Showing 1052 items

matching solid

-

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Eltham District Historical Society Inc

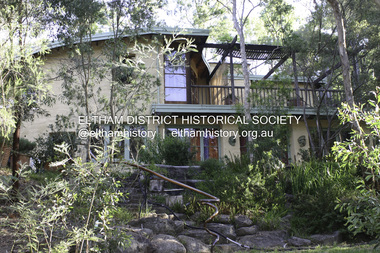

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Busst House, cnr Silver Street and Kerrie Crescent, Eltham, 2 February 2008

Considered the best of the early mud-brick houses built by Alistair Knox. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p143 The Busst house hidden by trees at the corner of Silver Street and Kerrie Crescent is considered the best of the early mud-brick houses built by Eltham architect, Alistair Knox. Knox himself said, that the Busst house was the most mature mud-brick house designed at that period. ‘It related with true understanding to its steep site and expressed the flexibility of earth building ………to develop a new sense of flowing form and shape’.1 Built in 1948 for artist Phyl Busst, a former art student at Montsalvat, the house helped usher in Eltham Shire’s distinctive mud-brick residential character. Knox was the pivotal figure of the style developed from the 1950s to the 1970s.2 Scarcity of building materials after World War Two encouraged mud-brick building because earth was a cheap and plentiful building medium. But when Knox began building in mud-brick in 1947, no council in Victoria knew anything of this ancient art and he needed a permit. Fortunately the Commonwealth Experimental Building Station at Ryde in NSW, had been experimenting with earth construction to help overcome the shortages of that time. They published a pamphlet that became available in Melbourne on the same day the Eltham Council was to consider whether the earth building should be allowed. Knox caught one of the three morning trains to the city in those days and bought several copies of the pamphlet to give to each councillor. On his return he found the councillors standing on the steps of the shire offices after lunch at the local hotel. He heard that earth building had been discussed before lunch and that they were not in favor of it. Knox gave each councillor a pamphlet. They passed that plan and by doing so, opened the door for all future earth building in Victoria and by default, in Australia.3 Mud-brick houses attracted artists to Eltham, for their aesthetic appeal and because they were cheap. Those who built their own houses, included film maker Tim Burstall, artists Peter Glass, Clifton Pugh, Matcham Skipper, Sonia Skipper and husband Jo Hannan. For Knox, mud-brick building was more than just a cheap building medium. He saw it as harmonising with the surrounding bush and as a way of counteracting the growing materialism of the age. He wrote of its impact on ‘ 20th century man. It should counteract the confusion that the perpetual flow of high technology products have upon him ..’.4 Building the Busst house on a steep site was difficult because most earth-moving equipment was then in its infancy. For instance drilling for explosives was done by hand, which was a slow and painful process. Knox, assisted by his foreman Horrie Judd and Gordon Ford (who was to become a famous landscape designer), built two large main rooms - a living room/ kitchen downstairs - and upstairs, a studio/bedroom. The studio/bedroom opens onto the balcony, which covers the living area. The bath made of solid concrete by stonemason Jack Fabro, is particularly deep. Sunshine pours through the three French windows of the north-east facing kitchen/living area, which is lined with timber. The large hearth can fit a family around the fire while the timber floors and solomite (compressed straw) ceilings add to the cosy atmosphere. The garden is thick with trees, and in the late 1990s, Ford put in a pool near the original dry wall he had built as a young man.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, alistair knox, alistair knox design, busst house, kerrie crescent, mudbrick construction, mudbrick houses, silver street -

Royal District Nursing Service (now known as Bolton Clarke)

Royal District Nursing Service (now known as Bolton Clarke)Photograph - Photograph, black and white, Barry Sutton, 26.06.1972

