Showing 1150 items matching "lamp"

-

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s - set 16, John Theodore, 15/10/1978 12:00:00 AM

Yields information about the official opening by the BTPS of its operations in Wendouree Parade at the time of the 1978 AGM and the building extensions.Set of 16 AGFA blue and white plastic mount 35mm slides of the 1978 AGM at the depot and tram operations in Wendouree Parade - 15/10/1978 (September 1978 Fares Please!) .1 - 27 at St Aidans Drive .2 - ditto with a Sovereign Hill roof Advert .3 - ditto .4 - ditto at Carlton St .5 - ditto .6 - 27 arriving Depot Junction - note the signal lamp .7 - ditto .8 - looking up the access track .9 - Building extension works underway 10 - ditto showing the pits .11 - showing the stockpile of gravel .12 - 1978 AGM in progress - note the landscaping .13 - ditto .14 - 27 on the 3 road extension .15 - 40 and 27 at the depot fan .16 - depot fan and 27. Various notations by John as to the slide number and the trams in pencil and ink.tramways, trams, btps, wendouree parade, meetings, depot, buildings, tram 40, tram 27 -

Ballarat Tramway Museum

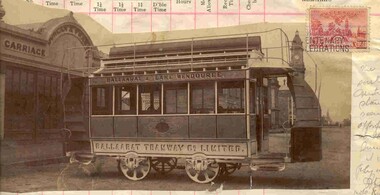

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, 1887

Black and white photograph contained within Reg. Item 2526, page 3 of the pattern Ballaarat Tramway Co. Ltd outside the Duncan & Fraser's Carriage Works in Adelaide. Has a Australian 2d stamp (1936 South Australian Centenary) over the top right hand corner. Has been cut from a larger photograph. Handwritten notes in pencil noting the time of the photograph, the tram weight, couplings, lamp brackets, the possible purpose of the photograph, the incompleteness of the tram when compared to actual running condition. Dated 7/1/1940. Also notes on the 3 legged stool used by the horse tram drivers and the double decked buses operating then in Melbourne ( Bourke St.). Has sketch of the stool in ink. Note Item Not formally Numbered.tramways, trams, horse trams, duncan & fraser, adelaide, double deck buses -

Ballarat Tramway Museum

Ballarat Tramway MuseumPostcard, Victoria Stamp Market and Melbourne, Gen. View Sturt Street, Ballarat

Printed black and white postcard of the Sturt St looking west from Grenville St. Has the large gas lamp in the centre of the intersection with Grenville St. Card had a stamp on the photo side, but has been removed - only the remnants of the gum and postmark remain. No horse tram lines visible. Photo assumed to be pre 1887. Written on the front "Best Wishes from Dorrie ?" and date "8/4/06". Printed along the lower edge "Published by Victoria Stamp Market, Melbourne" and "Printed in Germany". On rear is places for stamp, address only. Addressed to Mss L Schwarz, Waiwhitu Road, Lower Hutt, Wellington New Zealand. Written on the stamp position is "The ........ on other side". Titled "Gen. View Sturt Street, Ballarat." along bottom edge of the photo. trams, tramways, sturt st, postcards, grenville st -

Royal District Nursing Service (now known as Bolton Clarke)

Royal District Nursing Service (now known as Bolton Clarke)Photograph - Photograph, black and white, Barry Sutton, 11.05.1971

Mr. John Rossiter is the Minister of Health of Victoria. The RDNS Sisters are wearing their uniforms of grey dresses, red cardigans and grey peaked hats. The RDNS badge on their hats are made of metal with a royal blue circle containing the letters "Royal District Nursing Service". The inner section is divided in three parts; the upper and lower sections are silver and the centre section has the capital letters RDNS written in royal blue across it.Black and white photograph showing seven Royal District Nursing (RDNS) Sisters, four only partially seen, walking along a footpath with Mr. John Rossiter. Mr. Rossiter, who is in the centre of the photograph and group, has balding dark hair and is wearing a white shirt, striped tie, and a dark striped suit with a white flower in the button hole on his left lapel; a corner of a white handkerchief is seen in the left pocket of his jacket. The full view of three RDNS Sisters can be seen wearing their uniforms of a grey frock and dark cardigan and grey peaked hats with a round badge in the centre. In the background are some cars on the road, lamp posts and some trees. A white fence and a brick house with a tiled pitched roof is seen in the right hand side background.Photographers stamp. Quote No. KG 48royal district nursing service, rdns, rdns uniform, mr john rossiter -

Mont De Lancey

Mont De LanceyDecorative object - Horse Dairy Buggy Model, Chas W Davis

The collection of thirteen model horse drawn vehicles were carefully handmade by Mr Chas W Davis 1925 - 2002. He was a talented artist and saw doctor. This model of a horse drawn Dairy Cart replicates the vehicle that enjoyed respect from the public during the 1880 and early 1900's. A model of a horse drawn black open Davis Dairy Buggy or Cart which is a lightweight two wheeled one passenger open horse drawn carriage where the driver sits behind. It has two large gold painted spoked wheels with black rims and mudguards, blue painted seating and gold painted armrests, two gold coach lamps and gold patterned footrest in front of the driver. At the rear are three silver milk cans with two taps to dispense the milk. There are two long brown wooden shafts on each side to surround the horse. It has a model of a brown coloured horse with a black tail and mane, which has the necessary horse tack for carriage use to help the driver communicate with the horse. These carrier carts or vans were two wheeled medium weight Commercial Vehicles.DAVIS DAIRY painted in white lettering on each side of the cart.replicas, models, scale models, vehicles, carriages, horse drawn vehicles, toy horses, early commercial vehicles, milk cart -

Bendigo Historical Society Inc.

