Showing 253 items

matching container for food

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tea Container, J Marsh & Sons (Tin Container Fabricators), 1900-1940

... caddy tea tin container kitchen storage food storage food nectar ...Tin, "Choicest Nectar Tea" is an example of retail packaging, for domestic goods, the tin was made by J Marsh and Sons, Melbourne, for John Connell & Co Ltd, Melbourne, Victoria, Australia, 1900-1940Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset.Container; tea caddy for "Nectar Tea" brand, 1 lb. Packed by John Connell and Co Ltd, Melbourne. Blue and white vertical stripe decoration. On label "The Nectar Tea Caddy" and "Nectar, the finest tea the world produces, is a blend of the Choicest Pure Leafed Teas from the Gardens of Ceylon, India, Java"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tea canister, tea caddy, tea tin, container, kitchen storage, food storage, food, nectar tea, john connell, melbourne, j march & sons, john connell & co ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Container, 1900 to 1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s. Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Stoneware circular container with wide opening, brown top and off white base. Handholds moulded on each side glazed finish, cracks in base.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, container, stoneware container, kitchen storage, kitchen ware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Preserving Jar, 1932-1948

The Mason jar, named after American tinsmith John Landis Mason, who patented it in 1858, is a molded glass jar used in home canning to preserve food. The jar's mouth has a screw thread on its outer perimeter to accept a metal ring or "band". The band, when screwed down, presses a separate stamped steel disc-shaped lid against the jar's rim. An integral rubber ring on the underside of the lid creates a hermetic seal. The bands and lids usually come with new jars, but they are also sold separately. While the bands are reusable, the lids are intended for single-use when canning. Glass jars and metal lids are still commonly used in home canning while they have been largely supplanted by other methods for commercial canning (such as tin cans and plastic containers). Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset.Clear glass preserving jar with metal screw lid grooved base for lid clip."AGEE / MASON / JAR" imprinted into side of glassflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jar, glass jar, preserving jar, food preserving, food storage, agee mason, agee mason jar, john landis mason -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Fred Walker Cresco Foods, 1910

... food container... food container kitchen ware Flaked Rice Cresco Palm Flaked Rice ...Fred Walker 1884 – 1935 was an Australian businessman and founder of Fred Walker & Co. first in Hong Kong, then in Melbourne as the Fred Walker Company. He also set up Kraft Walker Cheese Co. in partnership with American businessman James L. Kraft in 1926, to market Kraft's patented method of processing cheese in Australia. Fred Walker & Co. is best known for creating Vegemite, a yeast extract-based food spread and Australian cultural icon. Kraft Walker Cheese Co. Is best known for manufacturing a cheese known as Red Coon around 1931, which later became known as Coon cheese. He founded the Fred Walker Company at 54 William Street and later moving to Flinders Street in 1911. This company specialised in canned foods, especially dairy products, exporting them to Asia. It manufactured Red Feather canned foods including butter and cheese from around 1910. He also went on to created Cresco Food Co. for his younger brother, which was the first factory to manufacture "flaked food" or dehydrated food products in Australia.A significant item that catalogues the start of dehydrated food production and sale in Australia was initiated by an Australian businessman and well-known entrepreneur. The history of Fred Walker gives insight into how many food brands in Australia now that we take for granted had his involvement in their early beginnings. Large cylindrical tin with push on lid, painted label on the sides in maroon, black gold and dark fawn colours with text.Palm Flaked Rice manufactured by the Cresco Co. Limited Melbourne Australiaflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, container, food container, kitchen ware, flaked rice, cresco, palm flaked rice, tin, fred walker, dehydrated food -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Storage Tin, Late 19th or early 20th Century

... -village Tin plating Food containers None. Container metal ...The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Container metal cylindrical plain tin with separate lid. Join line on side of cylinder. Very rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jug, Late 19th or early 20th Century

... -Village Tin plating Food containers None. Rusty tin jug with small ...The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Rusty tin jug with small pouring lip and handle. Very plain and possibly made from a jam tin and handle soldered on side.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Rolling Pin, First half of 20th Century