The photograph of the Royal District Nursing Service (RDNS) Holden Torana vehicles was taken in the RDNS Headquarters car park at the rear of 452 St Kilda Road. These cars are part of the RDNS fleet, with others housed at RDNS Centres. The cars were used by the RDNS District nurses to visit patients in their own homes. This photograph depicts two door Holden Torana cars of 1972.Royal District Nursing Service (RDNS) has had various modes of transport over the last 130 plus years. At first, from 1885 as Melbourne District Nursing Society (MDNS), their Trained nurses (Nurses) walked the streets and lane ways amid the slums of central Melbourne. As the Society expanded public transport was used, and bicycles were bought by the Society in 1903 and used in inner areas until 1945. During the Spanish flu epidemic, in 1919, MDNS appealed for assistance to procure Motor vehicles so the Nurses could visit an influx of cases. Through trusts, grants and donations four 'Ford T Model' cars were procured which enabled the Nurses to triple their visits. Through constant use the cars were in such a poor state two were sold in 1922 and the others later. In 1922-23 three Peugeot cars were purchased and a woman Chauffeur, 'Miss Sword', was employed who lived in the Home and was also in charge of the garage. MDNS was expanding and a Motor Auxiliary was formed in 1929 to take the Trained nurses (Sisters) to patients, and some Sisters used their own cars; even a motorcycle was used by one Sister in 1933. All these forms of transport were intermingled and in the early 1950s, and now as Melbourne District Nursing Service, seven Ford Prefect cars were bought followed by twelve Ford Anglia cars 1955. Having received Royal patronage; the now Royal District Nursing Service (RDNS) had its own fleet of Holden vehicles by the mid 1960s and the Motor Auxiliary ceased operating in 1971 as by then all staff employed were required to have a driving licence. Seat-belts had been introduced to Victoria in 1959 and District fitted them to their cars from 1962, even though they did not become compulsory until 1970. The Holden vehicles were replaced with grey Holden Torana vehicles. After several years the fleet was changed to white Toyota Corolla vehicles. The Melways Directory of maps was introduced in 1966, which was a boon to the Sisters, though it was a few years before it went beyond Seville, so a large paper map was used by the Sisters visiting patients in the areas passed Seville. By 2009 there were 598 cars in the fleet and the Sisters travelled 9 million 200,000 kilometres – this is equivalent to 12 trips to the moon and back. Black and white photograph of 14, some partly hidden, new grey Holden Torana two door vehicles parked in two rows in the RDNS concrete based car park. The cars are parked with their front lights, grill, bumper bars and number plates facing the left of the photograph. The cars are seen side-on with the full side-on view of the two cars at the beginning of the rows seen in the foreground of the photograph. The flat bonnet is the same width as the rest of the body of the car; the windscreen slopes upward and joins the flat roof; there are two wiper blades resting at the base of the windscreen. In line, and at the level of the windscreen, a quarter window, and two windows divided by a narrow pillar can be seen running along the side of the car above the slightly convex body work and front door. The rear window slopes back from the roof and the slope continues on the upper bodywork of the boot lid. A metal strip runs along the side of the car about half way down the bodywork, and another runs just up from the beginning of the front wheel arch to the rear wheel arch; beside the front wheel arch is the word 'Torana'. The round, with capital letters 'RDNS', insignia can be seen on the upper centre of the front door of the two cars. The solid wheel caps have the Holden logo on them. The front grill which runs between the headlights on either side of the car, slopes slightly backwards from the central Holden badge. The bumper bar below this is metal. Black number plates with white written capital letters and numbers 'LFA - 208' and 'LFA - 207' are seen on two of the cars in the front row. The tops of two front seats with headrests and the top of a long back seat can be seen inside the car. A tall brick fence is seen running along the rear and right hand side of the car park. In the left background is a two storey building with a flat roof, and behind this on its left is a part of a tall building and to its right part of a bare tree can be seen. To the buildings right rear part of a house can be seen. In front and to the right of this is a three storey brick building, with the top two storeys seen above the car park fence. Multiple windows run along both levels of this building which has a tiled hip roof. The tops of some bushes are seen behind parts of the car park fence.Barry Sutton Photographer's Stamp Quote KX83rdns, royal district nursing service, rdns transport, rdns headquarters, rdns car park -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Eltham District Historical Society Inc

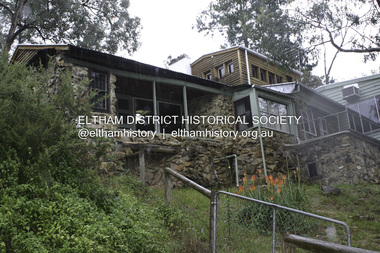

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Stonygrad, 34 Hamilton Road, North Warrandyte, 30 January 2008