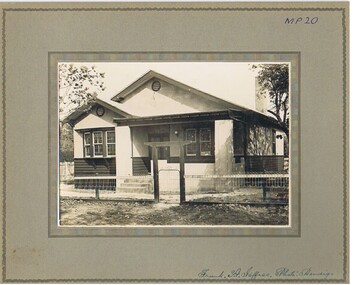

Bendigo Historical Society Inc.Photograph - T C WATTS & SON COLLECTION: MARKS STREET, BENDIGO, 1929

Andrew Balsillie (30/8/1874-28/7/1949. For 50 years he was associated with the Bendigo Mutual Permenant Land and Building Society and was its secretary from 1916 to 1945. He was the son of Andrew and Maria (nee Laing), who operated Edinburgh House selling ladies and gentlemen's clothing. Andrew Jnr. married Helen (Nellie) Calder in 1903.Black and white photographs (2) mounted on rectangular brown board. House, stained weatherboard board to sill height, rough cast above, bow lead- light window on right, leadlight windows on left, louvred vents to both front gables, tiled roof, roughcast verandah surround and pillars, 3 steps to veranda level, one chimney visible, small white veranda lamp, woven wire fence. Gate wooden gateway with lintel. On back of photo 18a: 'Sold Balsillie £875 sewered, or £825 plus sewerage. Stamp with T.C. Watts & Son, 253 Mitchell St., Bendigo., 12 April, 1929' On back of 18b. A. Balsillie, Marks St., £950 (crossed out ) £875, sewered or £825 plus sewerage.' May 1929.Frank A. Jeffree Bendigobuilding, residential, t.c. watts and son, balsillie, marks street bendigo -

Kiewa Valley Historical Society

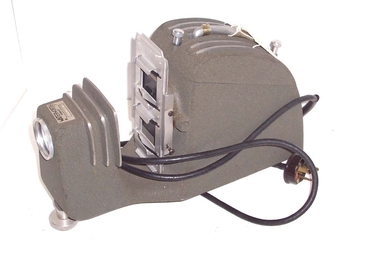

Kiewa Valley Historical SocietyTransformer Lamp System, late 1950's

This transformer lamp system, which has a dial to transform 240 volts to a minimum of 32 volts was used by electrical technicians to inspect internal parts of the large generators (even in small confined spaces). The reason for the reduction of the 240 volts to the 32 volts was for the safety of the inspector. The SEC Victoria Hydro Scheme's electrical generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro schemes was achieved from the mid 1900's to the 1960's. At this the point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This transformer lamp is very significant to the Kiewa Valley as it was introduced as a very small part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both industrial and larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley. This is also a specific electronic item which was manufactured in Melbourne and not sourced from Europe or Asia. This demonstrates the fast evolution of Australian technology to a high standard compatible to that of the rest of the world.This heavy hand held electrical transformer (transforms 240 volts to 32 Volts) an has one leather handle on the top with three small (gauze filtered) air holes. It also has two 2 pin directional cable distribution (clipsal) in/out points 10amps / 240 volts. There is one glassed in volts/ac meter and one variable switch (180 to 150 voltage in settings of 10 volt increments.There are two vents (one on each of the smaller sides). There is also one three pin electrical lead coming out from the top.On one side is a manufacturer's plaque with "ELECTRONIC A & R EQUIPMENT MELBOURNE" and underneath "TYPE 1719, PRI V. 180 250" underneath "V.A. 1250" underneath "CYC 50" underneath "SEC V. 115" underneath "SEC A. 10 . 8". The label on topside "CAUTION SET SWITCH TO 250 v BEFORE CONNECTING TO MAINS THEN, WITH EQUIPMENT OPERATING, SET METER TO RED LINE.kiewa hydro electricity scheme, victorian state electricity commission, transformers -

Bendigo Historical Society Inc.

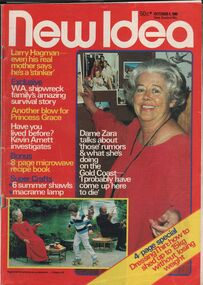

Bendigo Historical Society Inc.Magazine - AILEEN AND JOHN ELLISON COLLECTION: NEW IDEA OCTOPBER 1980

New Idea magazine from October 4th, 1980. on the cover: Larry Hagman - Even his real mother says he's a stinker! Exclusive W. A. shipwreck family's amazing survival story. Another blow for Princess Grace. Have you lived before? Kevin Arnett investigates. Bonus 8 pages microwave recipe book. Super crafts: 6 summer shawls -macramé lamp. Dame Zara talks about "those" rumours and what she is doing on the Gold Coast "I probably have come up here to die". 4 pages special: dressing thin: how to shed up to 15 kg. without losing weight. Price 50 cents. The magazine has 144 pages but from page 42 to page 129 there are a lot pages missing and the one left are all loose.books, magazines, women's magazine -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - WES HARRY COLLECTION: SYMONDS' CRITERION FAMILY HOTEL, BENDIGO

Photograph of a double storied stone building, it has a three quarters length open verandah along the first floor. The name 'Symonds Criterion Family Hotel' is painted above the first floor. There is a large lamp on a bracket on the right hand side of the building. To the left of the main structure there is a smaller weatherboard building with the word 'Hotel' painted along the top. There are several groups of people both on the ground and on the balcony, also in front of the hotel is a very up market buggy/wagonette with a coachman? Driving. This hotel was on the corner of Mundy and Hargreaves Streets, and is significant as centre of events as it overlooked the original Market Square. Original photo is part of the Batchelder Collection owned by the State Library of Victoria. Published in 'An American on the Goldfields' p. 38-39 with description and details. See also Mosaic No. 1232. *See Research field for further details. Symonds operated the Criterion Hotel 1858 - 1862.Batchelderbuildings, hotel, criterion family hotel, criterion family hotel. mundy street hargreaves street. market square. princess theatre. symonds, joseph s. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Slide/Film Strip Projector, c1960