A rolling pin is a simple tool used to flatten dough. The first civilisation known to have used the rolling pin was the Etruscans. Their advanced farming ability, along with a tendency to cultivate many plants and animals never before used as food and turn them into sophisticated recipes, were passed to invading Greeks, Romans, and Western Europeans. Thanks to the Etruscans, these cultures are associated with gourmet cooking. To prepare their inventive foods, the Etruscans also developed a wide range of cooking tools, including the rolling pin. Although written recipes did not exist until the fourth century B.C., the Etruscans documented their love of food and its preparation in murals, on vases, and on the walls of their tombs. Cooking wares are displayed with pride; rolling pins appear to have been used first to thin-roll pasta that was shaped with cutting wheels. They also used rolling pins to make bread (which they called puls) from the large number of grains they grew. Natives of the Americas used more primitive bread-making tools that are favoured and unchanged in many villages. Chefs who try to use genuine methods to preserve recipes are also interested in both materials and tools. Hands are used as "rolling pins" for flattening dough against a surface, but also for tossing soft dough between the cook's two hands until it enlarges and thins by handling and gravity. Tortillas are probably the most familiar bread made this way. Over the centuries, rolling pins have been made of many different materials, including long cylinders of baked clay, smooth branches with the bark removed, and glass bottles. As the development of breads and pastries spread from Southern to Western and Northern Europe, wood from local forests was cut and finished for use as rolling pins. The French perfected the solid hardwood pin with tapered ends to roll pastry that is thick in the middle; its weight makes rolling easier. The French also use marble rolling pins for buttery dough worked on a marble slab. Glass is still popular; in Italy, full wine bottles that have been chilled make ideal rolling pins because they are heavy and cool the dough. Countries known for their ceramics make porcelain rolling pins with beautiful decorations painted on the rolling surface; their hollow centres can be filled with cold water (the same principle as the wine bottle), and cork or plastic stoppers cap the ends. Designs for most rolling pins follow long-established practices, although some unusual styles and materials are made and used. Within the family of wooden rolling pins, long and short versions are made as well as those that are solid cylinders (one-piece rolling pins) instead of the familiar style with handles. Very short pins called mini rolling pins make use of short lengths of wood and are useful for one-handed rolling and popular with children and collectors. Mini pins ranging from 5 to 7 in (12.7-17.8 cm) in length are called texturing tools and are produced to create steam holes and decorations in pastry and pie crusts; crafters also use them to imprint clay for art projects. These mini pins are made of hardwoods (usually maple) or plastic. Wood handles are supplied for both wood and plastic tools, however. Blown glass rolling pins are made with straight walls and are solid or hollow. Ceramic rolling pins are also produced in hollow form, and glass and ceramic models can be filled with water and plugged with stoppers. Tapered glass rolling pins with stoppers were made for many centuries when salt imports and exports were prohibited or heavily taxed. The rolling pin containers disguised the true contents. The straight-sided cylinder is a more recent development, although tapered glass pins are still common craft projects made by cutting two wine bottles in half and sealing the two ends together so that the necks serve as handles at each end.Tiny rolling pins are also twisted into shape using formed wire. The pins will not flatten and smooth pastry, and the handles do not turn. The metal pins are popular as kitchen decorations and also to hang pots, pans, and potholders. https://www.encyclopedia.com/sports-and-everyday-life/food-and-drink/food-and-cooking/rolling-pinThe use of the rolling pin to make thin pastry or pasta.Wooden rolling pin with some damage on cylinder section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rolling pin, cooking, pastry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Storage Tin, Late 19th or early 20th Century

... -Village Tin plating Food containers None. Container metal ...The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin.The use of tin to protect and store food and other items, revolutionised the world.Container metal cylindrical plain tin with separate lid. Join line on side of cylinder. Very rusty.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Funnel, Late 19th or early 20th Century

