Showing 194 items

matching machine manufacturer

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - SEWING MACHINE NEEDLE SAMPLE CASE

... and Manufacturers of sewing machine needles. Old Box 85.... and Sons Patentees and Manufacturers of sewing machine needles. Old ...Red coloured covered case with three panels with covers, silver lettering on front cover. Folded sample case with Card A, Card B, and Card C with samples of needles attached with sizes and recommended sewing machines and specialized usage for each needle. Needles manufactured by Woodfield and Sons Patentees and Manufacturers of sewing machine needles. Old Box 85.''W.Woodfield & Sons, Manufactures Redditch, England'' Easemore Works.domestic equipment -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - COHN BROTHERS COLLECTION: ANNUAL REPORT 1968

Cohns or Cohn Bros. Limited Annual Report 1968. Registered Office : Bridge Street, Bendigo. Soft drink manufacturers. Printed booklet twelve pages in length. Directors : Leo R. Cohn (Chairman), Jack M. Cohn (Managing Director), Clifford B. Cohn, Francis H. Cohn, Albert McB. Fairfoul, Richard N. Levy. Secretary : Valentine F. Moyle. Includes four photographs - Bendigo - soft drink factory, Bendigo - 60 head filling machine, Wangaratta - soft drink factory, and Wangaratta - syrup room.bendigo, industry, cohn bros., cohns. cohn bros. limited. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Machine - CAST IRON COFFEE GRINDER

Black Cast Iron Coffee Grinder With Circular Copper Bowl on top and a curved metal handle which is attached to a central grinding mechanism. Main body shape almost square tapers slightly closer to the top. Coffee grinder has a large pullout tray contained in the bottom of the mill. 140 cm High x 40 cm Wide Previous Catalogue Number 103 Inscription T & C Clark & Co Manufacturer Additional Inscription contained in an elliptical brass plaque Paris Silver Medal 1878 Awarded T. & C. Clark & Co. Plaque Also contains images of a replica of the Jules-Clement Chaplain Art Nouveau Designed Silver Medal Exhibition Prize, Consisting of a laureate bust of Marianne Facing Left surrounded by the words Republique Francaise. Beside It An Image of Victory Hovering Above The Exhibition Wearing A Laurel Wreath Blowing A Bugle Announcing Manufacturing Success & Excellence & Below Him Cupin (Child Genius) Holding A Banner With T & C Clark & Co. Around The Outside Edge Exposition Paris Universelle Internationale De 1878.T & C Clarke Manufacturerdomestic equipment, food consumption, coffee grinder -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1953

The Schneider ES50 Club was built in 1953 and is the only one of its type. It was designed by Schneider to comply with specifications laid down by the Gliding Federation of Australia for a basic two seat training glider*. It was first flown on 10 May 1953 and delivered to the Renmark Gliding Club. The log book shows that it later passed to other gliding clubs, namely Millicent Gliding Club, Corangamite Soaring Club, Sydney Technical College Gliding Club. Overall, as at September 1967, the glider had logged over 5000 flights and a total airtime of 388 hours. The Museum volunteers have partly refurbished the ES50 to static display standard. [*Plans were also prepared for a single seat version which never eventuated] This glider is one of Edmund Schneider Pty Ltd earliest Australian designs. However, it was a later Schneider design, the ES 52 Kookaburra, which was accepted by many Australian gliding clubs for filling their need for a basic two seat training glider in the 1950s and 1960s. This is a two seat high wing aircraft of mainly wood and fabric construction. The cockpit area of the fuselage is fabric over tubular steel framing. Given serial number 3 by manufacturer and registered as VH-GHPaustralian gliding, glider, sailplane, schneider, es50, renmark gliding club, millicent gliding club, corangamite soaring club, sydney technical college gliding club -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, 1963

