Showing 9656 items matching "merry-go-round"

-

Disability Sport & Recreation Victoria

Disability Sport & Recreation VictoriaLapel pin, Perfection Sydney, Sawtell Bowling and Recreation Club pin

Small round pinText: "SAWTELL BOWLING & REC CLUB". Inset, gold coloured female figure bowling a lawn bowl against a green, blue and light blue background. -

Disability Sport & Recreation Victoria

Disability Sport & Recreation VictoriaLapel badge, VII World Wheelchair Games - Paralympics UK 1984 badge

Round lapel badgeVII WORLD WHEELCHAIR GAMES PARALYMPICS UK 1984 -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Memorabilia - Aircraft identification badge, Identification Badge, 1914 - 1918

Part of World War I plane - red Baron aircraft.Round metal badge.EIN AUS DRUCK AB MANOMETER -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyHames - one pair and one single, Horse Equipment

Horse harness that connects a horse to a horse drawn vehicle. 2 types 1. breast collar or breast strap 2. full collar or collar-and-hames. On either side of the collar are wooden or metal bars called hames.Short knob top, forged hook, nut and bolt joint, loose rein ring, chain bottom, steel cased. They go on the collar.hames, horse equipment, horse collar -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Portland Harbour, 30/08/1989

Port of Portland Authority ArchivesBack: B'30/8/89' - black textaport of portland archives, portland harbour -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Cape Grant Quarry, 09/07/1954

Port of Portland Authority ArchivesBack: Purple PHT stampport of portland archives, cape grant quarry -

Ringwood and District Historical Society

Ringwood and District Historical SocietyNewspaper, Scrapbook Clipping, Library Collection, Ringwood, Victoria, `

``Newspaper clipping from "The Mail" 1-6-94 P 7 Uproar as councillors go out of control again. By Christine McTigheCouncillors hurled abuse at each otheras a packed gallery demanded answers at a fiery Ringwood Council meeting last week.The Mayor, Margaret Cheevers, lost control of the floor. The acrimony was generated by accusations of fast-tracking developments, which have been decided on behind closed doors. City Manager, Mr John Paech denied that there had been any "undue haste"` -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - STREET SCENE WITH ALEXANDRA FOUNTAIN

Dear Mrs Williams. All well will will arrive in Emerald. Wednesday if anything should happen that I could not go will send a wire. M.H.place, streetscape, alexandra fountain -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - HARD TO GO BUNG, 1992

Hard To Go Bung.World War II Soldier Settlement in Victoria, 1945 - 1962. This is the story of Australia's most successful soldier settlement scheme.Rosalind Smallwood.history, australian, soldier settlement scheme victoria. -

RMIT GSBL Justice Smith Collection

RMIT GSBL Justice Smith CollectionPainting 12 - Top right

12 Top Right North East corner facing east corner 'So goes his story', Honore Daumier, 1808-1879 -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Medal - St Christopher medal

St Christopher medal given to soldier to protect him from danger. St Christopher Patron saint of travel.Silver coloured St Christopher medal with figure on front with "Behold Saint Christopher then go your way in safety" On back - Made in FranceAs abovemedal, st christopher -

Lakes Entrance Historical Society

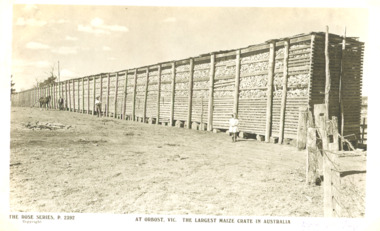

Lakes Entrance Historical SocietyPostcard - maize crib, Orbost Victoria, Rose series p 2392, 1923

At Orbost Vic. The largest maize crib in Australia 500 ft longNote on back of postcard reads Xmas 1923 To wish you a Merry Xmas and a very prosperous New Year from Yours Sincerely W J Cameron GenoaSepia postcard showing very long maize crib, horse and two men on left and small girl on right next to crib. Post and rail fence on right. Orbost Victoriapeople, agriculture, correspondence -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Nail, circa 1825