A funnel such as this is used to assist in pouring liquids into a narrow container such as a bottle or jar. An item like this could be commonly used in households for food preparation, cooking and soap making. It could also be used for pouring fuel, and medicinal purposes. Enamelware dates back to 1760 in Germany.This object is significant as an example of a type of item in common use in the 19th Century and that is still in use today.Funnel, white enamel with dark rusty metal rim. It has a triangular shaped hook on the top lip for hanging. The metal has been joined down one side.None.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, funnel, food preparation, beverage, laundry, fuel, food preservation, medicinal preparation, decanting, pouring -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

... . Each type of food came with its own kind of can, and each kind.... Each type of food came with its own kind of can, and each kind ...It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

... . Each type of food came with its own kind of can, and each kind.... Each type of food came with its own kind of can, and each kind ...It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Kitchen Canister set, Late 19th to early 20th century

... . This set of kitchen food containers is an example of colonial food ...This set of kitchen dry food canisters is made of metal; each container has a different height, width and capacity. The rolled thin metal has created a strong, round design with decorative rings on the circumference. The base and close-fitting lid protect the contents from vermin and most insects, and the handle on top aids in the removal of the lid. Metal containers like these are reusable and can be re-purposed, which is advantageous when living in regional or rural areas. The type of manufacture indicates that the set was made in the late 19th to early 20th century. Gradually, colourful and attractive plastic kitchenware began to replace metalware. One of the canisters is labelled 'coffee'; coffee plants and seeds were transported from Brazil into Australia in 1788 when the First Fleet arrived although their growth was unsuccessful. However, by the 1920s, a tenth of the Australian population was drinking readily stored coffee. Large quantities of harvested grains such as maize, wheat and barley were protected from pests by being stored in airy buildings, often raised from the ground. This was an age-old practice used by civilizations such as the ancient Egyptians and early Hebrews. Smaller quantities of food for short-term use in the homes were stored in woven baskets or clay pots.This set of kitchen food containers is an example of colonial food storage used in a domestic setting to store and preserve dry ingredients. These canisters give a snapshot of early domestic life in Australia. Canister set; four cylindrical cream coloured metal canisters with domed lids that have lift-up handles on top. They are made from rolled metal and the bases and lids have a side seam. Each canister is a different size and displays a label for different contents. The adhesive labels are vertical, and a gold colour with black vertical text. The cream paint has brush strokes and small areas have exposed green paint under the cream. The insides of the bases are painted dark grey but the lids have no paint underneath. The empty canisters can fit one inside the other. Labels, in descending order: "FLOUR" "RICE" "SAGO" "COFFEE"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, canister set, kitchen storage, food storage, metal canisters, dry food storage, food packaging, kitchen container, vintage, flour, rice, sago, coffee, kitchenalia, late 19th to early 20th centuries, nesting canisters -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tea Tin, First half of 20th Century

... food and other items, revolutionised the world. flagstaff hill ...The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin. https://www.shilohplastics.com.au/history-of-metal-packaging/The use of tin to protect and store food and other items, revolutionised the world.Tin container painted yellow with printed crosses and circles,. The lid is labelled "Robur Cross Stitch Company" and "R" imprinted in the centre although the lid is badly corroded. ‘Cross – Stitch’ (printed green in small crosses and circles) followed by ‘Nett Weight ¾ lb. (printed beige in crosses and circles). Pure Blended Tea. Robur Tea Co Ltd’ flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, robur tea co ltd, tea, tea caddy, tin, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, C. 1910 - 1930