This aircraft is one of 9 single seat ES 59 advanced club sailplanes manufactured by Edmund Schneider Pty Ltd in the 1960s. It was first flown in August 1963 and delivered to the Darling Downs Soaring Club at Toowoomba Queensland. At that Club it had 2603 flights and recorded a total airtime of 1475 hours. In addition to many local circuits and soaring and cross country flying, it was used at gliding competitions, including Nationals at Benalla in December 1964, State Championships at Oakey in April 1965, at Warwick in April 1966, and at (Inverell?) in March 1967. On at least 15 occasions flight times in excess of 5 hours duration were achieved. On 5 October 1970, the glider had a new life when it was relocated to Wollongong in New South Wales. It recorded 1927 flights with a total airtime of 1179 hours at the club between October 1970 and June 1988. Competition appearances included the State Championships held at Forbes in January 1972. Places away from Wollongong where the glider was launched include Cootamundra, Wagga, Temora, Marulon, Narromine, Leeton, Nowra, Goulburn, Horsham, Greenthorpe. On 15 June 1988 it was transferred to Ron Geake who transported it to Warrego in Northern Territory (flown once at Alice Springs), and then to Gympie in Queensland where it was flown about 20 times by the end of 1995. It was also flown on a small number of occasions at Forbes in New South Wales in 1996 and 1997. During 1998 and 1999 the glider was sparsely used (9 flights) at locations that have not been recorded. From May 1999 until transfer to the Australian Gliding Museum in May 2011 it apparently was not flown. Aggregate airtime hours for the glider stand at 2702 hours 53 minutes. It has been launched 4569 times. A good example of a Schneider ES59 sailplane from the 1960s. This type is of note because it was the first Australian designed and built sailplane to be used in a world gliding competition (Jack Iggulden in Argentina in 1963). This Schneider ES59 Arrow is a single seat wooden sailplane with one piece wing. The instruments are not present except for altimeter. Fin and rudder are of swept back design. Colour scheme is white with lemon yellow fuselage underbelly. The aircraft came to the museum on an open trailer that had been designed to carry the one piece wing. Plate in cockpit with details of manufacturer states; manufactured by E. Schneider Ltd, Adelaide SA; Type ES 59; Serial Number 62; Date August 1963.australian gliding, glider, sailplane, schneider, es59, arrow, darling downs soaring club, wollongong gliding club, ron geake -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumResistance Bridge Hartmann & Braun

Machined metal parts, polymer base, wooden box plinth. Uncoated metal, polished wood. Surface finish: wood varnish. [Stamped] on upper face, centre of front edge: Hartmann & Braun A.G./ Frankfurt a.M/ No 13881. [Stamped] on upper face, centre of back edge: Manufacturer’s symbol. Paint dot on upper face in top left corner approx. 0.7-1.0cm in diameter. -

Bendigo Historical Society Inc.

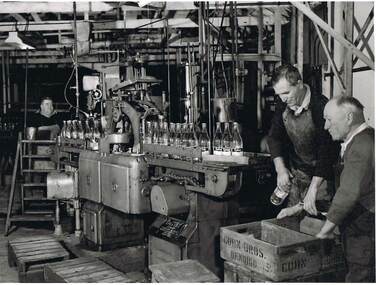

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: LABELLING MACHINE

Photograph. Cohn Bros. Collection. Black & white photo of a Bratby labelling machine. Bottles travel through the machine on a conveyor. One man is standing where the bottles enter the machine, another man is taking the bottles off the machine and packing them in wooden boxes. Another man is holding the box. There are a number of portable decking around the machine and a step ladder. ML45/5 (written on the back).organization, business, cohn bros, cohn bros. collection, labelling machine, brewers, cordial & aerated water manufacturers -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: BOTTLE WASHING MACHINE

Photograph. Cohn Bros. Collection. Black & white photo of two men taking the clean bottles off the machine and packing them into boxes. Bratby-Gem is the name on the side of the machine. ML45/4 (written on the back).organization, business, cohn bros, cohn bros. collection, bottle washing machine, brewers, cordial & aerated water manufacturers -

Bendigo Historical Society Inc.

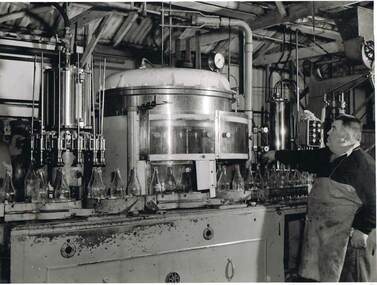

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: BOTTLE FILLING MACHINE

Photograph. Cohn Bros. Collection. Black & white photo of a man operating a bottle filling machine. The bottles travel on a conveyor to the filling point. They travel past a large container with a gauge on the top. There are other various pipes and pieces behind the man. He is wearing a bag apron tied up with string. ML45/3 (written on the back).organization, business, cohn bros, cohn bros. collection, bottle filling machine, brewers, cordial & aerated water manufacturers -

Bendigo Historical Society Inc.

