Showing 111 items

matching machinery operation

-

Bendigo Historical Society Inc.

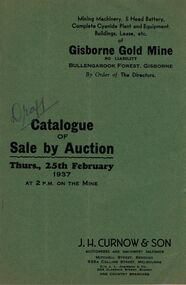

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - GISBORNE GOLD MINE

Two green covered auction catalogues with dark blue printing for an auction held on the 25th February 1937 of Mining Machinery, 5 Head Battery, Complete Cyanide Plant and Equipment, Buildings, Lease No. 7480, et. Sale held at the Gisborne Gold Mine No Liability, Bullet-proof Forest, Gisborne. Catalogues have descriptions of lots and sale prices written in the columns at the right side of the page. A Special Notice at the front of the catalogue mentions the plant will be first offered as a whole, with a view to recommencing operations. Yield is also mentioned.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - gisborne gold mine no liability, j h curnow & son, j l jamieson, bolton bros pty ltd -

Bendigo Historical Society Inc.

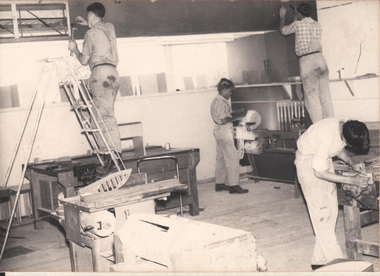

Bendigo Historical Society Inc.Photograph - SANDHURST BOYS CENTRE COLLECTION : WORKSHOP ACTIVITY

Residents working at various tasks, including lathe operation, using a vice, hammering. Machinery includes a lathe, saw bench with circular saw. -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Dynamo operations and machinery, I.C.S. Reference LIbrary Dynamos & Motors, Operation of Dynanmos & Motors, Dynamo-Electric Machnery, Geometrical Drawings, Mechanical Drawing, Steam Heating. Steam Turbines

... operations and machinery ...Non Fiction. Technical overview of dynamo motors & equipment & steam turbines/heating circa 1897 to 190-4Red covered bookNon Fiction. Technical overview of dynamo motors & equipment & steam turbines/heating circa 1897 to 190-4dsynamo operatios and machinery -

Kew Historical Society Inc

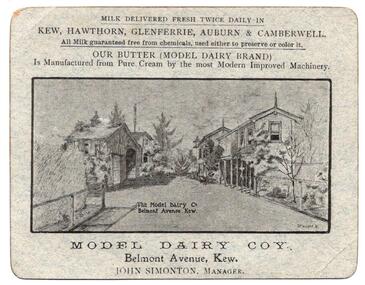

Kew Historical Society IncCard - Model Dairy Coy: Belmont Avenue, Kew, c.1907

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Digital copy of a business card advertising the Model Dairy in Belmont Avenue, Kew, managed by John Simonton. (The card was donated by John Harvey Simonton in 2021,)"Milk delivered fresh twice daily in / Kew, Hawthorn & Camberwell / All Milk guaranteed free from chemicals, used either to preserve or colour it / Our butter (Model Dairy Brand) / I Manufactured from Pure Cream by the most improved Machinery / [DRAWING] The Model Dairy Co Belmont Avenue Kew / Model Dairy Co / Belmont Avenue, Kew / John Simonton, Manager"model dairy -- kew (vic.), john simonton, belmont avenue -- kew (vic.), dairies -- kew (vic.) -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSewing Machine Accessories

(See Registration No. 26.3). Green rectangular cardboard box with lid containing 5 feet for various sewing operations, a screw for attaching them, a button hole guide and a hem guide.On lid in red, "Singer / Accessories for 66K Machine No. SIMANCO / 120842", "25527", "12466", "35931", "36583". 31.4 is etched with Singer logo and USA.domestic sewing equipment; accessories; containers -