This Kandy Koola Tea tin dates to the early 20th century and was made and sold in Melbourne, Victoria. It once belonged to the Giles family. About Kandy Koola Kandy Koola ran an advertisement in the West Gippsland Gazette on 2 May 1911 promoting its tea as perfect for a picnic. The text reads “Picnicing. All as hungry as hunters – made a fire of small twigs – put on our billy of fresh spring water – and waited. Soon bubble, bubble, bubble and the billy boiled. In goes the pure Kandy-Koola Tea. Tea! Tea is not the word – it tasted like nectar! One cup, two cups, three cups – then had to make a fresh billy full. Lazed away the rest of the day sipping our Kandy Koola and chatting. How good indeed! “All grocers sell Kandy Koola Tea. It is pure leaf, selected and blended with the greatest care and skill. Ask your grocer for Kandy Koola. Sold in three grades, i.e. red, blue and green packets” About the Giles Family There are many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by Vera and Aurelin Giles. The items are associated with the Giles Family and are known as the “Giles Collection”. These items mostly came from the simple home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton), whose photos are in the parlour. They married in 1880. Henry Giles was born at Tower Hill in 1858. He was a labourer on the construction of the Breakwater before leaving in 1895 to build bridges in N.S.W. for about seven years. Mary Jane was born in 1860 at Cooramook. She attended Mailor’s Flat State School where she was also a student teacher before, as family legend has it, she became a governess at “Injemiara” where her grandfather, Francis Freckleton, once owned land. Henry and Mary’s family of six, some of whom were born at Mailor’s Flat and later children at Wangoom, lived with their parents at Wangoom and Purnim west, where Henry died in 1933 and Mary Jane in 1940. The Giles family collection has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the Museum was established. The tin and the tea that was in the container are significant for their association with the Australian and Victorian food industry, being blended and packed by John Connell and Co, Proprietary Limited Melbourne.Container; tin, for Kandy Koola Tea, part of the Giles Collection. Round tin, green background, gold band on top and bottom, printed on gold background. Ceylon flavoured tea. Also five gold flowers of various sizes with scalloped band, large golden inscription “Kandy Koola Tea” and “Ceylon Flavoured” and “Blended and packed by John Connell & Co Pty Ltd Melbourne” “Kandy Koola Tea” and “Ceylon Flavoured”and and “Blended and packed by John Connell & Co Pty Ltd Melbourne”. Printed on lower band “MADE AND PRINTED BY WILSON BROS. NORTH MELB.” “1LBS NETT”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, giles family, 19th century domestic items, tea, tea merchant, tea tin, food and beverages, giles collection, henry giles, tower hill, warrnambool breakwater, mailor’s flat, wangoom, 19th century household goods, metalcraft, tinware, kandy koola tea -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Basket, 1890-1920s

Before the invention of woven baskets, people used tree bark to make simple containers. These containers could be used to transport gathered food and other items but crumbled after only a few uses. Weaving strips of bark or other plant material to support the bark containers would be the next step, followed by entirely woven baskets. The last innovation appears to be baskets so tightly woven that they could hold water. Depending on soil conditions, baskets may or may not be preserved in the archaeological record. Sites in the Middle East show that weaving techniques were used to make mats and possibly also baskets, circa 8000 BCE. Twined baskets date back to 7000 in Oasisamerica. Baskets made with interwoven techniques were common at 3000 BCE. Baskets were originally designed as multi-purpose vessels to carry and store materials and to keep stray items about the home. The plant life available in a region affects the choice of material, which in turn influences the weaving technique. Rattan and other members of the Arecaceae or palm tree family, the thin grasses of temperate regions, and broad-leaved tropical bromeliads each require a different method of twisting and braiding to be made into a basket. The practice of basket making has evolved into an art. Artistic freedom allows basket makers with a wide choice of colours, materials, sizes, patterns, and details.Before the advent of plastics (1907), the is now used for many different types and styles of storage container rattan, wicker or cane was used to make containers with a lid for the storage of linens etc. The subject item was probability used at the end of the Victorian era and into the Edwardian period around the 1900s as a household storage facility. These types of wicker or cane containers started to go out of fashion due to their fragility around the 1920s into the 1940s due as well to the introduction of synthetic materials. Wicker cane rectangular shaped domestic storage container with reinforced leather pads on 4 corner sides. lid fits inside the other. Black cane piece around top edge.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

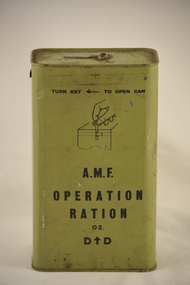

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Container - World War 1939-45 Ration pack, c1940