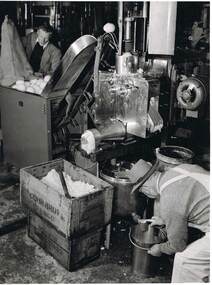

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: JUICING MACHINE

... & aerated water manufacturers juicing machine Photograph. Cohn Bros ...Photograph. Cohn Bros. Collection. Black & white photo of a juicing machine. One man is tipping a bag of fruit into the hopper. Another man is emptying the juice into a bucket. The fruit travels up a conveyor belt and into the machine where it is juiced and the pulp comes out a side chute into a box. ML45/2organization, business, cohn bros, cohn bros. collection, brewers, cordial & aerated water manufacturers, juicing machine -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MCCOLL, RANKIN AND STANISTREET COLLECTION: CENTRAL NAPOLEON GOLD MINING CO. N.L, 1934-1950

Pink Manilla Folder containing: General Correspondance Letters to and from suppliers of machinery and parts e.g. Electricity Supply Departments, Fred Milne & Son (Engineers), Thompsons Engineering & Pipe Co.Ltd, Miller & Co Machinery Pty Ltd, Alfred J Jorgenson, Bingle Machinery Co, The Richardson Gears Pty Ltd, Buckell & Jeffrey Pty Ltd, Commercial Union Assuarance Company Limited, Bendigo Machinery & Trading Co Pty Ltd, Ronaldson Bros & Tippett Pty Ltd (including a picture of a drawlift pump), J.G. Bloomfield, Ronaldson - Tippett list of 4583 Machines in Victoria & addfor crude oil engine, A.H McDonald & Co Pty Ltd & ad for crude oil engine, E Treliving letter & list of second hand materials for sale, J. Edwards-Retallack Machinery Manufacturers Representative, Hume & Iser Pty Ltd Timber & Hardware Merchants, Bendigo Timber Co Timber & Hardware Merchants, markings read 'Cent. Napoleon G.M.Co N.L Machinery', Correspondance dating from 16 July 1934 - 26 October 1950.organization, business, industrial - mining, mccoll rankin & stanistreet, mining, gold mining, central napoleon -

Puffing Billy Railway

Puffing Billy Railway1920's Station Cash Box Tin - Hobbs & Co London, 1920's

1920's Station Cash Box Tin Made by Hobbs & Co London Lever Machine Made Alfred Charles Hobbs (October 7, 1812 – November 6, 1891) was an American locksmith and inventor. Hobbs went to London as a representative of the New York company of Day & Newell, which was exhibiting at the Great Exhibition of 1851. Hobbs had brought with him his boss's (Robert Newell) Parautoptic lock, designed to compete with, and surpass, the locks available at the time in Britain. He was the first one to pick Bramah's lock and the Chubb detector lock at the Great Exhibition of 1851 and forced the lock manufacturers to improve their designs. The lock controversy continues a subject of great interest at the Crystal Palace, and, indeed, is now become of general importance. We believed before the Exhibition opened that we had the best locks in the world, and among us Bramah and Chubb were reckoned quite as impregnable as Gibraltar— more so, indeed, for the key to the Mediterranean was taken by us, but none among us could penetrate into the locks and shoot the bolts of these masters. The mechanical spirit, however, is never at rest, and if it is lulled into a false state of listlessness in one branch of industry, and in one part of the world, elsewhere it springs up suddenly to admonish and reproach us with our supineness. Our descendents on the other side of the water are every now and then administering to the mother country a wholesome filial lesson upon this very text, and recently they have been "rubbing us up" with a severity which perhaps we merited for sneering at their shortcomings in the Exhibition. In 1854 he was awarded a Telford Medal by the Institution of Civil Engineers for his paper 'On the Principles and Construction of Locks'. Sign on a strong room door. Hobbs became one of the founders of the lock making firm of Hobbs Hart & Co. Ltd. The company started in 1851 and was formally registered as Hobbs and Co. in 1852. But by 1855 it had become Hobbs, Ashley and Company. The name then changed to Hobbs, Ashley and Fortescue, with an address at 97 Cheapside in London. Then for the next ninety years the address was 76 Cheapside in London. In 1860 Hobbs returned to America and lived in Bridgeport, Connecticut, and went on to hold a dozen patents for firearm ammunition manufacturing. In 1880 he listed himself as a "Superintendent Of Cartridge Factory" Info from https://en.wikipedia.org/wiki/Alfred_Charles_HobbsHistoric - Railways - Station Cash Box Tin 1920's Station Cash Box Tin - Hobbs & Co London Metal Tin - painted Black, Gold and Red with Brass Lock and HandleHobbs & Co London Lever Machine Made1920's station cash box tin, puffing billy -

