baron Von Richtoven (Red Baron). metal part for tightening wing struts 4 of double toggle NA4963. 2. (x1) wooden pulley from wing NA4963 3. Pistol Bullet Spent NA4963metal part fro tightening wing struts 4 of double toggle NA4963 1-4 2. (x1) wooden pulley from wing NA4963.5 3/- Pistol Bullet Spent NA4963.6ww1, charles henry honybun -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Marlin spike, n.d

Used by Peter Carrison, donor's father-in-law, who was a boat builder. Originally used by Henty brothers for wire cable splicing. A marlinspike (/ˈmɑːrlɪnspaɪk/, sometimes spelled marlin spike, marlinespike, or [archaic] marlingspike) is a tool used in marine ropework. Shaped in the form of a polished metal cone tapered to a rounded or flattened point, it is used in such tasks as unlaying rope for splicing, untying knots, drawing marline tight using a marlinspike hitch, and as a toggle joining ropes under tension in a belaying pin splice.Metal spike with timber knob/handle. Circular groove around head of knob, which has a nail inserted in itmarine technology, maritime industry, rope making, rope work -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Decorative object - SMALL BRASS BOWL

Small round brass bowl with Pekingese dog as handle.Pekingese Peerage Englandornaments, metal, bowl -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Plaque - BRASS WALL PLAQUE, 1930

Round brass wall plaque impressed with scene of people around a table drinking and smoking. Ring for hanging attached to back.ornaments, metal, wall -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - BRASS JARDINIERE

Large brass Jardiniere with embossed vine & leaves decoration.J.S & S Made in England Solid Brass 11 1/2ornaments, metal, jardiniere -

Wangaratta RSL Sub Branch

Wangaratta RSL Sub BranchLeather Belt with Clip Clasp

Brown leather belt with brass clip clasp and brass adjustments, brown stitching that has faded.Nilleather, metal, belt -

Ballarat Base Hospital Trained Nurses League

Ballarat Base Hospital Trained Nurses LeagueProbe - Metal, Graduated

probe, metal, graduated -

Ballarat Base Hospital Trained Nurses League

Ballarat Base Hospital Trained Nurses LeagueMetal Bed Label

metal, bed, label -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Decorative object - BRASS PEACOCK ORNAMENT

Small brass ornament in shape of a peacock, painted in red and purple colours.ornaments, metal, peacock