Nails such as this solid copper nail were forged by blacksmiths. A nail of this length could have been used for the ship's decking. It was recovered from the shipwreck of the barque Children. The Children wrecking: The barque Children was one of the first vessels to be lost in the Western District the vessel was wrecked to the east of Warrnambool on 14th January 1838. When it ran ashore in hurricane-force winds, 22 passengers and crew were fortunate to escape being battered to death on the rocks. The Children broke up within 20 minutes, sweeping sixteen of those on board to their deaths. After eleven days, the survivors, all of whom were injured, were rescued and taken to Portland. According to Lloyd's Shipping Register 1837-1839, the Children was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. Registration number 123/1837, James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered in 1837” at Launceston registered number 6/1837. In 1838 the Children, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year carrying a general cargo including house bricks used for ballast. On the 11th of January 1839, the Children sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the Children were “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane-force storms, eventually clearing on the early morning of the 14th. However, it was too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The Children collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost including 8 children. The Henty brothers contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for James Henty and his brothers, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of establishing the Portland settlement stating. “Six stations have been occupied, one at Portland Bay three at the open country about 60 miles inland called ‘Merino Downs’ They have erected two houses at Portland Bay and two others at Merino Downs”.This nail is significant as part of the vessels original fixtures. The Children was delivering cargo intended for the Portland Bay settlement of her owners the James Henty brothers The wreck is also significant as one of the first vessels to have been lost in the Western District of Warrnambool. As a result the shipwreck of the Children is registered with the Victorian Heritage Register S116. Ship's nail, copper, with a washer attached. The nail has a round head, solid round shank and a flat end. It is bent, twisted and has indentations in the centre section. The nail was recovered from the wreck of the CHILDREN.warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, shipwreck artefact, the children, nail, copper nail, ship's nail, children shipwreck -

Bendigo Military Museum

Bendigo Military MuseumBook - BOOK, WW2, The Sun News - Pictorial, "THE FOURTH YEAR OF WAR IN PICTURES", 1944

Refer Cat No. 7503, 7504, 7505, 4 book collection.Hard cover book. Cover - cardboard, with red colour buckram cover, gold print on spine and embossed illustrations on front cover depicting map, aircraft and tank. End papers - illustrated, sepia tones artwork with aircraft and landscape battle scene. 255 pages - cut, plain, white paper. Illustrated in black and white photographs, maps and battle diagrams. Handwritten inscription on page opposite Title Page.Page opposite Title Page - handwritten black ink inscription - "Wishing Kevin a/ Merry Xmas/ from/ Nathalie 1944".books, pictorial, ww2. -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Bendigo Military Museum

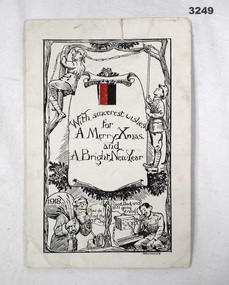

Bendigo Military MuseumCard - CARD, CHRISTMAS 1918, 1918

Card relates to George Ross FREEMAN No 2485, 57th Battalion AIF. Refer Cat No 3251P for Freeman's service details.Christmas card, folding, white background with black printing. Front has cartoon characters in uniform re Christmas & 57th Battalion Signals. Printed on front cover: "With sincerest wishes for a Merry Xmas and a Bright New Year" Handwritten inside: "From Ross To Mother"xmas, new year, 57th, cards -

Linton and District Historical Society Inc

Linton and District Historical Society IncPhotograph, Joyce Rowe, age 5, 1914

Joyce Rowe (afterwards Joyce Chung) was born in Portland in 1912 (#33359), the daughter of Joseph and Florence Rowe (née Nicol). Joyce seems to have been living with her Nicol grandparents in Linton when she started at Linton State School in 1917. In 1931 she married Martin (Mick) Chung (#6196)Black and white image of a young girl standing next to a chair. Image has been made as a postcard."To Ruby / with Love / Wishing you a / Merry Xmas & / a Happy New Year / Joyce age 5 / 5/10/14".joyce rowe, joyce chung -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkPostcard - Christmas and New Year Postcard, c. 1890s

This postcard is part of an album of postcards which date from late 19th century to mid 20th century.This postcard is in an album of postcards dating from the late 19th century to mid 20th century and, as such, indicate the popularity of postcards during that time.Print postcard depicting floral arrangement.On front: 'Handwritten under flowers: 'A merry christmas and a happy new / year' On back: 'To Mother / from Maggie / Xmas 1887'postcard, christmas, 1880s, new year, "green postcard album" -