National Wool Museum

National Wool MuseumSample, Card Clothing

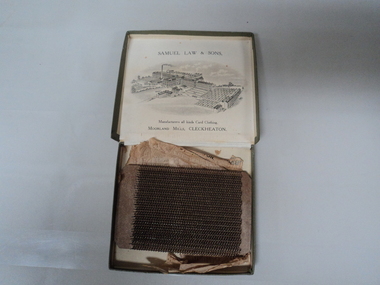

Card clothing sample manufactured by Samuel Law and Sons, Cleckheaton and probably sent to the Collins Bros Mill at the same time as W621. Card clothing is defined as 'the leather or other stiff material which holds the wire staples, the points of which project outwardly and form the carding teeth which operated on the fibres.' This fits into a carding machine ("The Textile Industries" vol. 8 - William S. Murphy, 1911).Card clothing sample, comprising rows of bent wires mounted on a thick rectangular leather base. Wrapped in tissue printed with an engraving of the factory where it was made and housed in an olive green lidded cardboard box, the interior of which is printed with an image of the manufacturer's factory.SAMUEL LAW & SONS, / Manufacturers all kinds Card Clothing. / Moorland Mills. / CLECKHEATON, England. SAMPLE OF CARD CLOTHING / FROM / SAMUEL LAW & SONS, / (branch of the English Card Clothing Company, Limited). / CLECKEATON. / MOORLAND MILLSsamuel law and sons collins bros mill pty ltd, carding, card clothing -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumStripper Harvestor, 1916

The first successful stripper harvestor ,a Nicholson & Morrow harvestor invented by James Morrow appeared at the Victorian Government trial at Dookie Experimental farm on Dec 27th 1883. Although the stripper harvestor was being manufactured in small numbers by the mid 1800's it did not take over from the tripper until 1904. Hugh McKay soon became the most successful manufacturer of stripper harvestors under the "Sunshine " name and by 1940 over 40,000 harvestors had been produced.This 1916 H.V. McKay harvestor Serial No.102736. The first machines looked like strippers ,but had a fan, sieves, elevators and a small grain storage bin.. The McKay Stripper Harvestor Sunshine -

National Wool Museum

National Wool MuseumPlaque - Donald & Sons Plaque, Donald & Sons Ltd, Unknown

Donald & Sons Ltd is a manufacturer and importer of wool presses and other machinery. Located in Masterton, NZ, they transported wool presses around the world. This plaque would have been attached to one of their machines.Gold colored organisational plaque with embossed lettering on the front, containing the organisation description.Donald & Sons Ltd Patentees, manufacturers and machinery importers. Masterton N.Z.wool press, new zealand, donald & sons -