Vassilieff dynamited rock from his own property to build his house. Stonygrad is reminiscent of a grotto and in parts, of a sculpture. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p135 Stonygrad, the home built by Expressionist painter and sculptor Danila Vassilieff, is reminiscent of a grotto and in parts, of a sculpture. Vassilieff, who amongst others influenced painter Sydney Nolan and Albert Tucker, was a member of the artists group the Angry Penguins.1 He was also a highly regarded art teacher at the nearby Koornong Experimental School and taught at Eltham High School. Art critic Robert Hughes described Vassilieff’s painting as ‘lyrical without social commentary’, and said Vassilieff was ‘the most oddly neglected artist in recent Australian History’.2 Vassilieff, who was born in 1897 in Russia, had an unusually adventurous life before he settled in Warrandyte. The 12th of 18 children, he lived on a farm in the Don Basin. Vassilieff trained with the Imperial Military Academy at St Petersburg and fought in World War One as an officer in the White Russian Army against the communists. In 1920 he was captured, then escaped from prison, stole a horse and rode bareback 150 miles to the Black Sea, helped at first by Tartar freebooters. He then travelled to India, Shanghai and arrived in Queensland as a refugee in 1923 where he began painting. He and his wife Anisia bought a sugar farm near Ingram,3 and later he constructed railway lines at Mataranka, in the Northern Territory.4 In 1929 Vassilieff went to Brazil for formal art training from former fellow-officer Dmitri Ismailovich, but he soon left to travel up the Amazon River. He then worked as a sidewalk artist in the West Indies and travelled for two years in England, France and Spain. In 1937 he arrived in Melbourne where he lived until his death in 1958. His first major Australian series was the Carlton streetscapes and from 1951 he sculpted in local hard limestone.5 Vassilieff rejected all dogma and regarded religious subjects as suitable only for decorative arts. In 1944 he helped defeat a communist attempt to take over the Contemporary Art Society. For a short time, from around 1955, Vassilieff taught at various Victorian schools.6 The Angry Penguins painted mainly between 1937 and 1947, and included Arthur Boyd, Albert Tucker, Sidney Nolan and Joy Hester. The group formed as they felt isolated from European thought and art (including Surrealism) from which their work was derived. They were also angry at what they considered to be the complacency and insularity of their society. They maintained Australians at first were scarcely aware of the threats of the Wall Street Crash and Hitler and were little interested in the Spanish Civil War. The Angry Penguins also objected to the White Australia Policy. Hughes said although most of the Melbourne Expressionists in the 1940s were unskilled and their work crude in style, they helped jolt Australian painting from its pastoral complacency. Their style influenced nearly every painting produced by significant figurative artists in Melbourne in the 1950s such as Charles Blackman. From 1939 Vassilieff built Stonygrad, mainly with local stone. The house stands at the end of a private road surrounded by trees with the quiet occasionally broken by the sounds of bellbirds. To build his house Vassilieff dynamited rock and cut trees from his own property. The original section of the three-level house is of irregular-shaped pieces of solid stone, exposed inside like the exterior. Vassilieff later built sections with timber and brick. Inside is rustic and cave-like, and several rooms are linked by arched openings with no doors. One undulating wall was carved out of rock from which two sculptured heads protrude. Several ceilings are of rough-hewn logs and the built-in table and bookcase are rough, as is a timber ladder leading to a bedroom. Not for the elderly or unsteady! Yet the general impression in the muted light is beautiful, with artistic originality.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, danila vassilieff, hamilton road, north warrandyte, stonygrad -

Federation University Historical Collection

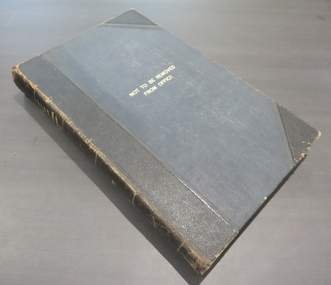

Federation University Historical CollectionBooks, H.E. Daw Government Printer, Ballarat School of Mines and Industries Departmental Papers, 1914-1950, 1914-1950