Kew Historical Society Inc

Kew Historical Society IncBadge - Fundraising Button, Hospital Day, 1914-1918

Most of the civic and sporting ephemera assembled by Francis Rigg were patriotic buttons. The use of these buttons as a means of raising revenue through patriotic sentiment occurred soon after Australia pledged allegiance to Empire. Buttons reflected ‘public sentiment, courage, patriotism, generosity and several [un- named] virtues’ such as the martyred mother of a ‘fallen’ hero. Attention was paid to attractiveness of design, encoded symbolism and high quality of production. Expressing ‘loyalty’, they were tokens to be kept for perpetuity. Female labour was used to operate the die that compressed the tin backing, photographic print and celluloid cover together. The pin was applied by hand. Women, of all ages, entered into the spirit of voluntary sales. Often they were sold at the entry and exit points of major pedestrian thoroughfares. The women of Kew set up a kiosk in front of the Post Office and the Railway Station to solicit their round, oval and square shaped wares. Pride in salesmanship was affected by publishing the name of the woman and her fiscal achievement in the major newspapers of the day. The button forms part of a collection of ephemera originally purchased by Francis Horace Rigg (19/10/1882-05/03/1946) of 50 Belford Road, Kew (Vic.). Frances Rigg was a local business identity in Kew, ultimately managing the local branch of the English, Scottish and Australian (ES&A) Bank at 175 High Street, Kew from c. 1920 until the 1940s. After Francis Rigg’s death, the collection of buttons and badges was inherited by his son, Ken Rigg (14/11/1922-19/01/2014). The collection was subsequently donated to the Kew Historical Society in 2015 by his grandson Adrian Rigg during the Gallipoli and Beyond Commemoration. The collection covers a period of almost 40 years. The majority of the badges are patriotic buttons, issued and sold during and immediately after World War 1 to raise funds for national and overseas causes. The collection also includes a number of locally significant sporting event buttons and sporting club medallions, issued in the 1920s and 1930s.Round metal button in red, white, blue and gold showing a sun setting over the sea with words printed in red around border and on lower outer rim.hospital day, patriotic buttons, first world war (1914-18) -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchAmmunition

Ammunition 7.62 X 39 Russian Drill Round X 1 round seems Damaged / Bent.ammunition, general -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumCake Tin, 1940's

Made and used by Internees at Camp 3, TaturaLarge round cake tin with large round hollow insert in centre. Small loop on side of tincake tin, hoefer family, camp 3, tatura, ww2 camp 3, domestic, food, preparation -

Whitehorse Historical Society Inc.

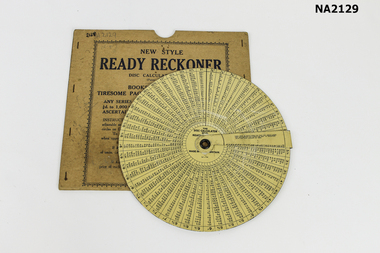

Whitehorse Historical Society Inc.Functional object - Disc Calculator

Flat round disc enclosed in cardboard container with round thumbhole at top which allows manipulation of disc.New Style Ready Reckoner --- Made in Great Britian.instruments, measuring -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Hammer, Ball & Peen , metal wood c1900, c1900

Among the early settlers in Moorabbin Shire were blacksmiths who made tools for the other settlers who were establishing the homes, market gardens, farms, orchards and various businesses. Early settlers were self reliant and repaired their own equipment for kitchen,dairy, farm, horses, carts using various tools . Besides for peening (surface hardening by impact), the ball-peen hammer is useful for many tasks, such as striking punches and chisels - usually performed with the flat face of the hammer. The peening face is useful for rounding off edges of metal pins and fasteners, such as rivets. The ball face of the hammer can also be used to make gaskets for mating surfaces. A suitable gasket material is held over the surface where a corresponding gasket is desired, and the operator will lightly tap around the edges of the mating surface to perforate the gasket materialThis hammer is typical of the type used by early settlers in Moorabbin Shire c1900A hard faced ball & peen hammer, also known as a machinist's hammer,[ is a type of peening hammer used in metalworking. It has two heads, one flat and the other, called the peen, rounded.early settlers, market gardeners, blacksmiths, tools, building equipment, hammers, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

Numurkah & District Historical Society

Numurkah & District Historical SocietyBlacksmith Tool (unknown use)

Round metal with handle. At the other end, the round metal has been flattened. On the end of the flattened piece is a rounded, thicker piece of metal (one end of this has been corroded away)blacksmith tools, forge, metal, iron -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Cato Lake looking from Sloane Street -- Coloured

