Showing 171 items

matching test equipment

-

Bendigo Historical Society Inc.

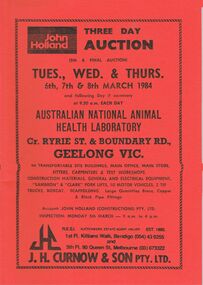

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - AUSTRALIAN NATIONAL ANIMAL HEALTH LABORATORY

Two red covered auction catalogues with black printing for a sale on the 6th, 7th & 8th March 1984 at the Australian National Animal Health Laboratory, Geelong, Vic. For sale were Transportable Site Buildings, Main Office, Main Store, Fitters, Carpenters & Test Workshops, Construction Materials, General and Electrical Equipment, Fork Lifts, Motor Vehicles, Tip Trucks, Bobcat, Scaffolding and Large Quantities Brass, Copper & Black Pipe Fittings. J. H. Curnow & Son Pty. Ltd. Were the auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - australian national animal health laboratory, john holland, j h curnow & son pty ltd, f c dyett, i m dyett, n f dyett, bolton bros pty ltd print -

National Vietnam Veterans Museum (NVVM)

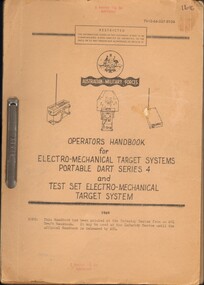

National Vietnam Veterans Museum (NVVM)Booklet, Australian Army, Australian Army: Operator's Booklet for Electro-Mechanical Target Systems Portable Dart Series 4 amd Test Set Electro-Mechanical Target System (2 copies), 1969

A cream coloured cover with black writing and sketches of equipment also in black. the booklet is held together by a metal clasp.australia - armed forces - service manuals, electro-mechanical target system -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, c. 1885

150 years of experience and commitment. Norwegians have been producing and exporting cod liver oil for more than 1000 years. But it was not before 1645 it was reported that cod liver oil could be used to prevent and cure disease. At the end of the 18th century the first scientific article was published to support this. In the middle of the 19th century, the pharmacist Peter Möller observed that people along the west coast of Norway consuming cod liver oil regularly were rarely ill. He dedicated himself to finding out how this healthy liquid could be produced with better taste and pureness at a lower price. He developed a method of using steam to extract the oil from fresh cod livers. Based on this technological advance, the company Peter Möller was founded in 1854 in Lofoten on Norway’s arctic coast, where you find pure, cold, clean seas and high quality raw material. Peter Joachim Möller (1793-1869) At first Möller’s Cod Liver Oil was believed to be a good source of vitamin D and A, and the health benefits were associated with these vitamins. Peter Möller believed, however, that there were other significant benefits from fatty acids and other ingredients in the cod liver oil – both known and unknown. Peter Möller was dedicated to understanding more about these benefits. His dedication and commitment is clear in Möller's vision to improve people’s health by delivering the highest quality omega 3 products. Timeline 1793 Peter Möller is born in Røros, Norway 26 April. 1819 Peter Möller travels to Christiania (Oslo) and is employed by the pharmacist Frantz Peckel at the Svane chemist. He is employed on condition that he passes his pharmaceutical exam within one year. 1822 Graduated as a pharmacist with a unanimous first grade and with the award of the Professor's special satisfaction. 1842 Together with professors A. Holst and Chr. Boeck, Peter Möller participates in the commission which develops the first Norwegian Pharmacopoeia. 1853 Peter announces his method to cod liver oil works along the coast. He equips cod liver oil factories with new equipment in Lofoten, Ålesund and Kristiansund. The facility outside Ålesund is the most important for testing the method. 1854 The Peter Möller company is established as production has started at the three factories. Sales are lower than anticipated even though the quality is considerably better with the new method. The consumers of cod liver oil had been used to the fact that “good medicine must taste bad” and would not believe that the new and better quality was as healthy. Therefore, the following years are used to introduce consumers to the product, and also to convert more producers to the new method. 1869 Peter Möller dies. There are 70 cod liver oil steamers which use his steam rendering method, and 5000 barrels are produced every year. Möller’s company increases the quality by better routines for quality controls. 1870 Severin A Heyerdal, Möller’s son-in-law, assumes the leadership of the firm after Peter's death. He continues the work by improving the quality of the cod liver oil. The goal was to make it as pure and unaltered as in the liver. At this time, Möller had already started selling its product in the USA. In 1870, WH Schieffelin & Co. ("The oldest drughouse in America") was engaged by Peter Möller in the USA. 1881 Frantz Peckel Möller assumes the leadership of the Peter Möller company. He saw it as his duty to further the work on cod liver oil, and through a combination of solid scientific education and an eminent sense of the great mercantile possibilities, he made Möller’s cod liver oil the number one in the world market. 1914 The first world war leads to Möller’s bottled cod liver oil being shut out of the export market. However, domestic sales are good. 1924 The subsidiary Møystad Möller & Co. is established for bulk exports and the Association of Medicinal Cod liver oil Exporters is established in Bergen in 1925. 1925/26 The green bottles are introduced. Medicinal cod liver oil exports remain almost constant, while total Norwegian cod liver oil exports increase. 1938 The factory on the Løren grounds in Oslo, Norway is built. The factory is in the same place today. Peter Möller’s Pharmaceutical Laboratorium A/S is also established to separate out the scientific business. Investment is made in a new facility for refining and bottling veterinary cod liver oil, and increased production of industrial cod liver oil. 1940 The outbreak of the 2nd world war sees exports fall dramatically, while cod liver oil’s significance as a dietary supplement receives increased attention. Domestic sales increase strongly. 1945 After the war, medicinal cod liver oil retains its high status as an important dietary supplement in the “rebuilding" of the country. Cod liver oil becomes an ”emergency product in ravaged areas where the supply situation is difficult. Competition from other countries such as the USA, England and Iceland increases, and Norway no longer dominates the market. 1983 Möller’s cod liver oil in capsule form is launched and palatable cod liver oil is launched. 1990 Peter Möller A/S merges with Orkla Borregaard A/S (now ORKLA) 2005 Peter Möller merges with CollettPharma. The new company is called MöllerCollett. 2007 Merger between MöllerCollet and DanskDroge. The new company is called Axellus. Oval in section with a thin neck, mauve tinted clear glass bottle with text embossed on side.On side : 'P.MOLLER', 'OL JECOR', 'GADOR VER', 'CHRISTIANIA'.cod liver oil, norway, peter moller, christiana, oslo -