Used at the Ballarat School of Mines and the Ballarat Technical Art SchoolThis collection of examinations is significant because of its completeness with the full range of examinations between 1914 and 1950.Large leather bound books, with leather spine, containing all examinations held at the Ballarat School of Mines (including the Ballarat Technical Art School and Ballarat Junior Technical School). The examination papers were supplied and printed by the Education Department, Victoria. Examinations include: Agriculture, Algebra, Architecture, Arithmetic, Applied Mechanics, Assaying, Biology, Botany, Boilermaking, Building Design, Blacksmithing, Bricklaying, Carpentry and Joinery, Coachbuilding, Cabinet Making, Civil Engineering, Cabinet Making, Commercial, Chemistry, Engineering Drawing, Economics, English, Electrical technology, Electricity and Magnetism, Electric Wiring, Electric Welding, Electrical Fitting, Electrical Trades, Food Analysis, Geology, Geological Mapping, Graphics, Geometry, Heat Engines, Heat Treatment, Hydraulics, Hand Railing, Instrument Making, Millinery, Milling and Gearouting, Machine Shop Practice. Metal Founding, Mining, Metallurgy, Mineralogy, Mathematics, Motor Mechanics, Mine Surveying, Mining Mechanics, Petrology, Physics, Painting and Decorating, Pattern Making, Plastering, Plumbing and Gasfitting, Printing, Refrigeration, Spelling, Science , Shorthand, Surveying. Signwriting. Sheet Metalwork, Toolmaking, Ladies Tailoring, Trigonometry, Typewriting, Welding, Commercial Geography. Millinery, Dressmaking, Needlework, Decorative Needlework, Architecture, Building Design and Construction, Art (Composition in Form and Colour), Art (Casting Clay MOdels) Art (Drapery), Art (Drawing the Human Figure From Casts), Art (Drawing the Antique from Memory), Art (Drawing from Memory); Art (Drawing Plant Forms from Nature, Art (Drawing Plant Forms From Memory), Art (Drawing from Models and Objects), (Drawing From a Flat Example). Art (Drawing in Light and Shade from a Cast of Ornament or Lower Nature), Art (Drawing Ornament from the Cast), Art (Drawing from Models or Objects), Art (Drawing fro Dressmakers' and Milliners' Fashions), Art (Drawing With the Brush), Art (Drawing from a Flat Example); Art (Modelled Design), Art (General Design), Art (Embossed Leatherwork), Art (Practical Plane Geometry), Art (Practical Solid Geometry), Art (Geometrical Drawing), Carpentry and Joinery, Art (Human Anatomy), Art (Historic Ornament), Art (House Decoration), Art (LEttering), Signwriting, Art (Light Metalwork), Art (Modelling), Art (Modelling the Human Figure from a Life), Art (Stencilling); Art (Wood Carving) Refrigeration, Teaching, Boilermaking, Blacksmithing, Carpentry and Joinery, Coachbuilding and Carriage Drafting, Electric Wiring, Electrical Fitting, Graining and Marbling, Instrument Making , Machine Shop Practice, Metal Founding, Milling and Gear Cutting, Motor Mechanics, Painting and Decorating, Sheet Metalwork, Toolmaking, Printing, Pattern Making, Plumbing and gasfitting, examinations, ballarat school of mines, ballarat technical art school, trades, education department victoria, agriculture, algebra, architecture, arithmetic, applied mechanics, assaying, biology, botany, boilermaking, building design, blacksmithing, bricklaying, carpentry and joinery, coachbuilding, cabinet making, civil engineering, commercial, chemistry, engineering drawing, economics, english, electrical technology, electricity and magnetism, electric wiring, electric welding, electrical fitting, electrical trades, food analysis, geology, geological mapping, graphics, geometry, heat engines, heat treatment, hydraulics, hand railing, instrument making, millinery, milling and gearouting, machine shop practice, metal founding, mining, metallurgy, mineralogy, mathematics, motor mechanics, mine surveying, mining mechanics, petrology, physics, painting and decorating, pattern making, plastering, plumbing and gasfitting, printing, refrigeration, spelling, science, shorthand, surveying, signwriting, sheet metalwork, toolmaking, ladies tailoring, trigonometry, typewriting, welding., dressmaking, needlework, decorative needlework, architecture, building design and construction, art (composition in form and colour), art (casting clay models), art (drapery), art (drawing the human figure from casts), art (drawing the antique from memory), art (drawing from memory), art (drawing plant forms from nature, art (drawing plant forms from memory), art (drawing from models and objects), (drawing from a flat example), art (drawing in light and shade from a cast of ornament or lower nature), art (drawing ornament from the cast), art (drawing from models or objects), art (drawing for dressmakers' and milliners' fashions), art (drawing with the brush), art (drawing from a flat example), art (modelled design), art (general design), art (embossed leatherwork), art (practical plane geometry), art (practical solid geometry), art (geometrical drawing), art (human anatomy), art (historic ornament), art (house decoration), art (lettering), art (light metalwork), art (modelling), art (modelling the human figure from a life, art (stencilling), art (wood carving), teaching, coachbuilding and carriage drafting, graining and marbling, milling and gear cutting, commercial geography, exams, examination book -

Ballarat Tramway Museum

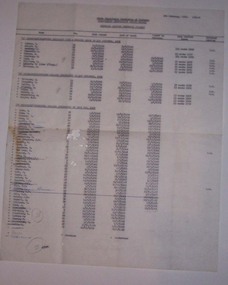

Ballarat Tramway MuseumDocument - List, State Electricity Commission of Victoria (SECV), "Tramways Traffic Personnel (Wages), Feb. 1970

Gives a list of names of people who worked on the Ballarat trams in the final 19 months of operations, some personal information and grade.Carbon copy of a typed list of SEC Ballarat Tramway traffic list dated 5 Feb. 1970, with hand alterations. Titled "SECV - Mid Western Electricity Supply Branch - Tramways Traffic Personnel (Wages)", gives a list of names, traffic number, position, date joined, date of birth, date passed as motorman, long service leave (taken or entitlement?) and whether a returned soldier - using letter "R.S." Three shown as "D.S." - disabled solider? List broken up into three components - "A" Motormen/Conductor Seniority List - Engaged prior to 1 Nov. 1952, - 9 Number, "B" engaged subsequent to 1 Nov. 1852 - 8 Number and "C" engaged since 30 May 1962 - 38 depending on the time. List A L Walker H Knight J Smerdon - crossed out A Turnbull - crossed out A Mercer R. Courtney W. Ward R. Williams D. Kellett - (also T/Insp.) A. Jeffreys List B D. McGregor D. Thomson I Willis D O'Leary - underlined J. Maher A. Morris D. Domaschenz R. G. Knight List C E Lake W. Maes I. Tierney B Munn N Cahill N Reynolds - crossed out W. Davies N. Hamilton L. McMahon - crossed out and (W/C) after name. J. Billman W. Nancarrow H. M. Van Oorschot W. Newell L. Bird D. Chambers H. Van Rooy H. Mannion N. Robe C. Harding - crossed out and (S/L) after name E. Van Rooy F. Edmonds - crossed out M. Blackman N. K. Alan - crossed out H. Hall J. Mason S. Davies W. F. Segrave J. F. Bolton - crossed out N. D. Hunt K. Butler - crossed out J. F. O'Brien - ruled out V. L. Gill R. K, Morris D. Everett T. Williams A. Reed R. Herauville - crossed out B. Melville I. Trenfield R. Walker - crossed out V. Thorne - crossed out B. Biddington - crossed out K. Jeffs - crossed out Hynos - in pen and crossed out Power - in pen W. Tuddenham - in pen See also list given in Reg Item 3462.1 and 3462.2 - difference in spelling for Willis = Wallis, and Power = Powell. No additional names, but not all this list names appears in the list in 3462.1Numerous crossings out of names as people left, and three additional names and numbers within circles giving sub totals and totals.personnel, sec, ballarat, crews -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - HANRO COLLECTION: HANRO JOURNAL