National Wool Museum

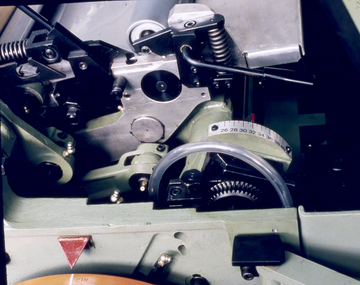

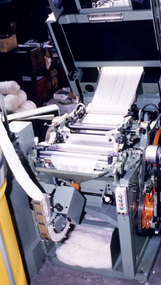

National Wool MuseumPhotograph - Slide, Stuart Ascough, NSC Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of combing machinery.wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machinery -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, NSC Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of combing machinery and wool. wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machinery -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machine, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of combing machinery. wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machinery -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, NSC Topmaking Comb, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing detail of topmaking comb machinery.wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machinery -

National Wool Museum

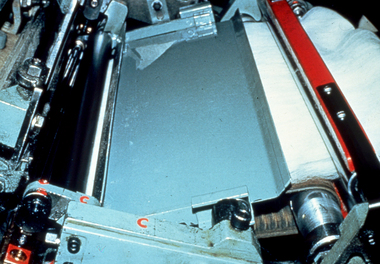

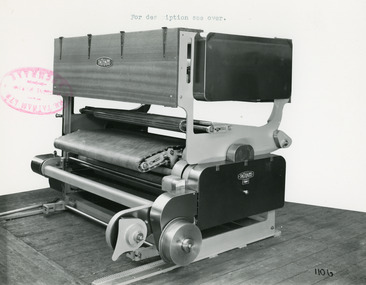

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

Vision Australia

Vision AustraliaPhotograph - Image, Queensland Institute for the Blind matting, cane and mattress workshop, August 1952

Fives images of the workshop machinery used by the Queensland Industrial Institute for the Blind in the manufacture of various products. 1 - Pitched brooms being made by Stewart Jewell (left) and Jack Dollier (right). 2 - Unknown worker at a basket station making a cane basket, surrounded by finished examples. 3 - Snowy Willis oversees the operation of the machine that bores holes into brush heads. 4 - Unknown worker operating a coir matting machine. There were apparently 10 such machines in use at the time this image was taken. 5 - Snowy Willis checking the bobbins being filled from a giant spool. In the background are empty bobbins stacked against walls and filled bobbins on spool holders. 6 - Roy Anderson checks the wadding on a recently filled mattress, whilst in the background Ellen McDevitt uses a portable sewing table to sew the ends of a filled mattress.6 x B/W photographs of the workshop machinery used by the Queensland Industrial Institute for the BlindC2-657: 2, Brush shop - pitch set brooms being made by blind workers C2-664: Basket shop - some of the various types of baskets made C2-654: Snowy Willis. Brush shop - a semi automatic brush stock boring machine in operation. C2-666: Matting shop - one of the ten coir matting looms in use. 1960. C2-659: Matting shop - bobbin winder and bobbin bank. C2-655: 15. 2 col wide. Bed shop wadding a fibre mattress. Also showing special sewing machine and movable table used in sewing the mouths of filled mattresses.queensland industrial institute for the blind, stuart jewell, jack dollier, snowy willis, roy anderson, ellen mcdevitt -

Buninyong & District Historical Society

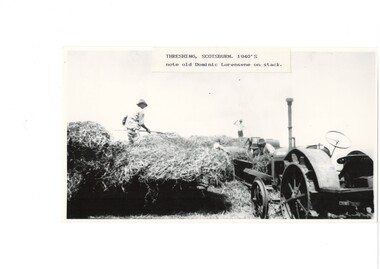

Buninyong & District Historical SocietyPhotograph - Copy of B/W photograph, Threshing machine at Scotsburn in 1940's, Not known

Photograph shows early farming method and illustrates some of the machines used at this timeThreshing machine in operation at Scotsburn in the 1940's. 3 workers and tractor visbleThreshing machine. 1940's. Note old Dominic Lorensene on stack.scene showing farm machinery in use. threshing machine vdriven by belt from stationary tractor., several man are working on the equipment, l -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Dredging, Lakes Post Newspaper, 1992

Date made June 1992Black and white photograph of heavy machinery loading sand into a truck and trailer on Bullock Island. This sand was dumped on the island during dredging operations at the entrance and around the Gippsland Lakes. Lakes Entrance Victoriaislands, dredging, machinery -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - DRAINAGE PROBLEMS 1910

