Showing 157 items

matching machine parts

-

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates how tram tickets could be punched and the manufacture of ticket punches.Brass cast, chrome plated, machined, device or ticket punch, used to cancel or punch paper tickets when purchased. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. . Chrome plate has been partly worn off. Secured by three screws, which are unusual. There are no manufacturer markings or numbers on the punch. Punch is very heavy in construction compared to other punches in the collection. Has been repaired by welding.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets. Possibly has a strong association with Les Denmead - could have personally been used by Les, or collected at the time of closure.Brass cast, chrome plated, machined, device used to cancel or punch paper tickets when purchased. Punch of the type that placed a circular hole in the ticket. Spring loaded, consists of two main parts with a pin & spring. Chrome plated wearing off. - see image.Has letter "A" punched inside of handles near pin.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch, State Electricity Commission of Victoria (SECV)

Has a strong association with Dave Kellett, motorman and inspector in Ballarat; issued to crews in order check and cancel tickets.Brass cast, chrome plated, machined, device used to cancel or punch paper tickets when purchased. Placed a hole in the ticket. Spring loaded, consists of two main parts with a pin & spring. Chrome plated wearing off. - see sketch on original worksheet.Has letter "U" punched inside of handles near pin.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch, Bell Punch Ltd

Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Steel cast, chrome plated, machined, device used to cancel or punch paper tickets when purchased. Placed a four pointed star hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. Has a circular steel ring for a finger hold. Chrome plate started to wear off in some places. Has letter "D6" punched onto one arm and "Supplied by Bell Punch Ltd Uxbridge" just below the slit in the punch for the ticket.Has letter "D6" punched inside of handles near pin and letter "C: on inside of both handles and "X" near the outer edge of one the insides of the handle.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

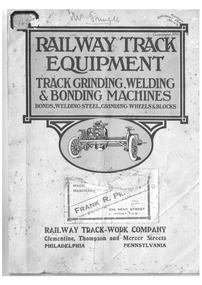

Ballarat Tramway MuseumDocument - Folder with papers, Railway Track-work Company and Clementine and Thompson and Mercer Sts and Philadelphia and Pennsylvania USA. and Perrot and Adams Ltd, "Railway Track Equipment - Track Grinding Machines, Welding and Bonding Machines - Bonds, Welding Steel, Grinding Wheels and Blocks", 1920's?

Yields information about the type and presentation of books or information folders that were sent to the Electric Supply Company of Victoria about tramway products available on the market and the company the produced them.Folder with 24 pages of advertising pamphlets bound into it with two metal clip binders advertising products available from the Railway Track-Work Company and titled ""Railway Track Equipment - Track Grinding Machines, Welding and Bonding Machines - Bonds, Welding Steel, Grinding Wheels and Blocks". Has brochures or pamphlets for: . The Universal Rotary Track Grinder . Reciprocating Track Grinder . The Atlas Rail Grinder . The Ajax Electric Arc welders .Vertical Rail Lifter . The Jackson Electric Tie Tamper. Generally the lead page of each pamphlet has been imaged. Provides a description of each item, along with method of operation and parts listing generally. The folder has on a number of pages and the back cover, a sticker from Frank R. Perrot (Now Perrot and Adams Ltd), Machinery Merchant of 394 Kent St Sydney. Railway Track-work Company , Clementine, Thompson and Mercer Sts, Philadelphia, Pennsylvania USA. For a full scan of the document see the hi res file.Numerous: Front cover sticky label "1620" in top left hand corner, "Mr Pringle" on front cover and stamp with words "Ballarat Tramway Preservation Society Catalogue No. 10" in ink on front cover. Inside front cover has a pencil note, behind the crease in the bottom right hand corner. On the first pamphlet "Ballarat Tramway Preservation Society Catalogue No. 10" in ink on top right hand corner. On parts page for the Reciprocating Track Grinder has the "Perrot and Adam Ltd" company stamp.trams, tramways, trackwork, equipment, rails -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Brass cast, was chrome plated, machined, device or ticket punch, used to cancel or punch paper tickets when purchased. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. . Chrome plate has been extensively worn off. There are no manufacturer markings or numbers on the punch. On the inside of one of the handles are two saw cuts that could have been used to identify the punch.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Brass cast body with steel pins and screws, chrome plated, machined, device used to cancel or punch paper tickets when purchased or inspected. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin, screws & spring in addition. . Chrome plate in good condition. The initials "ECV" have been cast in to the body of the main component. A relatively heavy unit compared to others, does not appear to have had a lot of use.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Has a strong association with the closure of the SEC operated Ballarat tramway system. Issued to crews in order check and cancel tickets.Brass cast, chrome plated, machined, device used to cancel or punch paper tickets when purchased. Placed a hole in the ticket. Spring loaded, consists of two main parts with a pin & spring. Chrome plated wearing off. Makes a round punch. No marks on the punch. The Donor advised that it was used for the "last tram ticket punch 1971 on last tram" - see gift sheet.trams, tramways, ticket punch, tickets, fares -

Bendigo Historical Society Inc.