BHS CollectionHanro Journal: The front has a solid front and back cover and is of a green material with a marble type pattern trimmed at the top and bottom right hand corners with light brown suede triangles. The curved spine of the book is also light brown suede and the binding extends to 4cm on to the cover. 5.5cm down from the top of the spine is a 4.9 x 3.3cm red sticker with gold trim top and bottom of three strips and flowers under and on top of the third strips. The sticker has a tear and dog ears at the bottom. In gold in the centre is the word JOURNAL. The back of the journal is the same as the front but has more wear noticeable at top left and a tear at the bottom. Inside the cover is a paper lining of blue and cream mottled background with red uneven swirl a cream cloth spine with cotton thread for attaching. When the Journal is closed the pages form a colourful pattern of red, yellow, blue and green. Inside the book is light blue paper, on the left top hand written in pencil is 11/-, underneath that is 20/-. Numbers 24100, 27236, 25951, 25844 and some dacomb shorthand further down the page. On the right hand side centre of the page is the heading, hand written in black ink which has been underlined in red is *Hanro (Aust) Bendigo Knitting Mills Pty Ltd May 13th 1926* Page 1 of the Journal :- The Journal is all hand written in black ink and ruled up in red pen. At the top headed *Journal*, underlined in red. The page is ruled up into ten columns of various sizes. First column is the date May 1926. The page lists the distribution of Ordinary and Deferred Shared and their amounts. Next is Expenditure, for the land and buildings and setting up of the business, plant and equipment and various assets acquired from Bendigo Knitting Mills Pty Ltd. At the back of the book is a Debit Note From *Hands chin & Ornis S.A. Liestal (Suisse) to *Hanro* (Aust.) Bendigo Knitting Mills Pty. Ltd. Dated 10th September 1932. Debit Note No. 319. *Our payment to Messrs. Jacky, Maeder & C0, Basle as per your letter of August 10th 1932. SFr. 37.70 pounds * Then hand written in pencil is *Charged ? 168*` Also at the back is a group of letters with a hand written note in pencil, on the front dated 20/01/33 attached with a metal clip and pin reads *Bad Debts to be written off* under that it lists the names, where they are from and the amount owning and the total. Box 116Bbendigo, industry, hanro journal., hanro. journal -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationLid, ship tank

The heavy cast iron, round lid was originally fastened into a large, riveted metal box, known as a ship tank. It has the name ‘John Bellamy London’ cast in capitals in a continuous circle on the outer edge of the lid face, and the words ‘Byng St Millwall’ on the inner circle. , of Millwall, London, manufactured boilers and ship tanks from the 1860s to the 1930s and came from a family of tank makers who began manufacturing tanks some time before 1856. Ship tanks were invented in 1808 by notable engineer, Richard Trevithick and his associate John Dickinson. Their patent obtained the same year described the tank’s superior cubic shape that allowed it to fit squarely as a container in vessels and thus use space efficiently, while its metal fabric preserved and secured its liquid or solid contents from damage. The containers revolutionised the movement of goods by ship and made wooden casks redundant. Research by Michael Pearson has determined that they were carried on passages to Australia from at least the 1830s conveying ships’ victuals and water storage, as well as general goods heading for the colonies. Pearson found photographic evidence of their use in the 1860s, and by the 1870s they appeared to be in common use. lids surviving from containers indicate that nearly all the tanks transported to Australia came from London manufacturers. It was usual for the brand name to also feature as a stencil on the tank but in most cases this eventually wore off. A tank without its original stencil survives at Wilsons Promontory. Tanks transporting ‘drinking water or perishable dry goods were hermetically sealed by the use of the tightly fitting lid with a rubber sealing ring ‘which was screwed tight with the aid of lugs cast into the lid and wedges cast into the rim of the loading hole’. The raised iron rod welded across the outer face of many lids such as the Bellamy example, allowed for screwing the lid tight. Once in the colonies, the ship tanks were often recycled and adapted for many resourceful uses such as packing cases, dog kennels, water tanks, oil containers and food stores and this invariably led to the separation of the lid and tank. The Bellamy lid could have been salvaged from a shipwreck but is more likely to have to have originated from a recycled tank that was brought to the lightstation for water storage purposes. Pearson writes that: Ship tanks show up at a wide range of sites, many of them isolated like lighthouses. They were, I think, usually taken there for the purposes they filled, usually water storage, as they were readily available, relatively light to transport, and probably very cheap to buy as second-hand goods containers. In rural areas they may have been scavenged for their new uses from local stores, to whom goods were delivered in them. Parks Victoria has identified five tank lids in the lightstation collections covered by this project. In addition to the Bellamy lid at Point Hicks, they include a Bow brand lid at Point Hicks and another at Cape Otway, unidentified lids at Cape Otway and Wilsons Promontory. Pearson and Miles Lewis have each recorded two versions of the Bellamy trade name on the lids; one being ‘John Bellamy Byng St. London’; the other, ‘John Bellamy Byng St. Millwall London’. The Point Hicks lid has the second version of the name, as do other examples in Victoria that Lewis has identified at Illawarra, Toorak; Warrock homestead, Casterton; Eeyeuk homestead, Terang; Ward’s Mill, Kyneton; and Boisdale homestead near Maffra, and in NSW at Ayrdale Park, Wolumla; and Bishop’s Lodge, Hay. Pearson’s list includes the same lids in NSW at Tumbarumba; the Quarantine Station, Sydney; Willandra Station; Bedervale, Braidwood; Gunnedah Museum; Walla Walla and Macquarie Island. The Point Hicks lid is currently stored in the lighthouse although it is unlikely that its use had any association with this building. The lid is in good condition and retains the central bung. Pearson notes that ‘surviving lids are far less numerous than the tanks themselves, presumably because the uses to which the tanks were put did not require the lid to be retained’.347 The Bellamy ship tank lid has first level contributory significance for its historic values. Circular cast-iron disc with raised outer ridge with inscription. It also has an inner depression with inscription. Two metal sections form handles over inner depression. Hole in middle of disc.Around perimeter of outer edge "JOHN BELLAMY LONDON" Around inner area "BYNG ST MILLWALL" -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Property Binder, 1184 Main Road, Eltham