AMF Operational Ration This ration pack was developed by Sir Stanton Hicks. It contained three meals, each waterproofed (a vital consideration for the tropics), which offered a balanced selection of meat, vegetables, fruit and vitamin supplements. Before the development of this ration pack, Australian soldiers were supplied with quantities of preserved food that were difficult for a man to carry and divide, and which often did not provide a nourishing diet. Sir Cedric Stanton Hicks (1892-1976), university professor and army catering officer, was born on 2 June 1892 at Mosgiel, New Zealand. University of Otago (B.Sc., N.Z., 1914; M.Sc. Hons, 1915; M.B., Ch.B., 1923) 1916-18 Hicks served as a non-commissioned officer in the New Zealand Expeditionary Force and he assisted Professor J. K. H. Inglis in the synthesis and production of Chloramine-T for use against meningitis among the troops. Hicks was appointed government analyst in 1918. On a Fellowship 1923, he travelled to England and studied at Trinity College, Cambridge (Ph.D., 1926) and caried out research in Switzerland, Germany and the United States of America. 1927 he was appointed to the new chair of physiology and pharmacology at Adelaide University, which he was to hold until 1957. During the Depression he studied the dietary patterns of five hundred families receiving relief. 1940 Hicks was appointed temporary captain, Australian Military Forces, and performed part-time duty as catering supervisor. Moved to Melbourne as chief inspector of catering, he began a campaign for applying scientific principles to the feeding of troops. 1943 the Australian Army Catering Corps was formed. Hicks altered the basis of the allowance for military rations from a monetary to a nutrient entitlement, improved the pay and promotion opportunities of cooks, established schools of cooking and catering, devised new methods for preparing food, supported the service's adoption of the Wiles steam-cooker, and designed jungle-patrol, emergency and air-drop rations. His 'Who Called the Cook a Bastard?' (Sydney, 1972) gave an account of his experiences in military catering.Men from most families in the City of Moorabbin area served in the Australian Military Forces during World War 2.A tin container , khaki colour, used for the storage of a food ration item for a soldier serving in the Australian Military Forces World War 11.TURN KEY ← TO OPEN CAN / diagram of key / A.M.F. / OPERATION/ RATION/ 02 / D↑Dworld war 11, australian military forces, sir cedric stanton hicks, army catering corps, soldier rations, food supplys, australian diggers, food preservation -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Container - Griffiths Tea Canister, 1900-1940

In 1873 James Griffiths migrated to Melbourne in order to start a tea Business. James lived in the Dandenongs at The Basin where he experimented with growing tea. Griffiths made tin canisters in the 2lbs size for their tea with common kitchen consumables listed on the front . The tins, when emptied, became useful kitchen canisters and helped promote the brand. Example of the names include Flour, Rice, Sugar, Sago, Candied Peel, Tapioca, Spices, Starch, Biscuits, Currants, Barley, String and of course Tea .Food storage rectangular tin, with a hinged lid. The outside is printed in cream and red with the name 'Griffith's Teas' and the word 'SAGO'. The text is set against a cream panel which is bordered with a decorative border of Australian native flora. The whole is set against a dark green background.On each other side of the tin is a different native Australian flower. The lid is impressed with a flannel flower.Printed on the front 'SAGO', also printed on the front and repeated on the top 'USE / GRIFFITHS' Teas / SYDNEY / MELBOURNE. ADELAIDE. BRISBANE'. On the front is the image of a train signal with the words 'SIGNAL / TRADE MARK'tea, james griffiths, canisters, city of moorabbin, cheltenham, melbourne, moorabbin, grocery stores, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Preserving Jar, 1932-1948

The Mason jar, named after American tinsmith John Landis Mason, who patented it in 1858, is a molded glass jar used in home canning to preserve food. The jar's mouth has a screw thread on its outer perimeter to accept a metal ring or "band". The band, when screwed down, presses a separate stamped steel disc-shaped lid against the jar's rim. An integral rubber ring on the underside of the lid creates a hermetic seal. The bands and lids usually come with new jars, but they are also sold separately. While the bands are reusable, the lids are intended for single-use when canning. Glass jars and metal lids are still commonly used in home canning while they have been largely supplanted by other methods for commercial canning (such as tin cans and plastic containers). Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset.Clear glass preserving jar "Agee Special" with metal screw lid grooved base for lid clip "AGEE Special MASON / JAR" imprinted into side of glassflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jar, glass jar, preserving jar, food preserving, food storage, agee mason, agee mason jar, john landis mason, agee special -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Preserving Jar, 1932-1948

