Showing 174 items

matching furnaces

-

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - colour, Clare Gervasoni, Furphy Water Cart, 2014, 01/11/2014

The water cart was in itself a complete invention of John Furphy and was first made in the 1880's. At the time no similar article was used in Australia. Few houses of the time were designed to collect rain water from the roof and hence, water needed to be collected elsewhere and transported for stock and domestic use. The method of carting water was then confined to horse drawn drays or sleds with mounted wooden barrels or casks. At the same time the growing demand for agricultural implements, led to the establishment of a foundry with a furnace to cast components rather than the time consuming task of forging. This became the catalyst for the efficient production of the robust and mobile water carrier known then, and now, as the Furphy Farm Water Cart.Four colour photographs showing a tank made by Furphy and Sons, Shepparton.furphy, shepparton, water storage -

Federation University Historical Collection

Federation University Historical CollectionBook, American Institute of Mining Engineers, Transactions of the American Institute of Mining Engineers, Vol 1, 1871-1873

Meetings of the institute were held in Wilkes-Barre, Bethlehem, Troy, Philadelphia, New York, Pittsburgh and Boston.Red hard covered book. Contents include: * List of members * Geological Distribution of MIning Districts in the United States (R.W. Raymond) * The Relation between the Speed and Effectiveness of Stamps (R.W. Raymond) * Remarks on the Waste in Coal-Mining (R. P Rothwell) * An Eccentric Theodolite (Francis Vinton) * The Use ad Advantages of the Prop Srew-Jack (E. Gaijot) * The Manufacture of Iron and Steel Rails ( John B. Pearse) * The importance of Surveying in Geology (Benjamin Smith Lyman) * Use of Blast-Furnace Slag (T. Egleston) * The Geonostical History of Metals (T. Sterry Hunt) * The Mining and Metallurgical Laboratories of the Massachusetts Institute of Technology (Robert H. Richards) Stamped "Department of Mining University of Melbourne"american institute of mining engineers, mining engineering, prop screw jack, mining districts in the united states of america, waste inn coal mining, lehigh zinc company, lake superior copper districtblast furnace, rolling versus hammering ingots, indianablack coal, pig-iron, longwall system of mining, wickersham process, midlothian colliary, virginia, plummet lamp, diamond drills -

Federation University Historical Collection

Federation University Historical CollectionBooklet, South Australian School of Mines and Technological Museum Annual Report, 1909, 1909

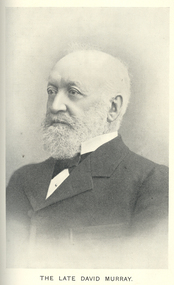

.3) South Australian School of MInes and Technological Museum Annual Report for 1908 and Prospectus for 1909. Includes images of the School Council (H. Adams, E.A. Roberts, E.W. Van Senden, Hon. Sir J. Langdon Bonython, Hon. Sir F.W. Holder, Hon. D.M. Charleston, Professor W.H. Bragg, J. Theo Scherk. L. Grayson, J.G. Bice, W.H. Matthews), The School, Plans of the Metallurgical and Chemical Laboratories, Physics Students, Assaying Furnace Room, David Murray, Museum, Noyes Electrical Engineering Laboratory, Model Scouring Plant at the Angas Wool laboratory, Sir George Ruthven Le Hunte, Wet Assay Laboratory. Electro-Technical Room.south australian school of mines, museum, e.a. roberts, e.w. van senden, hon. sir j. langdon bonython, hon. sir f.w. holder, hon. d.m. charleston, professor w.h. bragg, j.g. bice, w.h. matthews), the school, plans of the metallurgical and chemical laboratories, physics students, assaying furnace room, david murray, noyes electrical engineering laboratory, model scouring plant at the angas wool laboratory, sir george ruthven le hunte, wet assay laboratory. electro-technical room., h. adams, j. langdon bonython, f.w. holder, d.m. charlston, w.h. bragg, j. tho scherk, l. grayson, ruthven le hunte, south australia, schools of mines -