The donor received the projector from a relative. He used it in the City of Whitehorse and surrounding areasWaterworth Slide Film Strip Projector, Model A - 300 watt, without a fan but with ventilating slots on top and an open bottom for air to flow. It has a carrying handle and a power lead with 3 pin plug which is wired in permanently. The projector lamp is at rear under the carrying handle. Image is projected through three stage lens via via the image on the 35mm strip or slide. The front lens is adjustable for focus. A knurled nut enables a height adjustment at front. Slides are inserted through the holder - whilst one slide is shown the other can be loaded ready to be slid in front of the light. The film strip holder is missing. The unit is finished in a grey hammer finish paint used in 1960 t0 1980s. The operating instructions are filed in the supplementary envelope. The projector is stored in a hand made three ply hinged box.Waterworth Hobart 5553Aphotography, projectors -

Kew Historical Society Inc

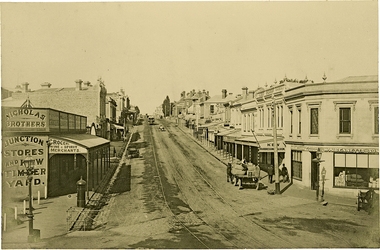

Kew Historical Society IncPhotograph, J F C Farquhar, High Street, Kew, 1891

At the beginning of the 1890s, the Kew businessman and Town Councillor, Henry Kellett, commissioned J.F.C. Farquhar to photograph scenes of Kew. These scenes included panoramas as well as pastoral scenes. The resulting set of twelve photographs was assembled in an album, Kew Where We Live, from which customers could select images for purchase.The preamble to the album describes that the photographs used the ‘argentic bromide’ process, now more commonly known as the gelatine silver process. This form of dry plate photography allowed for the negatives to be kept for weeks before processing, hence its value in landscape photography. The resulting images were considered to be finely grained and everlasting. Evidence of the success of Henry Kellett’s venture can be seen today, in that some of the photographs are held in national collections.It is believed that the Kew Historical Society’s copy of the Kellett album is unique and that the photographs in the book were the first copies taken from the original plates. It is the first and most important series of images produced about Kew. The individual images have proved essential in identifying buildings and places of heritage value in the district.In 1891, High Street was the centre of commercial activity in the Borough of Kew. It was unpaved and edged with deep bluestone gutters, which were designed to channel the significant flow of storm water down the hill to and beyond the Junction. On either side of the entrance to the shopping strip are two cast iron gas lamps that provided the only public street lighting before the Post Office was reached. Most shops, including the Nicholas Brothers’ Junction Store featured cast iron verandas. Further up the hill, Dougherty’s Greyhound Hotel was by this stage a local institution. Apart from the horse-drawn tram, the main form of personal and commercial transport in this period remained the horse, horse and cart, or buggy.The panoramic view predates the widening of High Street in the 20th century, and thus includes the original alignment of buildings on the south side. These included Henry Kellett’s shop.High Street, Kewkew illustrated, kew where we live, photographic books, henry kellett, high street - kew (vic) -

Mont De Lancey

Mont De LanceyDecorative object - Hampden Buggy Model, Chas W. Davis, Unknown

The collection of thirteen horse drawn vehicles were carefully handmade by Mr Chas W Davis 1925 - 2002. He was a talented artist and saw doctor. This model of a horse drawn Hampden Buggy replicates the vehicle that enjoyed respect from the public from c.1800's. It came in various types.A model of a Hampden buggy, c1900. The body is low to the ground, making it easy for passengers to board and disembark as well as allowing for speed and is lightweight for one horse to pull, making the journey cheaper than using four horses. It has four spoked wheels, two large and two small which have gold painted mudguards. It has brown padded seating, gold painted armrests and two coach lamps. There are two long shafts on each side to surround the biscuit coloured horsel with a white tail and mane, which has the necessary horse tack for carriage use to help the driver communicate with the horse. The original Hampden buggy was the inspiration of K.Booth, an American coach maker. It was designed for the ladies to show off their finery. Keep Bros. and Wood of Melbourne built many variations of buggies for wet or dry conditions.replicas, models, scale models, vehicles, carriages, horse drawn vehicles, toy horses -

Mont De Lancey

Mont De LanceyDecorative object - Coach Model, Chas W Davis

The collection of thirteen model horse drawn vehicles were carefully handmade by Mr Chas W Davis 1925 - 2002. He was a talented artist and saw doctor. This model of a three horse drawn enclosed coach replicates the vehicle that enjoyed respect from the public during the 1880's. There were four horse drawn models as well.A model of a black enclosed coach which is a four wheeled passenger horse drawn vehicle where the driver sits at the front behind the three brown horses. It has two large and two smaller gold painted spoked wheels with black rims, two gold painted coach lamps, black padded seating and four open windows with blinds that are rolled up. There are two doors with a step for easy access into the coach. A long brown wooden shaft separates the horses which also have black vinyl shaft style straps on both sides as well as the necessary horse tack for carriage use to help the driver communicate with the horses. A hand operated brake is next to the driver with the brake pads attached to the back wheels. There is a brown wooden slotted luggage rack at the back held on by two gold chains. On top of the coach is a decorative gold painted luggage rack. replicas, models, scale models, vehicles, carriages, horse drawn vehicles, toy horses, road transport, coaches -