Newspaper article: A sustainable award, Diamond Valley Leader, 1 November2006, Architect and building Llewellyn Pritchard won resource Efficiency Housing Award, finalist in HIA Greensmart Building of the Year Award. House – Environmental Leader (Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p186) In 2006 environmental awareness was mushrooming in the community, which is reflected in the award-winning house at Main Road near Wattletree Road, Eltham. At first sight, the building appears a mix of a classic Eltham mud-brick house and an avant-garde building style. The crown of solar panels stretching along the width of the curved roof, indicates that this is no ordinary house. In fact it signals a new building trend of minimal impact on the environment. Yet it utilises the environment with high technical expertise to achieve comfort and cut running and maintenance costs. In recognition of this, its designer/builder, Conscious Homes, won the 2006 National HIA Greensmart Resource Efficiency Award. For Conscious Homes director, Llewellyn Pritchard, this house reflects a philosophy, strengthened by his connection with Aboriginal culture, through his foster siblings. Pritchard believes the sustainable way indigenous Australians lived and their spiritual connection with land, demonstrates how humanity is part of the ecology. His interest in environmental design stemmed from growing up in bushy Eltham Shire, with its mud-brick tradition. This was followed by studying Architecture at RMIT in the early 1980s, and learning about passive solar design. Pritchard says this house demonstrates that environmental sustainability is not about sacrifice, but about exceptional levels of occupant comfort, savings in running costs and modern fittings and appliances.1 The solar panels on the north roofs are intentionally obvious to make a statement about what the building is doing. But inside the systems are hidden and interactive with conventional services, such as the underground water tank. The house is water and energy self-sufficient and at 12 squares is much smaller than conventional houses, to minimise resources. Yet it accommodates his family of four with three bedrooms, a living/dining and kitchen area and a bathroom/laundry. Importantly the building is designed to last hundreds of years, by being able to be modified as the need arises, such as for commercial use. In this way the structure minimises its environmental impact. The solid double mud-brick walls (which are insulated) include steel beams and supporting frame, allowing the future removal or alteration of any section. The materials are local, recycled and of low toxicity where possible.2 Inside and out, the mud-brick is rendered and sealed with a combination of cement and sand and a mud-based coating in a soft golden hue increases its life. Inside, the golden-brown timber is plantation Mountain Ash and the concrete floors throughout – of local stone aggregate with a clear seal – have a natural looking random stone appearance. The house sustains a stable temperature of around 20 degrees, assisted by the concrete slab floor. The many large double-glazed windows and highlights (windows set high on walls) provide cross-flow ventilation. The north-facing living area maximises heating from the lower winter sun and is cooler in summer, because the sun is higher. Heating comes from a solar hydronic slab system. All appliances and fittings are high efficiency energy or water rated. Appliances in the timber kitchen include a gas stove and a dishwasher, using the building’s own power and water. French doors open from the living area to a deck, concealing the treatment system for all waste water. This is pumped through sub-soil drippers to the indigenous garden beds and no-dig vegetable patch. Below the carport is the 80,000-litre rainwater tank and at the back, the boiler room houses the solar boiler, water tank access, domestic water supply pump, filter gear and hydronic slab heating controls. The solar system is backed up with gas, which is needed to heat water only in winter. Gas used is less than one quarter of that for an average home with ducted heating. Excess power is fed back to the grid and the building uses about one quarter of the mains electricity of an average home. Other local builders have followed Pritchard’s lead in resource efficiency for minimal environmental impact.main road, eltham, businesses, llewellyn pritchard, hia greensmart building of the year award., efficiency housing award, conscious homes australia pty ltd -