Handwritten notes from Bendigo Advertiser reports. (1) Mr J. H. Craig reports- Victoria Reef Quartz - Cleaned and tested No 3 boiler. Have bailed 3,905 tanks. Water now 2.953 feet from surface. At Lazarus - Bailed 4,828 tanks. At New Chum Railway - Cleaned and tested boilers and flues, effected repairs to machinery and shaft, and started bailing at 3 pm on Friday 29th inst, and bailed 965 tanks. Bendig Advertiser 3/8/1910 Page 2 Mining Intelligence. (2) New Chum Mines - Better progress is now being made in lowering the water in the deep level workings at the New Chum Mines. At the Victoria Quartz, the water which on Monday stood at 3073feet, has been lowered 70 feet during the past four days. The pumping service at the New Chum Railway was in operation yesterday, and the winding plant is fully occupied. There is a considerable quantity of water toraise, and the companies have a difficult task before them. Bendigo Advertiser 5/8/1910 Page 2. Document from Albert Richardson Collection of mining history.gold, drainage problems, new chum drainage association, new chum mines drainage problems 1910, bendigo advertiser 3/8/1910 page 2, mr j h craig, victoria reef quartz, lazarus, new chum railway, bendigo advertiser 5/8/1910 page 2, albert richardson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NORTH DEBORAH GOLD MINING CO N. L. - COPY OF CORRESPONDENCE, NORTH DEBORAH GOLD MINING CO N. L

Handwritten copy of correspondence dated 18th January 1950. Mentioned arer: Dividends, 9 pound 6 shillings per Share, Commenced Mining operations on Deborah Line of Reef, October 1937 and worked continuously since that date, amount of gold from the ore, Pyrites Concentrates treated todate, produced gold to a nett value of 53,000 pounds. Mine Plant Machinery, Buildings and Battery Equipment at Book value 25,420 pounds. Shaft to 1,300 feet. 90 men employed at Mine and Batteries, Annual Wages Sheet 32,000 pounds. Directors: Mr E . H. Noske (Chairman), Messrs G. W. Lansell, A. E. Dowling, G. A. Pell, T. Swinburne, W. J. Donovan. Legal Manager Mr J. J. Stanistreet. General Manager Mr S. ScDonald. Albert Richardson Collection. document, gold, north deborah gold mining co n. l., north deborah gold mining co n. l., copy of correspondence north deborah gold mining co n. l., deborah line of reef, mr e h noske, g w lansell, a e dowling, g a pell, t swinburne, w j donovan, mr j j stanistreet, mr s mcdonald -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - RED WHITE & BLUE EXTENDED - LETTER TO MR A RICHARDSON

Typed letter to Mr A Richardson from Hugh Sloane, Mount Clear, Ballarat, Vic. 3350 dated 30/5/68 thanking him for two letters and some information about the engines at the Red White & Blue Mine. He was interested to hear of such engines being installed at a gold mine and wished he could have seen them in operation. The description of the steam winding engine was most interesting and he was hoping the society could preserve some of the machinery.document, gold, red white & blue extended, red white & blue extended, letter to mr a richardson, hugh sloane, red white & blue mine, rustin & hornsby -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MCCOLL, RANKIN AND STANISTREET COLLECTION: INDENTURE BETWEEN KING EDWARD VIII AND MONUMENT HILL CONSOLIDATED MINE, 2/09/1936

Indenture document number 10878, Vol 317 Folio 35044. Foolscap 4 pages including a map, dated 2nd September, 1936, between King Edward VIII (Crown land) and Monument Hill Consolidated (Bendigo) No Liability 'carrying on operations in the Parish of Sandhurst, to occupy and use the land demised as a site for machinery buildings and offices to be used in connexion with 'mining purposes' ' Document signed by Right Hon William Charles Arcedeckne, (Baron Huntingfield) and J. Stanistreet, Manager, affixed with the Common Seal of Monument Hill Consolidated (Bendigo) No Liability. Map drawn on dark buff paper, and fixed to document. Map shows lease 10878 in the Mining District of Bendigo, Parish of Sandhurst, County of Bendigo. N.Area 2.2.24 ( 2 acres, 2 roods, 24 perches ) Lease site on Rowan Street, bordered by Ophir Street. Coloured in purple on plan with small red area. On bottom: ' Note Red Areas Excised. Scale 4 chains to 1 inch, M.M. Var. 8 degrees 32' E. On lease site, New Chum Gully marked, W.B. House, and Permanent Occy. marked on red area. On last page ownership of lease details from 1937 to 1942.bendigo, mining, monument hill consolidated, common seal of monument hill consolidated, nell gwynne mine, south nell gwynne gold mining company, bendigo mine, ophir street, rowan street, mackenzie street.indenture vol 317 fol. 35044. j stanistreet. -