Mont De Lancey

Mont De LanceyDecorative object - Black Buggy Model, Mr Chas W. Davis, Unknown

The collection of thirteen horse drawn vehicles were carefully handmade by Mr Chas W Davis 1925 - 2002. He was a talented artist and saw doctor. This model of a one horse drawn buggy replicates the vehicle that enjoyed respect from the public from 1833 until 1935. It came in four types.A model of a black enclosed buggy and horse, with two doors and two tinted windows. It is a two wheeled two passenger horse drawn carriage where the driver sits behind on the high seat with silver armrests. The body is low to the ground, making it easy for passengers to board and disembark as well as allowing for speed and is lightweight for one horse to pull, making the journey cheaper than using four horses. It has two black spoked wheels with silver rims, brown seating, silver handles on the doors and two black coach lamps at the back. There is a silver step on the side of the body near the footrest to aid alighting and disembarking.There are two long shafts on each side to surround the horse. It has a model of a brown coloured horse with a white tail and mane, which has the necessary horse tack for carriage use to help the driver communicate with the horse. replicas, models, scale models, vehicles, carriages, horse drawn vehicles, toy horses -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph Album, Photographs of Ballarat Buildings by Geoff Biddington, 1967, 1967

At one time Her Majesty's Theatre was known as the Memorial Theatre. When these photos were taken Geoffrey Biddington was highly involved with the Ballarat Branch of the National Trust. Lenaghan of Tourello "Master Dan Lenaghan, eldest son of Mr. and Mrs. R. Lenaghan, of Tourello, has been successful in obtaining a Government scholarship, tenable for four years at St. Patrick's College, Ballarat.(Melbourne Advocate, 02 March 1939) Black folders of Ballarat photographs as follows: .1) Ballarat City Council Logo on Ballarat Botanical Garden Gates .2) Ballarat Railway Station .3) Ballarat Town Hall .4) Ballarat Fire Station, Ballarat East .5) Interior of Ballarat Railway Stations .6) Ballaarat Municipal Libraries Barkly Street Branch, formerly Ballarat East Library .7) Entrance to Ballarat Presbyterian Church? .8) Former Ballarat Baptist Church, Dawson Street .9) Church with small steeple, erected AD 1860 .10) Brick Church with steeple .12) Gates of the former Ballarat Gaol .13) Gates of the former Ballarat Gaol .15) Craig's Hotel, Nominee Brian D. Foley .16) ? .17) Interior of Her Majesty's Theatre, Ballarat .18) Bailey's Mansion, later used as the St John of God Convent .19) Lal Lal Blast Furnace .20) Gates of St Patricks Cathedral Ballarat, looking towards the Cathedral Hall .21) .20) Gates of St Patricks Cathedra, Sturt Street, Ballarat .22) ? .23) Lenaghan's Tourello .24) Ballarat Terrace, c1967 .25) Entrance to Ballarat Terrace, c1967 .26) ? .27) Entrance gate to Novar, Webster Street, Ballarat .28) Interior of Ballarat Railway Station, c1967 .30) Pratt's Warehouse, Camp Street, Ballarat, c1967 .31) Entrance gate to Novar, Webster Street, Ballarat .32) Cast Iron Gate .33) Cast Iron Gate .34) Cast Iron Gate .35) Ballarat New Cemetery Gates .36) Cast Iron Post Cap .37) Cast Iron lamp .38) Cast Iron lamp .39) Ballarat Botanical Gardens Statuary Pavilion .40) 'Flight of Pompeii' statue in the Ballarat Botanical Gardens Statuary Pavilion ballarat city council logo on ballarat botanical garden gates, ballarat botanical garden gates, ballarat railway station, ballarat town hall, ballarat fire station, ballarat east, interior of ballarat railway stations, ballaarat municipal libraries barkly street branch, formerly ballarat east library, entrance to ballarat presbyterian church?, former ballarat baptist church, dawson street, church with small steeple, erected ad 1860, brick church with steeple, gates of the former ballarat gaol, craig's hotel, nominee brian d. foley, brian d. foley, interior of her majesty's theatre, ballarat, bailey's mansion, later used as the st john of god convent, lal lal blast furnace, gates of st patricks cathedral ballarat, looking towards the cathedral hall, gates of st patricks cathedral, lenaghan's tourello, ballarat terrace,, entrance to ballarat terrace, entrance gate to novar, webster street, ballarat, interior of ballarat railway station, c1967, pratt's warehouse, camp street, ballarat, c1967, cast iron gate, ballarat new cemetery gates, cast iron post cap, cast iron lamp, ballarat botanical gardens statuary pavilion, 'flight of pompeii' statue, architectural features -

Alfred Hospital Nurses League - Nursing History Collection

Alfred Hospital Nurses League - Nursing History CollectionBook - Illustrated textbook, Tom Jones et al, Manual of surgical anatomy: prepared under the auspices of the committee on Surgery of the division of medical sciences of the National Research Council, 1945

Book containing anatomical drawings and an explanatory index.Illustrated book with black cloth cover. Abbreviated title, series name and words 'national research council" stamped in silver on front cover along with logo of the Alfred Hospital in gilt. Abbreviated title authors surnames' and publisher's name stamped in silver on spine.non-fictionBook containing anatomical drawings and an explanatory index.human anatomy, medical education, ahnl, surgery -

Mont De Lancey

Mont De LanceyDecorative object - Horse Piano Box Buggy Model, Chas W Davis, Unknown

The collection of thirteen model horse drawn vehicles were carefully handmade by Mr Chas W Davis 1925 - 2002. He was a talented artist and saw doctor. This model of a horse drawn Piano Box Buggy replicates the vehicle that enjoyed respect from the public during the 1880 and early 1900's. A model of a red and black Piano Box Buggy c.1860 which was a lightweight two wheeled one passenger open horse drawn carriage with a black canopy roof where the driver sat behind. It has two large and two smaller gold painted spoked wheels with black rims, brown painted seating, two gold coach lamps and a black patterned footrest in front of the driver. The canopy has thin gold struts to open and close it depending on the weather. There are two long brown wooden shafts on each side to surround the horse. It has a model of a biscuit coloured horse with a white tail and mane with the necessary horse tack for carriage use to help the driver communicate with the horse. It was also known as the 'Bonner Buggy' and had many variations. Coach builders designed and made their own style, giving it their own name. There could have been scores of different Piano Box buggies.replicas, models, scale models, vehicles, carriages, horse drawn vehicles, toy horses -