Australian Gliding Museum

Australian Gliding MuseumEquipment - Glider – Hang Glider Type, 2013 - 2014

Otto Lilienthal (1848-1896) from Berlin, Germany, is widely credited as being the first person to make repeated successful gliding flights. He was known for adopting a thorough scientific approach founded on observations of the flight of birds in relation to the problem of inventing a man carrying heavier than air machine that would fly. He developed and tested bird-like gliders controlled by weight shift by the pilot (a similar method to modern hang gliders). The pilot held on to the glider with his forearms resting in hoops mounted on the main structural beam connecting the wings. The weight shift was achieved by the pilot swinging his trunk and legs. In contrast, the pilot of a modern hang glider is suspended below the glider and, with the use of an A-frame, allows the whole body to be moved around to achieve control. The Lilienthal design apparently had a tendency to pitch down and a tailplane was added to mitigate this problem. Lilienthal flew from hills in the Rhinow region and from a conical hill he built near Berlin. He made over 2000 flights. Importantly, for others seeking to progress manned flight at the time and also for the historical record, reports of Lilienthal’s flights (some with photographs) were published and Lilienthal detailed his experiences and corresponded with other flight pioneers. Lilienthal’s work became well known and influenced Orville and Wilbur Wright in their initial experiments with gliders in 1899 (although in their quest to design and fly an aeroplane they relied on new data created by wind tunnel testing). The replica built by Bruce Hearn is of the 1893 Lilienthal glider. It is very similar to the “Normal-Segalapparat” (Normal Glider) for which patent protection was later granted a few years later. The Lilienthal replica glider is an important addition to the AGM collection as it represents the beginning of successful gliding flight. Hang glider made of wood with wire bracing – yet to be covered with authentic cotton fabric. The glider has a small plate with identification details including name of builder (Bruce Hearn) glider, hang glider, lilienthal, hearn, replica -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

