Showing 8591 items matching "wools"

-

National Wool Museum

National Wool MuseumRibbon

Ribbon awarded to Mr Charles Wilson Peel of 'Callenondah' at Gnawarre. Mr Peel ran a superfine merino stud. This ribbon is from the Geelong Agricultural & Pastoral Society 1973 Show.Dark red wool ribbon with yellow stamped text. -

National Wool Museum

National Wool MuseumRibbon

Ribbon awarded to Mr Charles Wilson Peel of 'Callenondah' at Gnawarre. Mr Peel ran a superfine merino stud. This ribbon is from the Geelong Legacy Fleece Show 1969.Navy blue wool ribbon with stamped yellow text. -

National Wool Museum

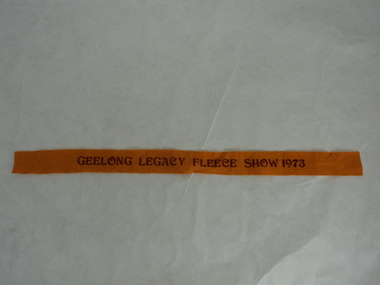

National Wool MuseumRibbon

Ribbon awarded to Mr Charles Wilson Peel of 'Callenondah' at Gnawarre. Mr Peel ran a superfine merino stud. This ribbon is from the Geelong Legacy Fleece Show 1973.Yellow/gold wool ribbon with red stamped text. -

National Wool Museum

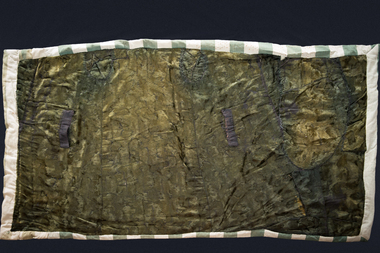

National Wool MuseumQuilt, Travelling rug

Part of the Wagga collection. Maker unknown, c. early 1940s. Possibly from South Australia. This 'travelling rug' was found in an opportunity shop in Campbell's Creek near Castlemaine in Victoria. Unfortunately, nothing is known about the maker but it could be surmised that the quilt had many uses. It is heavy and designed for warmth, lined with a woollen blanket and hessian. Its size suggests usage in an open buggy or car when travelling or as a picnic rug along the way. The sturdy canvas backing is of the type commonly used for awnings, chair coverings or tent cloth. The quality of the green velvet made it ideal for further use as a quilt after the original use as an overcoat or smoking jacket for either a man or a woman. Apart from the original machine stitched seams in the garment, it is sewn together by hand using herringbone stitch. It is not known if this quilt was designed to be used with a cover. However, the arrangement of pieces in the garment to create a shape with straight edges may suggest that this may have been a consideration.Travelling rug made of wool, cotton and green velvet.No. 27 "Travelling rug" Maker Unknown Running Stitch Collection...quilting history, handicrafts, running stitch group, blankets, running stitch collection, highlights of the national wool museum: from waggas to the wool quilt prize - exhibition (22/09/2001 - 02/12/2001), quilting - history -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

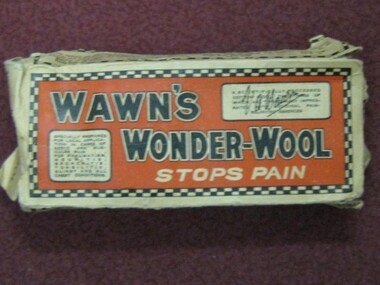

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchMedical

Warn's Wonder Wool (muscle pain treatment) G.M.Frostmiscellaneous, ww2, army -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia

Spool of Spun Wool. Product of Stawell Woollen Millsstawell -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, 1980's

Stawell Founded on Gold. Wool Locker Hooking Display stawell -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionCoin - Operation Resolute Coin, Operation Resolute Coin Rotation 74

Operation Resolute Rotation 74 Coin with the wool case -

Bendigo Military Museum

Bendigo Military MuseumFootwear - SOCKS, ARMY, C.1960’s

Two pairs of khaki Army issue socks - wool.uniforms - army, costume male underwear / footwear, socks -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchUniform - Headgear RAAF, Officers Peak Cap

WW2 RAAF Officers cap to go with uniform catalgue number 00014.Wool Cap with peak and black bound. Tel 1926 -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Forest Green Childrens jumper with geometric ‘alpine’ pattern with long sleeves and ribbed cuffs and round neck collar. Textured geometric pattern is created with purl stitches and extends both on the front and back of the jumper, as well as down the sleeves.[white label at back neck printed with blue ink] KATHRYN REGD SIZE 1 / LENGTH 84cm / WEIGHT 12kg / Made in Australia ACRYLIC/WOOLchildren's knitwear, knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