Melbourne Tram Museum

Melbourne Tram MuseumSlide - Set of 5, Keith Caldwell, Oct. 1978

Set of 5 Agfa colour slide, blue and white plastic mount, photo by Keith Caldwell Oct 1978 of trams in Bourke St. .1 - W7 1027 at Exhibition St with the Southern Cross Hotel in the background. Tram has the destination of West Preston Route 88. In the view is a sign for the "Melbourne Hotel". "1-11-78" .2 - Z44 and Z51, west bound with the new building for the State Savings Bank of Victoria in the background along with London Stores, McEwans hardware store and the Rochelle House. Route 95. .3 - Z83 as for .2 .4 - Z75 - west bound between Queen and William St. .5 - Z83 outbound at the corner of Bourke and Spring Streets and Z94 inbound turning on the curve, both route 88. Photo taken from the steps of Parliament House and has one of the ornate lamps in the view. Has the Imperial Hotel in the background, along with Hoyts the Cinema Centre, Windsor Hotel.1 - has "1-11-78" written in red ink.trams, tramways, bourke st, parliament, route 88, west preston, route 95, w7 class, z class, spring st, tram 1027, tram 44, tram 51, tram 83, tram 75, tram 94 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: PHOTO OF SHOP FRONT DISPLAY WINDOW

See Item 11000.189Photo of shop Front Display Window: A black and white photo of large open windows with a central door. In the window on the left side wall is a display sign with *Hanro* A stand along display sign with a golfer swinging a club and two golf balls near by. Casual wear and shirts are displayed around with spools of thread. A Chair with cardigans is also displayed. Some plants are in the window and in the front is a sign with *Benknit Sports Wear for men and women, Product of Hanro (Aust) Bendigo Knitting Mills Pty Ltd. In the right window is a display of lingerie with yards of material draped through out the window. At the bottom of the photo is the imprint of the photographer *Bartlett Bros, Bendigo. A small tear at the top middle. The reflections in the windows is of the veranda with a lamp hanging from underneath and trees. On the back is the circular *Royal Historical Society of Victoria Bendigo Branch in blue ink. At the right top side in black ink in *MP368*. Box 116ABartlett Bros, Bendigo.photograph, streetscape, window display, hanro. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Education, Braille playing cards, 20thC

Braille is a system of touch reading and writing for blind persons in which raised dots represent the letters of the alphabet Braille is read by moving the hand or hands from left to right along each line. Residents of Moorabbin Shire used these cards at social gatherings. In the early 1800s Charles Barbier, who served in Napoleon Bonaparte’s French army, developed a unique system known as “night writing” so soldiers could communicate safely - without lamps- during the night. Louis Braille, born Coupvray, France 1809 lost his sight at a very young age, 1819 he was enrolled at the National Institute of the Blind in Paris.and began to modify Charles Barbier’s “night writing” code in an effort to create an efficient written communication system for fellow blind individuals. . He spent the better part of the next nine years developing and refining the system of raised dots that has come to be known by his name, Braille. The code was now based on cells with only 6-dots instead of 12 ..Braille died in 1852 but his code spread around the world France 1854, USA 1860 , and blind individuals from all over the world benefit from Braille’s work daily. Today, braille code is transcribed in many different languages worldwide.Blind individuals from all over the world benefit from Braille’s work daily and these cards were used by residents of Moorabbin ShireCardboard pack of ordinary playing cards with braille imprints left top of each card. Pack is incompleteFront: PLAYING / CARDS / for the BLIND / To be obtained from the / NATIONAL INSTITUTE / FOR THE BLIND / Great Portland Street / LONDON W1. Hand written : O'Dean Lounge braille louis, barbier charles, visually impaired, braille playing cards, braille, library, braille sheet music, braille ketboards -

Puffing Billy Railway

Puffing Billy RailwayEmerald Station Sign

Station Sign - Emerald Emerald Station is situated on the Puffing Billy Railway in Victoria, Australia. It was opened with the Railway on 18 December 1900 and comprised a platform track and a loop siding. A passing loop was added between the two a few years later. There was also a spur siding off the Down end of No. 3 Road. Two standard 12 ft by 20 ft timber portable station buildings with a Van Goods Shed between (all adjoining) were provided on the platform and a Goods Shed on the No. 3 Road loop siding. Other buildings included Tea Rooms, lamp room and toilets along with a cattle race and loading bank. The station building was later reduced in length by one of the portables which housed the General and Ladies' waiting rooms. Emerald today remains very similar to the early days, but has had other Roads added into a Carriage Workshops, a turntable and storage sidings. Also, a Signal and Telegraph Branch depot in the form of a large Goods Shed and a multi-purpose yard building in the form of a Locomotive Depot administration building have been added. During 2009, the station building underwent stage one of an internal restoration to its former glory. ref: https://en.wikipedia.org/wiki/Emerald_railway_station,_Victoria photos at http://www.vicrailstations.com/Gembrook/Emerald/Emerald.html Historic - Victorian Railways Station sign used at Emerald Station Station Sign - Emerald Metal rectangle Station Name Sign with white enamel back ground and black lettersEmeraldstation sign, puffing billy, emerald station -

Bendigo Military Museum

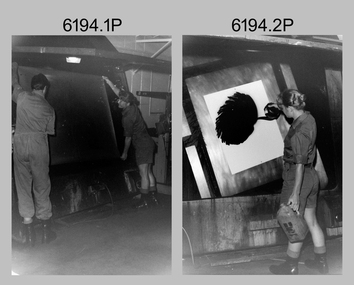

Bendigo Military MuseumPhotograph - Lithographic Technicians and Equipment at the Army Survey Regiment, Fortuna Villa Bendigo, c1990s