National Wool Museum

National Wool MuseumTool - Knitting Pins, 1960-69

The donor (Lynn Fitzpatrick) purchased these knitting needles 20 years ago from an opportunity shop. Aero Knitting Pins are a discontinued brand that were popular in the 1960s, 70s and 80s. They are made of smooth, aircraft-quality anodized aluminium. To this day, they are a popular and sort after knitting needle. Being a long-lasting product, they are often given as heirlooms. Abel Morrall was a major needle manufacturer from Studley, a town near Redditch. In 1785, Michael Morrall who was taught the art of needle making by a maternal uncle, moved to Studley. He founded the Abel Morrall company with his brother Abel, and another unnamed brother-in-law. Within five years the company was producing 40% of the 2.5 million needles that were made each week in the Redditch area. In 1811 the company introduced the concept of creating the eyes by using a stamping press. Additional machines were invented by them throughout the 19th century leading to major improvements in the way needles were produced. Abel Morrall demonstrated their needle making machinery at the Great Exhibition of 1851 and Queen Victoria personally inspected it. The company selected the demi-griffin for its trademark in 1861, which can be seen on older products produced by the company. Set of four knitting needles stored within paper packaging. Packaging features black, red, and white ink, detailing the selling points of the Aero Knitting Pins. The packaging folds with 3 main sections, each providing different insights into the knitting needles. Examples of this are " CANNOT SOIL LIGHT WOOL", "...SPECIALLY TAPERED POINTS WHICH WILL NOT INJURE THE FINGERS" and "RUSTLESS-NON-GLITTER FINISH". As the packaging unfolds, the grey knitting needles become visible. The needles can be removed from the packaging by sliding them through small bands of paper that hold the needles secure while in transportation. The four knitting needles are a “NEUTRAL” grey colour finished in a double point style.Printed. Orange, White and Black Ink Numerous, see multimediaabel morrall, knitting needles, knitting pins, 1960s home knitting -

National Wool Museum

National Wool MuseumLetter

Letter from H. Krantz Sohne, Manufacturers of Finishing Machinery, Aachen, Germany to Arthur Heaton & Co. Ltd, Valley Works, Liversedge, Yorkshire, England, dated 2 Nov. 1931. This letter contains a quotation for obtaining a Kettle Decatizing apparatus and a Cloth Winding Machine. It was sent with two photographs of the machinery in question.textile machinery textile finishing, h. krantz s?? arthur heaton and co. ltd, decatizing, winding machinery, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumPhotograph

Photograph of a Cloth Winding machine, as produced by H. Krantz Soehne (manufacturers of finishing machinery) of Aachen, Germany. It was sent to Arthur Heaton & Co. Ltd as part of a price quotation and was for winding on the decatized cloth.Photograph, 1931, of a Cloth Winding machine, as produced by H. Krantz Soehne (manufacturers of finishing machinery) of Aachen, Germany.H. KRANTZ SOEHNE / AACHEN. 362textile machinery textile finishing, h. krantz s?? arthur heaton and co. ltd, winding machinery, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumPhotograph

Photograph of a Tentering machine, as produced by H. Krantz Soehne (manufacturers of finishing machinery) of Aachen, Germany.Photograph of a Tentering machine, as produced by H. Krantz Soehne (manufacturers of finishing machinery) of Aachen, Germany, c.1930.H. KRANTZ SOEHNE / AACHEN. 853textile machinery textile finishing, h. krantz s??, tentering, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumBooklet, Why Not...?

"Why Not Help the Country in its Economy Campaign by Economising Yourself and thus Increase Your Profits ?" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926. Promotes the advantages of buying a new scouring machine.Booklet, c.1926. Produced by James Bailey, textile machinery manufacturer, Huddersfield, to promote a new scouring machine.textile machinery textile finishing, james bailey, textile machine maker, scouring, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumBook, Concerning wool

"Concerning Wool"- The Australian Wool Board and The Associated Woollen and Worsted Textile Manufacturers of Australiatextile production machine knitting wool growing wool processing wool - chemistry, australian wool board associated woollen and worsted textile manufacturers of australia, felting, spinning, textile production, machine knitting, wool growing, wool processing, wool - chemistry -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates how tram tickets could be punched and the manufacture of ticket punches.Brass cast, chrome plated, machined, device or ticket punch, used to cancel or punch paper tickets when purchased. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. . Chrome plate has been partly worn off. Secured by three screws. For another example see Reg Item 7468 with large screws. There are no manufacturer markings or numbers on the punch. Punch is very heavy in construction compared to other punches in the collection.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates how tram tickets could be punched and the manufacture of ticket punches.Brass cast, chrome plated, machined, device or ticket punch, used to cancel or punch paper tickets when purchased. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. . Chrome plate has been partly worn off. Secured by three screws, which are unusual. There are no manufacturer markings or numbers on the punch. Punch is very heavy in construction compared to other punches in the collection. Has been repaired by welding.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Brass cast, was chrome plated, machined, device or ticket punch, used to cancel or punch paper tickets when purchased. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. . Chrome plate has been extensively worn off. There are no manufacturer markings or numbers on the punch. On the inside of one of the handles are two saw cuts that could have been used to identify the punch.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumMemorabilia - Display panel, The North Eastern Steel Co. Ltd. Middlesborough, Standard Section of Tramway Rails