Bendigo Military Museum

Bendigo Military MuseumUniform - UNIFORM, ARMY, Yakka Victoria et al, 1969-73

H. R. WILLIS No 342872, refer cat No 5231.3 for his service details.1. Shirt - Cotton khaki, long sleeved. 2. Shirt - Cotton, khaki, long sleeved, embroidered crown on upper sleeves. 3. Trousers - polyester/wool, khaki. 4. Jacket - polyester/wool, khaki. 5. Belt - polyester/wool, khaki, yellow metal buckle. uniform, army -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Three-piece brown and yellow outfit consisting of jumper, pants and hat. Jumper is long sleeved with a high crew neck and five yellow stripes above ribbing along bottom. Pants are brown with wide legs that dramatically taper into the ribbed cuff at bottom. Body of hat is brown and tapers into a long point and has a brown and yellow pompom at the tip. The hat is shaped with a tuck at the back neck near cuff..1 [Label at back neck of jumper with blue lettering woven into label] KATHRYN REGD / 24 ALL WOOL CREATED BY ROBERT BLAKEknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, pom poms, wool -

Williamstown High School

Williamstown High SchoolSchool cap, J.T. Lynch

Black felted wool peaked cap with green wool under peak. Red button (faded to tan) on top. Logo with fish and anchor and 'Hold fast' in red and yellow.Inside hat: Made specially for Williamstown High School by J.T. Lynch, Moonee Ponds Name: Ray Hill IIIB Size: 7williamstown high school, cap, school uniform -

Whitehorse Historical Society Inc.

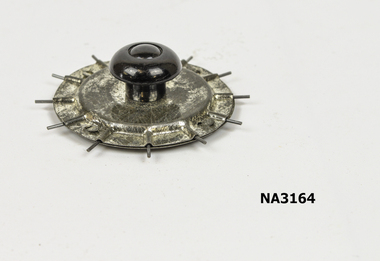

Whitehorse Historical Society Inc.Tool - Daisy Wheel

From the Betty McPhee sewing collectionCircular 5cm wheel with a knob in centre and divided with spokes on which is wound the wool to form daisy's used in embroidery. The knob enables the wheel to be turned to separate the spokes for the wool.handcrafts, equipment -

Kilmore Historical Society

Kilmore Historical SocietyFootwear - Pair of child's fawn leather boots, Pair Child's boots, Unknown

Pair of child's leather boots. Fawn leather on upper, brushed cotton lined, wool rubber sole and heel. Decorative tan leather and stitching around upper. Silver coloured zip on arch with decorative stitching to toe. Stiff toe puffs and heel supportsOn sole ink stamped 'LEATHER UPPER COTTON LINED FIBER INNER SOLE WOOL RUBBER SOLE' Under decorative tan leather on upper Ink stamped '2 585 SIZE 9' On inner sole Ink stamped 'WRAY'S NATURAL FORM FOOTWEAR MADE IN ENGLAND" -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

Bendigo Military Museum

Bendigo Military MuseumUniform - UNIFORM, ARMY NURSES, Fletcher Jones, 1991

Winter Service Dress Capt Linda Elliot, R.A.A.N.C Refer Cat No 4308.1) Jacket, khaki wool/polyester with rank epaulettes 3 pips, white metal buttons, red lanyard. .2) Shirt, light khaki polyester. .3) Trousers khaki wool/polyester. .4) Beret felt dark green colour with A.A.N.C badge. .5) Belt, plastic webbing, khaki colour with metal clasp buckle. .6) Tie wool khaki. .7) .8) Socks wool khaki..1) Epaulettes on shoulder, Officer rank Capt R.A.A.N.C .4) Beret badge, R.A.A.N.Cuniforms, service dress, raanc -

National Wool Museum

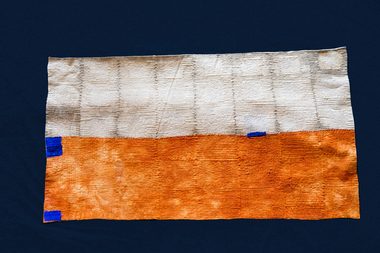

National Wool MuseumQuilt, Bow Wow Bowerbird

Winner of Expressions 2004 Wool Quilt prize. The stitch as a measure of time is explored in this quilt. It is from a series i have been working on about my local environment. Shaped by time and the elements, Bow Wow Gorge us visited by more than 150 bird species.Quilt is a combination of silk, wool, baft, linen, and rayon thread. Two halves of the quilt have been hand sewn together and are a rusty red and grey in colour with small blue patches using plant dyes. Machine stitched, hand sewn, and applique, the quilt has long pockets and panels added to the back.Bow Wow Bowerbird 2004 Pamela Fitzsimonhandicrafts quilting textile, national wool museum, fitzsimons, ms pamela, geelong, victoria, handicrafts, quilting, textile -

National Wool Museum

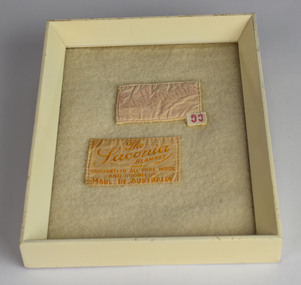

National Wool MuseumTextile - Blanket labels

Collector's note: "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. Two blanket labels, framed, on blanket backing Castlemaine Pure Wool/The Laconia Blanket/Guaranteed All Pure Wool And Odorless/Made in Australiawool, blanket, blanket fever, sampler, labels -

Bendigo Military Museum

Bendigo Military MuseumUniform - UNIFORM, AWAS, 1942/43

Mrs M E Cawthan AWAS1. Jacket - wool, khaki, metal buttons. Rising Sun on each lapel. 2. Dress - Cotton, light khaki, no buttons. 3. Belt - Wool, khaki, metal buckle.uniform, awas -

Dunkeld Museum Inc.