The Mason jar, named after American tinsmith John Landis Mason, who patented it in 1858, is a molded glass jar used in home canning to preserve food. The jar's mouth has a screw thread on its outer perimeter to accept a metal ring or "band". The band, when screwed down, presses a separate stamped steel disc-shaped lid against the jar's rim. An integral rubber ring on the underside of the lid creates a hermetic seal. The bands and lids usually come with new jars, but they are also sold separately. While the bands are reusable, the lids are intended for single-use when canning. Glass jars and metal lids are still commonly used in home canning while they have been largely supplanted by other methods for commercial canning (such as tin cans and plastic containers). Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset.Clear glass preserving jar "Agee Special" with metal screw lid grooved base for lid clip "AGEE Special imprinted into side of glassflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jar, glass jar, preserving jar, food preserving, food storage, agee mason, agee mason jar, john landis mason, agee special -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Fruit Preserving Jar, John Landis Mason, 1858-1910

The Masons patent of Nov 30th, 1858 phrase was originally embossed on countless glass fruit jars and canning jars, most ranging in age from circa 1858 to the mid-1910s. John Landis Mason was awarded patent No 22186, issued on November 30, 1858, by the U.S. Patent & Trademark Office it was termed an "Improvement in screw-neck bottles", for his invention concerning the process of creating a threaded screw-type closure on bottles and jars. Similar screw-threading had been done before on some bottles, but the process of forming the upper lip area of the container so that it was smooth, even, and sturdy enough for a lid of standard size to be screwed thereon was difficult and expensive to do properly, often with unsatisfactory results. His improvement revolutionized home canning in the United States and many other countries. In any case, throughout the next 60-odd years, production of jars with the Nov. 30, 1858 embossing continued at a high rate, with untold tens of millions being produced. The phrase was soon considered an important marketing device, adding to the perception of quality and reliability of the container to the average consumer. This perception continued to at least 1879 21 years after the patent was issued, nearly every glass bottle factory was likely producing their version. The 1880s and 1890s likely saw the peak of popularity of these jars. A considerable percentage have a mold number or letter on the base, a means of identifying the particular mold in use at the factory.An early item used in most kitchens by women who preserved fruit and vegetables before the arrival of refrigeration giving a snapshot into the domestic lives of families during the late 19th to early 20th century's and how they preserved food for later use without refrigeration. Preserving jar, glass, with metal screw top lid. Glass has side seams, impurities and slightly concave base. It has been hand blown into a mould. Inscription is moulded into glass. Moulded into glass: MASON'S / PATENT / NOV 30TH / 1838"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, food preserving, mason jar, john landis mason, domestic container, glass jar, fruit & vegetable jar, domestic jar, food preparation, handmade glass, blown glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Fruit Preserving Jar, John Landis Mason, 1858-1910

The Masons patent of Nov 30th, 1858 phrase was originally embossed on countless glass fruit jars and canning jars, most ranging in age from circa 1858 to the mid-1910s. John Landis Mason was awarded patent No 22186, issued on November 30, 1858, by the U.S. Patent & Trademark Office it was termed an "Improvement in screw-neck bottles", for his invention concerning the process of creating a threaded screw-type closure on bottles and jars. Similar screw-threading had been done before on some bottles, but the process of forming the upper lip area of the container so that it was smooth, even, and sturdy enough for a lid of standard size to be screwed thereon was difficult and expensive to do properly, often with unsatisfactory results. His improvement revolutionized home canning in the United States and many other countries. In any case, throughout the next 60-odd years, production of jars with the Nov. 30, 1858 embossing continued at a high rate, with untold tens of millions being produced. The phrase was soon considered an important marketing device, adding to the perception of quality and reliability of the container to the average consumer. This perception continued to at least 1879 21 years after the patent was issued, nearly every glass bottle factory was likely producing their version. The 1880s and 1890s likely saw the peak of popularity of these jars. A considerable percentage have a mold number or letter on the base, a means of identifying the particular mold in use at the factory.An early item used in most kitchens by women who preserved fruit and vegetables before the arrival of refrigeration giving a snapshot into the domestic lives of families during the late 19th to early 20th century's and how they preserved food for later use without refrigeration. Preserving glass jar. Glass lip with metal screw top lid. Inscription pressed into glass."Mason's Patent Nov 30th 1858"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, food preserving, mason jar, john landis mason, domestic container, glass jar, fruit & vegetable jar, food storage, preserving jar -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1870s-1910s