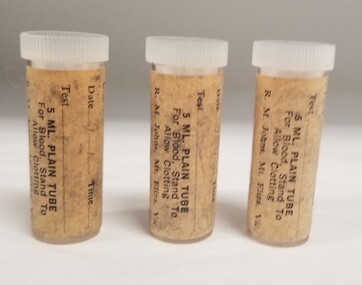

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Equipment - Group of 5ml plastic medical collection tubes

Used to collect medical samples, including blood.Three plastic medical collection tubes, with caps. Labels attached to each of the tubes reads 'P2/Name/Date/Time/Test/5 ML PLAIN TUBE/For Blood, Stand To/Allow Clotting/ R.M. Johns, Mt. Eliza, Vic.'pathology -

Moorabbin Air Museum

Moorabbin Air MuseumProwse Collection Box WP11 See details in Description section

-

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - Wamira NIA E37 Documents and drawings

-

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Medical Tray

White ceramic tray with 12 indentations for pathology Testing Tray (possibily blood)medical -

Moorabbin Air Museum

Moorabbin Air MuseumBook (item) - Electrical & Wireless Equipment of Aircraft - incl. Repair/Overhaul & Testing Magnetos by S.G. Wybrow 5th ed 1945

-

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - Commonwealth Aircraft Corporation Limited Plant Equipment Capacities For Manufacture And Testing

-

Puffing Billy Railway

Puffing Billy RailwayPlatform Scales, Avery

Averys Ltd was the holding company for the 32 operating companies in the Avery Group. The Group's main activity was the design, manufacture, sale and servicing of a wide range of weighing machines, physical testing machines and fluid measuring equipment. The company's history can be traced back to 1730, with the manufacturing by hand of steelyards and beam scales in a small workshop in Birmingham. When legislation was introduced at the turn of the century requiring the stamping of all weighing machines used for trade Avery branches were set up in some 100 towns in the United Kingdom. This was the beginning of the sales and service organisation that expanded to cover not only every important town in the United Kingdom but was also established in many overseas countries. Historic - Railway Platform Scales Avery Platform Scales - Iron and glassavery scales, puffing billy, platform scales, scales -

Uniting Church Archives - Synod of Victoria

Uniting Church Archives - Synod of VictoriaManual - Leadership Training Handbook, The General Court of Australia, Methodist Order Of Knights Leadership Training Handbook, 1968

... and Decorations; Equipment; Uniforms; Merit Badge Tests; Badge ...This handbook contains all the information required for the organising and running a Methodist Order of Knights Court. Index: The Order and the Church; The Nature of the Order; Organisation and Control of the Order; Regalia; Officers and Companions of the Local Court; The Degrees of the Order; Ritual work in the Local Court; Awards and Decorations; Equipment; Uniforms; Merit Badge Tests; Badge Presentation Service; Inauguration Ceremony for New Courts; Service of Dedication for Court Officers; Leadership; Programming; Chairmanship; Know Your Companions; How shall we organise; Weekly programme; Your story and how to tell it; Devotional work; Chancellors; Suggested Introductory letter; Specimen accounts for Chancellors; Appendix for further reading.MOK234.1.1; MOK234.1.2: 99 page book issued by the authority of The Methodist Order of Knights General Court of Australia. The cover of the book is pale blue with royal blue text and image of the Albert Street Methodist Church, Brisbane. MOK234.2 : 87 page book : A General Court Publication 7/65 Methodist Church of Australasia Methodist Order of Knights Leadership Training Manual. This book has the same content as MOK234.1 but has a light green paper cover and no illustrations of badges and awards.non-fictionThis handbook contains all the information required for the organising and running a Methodist Order of Knights Court. Index: The Order and the Church; The Nature of the Order; Organisation and Control of the Order; Regalia; Officers and Companions of the Local Court; The Degrees of the Order; Ritual work in the Local Court; Awards and Decorations; Equipment; Uniforms; Merit Badge Tests; Badge Presentation Service; Inauguration Ceremony for New Courts; Service of Dedication for Court Officers; Leadership; Programming; Chairmanship; Know Your Companions; How shall we organise; Weekly programme; Your story and how to tell it; Devotional work; Chancellors; Suggested Introductory letter; Specimen accounts for Chancellors; Appendix for further reading.methodist order of knights -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Equipment - Natural Gas Conversion Testing Kit