Flanged Tramway Rails - sections from The North Eastern Steel Co. Ltd. Middlesborough - see https://www.gracesguide.co.uk/North_Eastern_Steel_Co 1 - Walthamstow & District Light Railways BS Section No. 3C - 106 lbs. per yard 1904 - Dick Kerr & Co. Contractors London. See https://en.wikipedia.org/wiki/Tottenham_Outrage 2 - Bath & District Tramways 95 lbs per yard 1903 - George Hopkins & Sons Engineers London 3 - Burton on Trent Tramways 90 lbs per yard 1903 - Messrs Kincaid, Waller & Manville, Consulting Engineers 4 - Swindon Corporation Tramways BS Section No. 4 C, 111 lbs per yard, 1904 - Messrs J G White & Co. Ltd, Contractors London 5 - Wigan Corporation Tramways BS Section No. 5, 100 lbs per yard, 1903 - Messrs J G White & Co. Ltd, Contractors London 6 - Derby Corporation Tramways BS Section No. 6, 107 lbs per yard, 1904 - Messrs J G White & Co. Ltd, Contractors London 7 - Nottingham Corporation Tramways BS Section No. 1 , 90 lbs per yard, 1903, J. G. White Ltd, London, Contractors. 8 - Swindon Corporation Tramways, BS Section No. 4, 105 lbs per yard - Messrs J G White & Co. Ltd, Contractors London, Messrs Lacy & Sillars Consulting Engineer 9 - Kalgoorlie Electric Tramways BS Section ? 96 lbs per yard. 1904 - Messrs J G White & Co. Ltd, Contractors London 10 - Leicester Corporation Tramways & Track? 100 lbs per yard 1903, I George Maybey? MICE Engineer 11 - Ipswich Tramways 90 lbs per yard, 1902, Dick Kerr & Co. Contractors London Shows the type of tramway rail and cross section produced by The North Eastern Steel Co early 1900's, the relationship to the British Standard and who used them. Provenance of the item not fully known. Possibly given to the Electric Supply Co of Victoria at the time when they would have been ordering rails for use in Ballarat. May have been collected by other parties.Plywood sheet, covered in black cloth displaying 11 different British Standard Rail Sections made by The North Eastern Steel Co. Ltd. Middlesborough , early 1900's. Each section secured with two 20mm (¾”) long, 3mm dia (1/8”) machine screws, countersunk with a slotted head from the rear. All nickel plated on both sides, engraved as to the tramway used on, date of production on the head of the rail, Designing Engineers on the web and the manufacturer on the foot of the rail. Cloth secured with staples and drawing pins on the rear. On the rear is a chalked sign, the principal one being "No Thoroughfare"Engraved as listed.tramway rails, rails, tramways, north eastern steel co, middlesborough, walthamstow, bath, burton on trent, swindon, wigan, derby, nottingham, kalgoorlie, leichester, ipswich, j g white & co, dick kerr -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - Bensen Gyro-Copter

Historical Details: . Description: The Bensen Gyro-copter was designed by Dr Igor Bensen. Formerly the chief research engineer for the helicopter manufacturer Kaman Aircraft Corporation. Designed in the early 1950’s it was initially intended to be the predecessor of a series of light we. Level of Importance: Regional -

Kew Historical Society Inc

Kew Historical Society IncLeisure object, Hilary Page, Billie and His Seven Barrels, 1950

The Kew Historical Society’s collection includes a wide range of leisure objects. Many of the items are European-made, generally of British origin, however there are a number that were made for the Australian market by Australian manufacturers. There were clearly a huge range of toys produced for the Australian and International children’s market in the Nineteenth and Twentieth centuries. The examples of toys in the collection include examples of alphabet toys, arcade toys, baby toys, construction toys, dolls, doll accessories, educational toys, soft toys, tin toys, toy animals, toy blocks, toy machines, toy typewriters, etc. Boxed children's construction toy, suitable for children 2-2.5 yearstoys, games and puzzles, hilary page, kiddicraft