These 10 photographs were most likely taken in the 1990s in Lithographic Squadron at the Army Survey Regiment, Fortuna, Bendigo. In photos .1P to .2P the technicians are applying a UV-sensitive pigmented dye emulating one of the print colours to a white opaque polyester sheet mounted on a rotating table in a whirler. The coated sheet was dried before placement in a vacuum light frame beneath a stud registered map negative. They were then exposed to a carbon arc lamp. For more photos and details on the process, see item 6059.5P. In photos .3P to .5P the technician is preparing a orthophotomap film positive. Photo .6P is the rear view of the tri-linear film punch. In photos .7P and .8P the technician is operating a heavy-duty guillotine to trim bulk printed map stock. Cartographers normally provided trim marks to specified map dimensions as guidance to the printer. The trimming stage, like all the other printing processes required high levels of accuracy. These guillotines were extremely powerful to cut through bulk quantities of printed maps. For more photos and details on this process, see item 6069.6P. In photo .9P the technician is operating a daylight film contacting frame. In photo .10P LT Ian Stoddart is taking a well-earned break.This is a set of 10 photographs of lithographic technicians undertaking tasks at the Army Survey Regiment, Bendigo c1990s. Photos .1P to .7P and .9P to .11P are on 35mm negative film and scanned at 96 dpi. Photo .8P is printed on photographic paper and scanned at 300 dpi. They are part of the Army Survey Regiment’s Collection. .1) and .2) - Photo, black & white, c1990s, unidentified printer technician and SPR Janet Murray using the map proof whirler. .3) to .5) - Colour, c1990s, Mick ‘Buddha’ Ellis preparing an orthophotomap film positive. .6) - Photo, Colour, c1990s, rear view of tri-linear film punch. .7) & .8) - Photo, Colour, c1990s, unidentified technician operating a heavy-duty guillotine. .9) - Photo, Colour, c1990s, printer technician SPR Shona Hastie operating a daylight film contacting frame. .10) - Photo, Colour, c1990s, LT Ian Stoddart taking a well-earned break. .1P to .10P– no annotationroyal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, litho -

![Photo of Queen Elizabeth II Silver jubilee dish laid upon the dish's matching red felt box. The cool-to-touch silver dish has engravings upon its face including the royal mark of Queen Elizabeth the Second, 'EIIR' under surmounted by St Edward's crown, '1952' on the left of the dish, 'Royal Australian Army Nursing Cross' is embossed within an oval central press, surmounted by St Edwards crown, in the centre of the oval is a Nightingale oil lamp, across the bottom of the central oval is a scroll embossed with the motto 'Pro Humanitate' Latin for 'For Humanity'. Underneath the central embossment and aligned with the royal Elizabeth sigil is an engraving of the dates '1902 - 1977' [seemingly this date was engraved after the making of the dish, it is unknown how long after the presenting of the dish the engraving was added.] Underneath those dates are engravings/marks of silver, nickel and makers quality marks. Upon flipping the dish over, on the slight foot of the dish is an embossing of 'Nickel Silver' and an engraving of the silver quality number '49'. The red felt box lid is also pictured, white satin with soft cushioning to protect the dish when closed. This photograph is taken upon a black background, with a scale card and object number included.](/media/collectors/64a5077bc83bd7b7b94f4211/items/67d1436203274031f6b50116/item-media/67d1462403274031f6b51496/item-fit-380x285.jpg) Returned Nurses RSL Sub-branch

Returned Nurses RSL Sub-branchCeremonial object - Queen Elizabeth II Silver Jubilee Dish, Goldsmith's Company Assay Office, c. 1977

The Queen Elizabeth II Silver Jubilee Medal was awarded to citizens in the Commonwealth (Canada, United Kingdom, Australia and New Zealand) for their healthcare/nursing services. This ceremonial dish appears to serve the same or similar purpose to the medal, it is unknown whether the dish was awarded, or whether it was purchased and customised to reflect the respect of service that the medal from the same year served. This dish is peculiar, which in turn increases the significance of the object. Though similar to the Queen Elizabeth II Silver Jubilee Medal in social purpose, it is less historically significant. However, due to the nature of the collection at large, this object is of medium to high significance. Additionally, it may be a crucial object in reflecting thoughts, feelings and social organisation of Australian nurses. Nickel silver dish with several engravings and embossing, small dish foot, shallow dish, including Royal Australian Army Nursing Corps logo upon the centre of dish. 'EIIR' (Royal Elizabeth the Second sigil.)/[surmounted by St Edward's Crown]/'1952'/'Royal Australian Army Nursing Corps'/[surrounding Nightingale oil lamp, surmounted by St Edward's Crown.], 'Pro Humnitate'/[scroll embossing.]/'1902-1977'/'D-M S'[Makers mark]/Lion passant mark [indicates a fineness of 925/1000 sterling silver]/British silver hallmark [Leopard face that indicates the London Assay Office]/'C'[Denotes the date of silver pressing, capital C indicates 1977.]/Portrait of Queen Elizabeth the Second [Duty mark reflecting a tax on precious metals collected between 1784 and 1890 and that the tax had been paid.] On the base of dish: 'Nickel Silver' [material]. / '49'. silver jubilee, queen elizabeth ii, queen elizabeth 2, queen elizabeth the second, royal australian army nursing corps -

Alfred Hospital Nurses League - Nursing History Collection

Alfred Hospital Nurses League - Nursing History CollectionBook - Illustrated book, M. K. (Muriel Knox) Doherty 1896-1988 et al, Modern practical nursing procedures, 1949