... Conversion Badge. Equipment Natural Gas Conversion Testing Kit ...All items belonged to Harold Victor Allen who worked for Colonial Gas Association Ltd. Firstly at Footscray and then Box Hill in the 1960's. Retired in 1971. Born in Ballarat in 1906. Apprenticed and worked there till 1945, then moved to Footscray. Eileen, his wife, worked with Harold, helping with the Natural Gas Conversion during Harold's Box Hill time.Change over in Victoria from Gas fired gas supply to Natural Gas supply to Victoria from about 1965 -1. Gas testing kit in green metal box, with silver handle and clasp (silver colour)|2. Suction ball and pump body.|3. Detector tubes of glass capillary. 4. Instruction Manual. 5. Sealing cap ( box of 10) All spare parts |6. Natural Gas Conversion Badge.H.V.Allen MSAgas technology, appliances & accessories -

Ambulance Victoria Museum

Ambulance Victoria MuseumSuction Unit, Laerdal, Laerdal, Pre 1997

Mobile suction unit with power. Possibly used from the late 1970s and into the 1980s for mechanical suction control. Possibly used in non MICA rural ambulances. Maintenance sticker on object indicates that it was last serviced in 1997. This suggests that the equipment may have been in use to that date.Grey plastic case with handle containing suction equipmentCHEMTRONICS P/L SAFETY TESTED PERFORMANCE TESTEDsuction -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - RAAF Basic Electronics and Testing Practices Manual, Basic Electronic Technology and Testing Practices: Testing Equipment

... Electronic Technology and Testing Practices: Testing Equipment ...Australian Air Publication (AAP) 7002-028-7 -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Instruction Book, Westinghouse Brake Company of Australasia Limited and The Westinghouse Brake & Saxby Signal Co. Ltd. of 82 York Road and Kings Cross London, "Westinghouse Railway Operating Data", 2000

Photocopy of 54 data sheets published by Westinghouse Electric & Manufacturing Company of East Pittsburgh Pa, USA c1920. Consists of plastic cover, header page with Westinghouse logo, contents sheets (2 pages), forward, 67 pages (single side photocopy) and heavy rear card cover bound with a green comb binder. Original material lent by Craig Tooke of the Melbourne Tramcar Preservation Association at Haddon. Photocopied by Warren Doubleday March 2000. List of contents produced 30/6/2000 and then bound. Contains data sheets regarding motors, commutators, brushes, armatures, bearings, field coils, pinions, lubrication, air piping, axle collars, resistance grids, gear cases and other technical information. Westinghouse Railway Operating Data 30/6/2000 List of Contents Page No. Care and repair of commutators 1 Undercutting commutators 2 Railway Motor carbon brushes 3 Brush holders 4 Flashing of railway motors 5 Soldering railway armatures 6 Armature Winding 7 Banding armatures 8 Railway Motor Bearings 9 Lubrication of railway motor bearings 10 How to babbitt motor bearings 11 Oil, grease and waster for motors and gears 12 Saturation of motor bearing waste 13 Testing Polarity of Field Coils 14 Charging of storage batteries on Interurban & street rail cars 15 Precautions to be taken with blower installations on motor cars 16 Putting on Railway Motor Pinions 17 How to take armatures out of box frame motors 18 Dipping and Baking of Railway Motors 19 War time dipping and baking outfits 20 Dipping and baking railway motors will decrease troubles 21 Protection of Motor Bearings from Dust 25 Winter Operation of Railway Motor equipments 26 Installation of Air piping to prevent freezing 27 Maintenance of Traction Brake Equipment 28 Maintenance of controller fingers and contacts 29 Hand operated circuit breakers 30 Railway Motor Testing I 31 Railway Motor Testing II 33 Railway Motor Testing III 35 Railway Motor Testing IV 36 Railway Motor Testing V 37 Removing and replacing railway motor armature shaft 39 Mounting and Maintenance of car resistors 40 Lubrication of control apparatus 41 Maintenance of fuse boxes for railway service 42 Does it pay to dip and bake armatures 43 Dipping and Baking as a financial asset 44 Shop Organisation 45 Tinning Malleable Iron Bearing shells 46 Life of armature bearings or railway motors 47 The assembly of complete sets of commutator segments 48 Electric welding as a factor in reclamation 50 Metal to Metal press, shrink and clamping fit allowances 52 Life of railway motor carbon brushes 54 General information of grid resistance design for the operating man 56 Stopping a car by braking with the motors 57 Railway Motor shafts and their maintenance 58 Axle collars 59 Gear cases 60 Ventilated railway motors 62 Revamping Loose armature bearings 64 Life of axle bearings of railway motors 65 Heat-treated bolts for railway service 66 Document imaged over 7 parts 7-9-2016 - see hi res files. trams, tramways, westinghouse, motors, data sheets, technical information -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, The Electric Railway Improvement Co. (ERICO), "Notes on Bonding and Return Circuits", c1916