Lakes Entrance Historical Society

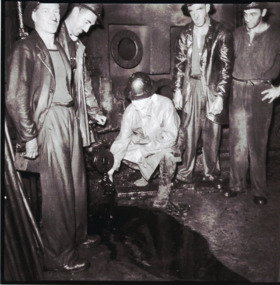

Lakes Entrance Historical SocietyPhotograph - Oil Industry, H D Bulmer, 1945

Also six black and white photographs showing activities and machinery in workroom of Lakes Oil Limited deep shaft Lakes Entrance 05322.1, .2, .3, .4, .5, .6 All 17 x 17 cmBlack and white photograph showing Mr Demaine Manager Director of Lakes Oil Limited with his hand in the oil flow with four workmen in the workrooms of the oil shaft. Plus six black and white photographs of operations at same oil well site Lakes Entrance Victoriaoil and gas industry -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

This image is a reproduction of an 1899 original depicting the 'Williams Good Luck Mine' on the Mopoke Reef (also called 'Morepork Gully') in the Dingle Ranges, approximately three miles from Beechworth. A large opening to a mine can be seen behind the men in the photograph, with a wheeled cart on a track leading to the men's position, where the soil and rocks have been hauled away. This photograph interestingly contains dogs alongside the miners. While dogs have been recorded as deterrents to thieves in the Victorian goldfields, these dogs appear as companions to these men. Following the discovery of gold at Beechworth in 1852, rushes quickly followed at surrounding creeks and gullies in the district. In the late nineteenth and early twentieth centuries, small syndicates of miners continued to work old or abandoned quartz reefs, often persisting without the assistance of heavy machinery to remove the large amounts of rock, in order to obtain yields at ever greater depths. The group of miners in this photograph are Mr. Roger Williams and Sons, who revived operations at the ‘Old Good Luck’ mine on the Mopoke Reef in the Dingle Range near Beechworth around 1892, working the site for more than two decades. An emigrant from Cornwall with experience in the tin mining industry, 19 year old Roger Williams senior sailed to New Zealand in 1840, then to Australia where he spent time in the Bendigo Gold Fields before settling in Beechworth in the early 1860s. Mr Williams senior worked on various mining activities in the district, including the Rocky Mountain Tunnel project. Conversant with the character of gold-bearing reefs in the area, the syndicate dug an eight hundred foot tunnel, digging down as far down as two hundred feet with little capital save their labour, to connect and provide better working access to the mass of reefs and veins in the vicinity. Progress was hampered by poor air quality charged with fumes from dynamite and large quantities of rock had to be crushed to obtain payable yields. The Victorian Goldfields are filled with ruins and remnants of the area's rich mining history, ranging from small alluvial diggings to the remains of huge mining companies. Site names often changed several times throughout the nineteenth and twentieth centuries. Some sites were abandoned and forgotten, others were worked continuously over many decades. The names of mines were often repeated at different locations throughout the Victorian Goldfields. For example, there is a Mopoke Gully heritage mine near Fryers Creek, Victoria. 'Mopoke' is a common onomatopoeic name for Morepork and Australian Boobook owls.This image has historical, social and research significance for patterns of emigration during of the Victorian Gold Rush, and the historical, social and environmental impacts of mining at Beechworth at the turn of the nineteenth and twentieth centuries. As gold became scarce and government support and large company investment waned, poor hard-working miners laboured intensively to make a living through periods of high unemployment. This image can be compared and studied alongside other historical mining photographs and objects in the Burke Museum Collection. It has potential to improve our understanding of miners working conditions and the shifting character of mining in the Beechworth district.Sepia coloured rectangular photograph printed on gloss photographic paper mounted on card. Obverse: Williams/ Good/ Luck Reverse: A02498/ 1997. 2498/ Good Luck/ Mine/ 1899/ Mopoke. burke museum, beechworth museum, beechworth, gold fields, gold rush, victorian gold rush, gold ming history, colonial australia, australian gold rushes, mining technology, beechworth historic district, indigo gold trail, migration, indigo shire, good luck gold mine, victorian goldfields, mining syndicates, gold fever, quartz-mining, small-scale mining, old good luck mine, mopoke gully, quartz reefs beechworth -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