Stawell Historical Society Inc

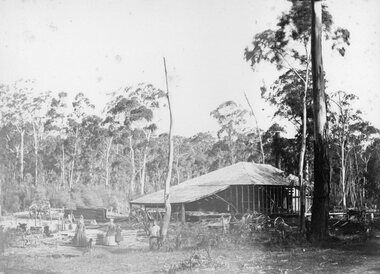

Stawell Historical Society IncPhotograph, Saw Mills at Childe’s Glenbower Creek in Halls Gap 1866

Saw Mills Halls Gap (Childe’s Glenbower Creek). Part of a collection of Photographs by Mr. O.G. Armstrong as commissioned by the Shire of Stawell for the Inter-colonial and Paris Exhibition in Melbourne in 1866. During the years of gold, the hardwood forests around Stawell were ravaged to provide timber for the mines. It was used undergrounds to shore up workings, and millions of feet of it were fed into furnaces and kilns in which the quartz was roasted. In the years after the gold boom, hardwood from the Grampians was milled for building timber. Wherever there are large tracts of natural bushland, fires are always a danger. A huge fire in January 1939 caused havoc in the Grampians, burning out towns and sawmills such as the one pictured. There have been no sawmills in the Grampian since that fire. stawell industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, solid colour brown glass,concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. Label "c.1850's STUBBY ALE", "ENGLISH HAND MADE, CORK & WIRE SEAL", "PONTIL MARK ON BASE $6" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020 The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, opaque brown glass, concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. "STUBBY 1850-1900 SMALL SIZE", ENGLISH 3 PIECE MOULD, HAND MADE TOP", "PAPER LABEL, CORK & WIRE SEAL $6flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - COSTERFIELD SMELTING AND REFINING CO WORKS

Three Auction catalogues with greenish covers for a sale on 3rd July, 1941 at the Costerfield Smelting and Refining Co. Works, Costerfield of Machinery, Plant & Equipment comprising - 4 Diesel Engines, Jaques Crusher, 2 Boilers, Chilian Mill, Huntington Mill, 2 Steam Engines, Blast and other Furnaces, Exhaust Fan, Lighting Plant, Cyanide Plant, Pumps, Buildings, Piping, Tools, etc. One copy has 'Marked Catalogue' written across the top of the front cover. Some of the lots have the price written beside them, some have a note and some prices are written on the right side of the page. Signed at the end - J. H. Curnow & Son 21/7/41. J. H. Curnow & Son were the auctioneers and the Cambridge Press were the printers of the catalogue.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - costerfield smelting and refining co works, j h curnow & son, j l jamieson, the cambridge press -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - Seal Embossing Press

The Corona Paint Company Pty. Ltd. Bendigo was formed in November 1920 with £10,000 capital, in £1 shares. By July 1921, the Company had completed its factory and plant at Bendigo East, ready to begin the manufacture of paints. The Corona Paint works were opened on Saturday 28 January by the Prime Minister (Mr. Hughes) during a visit to Bendigo. Many new manufacturing industries were opened during this time after calls to address the decline of mining in the region. The factory of the CORONA PAINT COMPANY, BENDIGO, was advertised for sale in The Argus on 5 October 1923. It consisted of a “building on a railway siding, plant and machinery, including dry grinding plant, kalsomine mixer, paint mill, furnace, electric motor, etc., large stores of raw and finished material, kalsomine with range of 21 colours, oil paints, &c.”A cast iron embossing press. It's painted black with gold coulered floral decorations. The base is 18 centimetres long, nine centimetres wide and one and a half centimetres thick. A curved protrusion rises from the base that is eight centimetres by four centimetres which narrows to four centimetres by two and a half centimetres with a three-quarter centimetre wide slot. Inside the slot is a lever action with a ten centimetre by two and a half centimetre wooden handle. There is a removeable die on the end of the lever and an opposite removeable die the base. A small oval metal disc with paten no 3965 on is attached. The seal is The Corona Paint Company proprietary Limited seal embossing press, corona paint company -