Dunkeld Museum Inc.Wool Press, Womersley Wool Press, Late 19th century

Manufactured in Dunkeld Victoria by the local blacksmith. Believed to be a copy of a model which originated in New Zealand.One of the few remaining doule box wool presses still in existence.Double box wool press. Made of timber and iron. Manufactured in Dunkeld. Both boxes are filled then the top box is hinged to be placed on top of the lower box before the wool is pressed.J. H. C. Womersley, maker, Dunkeld on the lower box.Shield and decoration on sides of the lower box and the top box.blacksmith, wool, press, western district -

Hymettus Cottage & Garden Ballarat

Hymettus Cottage & Garden BallaratTextile - Bookmark, Corner bookmark

This small handcrafted bookmark was made by one of the Jones sisters, Gwen or Edna of 'The Union' homestead at Woolsthorpe in Western Victoria. An Australian domestic example of a corner bookmark of a type popular in the 1950s.Two small pieces of blue felt cut into shape of lady's face and stitched together with features added with wool stitching. Wool thread as hair stitched to hang outside the pages.Nilbookmark, felt, woolsthorpe, victoria -

National Wool Museum

National Wool MuseumArcadian wool Classer Specifications

White paper with blue letteringArcadian Wool Classers Specification. arcadian wool, wool classers, geelong -

National Wool Museum

National Wool MuseumTextile - Blanket, Eagley Woollen Mills, 1960s

Note from collector: Once I had gathered a dozen or so blankets, I started noticing the many different labels; where they were made, by who, the logos and fonts used. Then the labels became a thing, then the blankets had to have a label to join the collection. My favourite labels are by Physician, they had at least 4 different labels over the decades but the best has to be the Lady In Bed logo. Physician, Onkaparinga, Eagley and others matched the colour of the label to the colour of the blanket - a nice touch. Strangely, Castlemaine labels were always sewn on the back of the blanket where all the other mills sewed theirs on the front. To this day I always roll or fold a blanket with its label on display.Note from collector- "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. " Queen sized brown, green and blue checked blanketEagley Blanket, Pure Woolblanket, blanket fever, wool, eagley woollen mills, victoria -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Trousers - Boy's

Boy's short grey flannel trousers lined with grey cotton.Alexanders 11 All Woolcostume, children's -

Bendigo Military Museum

Bendigo Military MuseumHeadwear - BERET & BADGE, 1960’s

Beret and badge issued to Geoffery Charles Murray No 3411521, Vietnam 3 Cav Regt 27.11.67 to 22.10.68, Survey Corp 15.10.69 to 15.10.70.Black Woolen Beret with a Silver Armoured Corp Badge“Kent pure wool large”military-equipment, beret, armoured corp -

Waverley RSL Sub Branch

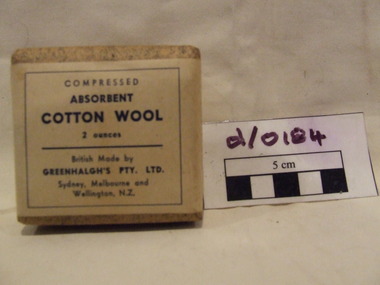

Waverley RSL Sub BranchPack Cotton Wool Absorbent, Greenhalgh's Pty. Ltd.British Made, WWII

Cotton wool absorbent in canvas pack with makers name on front -

Lara RSL Sub Branch

Lara RSL Sub BranchUniform - Russian paratrooper red beret

The Soviet Union was one of the first countries to realize the unique potential of parachute forces. As early as 1927 there were reports of parachute troops being used against bandits in Central Asia. Within the next two to three years Leonid G. Minov began to organize the first military parachute units. He traveled to the United States to study parachute strategy and techniques employed in air rescue missions. He returned to his country with a supply of American-made Irvin parachutes. In April 1930, Soviet industry produced its first run of domestic parachutes, not surprisingly patterned on the Irvin style.Red felted wool beret withblack leather hat trimfabric informatiion labelt i.e. dry cleanrussian front 1918-1919, russian paratroopers history of russian paratroopers, history of change in aircraft to cater for paratroopers -

Bendigo Military Museum

Bendigo Military MuseumUniform - TIES, C. 1960 - 1980

Military issue ties, frayed ends result from each being cut from a large roll. Peter Dodd collection, refer Cat No 2436.2P.1).2) Ties, khaki colour, wool, the ends on are frayed.ties, uniform