Reference book to help facilitate standardisation of nursing procedures.Illustrated book with red binding Title and authors surnames embossed on front cover along with gilt embossed logo of the Alfred Hospital. Title, authors surnames and publisher's name embossed in gilt on spine.non-fictionReference book to help facilitate standardisation of nursing procedures.nursing, nurses, nursing-study and teaching -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects. 'Philips" electric Shaver, c1977

Established in 1891 in Eindhoven, the Netherlands, Philips & Co. was founded to meet the growing demand for light bulbs following the commercialization of electricity. Science and technology underwent tremendous development in the 1940s and 1950s, with Philips Research inventing the rotary heads that led to the development of the Philishave electric shaver, and laying down the basis for later ground-breaking work in transistors and integrated circuits.Philishave was the brand name for the electric shavers manufactured by the Philips Domestic Appliances and Personal Care unit of Philips They used the Philishave brand name for their shavers from 1939 to 2006. The Philishave shaver was invented by Philips engineer Alexandre Horowitz, who used rotating cutters instead of the reciprocating cutters that had been used in previous electric shavers. The shaver was introduced in 1939, though initial production was limited due to the outbreak of World War II. A more ergonomic egg-shaped single-head model was introduced in 1948 and was designed by US industrial designer Raymond Loewy. Global sales increased markedly after a double-head model was introduced in 1951. As a spin off from the light bulb and research is the dynamo-powered bicycle lamp. Its rotating power system inspires the Philishave triple head electric razor. A triple-head model was test marketed in Australia and New Zealand in 1956, but would not be introduced globally until 1966. The brand name Philishave was phased out in 2006 so shavers now bear only the Philips name. Mr Alfred William ( Bill ) Roper, 1913 - 1996 grew up in Ripponlea, ( East St Kilda ) Victoria. As a child he went with his father Arthur Leopold Roper to purchase vegetables from the Moorabbin Chinese market gardeners at the Hotham St. / Nepean Highway corner. c1920 . Bill served in WW2 in New Guinea and post war was Army Auditor, Victoria Barracks, St Kilda Road Melbourne. His staff presented this 'Philishave upon his retirement and he used it until his death1996. He lived in Carlton, Belgrave, Ascot Vale, South Yarra, East St Kilda and moved to Bentleigh in 1987.A ‘Philishave’ triple head electric razor , with cord, head protector and cleaning brush in a hinged plastic case The case has compartments, for Razor and cord, that are lined with a mustard coloured, soft, synthetic material .Case top PHILIPS ; inside EXCLUSIVE PHILISHAVE Razor Handle front PHILIPS / PHILISHAVE; back Type HP 1121/ 110-130V/ 220-240 V / PHILIPS Shield / ? Shield / BS 3456 / V 75255 / MADE IN HOLLAND Nameplate Presented to / BILL ROPER / On the occasion of his retirement / BY THE STAFF OF / DEFENCE AUDIT BRANCH / May 1977 philishave, royal philips electric company, razors, electric razors, bentleigh, moorabbin, market gardeners, st kilda markets, world war 2 1939-1945, department of defence melbourne, melbourne, roper alfred william, roper arthur leopold, ripponlea, chinese market gardeners -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Baleen

A baleen whale has hard bristly baleen that hangs from its upper jaw inside its mouth instead of teeth. Baleen is made from a protein called keratin, just like human hair and fingernails, and its colour can vary between species, from black to yellow or white. The whale uses the tough, flexible baleen like a sieve to catch its food, filtering the small sea creatures out of the sea water it releases from its mouth. In the19th Century, whales were hunted for the products that could be made from their bodies, such as oil for lubricating machinery, soap making, lamps, heaters and fuel for the lighthouse lights. The flexible baleen was used for whip handles, carriage springs and umbrella ribs. It was also used for the skirt hoops, hat ribs, and rigid ‘stays’ in tightly fitting bodices to enhance their figures. The Southern Right Whales, as well as Blue Whales and Humpback Whales, are baleen whales. The Southern Rights annually visit the ocean off the southwest coast during the breeding season. In the early 1800s whalers hunted along this coastline in their dangerous pursuit of money for the precious cargoes of whale oil and bones. The population of these large animals dwindled quickly and by the late 1840s the whaling industry dwindled. Whaling recommenced from the 1940s to the 1980s when the whale products were used to make margarine and dog food. The baleen sample has been used to educate people about whaling and about the properties of baleen. The baleen sample is significant for its association with 19th century women's fashion. It helps to understand how garments were supported to shape a woman's figure. The baleen sample represents a period when whales were hunted and killed to provide income and products for for the local settlers and for the export industry.Baleen sample from a whale's jaw. Its black shiny hard yet flexible surface is slightly rippled and textured. One end is fringed and the other and a smooth cut edge. The colour varies in places, with stripy brown colouring. flagstaff hill maritime museum and village, great ocean road, shipwreck coast, baleen, whalebone, baleen whale, keratin, 19th century, whaling industry, women's fashion, stays, bodice, women's figures, fashion, clothing, whale oil, baleen colour, whale hunting, whale products, southern right whale, blue whale, humpback whale, southwest victoria, whalers, whale bones -

Bendigo Historical Society Inc.