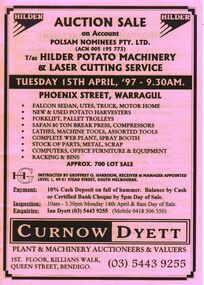

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - POLSAM NOMINEES PTY LTD

Pink paper catalogue with black printing for a sale on account of Polsam Nominees Pty. Ltd. T/as Hilder Potato Machinery & Laser Cutting Service on 15th April '97 at Warragul. For sale were vehicles, potato harvesters, forklift, pallet trolleys,80 ton press, compressors, lathes, machine tools, assorted tools, complete web plant, spray booth, parts, metal, scrap, computers, office furniture & equipment, racking and bins. Announcement printed in the front of catalogue mentions that J. H. Curnow & Son Pty. Ltd. Are combining their name with the Dyett family and trading as Curnow Dyett, Real Estate Agents, Auctioneers and Qualified Valuers.business, auctioneers, curnow dyett, ian dyett collection - auction catalogue - polsam nominees pty ltd, hilder potato machinery & laser cutting service, geoffrey o harrison, ian dyett, curnow dyett, j h curnow & son pty ltd, occupational health and safety act 1985, noel dyett, ian dyett, fred dyett -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Steel cast, chrome plated, machined, device used to cancel or punch paper tickets when purchased. Punch of the type that placed a hole that appears to be two joined rectangles in the ticket. Spring loaded, consists of two main parts with a pin & spring. Chrome plated wearing off. - see image. Assumed used in Ballarat.Has number "31" punched on handles near pin, both sides.trams, tramways, ticket punch, tickets, fares -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - DAP (Bristol) Beaufort Mk V A9-13 (T9552, "Nk-B")

Historical Details: The DAP Beaufort A9-13 was the 13th locally built Australian mark V Beaufort Bomber, with the first 20 being assembled from imported UK parts, but fitted with Australian built Pratt and Whitney 1830 Twin Row Wasp engines. A9-13 was originally built to an. Description: The DAP (Bristol) Beaufort Bomber A9-13, the 13th example built in Australia, was acquired in 2011 with Government funding assistance under the Australian National Cultural Heritage Account. The Beaufort Bomber was the first product of the Department o. Level of Importance: Nationalbeaufort -

Tennis Australia

Tennis AustraliaPinball machine, Circa 1970

'Volley' pinball machine by Gottlieb & Co. In two parts, body with metal legs and upright back section. Bolts attached in bag. Materials: Wood, Metal, Glass, Plastic, Painttennis -

Clunes Museum

Clunes MuseumManual - FARM MACHINERY MANUAL, Between 1923-1929

.1 Sunshine Reaper & Binder Instructions for assembling and starting .2 Sunshine Stripper Harvester 6ft. Instructions for starting and working .3 Duplicate Parts for Sunshine Reaper & Binder with 6 and 8ft cut .4 Duplicate Parts for 3 furrow Sunrise Stump Jump Disc Plough .5 Duplicate Parts for Sunshine Steel Frame Harvesters Types A-H .6 Duplicate Parts for Sunrise Stump Jump Mouldboard Ploughs 3,4,5,6 furrows .5 Machine brought through H. Cunninghamsunshine harvester, sunshine reapers & binders, duplicate parts book, stump jump plough, stump jump mouldboard plough, steel frame harvester, operating manual -