Federation University Historical Collection

Federation University Historical CollectionBook - Catalogue, Price List of Assay Material, Balances, Chemical & Scientific Apparatus and Pure Chemicals, Fourth Edition, c1905

... furnaces ...Red hardcovered 110 page catalogue from the Felton, Grimwade & Co.. Includes numerous line and photographic illustrations.non-fictionj.w. glover, john w. glover, assay, chemistry, mining, felton grimwade & co, assay moulds, tongs, tools, balances, oertling, balance weight, compressed oxygen, crucibles, furnaces, muffles, scales, hammers, gas burners -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaPrint - Digital collage, 586, Captured, 2011

"Art is the vehicule for communications far Beyond the confines of a space, while design is the aesthetic cradle in which messages are nurtured and processed." "A 586 rework of the iconic building that has withstood the redevelopment of the Melbourne Docklands and defied the odds. On display a large format print 700mm x 1400mm print. Also a limited run of smaller prints on archival paper also available to support Melbourne's first non-profit charitible organisation that is still self funded, ie. not government funded." During the Open House Melbourne 30-31 July 2011, the artist nicknamed "586" participated in one of the Norla Dome Project Space events sponsored by Bendigo Wealth. Made in Melbourne, 586 is an urban digital experimentalist who blends social narrative with found image creating messages that inspire social consciousness and free thought. Cast in a local foundry back in 1991, 586 was a number, amid hundreds of men working between the ladie and the furnace in a clock on - clock off automated industrious landscape. Legend tells of a time when correspondance to workers was addressed to their number, not their name. Disapproval spread rapidly and a revoit soon followed, eventually the power of the masses won out, but the demoralizing treatment of the worker would go on to shape 586's perception and became the catalyst for a personal protest against social imbalance. This print was on display and smaller prints were also sold to raised funds for the Mission.DigitalLarge digital print of a design that overlays various symbols ( 4 flying angels ), the sails of a sailing ship and contemporary cityscapes and seascapes. centrally features a full photograph of the Mission to seafarers building at 717 Flinders St. Melbourne. Mounted in a large black frame and glazed with perspex .mission to seafarers, flinders street, melbourne, windvane, dome, flying angel, sea, norla dome, bendigo wealth, artist 586, 2011, artwork-paintings, open house, norla dome project space -

Bacchus Marsh & District Historical Society

Bacchus Marsh & District Historical SocietyCeramic, Tile manufactured by Darley Firebrick Company

The manufacture of firebricks is believed to have begun in Bacchus Marsh in the 1880s when William Thomas Wittick in partnership with a Mr Ackers, and later a Mr Telford, quarried a rich deposit of fire clay at Darley. In 1902 financial assistance was provided by David Mitchell a significant businessman and contractor from Melbourne and the business then expanded and became a major supplier of refractories for gas works in Melbourne, with side lines in moulded fire bricks for foundries and smelting furnaces and complete kiln lines for potteries. The business traded under the name Darley Firebrick Company and later as Darley Refractories Ptd Ltd and was in business for over 100 years. The tile (aka refractory) described in this record was possibly produced for use in very high temperatures (in excess of 1,000°F [538°C]) encountered in modern manufacturing. More heat-resistant than metals, they are used to line the hot surfaces found inside many industrial processes. The date the tile was produced is unknown.Rectangle shaped ceramic tile'Darley 26' inscribed within a circledarley firebrick company, refractory materials, wittick family bacchus marsh, william thomas wittick 1857-1939, darley refractories ptd ltd -