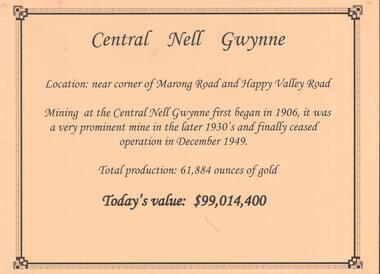

Bendigo Historical Society Inc.Document - CENTRAL NELL GWYNNE GOLD MINE

Interpretive sign and 4 photos Central Nell Gwynne Gold Mine, used in display. Central Nell Gwynne was located near the corner of Marong Road and Happy Valley Road. Opened in 1906, ceased operation in December 1949. Total production: 61,884 ounces of Gold. Today's Value: $99,014,400. Photos: a. Colour photo, concrete footings at mine site, April 2012. b. Colour photo, Central Nell Gwynne poppet head, April 2012.Poppet head painted white with red trim. Concrete footings in foreround. c. Central Nell Gwynne mine site 1930's. Poppet head and engine room sheds on LH side, trestle way to primary crusher and crushing battery. Tailing dam in immediate foreground. on RH side. Sand heaps in middle foreground. d. Central Nell Gwynne Mine 1930. Underground view, men holding carbide lamps working at 265 level in mine. Large quartz spur formation visible in foreground.bendigo, mining, central nell gwynne -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Photocopies, Public Records Office of Victoria, "The Electric Supply Company of Victoria Limited - Directors' Report" - ESCo Annual Reports - 1920 - 1934, 1994

Photocopies of the annual or Directors' reports for the Electric Supply Co. of Victoria Limited (ESCo) for the period 1920 to 1934. All dated 31 March 19xx. Gives details of the electricity and tramways departments such as the lamps connected and Balance Sheets. Some reports have a statutory declaration on the rear. Photocopies arranged by Alan Bradley c 1994 from files of Company Records held in the Public Records Office of Victoria. Item Year 1244.1 - 1920 1244.2 - 1921 1244.3 - 1922 1244.4 - 1923 1244.5 - 1924 1244.6 - 1925* 1244.7 - 1926* 1244.8 - 1927 1244.9 - 1928 1244.10 - 1929* 1244.11 - 1930* 1244.12 - 1931 1244.13 - 1932 1244.14 - 1933 1244.15 - 1934 * 4 pages, all others three. The fourth page gives the Statutory declaration of the agent of the Company lodging the copy of the English balance sheet in Victoria. Declaration by George Cole of Bendigo, or Percival John Pringle in Ballarat. Reports cover activities in both Ballarat and Bendigotrams, tramways, annual reports, esco, john pringle -

Mont De Lancey

Mont De LanceyDecorative object - Hansom Cabriolet Model, Chas W Davis, Unknown

The collection of thirteen model horse drawn vehicles were carefully handmade by Mr Chas W Davis 1925 - 2002. He was a talented artist and saw doctor. This model of a two horse drawn enclosed Hansom Cabriolet replicates the vehicle that enjoyed respect from the public from c.1833 until 1935. A model of a black enclosed coach which is a four wheeled passenger horse drawn vehicle where the driver sits at the front behind the two white horses. It has two large and two smaller gold painted spoked wheels with black rims and gold mudguards on the rear wheels, two gold painted coach lamps, red vinyl padded seating and four open windows with rolled up blinds. There are two doors with a step for easy access into the coach. A long brown wooden shaft separates the horses as well as the necessary horse tack for carriage use to help the driver communicate with the horses. A hand operated brake pad is on the rear wheels. The first Hansom Cabs were clumsy, dangerous awkward vehicles. The drivers were suspected of 'Rude Bohemia'. It took the refinement of Joseph Aloysius Hansom himself to clear airs and remodel the cab to a safe vehicle. It enjoyed respect from c.1833 until 1935. It came in four types.replicas, models, scale models, vehicles, carriages, horse drawn vehicles, toy horses, road transport, coaches -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Newsletter, City of Moorabbin Historical Society Feb 2011, February 2011

The City of Moorabbin Historical Society was formed c 1960 by a group of Moorabbin residents who were concerned that the history of the area should be preserved. A good response to a call for items related to the historical area of Moorabbin Shire brought donations of a wide variety of artefacts which are now preserved by the current members of CMHS at Box Cottage Museum . Helen Stanley, Secretary of CMHS, began producing a Newsletter for members in April 2007 to provide current information and well researched items of historical interestHelen Stanley has produced a bi-monthly Newsletter, 2007 - 2013, for the members of the City of Moorabbin Historical Society that contains well researched interesting historical items, notification of upcoming events, current advice from Royal Australian Historical Society , Museums Australia Victoria and activities of Local Historical Societies. The Newsletter is an important record of the activities of the CMHS and this month Celebrates the 50th Anniversary of CMHS. The puzzle around the naming of the suburb McKinnon tells the story of Daniel, Donald and Laughlin MacKinnon. 5 x A4 paper printed on 1 side Issue 20 of the bi-monthly, City of Moorabbin Historical Society Newsletter produced by Society member and Secretary, Mrs Helen Stanley in February 2011. Notice for meeting February 27th and the Subscription $5 is due. Despite the recent heavy rain the Cottage and grounds were unaffected, however an possum / rat appears to have entered the Cottage via the Chimney and caused the breakage of 2 glass kerosene lamps that were on the mantelpiece and lots of droppings before escaping. Teresa Murphy, editor of ‘The Moorabbin Leader’ Newspaper, visited Box Cottage and discussed a proposed regular feature ‘Down Memory Lane’. Volunteers are requested for Open Days, and are reminded of the Visitors’ Book, Children’s Treasure Hunt Cards and the Volunteer Hours Record. Accompanying it is the Story of Daniel MacKinnon b Glasgow arrived Port Phillip 1839 died 1889, his son Donald MacKinnon b 1859 Terang, Victoria – 1932 and Laughlan MacKinnon b1817 Isle of Skye -1888 no relation to eitherCITY of MOORABBIN HISTORICAL SOCIETY / FEBRUARY 2011 NEWSLETTER city of moorabbin historical society, stanley helen, mackinnon daniel, mackinnon donald, mackinnon laughlin, melbourne, moorabbin, brighton, cheltenham, ormond, bentleigh, mckinnon, market gardeners, pioneers, early settlers, moorabbin shire, box cottage museum, city of moorabbin, box william, glen eira historical society, the moorabbin leader newspaper, murphy teresa, the argus newspaper