Albert Park-South Melbourne Rowing Club

Albert Park-South Melbourne Rowing ClubMoore Sculling Machine

"Grace Blake’s conversations with older members of the Club have elicited the following information during July 2014: • Don Christie recalls the machine being acquired by (or donated to) SMRC in the 1960s. SMRC later donated it to APRC. • Bob Duncan remembers it being at APRC. • Max Shaw joined the club in 1946 but doesn’t recall it at all. • Peter Watson recalls collecting the rowing machine from the old APRC club house before its demolition (c. 1995). The AP-SMRC machine carries a ‘maker’s plate’ with the name Moore... Moore Crane and Engineering Company Pty Ltd was a subsidiary of Malcolm Moore Industries Ltd whose manufacturing engineering works were located on Williamstown Road, Port Melbourne from 1927. The founder established the main business in 1921 and retired in 1953.21 The business was delisted from the Australian Stock Exchange in 1976. Grace Blake advises that some of the earlier SMRC members were plumbers and therefore worked in trades connected with engineering. She reports that Peter Watson recalls some of his contemporaries completing their engineering apprenticeships at Malcolm Moore Industries Ltd in the 1970s. There are still many unanswered questions concerning the history and provenance of the rowing machine at the time of writing this report, but the connection with a local engineering works is certainly fascinating. Questions to explore in the future include: Did Moore manufacture the machine, or import it (and perhaps assemble it) under licence? Was this machine a ‘one-off’ or did Moore make / distribute others within Australia? When, why and how did SMRC acquire the machine? Why did SMRC decide not to retain it, but to pass it over to APRC? And how did APRC use it?" 2014 Significance Assessment, pp38-40. "The ‘Moore’ Rowing Machine at the Albert Park – South Melbourne Rowing Club (AP- SMRC) is a rare example in Australia of the Kerns patent design from 1900. This machine may not, however, be that old in construction or use. The AP-SMRC machine is almost intact, appearing to lack only the leather straps for fastening the rower’s feet to the foot-rests. Spalding manufactured the design in the USA in the early decades of the 20th century, but the metal elements in its models are traditionally black. The bright red paint on the AP-SMRC machine suggests something different. The AP-SMRC machine carries a maker’s plate that associates it directly with a local engineering business, Malcolm Moore Industries Ltd of Williamstown Road, Port Melbourne. Club members recall the machine being at the South Melbourne Rowing Club in the 1960s, and being transferred at a later date to the Albert Park Rowing Club. The machine has not been used since the founding of the amalgamated AP-SMRC and requires careful conservation. The ‘Moore’ rowing machine is of national research significance as a rare survivor, in Australia, of the well-regarded Kerns patent design that was popularised by Spalding in the northern hemisphere. The English River and Rowing Museum website quotes a testimonial from an AG Spalding & Bros’ Mail Order Catalogue: ‘This machine was described by ‘an experienced oarsman’ ... “to be the most perfect rowing machine ever produced”. A feature was the adjustment of the resistance so “the weaker sex can use the machine”’. Its historic significance lies in its rarity (and perhaps uniqueness) as an aid to the training of rowers at two successful clubs on Albert Park Lake. Additional historic significance lies in the connection that the rowing machine represents between local rowing clubs and a major local manufacturing engineer. The ‘Moore’ rowing machine bridges the realms of innovation and application, of industry and recreation, of land-based and aquatic sports, and of two neighbouring rowing clubs on the Albert Park Lake." 2014 Significance Assessment, p43"A rowing machine that appears to be built to the Kerns patent design from 1900 but may not be that old in construction or use. The machine is heavy and includes parts made from cast iron. The cast iron components are painted in a distinctive bright red. The wooden seat moves on timber slides. Resistance is created by spring mechanisms at the ends of two frame elements that connect with two wooden ‘oars’, and by the central chain-driven system that co-ordinates with the rower’s movements. The machine carries a maker’s plate with the single word ‘Moore’ in an oval design, using white letters against a navy background, fastened to the base board and close to the foot-rests." 2014 Significance Assessment, p38Moorerowing, apsm rowing club, significance assessment, malcolm moore industries ltd, kerns, 1900, sculling machine, albert park rowing club, south melbourne rowing club, albert park lake, rowing machine, ergo -

National Wool Museum

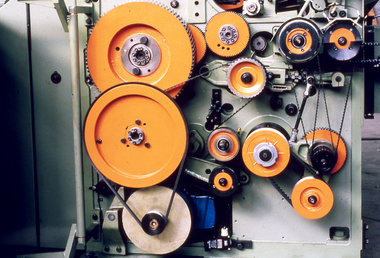

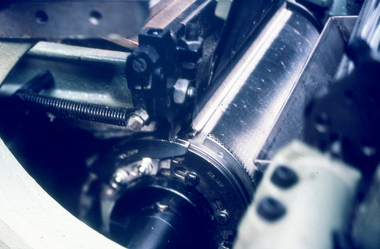

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of combing machinery with orange and black cogs.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

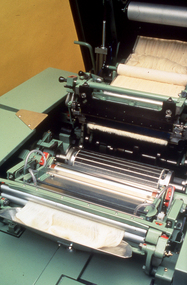

National Wool Museum

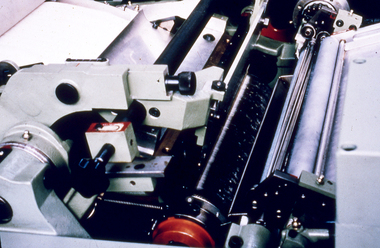

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing an exterior detail view of combing machine.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing an exterior detail view of combing machine.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