Cato Lake view from Sloane Street. This photo is one of three showing Stawell Council Works deepening Cato Lake in February c 2002. Tracks from a tractor can be seen all round the lake. Willows branches hang either side of the view with trees along the horizon. The Presbyterian Church tower, Senior Citizen room and Anglican Church can be seen amongst the trees in the background.Coloured photograph of Cato Lake. The view is from Sloane Street and the lake was in the process of being lowered for the deepening of the lake by Shire Council Works. Tractor tracks can be seen all round the lake. Willows hang either side of the view with trees along the horizon. The Presbyterian Church tower in the background near the Senior Citizen room and Anglican Church to the right.Date on back of photo in biro 12.2.2002.stawell -

Vision Australia

Vision AustraliaPhotograph (item) - Image, Jason Morgan, 2023 Christmas decorations at Kooyong, 23/11/2023

Image taken by staff member of Christmas decorations facing Glenferrie road, including an oversized inflatable Santa, a smaller inflatable Santa with his reindeer and Christmas tree and a banner that reads "Merry Christmas from Vision Australia, home of Carols by Candlelight".vision australia, buildings -

Bendigo Historical Society Inc.

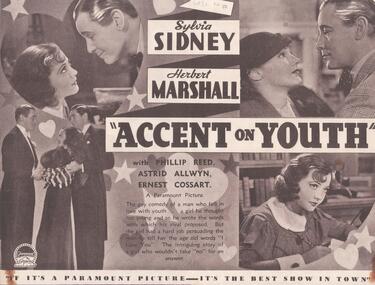

Bendigo Historical Society Inc.Programme - THEATRES COLLECTION: PLAZA THEATRE PROGRAMMES

Thirteen programmes for the Plaza theatre. 1) ''Accent on Youth'' with Sylvia Sidney and Herbert Marshall. 2) ''Transatlantic Merry-go-Round'' with Nancy Carroll and Gene Raymond. 3) ''We Live Again'' with Anna Sten and Fredric March. 4) ''Lilies of the Field'' with Winifred Shotter and Anthony Bushell. 5) ''Carnival in Spain'' with Marlene Dietrich, Lionel Atwill, Cesar Romero. 6) '' Kid Millions'' with Eddie Cantor and Ann Sothern. 7) ''The Mighty Barnum'' with Wallace Beery. 8) ''All the King's Horses'' with Mary Ellis and Carl Brisson. 9) ''Behold my Wife'' with Sylvia Sidney and Gene Raymond. 10) '' Without Regret'' with Elissa Landi, Paul Cavanagh, Kent Taylor and Frances Drake. 11) '' Clive of India'' with Ronald Colman and Loretta Young. 12) ''Texas Trail'' with William Boyd, Russell Hayden, Judith Allen, George Hayes. 13) ''Danny Boy'' with Ronnie Hepworth, Frank Forbes-Robertson, Dorothy Dickson, Cyril Ritchard.entertainment, theatre, plaza -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Bendigo Historical Society Inc.

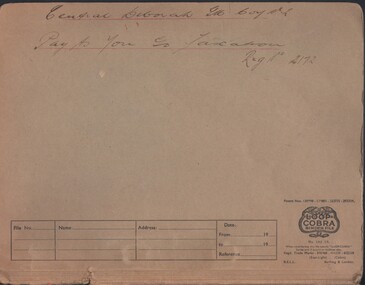

Bendigo Historical Society Inc.Document - MCCOLL, RANKIN AND STANISTREET COLLECTION: CENTRAL DEBORAH MINE NL - TAXATION FORMS, 1944 - 1954

Document: McColl, Rankin & Stanistreet Collection: pay as you go taxation reg. No. 2172, Central Deborah Mine. Manilla folder containing instalment deductions remittances to taxation dept. for 1954. Folder has ' Central Deborah GM Coy NL, pay as you go taxation, Reg. No. 2172' written on front cover in faded black ink.organization, business, central deborah gold mine, mccoll, rankin & stanistreet collection: central deborah gold mine nl, taxation -

Bendigo Military Museum

Bendigo Military MuseumUniform - BUTTON COLLECTION, 1930' - 1945

.1). .2), .3) Buttons, black plastic, round, palmtree and "RWAFF" .4) Button, black plastic, sheild, "British Red Cross Scoeity .5) Smaller version of .4) .6) Button, black plastic, round palm tree and RWAFF .7) Button, black plastic, round with crown and anchor .8) Button, metal, brass, round with coat of arms .9) Button, metal, brass, round with crown and anchor .10) Button, metal, brass, round with crown over wings .11) Button, metal, brass, round with crown over wingsbuttons, collection