... collection. The salad oil bottle is an example of the type of food ...This clear, green tinged, Half Whirley (or Whirly) salad oil bottle has been handmade by a glassblower from 1870s-1910s. A bottle with such elaborate decoration would have been sought after as there was no need to decant the sauce into another jug or bottle to make it acceptable for table service. It is possible that this bottle was recovered from the Loch Ard, wrecked in 1878. A diver found the bottle on a shipwreck in the coastal waters of Victoria about 100 years from when it was made. The diver who found this bottle has recovered objects from several different shipwrecks between the late 1950s and early 1970s. A sizeable proportion of those objects was from the wreck of the famous clipper ship Loch Ard. This salad oil bottle may very well have been amongst that ship’s cargo. It is part of the John Chance Collection. A paper titled ‘Glass Bottles from the Loch Ard Shipwreck (1878): A Preliminary Study’ by Iain Stuart, (published in Australian Historical Archaeology, 9, 1991) included a study of twelve salad oil bottles from the wreck of the Loch Ard. The bottles were of this same Half Whirley design (half meaning that it was Whirley on the upper half but not on the lower half of the body), as well as the same colour and size. A diagram of one of these twelve bottles matches the bottle in our collection. The paper mentions that eleven of the twelve bottles have a number on their base, just as this one has. It is estimated that foreign and salad oil bottles totalled four percent of all of the bottles carried as cargo on the ship. The Half Whirley bottle has side seams from below the lip to the base, indicating that the bottle was made in a two-piece mould that included the heel, body, shoulder and neck. The fancy ‘whirly’ twist pattern and panelled sides would have been cut into the mould’s inner surface. The uneven thickness of the ridge around the base comes from adding a separately moulded and embossed base after the bottle was removed from the mould. The applied finish (mouth and lip) was also added to the bottle. The elongated bubbles in the glass are evidence of the glass being mouth blown into the mould, thus forming the shape and pattern from the inside shape of the mould. The bottle probably had a glass stopper with a round top and wedge-shaped shank with a ground surface, allowing the bottle to be re-sealed. The ring between upper and lower lip allows the closure to be sealed and anchored. The embossed numbers are either “133” or “833” and may represent a particular bottle pattern, manufacturer or filler. Although the bottle is not currently linked to a particular shipwreck, it is recognised as being historically significant as an example of bottles imported for use in Colonial Victoria in the mid-to-late 19th century. This whirley salad oil bottle is matches the whirley salad oil bottles recovered from the Loch Ard in the 1990s, adding depth of interpretation to the array of salvaged Loch Ard artefacts in Flagstaff Hill’s collection. The salad oil bottle is an example of the type of food condiment containers that were used in Victoria’s early days. The bottle is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks, including the Loch Ard, have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Bottle; glass Half Whirley salad oil bottle, green-tinged, with some opalescence. Handmade, elaborately decorated bottle with round neck and base, and five-sided body. Applied double lip; straight upper, flared lower. The lower neck and shoulder have twisted spiral whirley patterns in the glass. The body tapers slightly inwards towards the base. It has five plain panels, one wider than the others. Side seams run from below the lip to the heel. The heel of the bottle is uneven in width, height and density where it joins the body of the bottle. The base is not level. Embossed characters on base. Glass has elongated bubbles towards the base and orange-brown sediment inside, on one side. Embossed "133" or “833” (the first character may be an “8”) flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, handmade, mouth blown, blown bottle, 19th century bottle, collectable, bottle, green glass, tinged green, two piece mould, food bottle, oil bottle, salad oil bottle, whirley, whirly, half whirley, condiment bottle -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - PEWTER TANKARD: JAMES YATES