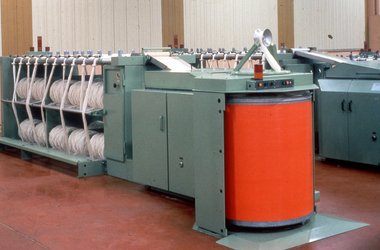

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Wool Combing Machine, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior of a factory, depicting wool combing machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machines, China, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior of a factory, depicting combing machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Wool Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of wool combing machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Carding Machine, Thibeau Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing exterior of carding machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

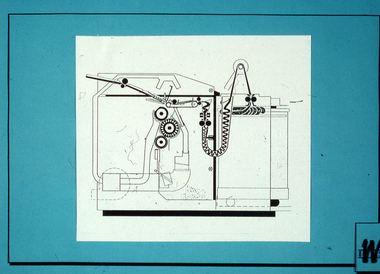

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a graphic illustration in black and white, depicting the mechanics of a combing machine.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

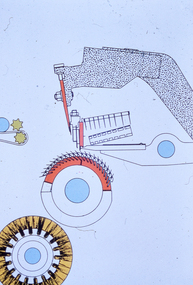

National Wool Museum

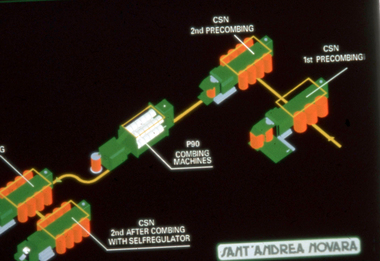

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a graphic illustration in white, blue, yellow and orange on a white background, depicting the mechanics of a combing machine.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail view of combing machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machines, NSC Schlumberger, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a factory interior with combing machines, including red barrels and orange painted building pillars.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumTextile - Cloak, Dr Deanne Gilson, Murnong Daisy Cloak (Women Gathering Food) Cloak, 2022

Standing proud, still here, the spirit of ten ancestral matriarchs adorned in contemporary ceremonial cloaks. Representing our women past, present and future, her Spirit, our culture, our Country (spelt with a capital for its importance and this is part of First Peoples protocols on acknowledging Country, our strength, our resilience and healing towards a sustainable future. The murnong was one of the main food sources for First Peoples before colonisation as it grew right across Wadawurrung Dja. The introduction of the sheep and cattle saw the murnong eaten roots and all and it quickly became less plentiful. The tubers were eaten raw or roasted on a fire. Water could be added to make a paste for small children to eat. The woman’s wooden digging stick that was used to gather and harvest plants was often buried with the woman for her afterlife and is considered sacred women’s knowledge. All parts of the plants and trees were and still are honoured as sacred medicine, healing plants and bush food knowledge.Yellow flower and female figure motif on black background on outer cloak, black and white diamond, and circle design in lining. Solid black trimming. Cloak is machine sewn and handstitched with hand stitching on shoulder seam.deanne gilson, wadawurrung dja, first nations art, cloak, murnong -

National Wool Museum

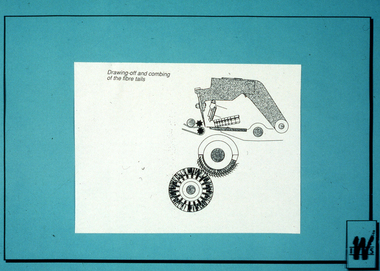

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a graphic illustration in black and white, depicting the mechanics of a combing machine.wool, industry, australia, australian wool board international wool secretariat, factory, wool bales, training -

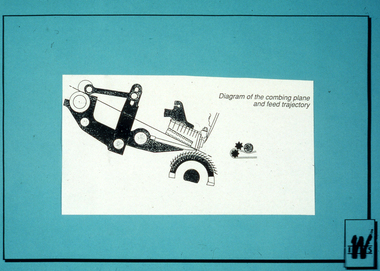

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a graphic illustration in black and white, depicting the mechanics of a combing machine.wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machine -

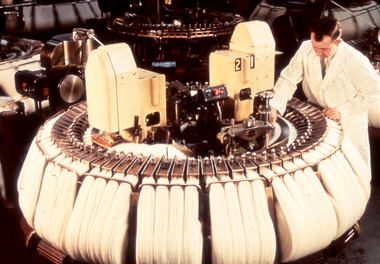

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Noble Comb, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a man in a white coat operating a wool combing machine inside a factory.wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machine -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Training, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a graphic illustration in colour, depicting the mechanics of a combing machine.wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machine