Book, titled, "Notes on Bonding and Return Circuits" consisting of 20 pages, printed in black ink. Prepared by The Electric Railway Improvement Co. of Cleveland, Ohio, USA. Gives costs of welding, bonding, rail resistance, voltage drops, testing methods, electrolysis, rail expansion, rail section, sleeper track, treatment of ties (sleepers), and the monthly average price of copper from period 1885 to Dec. 1915, the power required for electric traction and a list of clients. Date of printing not given in document, estimated to be c1916. See also item Reg. No. 1638 for a book on equipment for welding and bonding.trams, tramways, trackwork, rail bonding, erico, welding -

Ballarat Tramway Museum

Ballarat Tramway MuseumMagazine, Jack Richardson, "Tram Tracks - The Electric Traction Monthly", Oct to Dec. 1946

Three issues of "Tram Tracks - The Electric Traction Monthly" of the Australian Electric Traction Association. Each issue has a standard cover, of the magazine name etc, with a small advertisement for the Model Dockyard but are in different colours, all have been saddled stapled with two staples. The Volume and date details have been over stamped using a hand stamp. Back covers, inside back covers have the same advertisements. The three issues contain advertisements for Hartleys Sports store, Hearns Hobbies, Wattle Park, Johnson's Variety Store, Barnes Tennis Centre, The Model Dockyard, Meadmore Model Engineering and Austral Bronze Pty Ltd, Christie Scale Model Railway and Equipment, Herbert Small (Meccano) and Bassett-Lowke Models. 2464.1 - Vol. 1, No. 6 - 12 pages, Oct. 1946, with cover printed in blue. Has articles on staff and ticket working on VR tramways, Tramway rolling stock classification, rolling stock listing for SEC Bendigo, and the first 65 years of electric traction. News items on Sydney, Melbourne, Ballarat, Newcastle, Hobart and AETA. Inside front cover has a photo of Y1 611. 2464.2 - Vol. 1, No. 6 - 16 pages, Nov. 1946 with cover printed in brown. Has articles on bus profits, route symbols on Australian tramways, Hobarts double deckers, high current collection tests, rolling stock listing for SEC Geelong, VR Electric locos, and the first 65 years of electric traction continued. News items on Sydney, Melbourne, Ballarat, VR, Brisbane, Adelaide, Perth, Fremantle, Kalgoorlie, overseas and AETA. Inside front cover has photos of Sydney R and R1 class trams. 2464.3 - Vol. 1, No. 7 - 12 pages, Dec. 1946 with cover printed in green. Has articles on NSW tram and bus losses, proposed abandonment of the Sandringham - Block Rock line, Elwood Depot, rolling stock listing of NSW Service stock. Has news items on Brisbane, Sydney, Newcastle, Melbourne, Adelaide and AETA news. trams, tramways, electric traction, aeta, models, australian tramways -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - Research at Woomera Lithgow Salisbury Long Tom missile Fatigue testing Small arms Chemicals Explosives Mirage construction Textiles for military Marine diesels Tank transporters, Australian defence equipment research testing and supply

... Moorabbin melbourne Australian defence equipment research testing ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - Equipment testing using a small digital computer, GAF Malkara missile Equipment testing