Puffing Billy Railway

Puffing Billy RailwayEquipment - Victorian Railways Carriage Foot Warmer

During prestige, long distance train journeys some carriages had air-conditioning, and the majority of passengers had to brave unheated carriages. To offer some comfort during the winter months, the non-air-conditioned carriages were provided with footwarmers. These were metal containers roughly 100 mm thick and 300 mm wide, and about 750 mm long, which were filled with salt crystals (concentrated crystalline hydrated sodium acetate). The footwarmers were covered by sleeves of thick canvas, and two footwarmers were usually placed in each compartment of non-air-conditioned carriages. To activate the chemicals, the footwarmers were heated almost to boiling point. This was done by removing the canvas sleeves and placing the footwarmers in a large bath of very hot water. After they had been heated, they were removed from the bath and the sleeves refitted. They were then ready to be placed in the carriages. The McLaren patent foot warmer was used on railways in New South Wales, Queensland, Victoria and South Australia as well as South Africa and New Zealand. It was during the 1901 royal visit by the Duke and Duchess of Cornwall that these foot warmers were first used in New Zealand in the royal carriage. Before railway carriage heating was introduced, McLaren patent foot warmers were placed on the floor of New South Wales government railway carriages from 1891 to provide a little passenger comfort. The rectangular steel container worked a bit like a hot water bottle but instead of water contained six and a half kilograms of loosely-packed salt crystals, (concentrated crystalline hydrated sodium acetate). This was permanently sealed inside the container with a soldered cap. After the foot warmer was heated in vat of boiling water for about one and a quarter hours the crystals became a hot liquid. (The melting point for sodium acetate is 58 degrees). There was a whole infrastructure of special furnaces set up at stations for the daily heating of foot warmers. By 1914 the Victorian railways had 4,000 foot warmers in service and by 1935 there were 33 furnaces at principal stations to heat them. After about 10 hours the container was picked up by the handle and given a good vertical shake which helped the cooled liquid reform into a solid mass of hot crystals. Staff or sometimes passengers shook them en route when the foot warmers began to get cold. However, as they were heavy this was only possible by fit and agile passengers. At the end of the journey the containers were boiled again for reuse on the next trip. Sodium acetate railway foot warmers were introduced in Victoria in 1889, Adelaide to Melbourne express in 1899. "Shaking up" on this service took place at Murray Bridge and Stawell on the tip to Melbourne and at Ballarat and Serviceton on the trip to Adelaide. The use of foot warmers began to decline in New South Wales from the 1930s with the first trial of carriage air-conditioning in 1936, steam heating from 1948 ad LP gas heating from 1961. By the early 1960s the main services using foot warmers were the overnight mail trains. info from : http://www.powerhousemuseum.com/collection/database/?irn=67564#ixzz4UBNzVf6t Under Creative Commons License: Attribution Non-Commercial There was a whole infrastructure set up at stations for the daily heating of foot warmers in special furnaces. In Victoria alone in 1935 there were 33 heating works.Historic - Victorian Railways - Carriage Heater - Foot warmerA rectangular-shaped stainless steel casing with a welded seam down the back and welded ends. There is a handle at one end for carrying and shaking. Inside the foot warmer are two baffle plates and three trays to contain the sodium acetate. There was a cast-iron ball in each internal compartment. puffing billy, victorian railways, carriage haeter, foot warmer, passenger comfort, station furnace, railway ephemera, early heating methods -

Federation University Historical Collection

Federation University Historical CollectionBook, Australasian Institute of Mining Engineers, Transactions of the Australasian Institute of Mining Engineers, Volume X, 1905, 1905