Eltham District Historical Society Inc

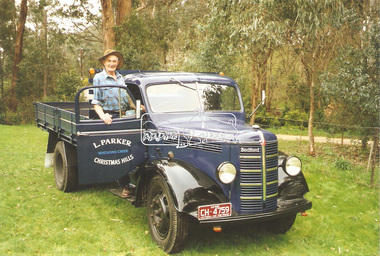

Eltham District Historical Society IncPhotograph, Len Parker's Bedford truck at the Tosch home in Panton Hill, c.1952

Len Parker's Bedford truck is featured in one of the public art mosaics in Were Street, Montmorency. Mr Parker by Grace de Visser (EDHS Newsletter No. 249, December 2019) Len Parker was a regular sight around the district for almost 40 years, selling fruit and veggies from the back of his truck to his regular customers between 1939 and 1978, first in a 1927 Chevy then a 1949 Bedford truck. Len’s connection to the Eltham district started long before he was born. His father Fred first came through the district in the early 1900s. With horse and cart buying and selling what was available at the markets using his mothers’ home in North Melbourne as his base. Fred settled and developed a market garden in the rich soil along the creek at Watsons Creek, Christmas Hills in 1903. Ada Watson was almost five years old and one of eight siblings aged two to sixteen, when her Grandfather and Father both named Christopher Watson brought the Eltham Hotel and they moved from Richmond. Ada’s mother was formerly Emily Silk whose parents Martha and John Silk had been farming in Eltham around 1858 and much later a dairy farmer in Fitzroy. In 1917 at St Margaret’s Church Eltham, Fred aged 44 married Ada aged 35 who was still living and working at the Eltham Hotel. Six years later Ada died from cancer leaving Fred with two small children, Rose five and Len three. Len as a young boy, like his father before him worked the land with horses, growing vegetables, mainly potatoes, cabbages, pumpkins, beans, and tomatoes, selling the excess at the market. Len took over from his ageing father Fred, who had established similar rounds selling door to door with a horse and cart. Len preferred mechanical horsepower to the real kind! In 1939 at the age of eighteen Len brought an old 1927 Chevy Truck. He was taught how to drive it and two weeks later got his driver’s Licence. The Chevy truck had an old wagon on the back with no doors, only hessian bags to keep the wind out! Len had paid 75 pounds for it, kept it for ten years and sold it for the same price! Len’s blue 1949 Bedford was brought new in 1950 for 900 pounds with only a tray back on it. Straight away Len had a wooden frame covered with canvas added, with a roll up front and back. In later years, more solid sides replaced the canvas. Benches were added to hold the boxes of fruit and vegetables, with room to move in the middle, a fruit shop on wheels. Len had large scales attached to a box for weighing the fruit and veggies and many a district baby was also weighed on them. Len would stop at customer’s homes, take their orders and with his big cane basket on his arm deliver their order to their door. On his rounds he always wore a big soft back leather apron and a black or navy beret. If it was cold, he wore a ‘bluey’ jacket on his tall slender frame. Len would go to the markets early Thursday morning, only buying what was not grown at home or brought from his brother in law’s orchard. On his way home Len would start his ‘rounds’ in Lower Plenty and then Montmorency and parts of Eltham. Friday’s regulars were in Research, Kangaroo Ground and Panton Hill. Saturdays were Panton Hill and Christmas Hills. When Len retired in 1978, due to changing social times, women were working more and supermarkets starting to take over; his ageing truck was retired too. In 1999 his son Jim had the Bedford restored, Len was very happy to see ‘Beddy’ all shiny and new once again with just a tray back, like when it was new. Jim still drives the ‘Beddy’ to Heritage Truck shows twenty years on. Len married, had five children and lived most of his life, (except during World War 2 when he served in New Guinea), at Watsons Creek, Christmas Hills dying there in 2006 and is buried at the Kangaroo Ground cemetery with his wife of 64 years, Stella nee Tosch 1917 - 2007. Grace de Visser, the author of this article, is the daughter of Len Parker and a descendant of the two former owners of the Eltham Hotel, both named Christopher Watson. bedford truck, len parker, panton hill, tosch property -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Len Parker's Bedford truck, c.1962