Pewter Tankard. (previously #100 from mechanics Institute Eaglehawk) Damaged upper rim. 16cm high, inscribed ' James Yates' QUART. See research tab. Also impressed into side Crown, E 7, VIC.domestic equipment, food consumption, tankard -

Bendigo Historical Society Inc.

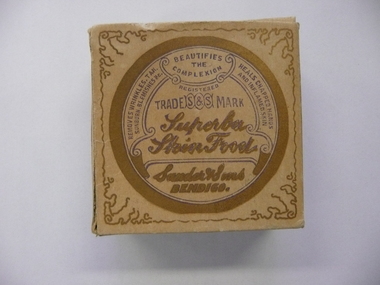

Bendigo Historical Society Inc.Container - SUPERBA SKIN FOOD

... sheet. Container SUPERBA SKIN FOOD ...Small round tin in original box, containing Superb Skin Food, sole manufacturers Sander & Sons Bendigo, Vic, Australia. With directions sheet.Sander & Sons Bendigopersonal effects, cosmetics, cream -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - SPICE SET

... DOMESTIC EQUIPMENT Food storage & preservation kitchen Tin ...Tin container labelled on lid in red, Spices, decorated in gold with flowers, containing six round gold tins marked nutmeg, cinnamon, ginger, allspice, cloves and pepper.domestic equipment, food storage & preservation, kitchen -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CHOCOLATE BOXES COLLECTION: CADBURY'S KING GEORGE CHOCOLATE BOX

... DOMESTIC EQUIPMENT Food storage & preservation container chocolate ...White cardboard Cadbury's King George chocolate box with brass clasp & gold lettering on lid.Cadbury, Bournville, Engdomestic equipment, food storage & preservation, container chocolate box -

Bendigo Historical Society Inc.

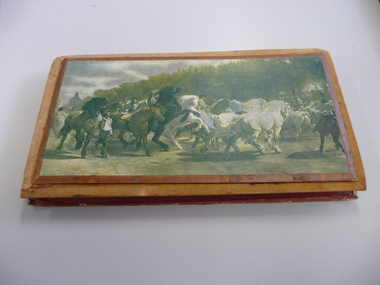

Bendigo Historical Society Inc.Container - CHOCOLATE BOXES COLLECTION: MACROBERTSONS CHOCOLATE BOX

... DOMESTIC EQUIPMENT Food storage & preservation container chocolate ...Large rectangular MacRobertsons chocolate box with scene of men with horses, mounted on gold velvet lid with a burgundy iridescent base in a grape & vine pattern.This box made by MacRobertson Fitzroy Melbournedomestic equipment, food storage & preservation, container chocolate box -

Bendigo Historical Society Inc.

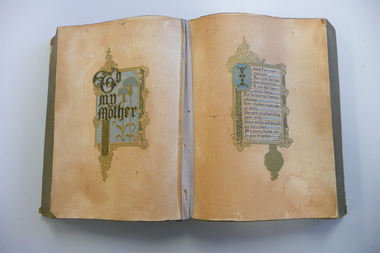

Bendigo Historical Society Inc.Container - CHOCOLATE BOXES COLLECTION: CHOCOLATE BOX IN THE SHAPE OF OPEN BOOK

... DOMESTIC EQUIPMENT Food storage & preservation container chocolate ...Carboard chocolate box in shape of an open book with blue, black & gold inscription, To my Mother on one side and a poem on the other.domestic equipment, food storage & preservation, container chocolate box -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Container - CHINESE SEWING BASKET, 1900-1940

Large round rattan Chinese sewing basket with lid, woven inside with reddish tones.domestic equipment, food storage & preservation, chinese