Fabric covered hardcovered book of 367 pages. Includes a number of pullout plans. Contents * Mount Lyell Mining Field Tasmania by Professor J.W. Gregory * Concentration of solver-led ores (with 6 plates) by V.F. Stanley Low * Phosphate Deposites of Ocean and Pleasnt Islands (with 15 plates) by F. Danvers Power * Coal and Coal Mining in New SoPleassant Isuth Wales by Thomas Parton * Method of TImbering at the Mount Rex Tin Mne, Ben Lomand, Tasmania by Mark Ireland * Peck's Centrifugal Elevator by W. Peck * A Portable Assay Furnace by J.J. Gillio * NOtes on Sampling by A.C. Thomas * The Career of the Gold Dredge i n New South Wales by David K. Blair * The Transmission of Power by COmpressed Air in Mines by R.W. Chapman * The Misplacement of Mning Shafts and Adits in Victoria (with 7 figures) * The Indicators of the Daylesford Gold Mines, Victoria * Mining Accounts by R.N. Kirknon-fictionausimm, a.s. kenyon, frank a. moss, mount lyell, j.w. gregory, coal, gold dredge, transmission of power, mining shaft audits, daylesford gold mines, spitzkastens, ocean island banaba, pleasant island nauru, pinnacles on flat reef pleasant island, ocean island, blow hole howe bay, rock phosphate, thomas parton, mark ireland, mount rex tin mine, ngapara dredge, w. peck, w.h. vale, daylesford, jim crow diggings, glenmona gmc, f. danvers power, leigh g. hancock, workers' industrial union of australia (barrier district) -

Orbost & District Historical Society

Orbost & District Historical Societyblack and white photograph, 1924

This photograph shows the main road near Bellbird, East Gippsland, in 1924. This road would have been the Princes Highway, a main thoroughfare through to New South Wales. Bellbird Creek is a small rural location between Orbost and Cann River. There was no township at Cabbage Tree at this time. The Cabbage Tree Creek township was established to support the booming timber industry of the mid 20th century. Five timber mills worked full time supporting the families that were drawn to the area's wealth of natural resources. Nestled on the banks of the Cabbage Tree Creek, the township was built by those mills to house their workers. Today although the timber mills have disappeared, some of the buildings still remain. Little now remains to remind of the saw-milling history apart from photographs and some relics - a boiler and a brick furnace. There was also a thriving agricultural community farming dairy, beef, seed beans and fresh peas and beans that were sent to the Victoria Market in Melbourne. Dairy farming still plays an essential role in the township. this is a pictorial record of the Princes Highway, the main road from East Gippsland to the New South Wales border.A large black / white photograph of a very wet and boggy bush road.on front - "Main Rd near Bellbird 1924"road princes-highway bellbird-creek-1924 -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence, James Oddie, Statement from James Oddie, 09/06/1886

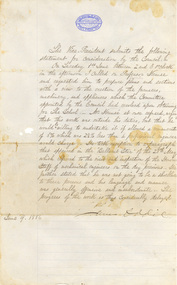

James Oddie was Vice-President of the Ballarat School of Mines in 1886.Blue, lined, foolscap paper from Ballarat School of Mines Logo. It is handwritten by James Oddie for the Ballarat School of Mine Council and is in regards to the duties of Professor Ferdinand Krause."The Vice-President submits the following statement for consideration by the Council: - On Tuesday 1st June between 2 and 3 o'clock in the afternoon I called on Professor Krause and requested him to prepare plans and sections with a view to the erection of furnaces, machinery, and appliances which the committee appointed by Council had resolved upon obtained for the School. Mr Krause at once refused, urging that this work was outside his duties, but that he would be willing to undertake it if allowed a remuneration of 5% which was 2 1/2 % less than a professional engineer would charge. He took exception to a paragraph that appeared in the "Ballarat Star" of the 28th May which referred to the visit and inspection of the Honorary Staff or mechanical engineers on the day previous. He further stated that he was not going to be a shoeblack to these persons and his language and manner was generally offensive and insubordinate. The progress of the work is thus considerably delayed. James Oddie"ballarat school of mines, oddie, krause, mining, furnace, james oddie, ferdinand krause -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Hematite (iron oxide)