... Moorabbin melbourne GAF Malkara missile Equipment testing Document ... -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, British Engineering Standards Association and Australian Commonwealth Engineering Standards Association, "Tramway Axles", 1921 to 1933

.1 - Book - 16 pages + light grey cover, issued by the British Engineering Standards Association, British Standard Specification for Tramway Axles. Dated August 1921. Has standard Number 101-1921. Provides materials specification, testing and an index. Inside the front cover is a typed quarto sheet, that has been folded into four referring to the standard and "Amendments suggested to clauses 1, 8, 9 , 12 and 13". .2 - Book - 24 pages + grey covers, - Tentative Australian Standards specification for Tramway Axles, published by the Australian Commonwealth Engineering Standards Association, No. C 44 - 1927. Provides materials specification, testing and an index. .3 - Book - 28 pages + light grey cover, issued by the British Engineering Standards Association, British Standard Specification for Tramway Axles. Dated August 1921. Has standard Number 102-1930. Provides materials specification, testing and an index. On front cover and inside cover has amendments and a note that the British standard had been endorsed by Australian Standard C44 in Dec. 1933..1 - has the stamp of the "Tait Book Co. 39 Queen St. Melbourne" .2 - has in the top right hand corner, the ESCo Ballarat company stamp and the date "31 May 1928" .3 - on front cover stamp " Library Copy M.E.S." and a library label noting that the book is on loan from the Melbourne library and is dated 22/1/1935. Provides materials specification, testing and an index. On the lower edge has the stamp of the "Tait Book Co. 39 Queen St. Melbourne".trams, tramways, tramways, electrical equipment, axles -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, British Engineering Standards Association, "Cast Steel Wheel Centres for Electric Tramcars", "Wrought Iron Wheel Centres for Electric Tramcars", 1922

.1 - Book - 20 pages + light grey cover, issued by the British Engineering Standards Association, British Standard Specification for "Cast Steel Wheel Centres for Electric Tramcars". Dated April 1922. Has standard Number 150-1922. Provides materials specification, testing and an index. .2 - Book - 16 pages + light grey cover, issued by the British Engineering Standards Association, British Standard Specification for "Wrought Iron Wheel Centres for Electric Tramcars". Dated April 1922. Has standard Number 149-1922. Provides materials specification, testing and an index. Both copies has the stamp of the "Tait Book Co. 90 William St. Melbourne" on the lower edge and in the top right corner, the ESCo Ballarat company stamp and the date "14 September 1923". trams, tramways, tramways, electrical equipment, wheels -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Commonwealth Engineering Standards Association, "Electrical Performance of Traction Motors - Direct Current Series Wound", 1925

Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard C.2 - 1925, "Electrical Performance of Traction Motors - Direct Current Series Wound". Dated Dec. 1925. Provides an index and information about enclosures, ratings, testing and information to be supplied.On top right hand corner has stamp of the "The Electric Supply Co. of Victoria Ltd Ballarat" and date "17 April 1934".trams, tramways, tramways, electrical equipment, motors -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Commonwealth Engineering Standards Association, "Contactor Starters for Electric Motors", "Dimensions of insulated annealed copper conductors for electric power and light including voltage tests", "Vulcanised Fibre for Electrical Purposes", "Bus-bars and connections constructed of bare copper or aluminium", "Fixed Condensers for Radio Reception Purposes", "Graphic (Recording or chart recording) ammeters, voltmeters and wattmeters.", "5-Amp two pin wall plugs and sockets for domestic purposes (without earthing connection)", "Electric Cable Soldering Sockets", "Graphical Symbols and Schedule of Outlets for the Electrical Equipment of Buildings", "Porcelain Insulators for overhead powerlines and outdoor switching Structures", 1927-1939