This image is a reproduction of an 1899 original depicting the 'Williams Good Luck Mine' on the Mopoke Reef (also called 'Morepork Gully') in the Dingle Ranges, approximately three miles from Beechworth. The foreground of the image is littered with piles of smashed rock and detritus, known as ‘mullock’, beside a reinforced mine shaft, a vertical access passageway allowing miners to enter the mine and haul ore out using lifting technology such as a poppet heads, whims or windlasses. A group of miners and a dog appear close to an open-sided miner’s hut. Following the discovery of gold at Beechworth in 1852, rushes quickly followed at surrounding creeks and gullies in the district. In the late nineteenth and early twentieth centuries, small syndicates of miners continued to work old or abandoned quartz reefs, often persisting without the assistance of heavy machinery to remove the large amounts of rock, in order to obtain yields at ever greater depths. The group of miners in this photograph are Mr. Roger Williams and Sons, who revived operations at the ‘Old Good Luck’ mine on the Mopoke Reef in the Dingle Range near Beechworth around 1892, working the site for more than two decades. An emigrant from Cornwall with experience in the tin mining industry, 19 year old Roger Williams senior sailed to New Zealand in 1840, then to Australia where he spent time in the Bendigo Gold Fields before settling in Beechworth in the early 1860s. Mr Williams senior worked on various mining activities in the district, including the Rocky Mountain Tunnel project. Conversant with the character of gold-bearing reefs in the area, the syndicate dug an eight hundred foot tunnel, digging down as far down as two hundred feet with little capital save their labour, to connect and provide better working access to the mass of reefs and veins in the vicinity. Progress was hampered by poor air quality charged with fumes from dynamite and large quantities of rock had to be crushed to obtain payable yields. The Victorian Goldfields are filled with ruins and remnants of the area's rich mining history, ranging from small alluvial diggings to the remains of huge mining companies. Site names often changed several times throughout the nineteenth and twentieth centuries. Some sites were abandoned and forgotten, others were worked continuously over many decades. The names of mines were often repeated at different locations throughout the Victorian Goldfields. For example, there is a Mopoke Gully heritage mine near Fryers Creek, Victoria. 'Mopoke' is a common onomatopoeic name for Morepork and Australian Boobook owls.This image has historical, social and research significance for patterns of emigration during of the Victorian Gold Rush, and the historical, social and environmental impacts of mining at Beechworth at the turn of the nineteenth and twentieth centuries. As gold became scarce and government support and large company investment waned, poor hard-working miners laboured intensively to make a living through periods of high unemployment. This image can be compared and studied alongside other historical mining photographs and objects in the Burke Museum Collection. It has potential to improve our understanding of miners working conditions and the shifting character of mining in the Beechworth district.Sepia coloured rectangular photograph printed on gloss photographic paper mounted on card.Obverse: Reverse: A02497/ 1997.2497/ 'Good/ Luck/ Mine'/ Morepork/ Gully/ Mrs Joyce/ Bright/ Tunnel/ 800 ft/ 1899. burke museum, beechworth museum, beechworth, gold fields, gold rush, victorian gold rush, gold ming history, colonial australia, australian gold rushes, mining technology, beechworth historic district, indigo gold trail, migration, indigo shire, good luck gold mine, victorian goldfields, mining syndicates, gold fever, quartz-mining, small-scale mining, old good luck mine, mopoke gully, quartz reefs beechworth