Hematite is an iron ore significant for its high iron content (70%) and as being one of the two main iron oxide minerals, the other being magnetite. Hematite has a rating of 5-6 on the Moh's hardness scale and is often found as an accessory mineral in many igneous rocks. (an accessory mineral being "any mineral in an igneous rock not essential to the naming of the rock" - Britannica) Hematite has historically been the mainstay of South Australia’s iron ore production. (Magnetite: South Australia’s potential) Making up the eastern section of the Gawler Rangers, the Middleback Range is a mountain range on the eastern side of Eyre Peninsula in South Australia that has been a source of iron ore (its main commodity in minerals) for over a century. (see https://www.mindat.org/loc-22576.html). "Large reserves of high-grade iron ore were identified in 1890 in the Middleback Range, west of Whyalla. From 1915 these ores were shipped to Newcastle and later to Port Kembla, both in New South Wales. Local production of pig iron began when the first blast furnace was opened at Whyalla in 1941, and construction of an integrated iron and steel plant began there in 1958." (Britannica, South Australia: Resources and power). This area is home to 24 mines/mineral deposits (according to mindat.org, thought the Sarig Map provided by SA gov on their Energy and Mining website indicates significantly more mining leases).This mineral specimen was collected from the Middleback Ranges before the area was identified as holding large reserves of iron ore and being commercially mined and is representative of South Australia's significant and ongoing history of iron ore mining, and its contribution to Australia's steel manufacturing industry of the early 20th century (this specimen being collected in the prelude to these events).A small ferric oxide mineral composition a mid-blue-grey in colour with specks of rust-brown throughout.HEMATITE / (iron oxide) / Locality: Middleback Ranges, S. Aust.middleback ranges, iron ore mining, mining, south australia -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Federation University Historical Collection

Federation University Historical CollectionNewspaper, Lal Lal Iron and Coal as reported in the Ballarat Courier, 10/07/1923

.1) Pages 7 to 10 of the Ballarat Courier, 10 July 1923. Page 7 includes the article 'Cheap electricity' and poses questions such as 'should Ballarat look to Morwell for cheap power?', and should an independent power plant be installed at Crockers, Arnolds, Harry Hall, Ewins, Harry Davies, Fred Halls, The London Drapery there. Page 9 includes articles on Ripon's roads, Mount Cole Springs; Soldier Settlement Rates Beaufort; Creswick brass band Officers; Daylesford Road Deviation to Hepburn Springs; Dereel Public Telephone; State Electricity Supply for Beaufort; Newlyn Valedictory to Mr and Mrs W. E. Bennett Page 9 - Racing at Ascot; Avoca Golf Tournament, Chinese Herbalists Page 10 - Auctions and house sales Advertisements include Harry Davies; Fred Halls; C. Marks and Co., London Drapery, Creer the Cashman; Chamberlain's Cough Remedy; Cornell's Little Liver Pills; Paynes; W. Fley Chemist; Bickart and Dawson; Rivers; Allchin Bros; J. Bartam & Son .2) Ballarat Courier, 30 July 1937, page 1 and 2 Page 1 reports Lal Lal's Iron Ore Company being formed. Page 2 reports the Prospectus of the lal lal Iron and Steel Blast Furnaces Mining Company, No Liability; Mining News - Wattle Gully; Commercial News Advertisements include Crockers, Arnolds, Harry Hall, Ewins, Harry Davies, Fred Halls, The London Drapery electricity, lal lal, lal lal iron, lal lal coalfield, morwell, gippsland, crockers, arnolds, harry hall, ewins, harry davies, fred halls, the london drapery, lal lal brown coal, ripon's roads, mount cole springs, soldier settlement rates beaufort, creswick brass band officers, daylesford road deviation to hepburn springs, dereel public telephone, state electricity supply for beaufort, newlyn, w.e. bennett, ascot, avoca golf tournament, chinese herbalists, c. marks and co., london drapery, creer the cashman, chamberlain's cough remedy, cornell's little liver pills, paynes, w. fley chemist, bickart and dawson, rivers, allchin bros, j. bartam & son, lal lal iron and steel blast furnaces mining company, wattle gully -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph Album, Photographs of Ballarat Buildings by Geoff Biddington, 1967, 1967