.1 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Contactor Starters for Electric Motors" C49-1927, December 1927. .2 - Book - 56 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Dimensions of insulated annealed copper conductors for electric power and light including voltage tests" C50-1928, June 1928. .3 - Book - 36 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Vulcanised Fibre for Electrical Purposes" C51-1928, May 1928. .4 - Book - 16 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Bus-bars and connections constructed of bare copper or aluminium" C52-1928, May 1928. .5 - Book - 16 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Fixed Condensers for Radio Reception Purposes" - C53-1928, February 1928. .6 - Book - 32 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard "Graphic (Recording or chart recording) ammeters, voltmeters and wattmeters." C54-1928 March 1928. .7 - Book - 20 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "5-Amp two pin wall plugs and sockets for domestic purposes (without earthing connection)" C55-1928, August 1928, .8 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard "Electric Cable Soldering Sockets" C56-1929, March 1929. .9 - Book - 8 pages + brown covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Australian Standard "Graphical Symbols and Schedule of Outlets for the Electrical Equipment of Buildings" C64 and 65-1935, October 1935. .10 - Book - 24 pages + brown covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Australian Standard "Porcelain Insulators for overhead powerlines and outdoor switching Structures" C67-1939, August 1939. On top right hand corner has the date stamp of the "The Electric Supply Co. of Victoria Ltd Ballarat" for items .1 to .8, SEC stamp on .10. trams, tramways, power station, standards, materials, electrical systems -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Manual, Kingcrome and Austlift, "Kingcrome Workshop chain block", 2015

Set of three documents involved in the acquisition and installation of a crane trolley and two tonne chain block at the depot December 2014. Purchased from GB Fasteners December 2015. .1 - "Kingcrome Workshop chain block" - owners assembly and operating manual. .2 - "Austlift Beam Girder Trolley Instruction Manual" - ditto .3 - "Austlift Test certificates" - for the above girder trolley.tramways, trams, btm, equipment, certificates, depot -

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumTool - Cranks for Barlow winch

Started way back in the mid sixties, Malcolm Barlow first started to build BARLOW winches in a small garage in Sydney. Even though, or maybe because of the uncanny resemblance of those early winches to the American manufactured BARIENT winches, they have stood the test of time.Australian made yachting winch equipment made in the 1960sA wooden box containing 3 winchesBarlow, Australia yachting, barlow winches, winches -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook - Instruction, Westinghouse Traction Brake Co, "Westinghouse - T5001-1 Straight-Air Brake Equipment", March 1923

Has a table of contents, outlines the rules of operating brake equipment fitted to tramcars, the SM3, SX2 brake valve, locomotive straight air, installation piping, wiring, maintenance - piston travel, lubrication, car tests, hints to Motormen and Conductors and General Hints. Schedule for SM-1 and featherweight equipment. Includes instructions on compressors, air intakes, valves, cylinders and governors.Provides instructions about Westinghouse air brake equipment used on tramcars around the world.Instruction - 48 pages + light brown card cover centre stapled with cloth binding on outer edge + 13 fold out drawings inside the rear cover, titled "Westinghouse - T5001-1 Straight-Air Brake Equipment". Dated March 1923. On first page a signature in ink - "W. Armstrong"?brakes, electrical engineering, •electrical equipment, •westinghouse, •air compressors, •instructions, •maintenance -

Kew Historical Society Inc

Kew Historical Society IncEquipment, ACME, The ACME British Made Wringer, 1920-1929

A large device for drying laundry consisting of two rollers between which the wet laundry is squeezed (or wrung); a mangle. American English uses the term 'wringer' whereas UK English uses the term 'mangle'. Later devices were typically electrified.Intact item of household (laundry) equipment.Domestic laundry equipment. Wringer of Mangle. Two rollers in Metal frame. Hand operated."ACME M 14 A WRINGER / ROLLS 14" / ROLLS 14" "THE ACME BRITISH MADE WRINGER / THE WRINGER WITH THE FIVE YEARS GUARANTEE" "USE THIS BOARD FOR MANGLING ONLY / IT FITS ON THE OTHER SIDE OF THE WRINGER / CLOTHES SHOULD BE FOLDED CAREFULLY AND MANGLED SLIGHTLY DAMP. EVEN IF YOU ARE GOING TO IRON IT WILL SAVE HALF THE LABOUR IF YOU MANGLE FIRST." "TESTED AND APPROVED SERIAL No.166 / GOOD HOUSEKEEPING INSTITUTE LONDON / Conducted By GOOD HOUSEKEEPING INSTITUTE MAGAZINE." acme wringer, mangle, laundry equipment