Len Parker's Bedford truck is featured in one of the public art mosaics in Were Street, Montmorency. The little girl is Grace de Visser's sister. Mr Parker by Grace de Visser (EDHS Newsletter No. 249, December 2019) Len Parker was a regular sight around the district for almost 40 years, selling fruit and veggies from the back of his truck to his regular customers between 1939 and 1978, first in a 1927 Chevy then a 1949 Bedford truck. Len’s connection to the Eltham district started long before he was born. His father Fred first came through the district in the early 1900s. With horse and cart buying and selling what was available at the markets using his mothers’ home in North Melbourne as his base. Fred settled and developed a market garden in the rich soil along the creek at Watsons Creek, Christmas Hills in 1903. Ada Watson was almost five years old and one of eight siblings aged two to sixteen, when her Grandfather and Father both named Christopher Watson brought the Eltham Hotel and they moved from Richmond. Ada’s mother was formerly Emily Silk whose parents Martha and John Silk had been farming in Eltham around 1858 and much later a dairy farmer in Fitzroy. In 1917 at St Margaret’s Church Eltham, Fred aged 44 married Ada aged 35 who was still living and working at the Eltham Hotel. Six years later Ada died from cancer leaving Fred with two small children, Rose five and Len three. Len as a young boy, like his father before him worked the land with horses, growing vegetables, mainly potatoes, cabbages, pumpkins, beans, and tomatoes, selling the excess at the market. Len took over from his ageing father Fred, who had established similar rounds selling door to door with a horse and cart. Len preferred mechanical horsepower to the real kind! In 1939 at the age of eighteen Len brought an old 1927 Chevy Truck. He was taught how to drive it and two weeks later got his driver’s Licence. The Chevy truck had an old wagon on the back with no doors, only hessian bags to keep the wind out! Len had paid 75 pounds for it, kept it for ten years and sold it for the same price! Len’s blue 1949 Bedford was brought new in 1950 for 900 pounds with only a tray back on it. Straight away Len had a wooden frame covered with canvas added, with a roll up front and back. In later years, more solid sides replaced the canvas. Benches were added to hold the boxes of fruit and vegetables, with room to move in the middle, a fruit shop on wheels. Len had large scales attached to a box for weighing the fruit and veggies and many a district baby was also weighed on them. Len would stop at customer’s homes, take their orders and with his big cane basket on his arm deliver their order to their door. On his rounds he always wore a big soft back leather apron and a black or navy beret. If it was cold, he wore a ‘bluey’ jacket on his tall slender frame. Len would go to the markets early Thursday morning, only buying what was not grown at home or brought from his brother in law’s orchard. On his way home Len would start his ‘rounds’ in Lower Plenty and then Montmorency and parts of Eltham. Friday’s regulars were in Research, Kangaroo Ground and Panton Hill. Saturdays were Panton Hill and Christmas Hills. When Len retired in 1978, due to changing social times, women were working more and supermarkets starting to take over; his ageing truck was retired too. In 1999 his son Jim had the Bedford restored, Len was very happy to see ‘Beddy’ all shiny and new once again with just a tray back, like when it was new. Jim still drives the ‘Beddy’ to Heritage Truck shows twenty years on. Len married, had five children and lived most of his life, (except during World War 2 when he served in New Guinea), at Watsons Creek, Christmas Hills dying there in 2006 and is buried at the Kangaroo Ground cemetery with his wife of 64 years, Stella nee Tosch 1917 - 2007. Grace de Visser, the author of this article, is the daughter of Len Parker and a descendant of the two former owners of the Eltham Hotel, both named Christopher Watson. bedford truck, len parker -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Len Parker with his restored Bedford truck, 1999

Len's Bedford truk is featured in one of the Montmorency Were Street shopping precinct mosaics. Mr Parker by Grace de Visser (EDHS Newsletter No. 249, December 2019) Len Parker was a regular sight around the district for almost 40 years, selling fruit and veggies from the back of his truck to his regular customers between 1939 and 1978, first in a 1927 Chevy then a 1949 Bedford truck. Len’s connection to the Eltham district started long before he was born. His father Fred first came through the district in the early 1900s. With horse and cart buying and selling what was available at the markets using his mothers’ home in North Melbourne as his base. Fred settled and developed a market garden in the rich soil along the creek at Watsons Creek, Christmas Hills in 1903. Ada Watson was almost five years old and one of eight siblings aged two to sixteen, when her Grandfather and Father both named Christopher Watson brought the Eltham Hotel and they moved from Richmond. Ada’s mother was formerly Emily Silk whose parents Martha and John Silk had been farming in Eltham around 1858 and much later a dairy farmer in Fitzroy. In 1917 at St Margaret’s Church Eltham, Fred aged 44 married Ada aged 35 who was still living and working at the Eltham Hotel. Six years later Ada died from cancer leaving Fred with two small children, Rose five and Len three. Len as a young boy, like his father before him worked the land with horses, growing vegetables, mainly potatoes, cabbages, pumpkins, beans, and tomatoes, selling the excess at the market. Len took over from his ageing father Fred, who had established similar rounds selling door to door with a horse and cart. Len preferred mechanical horsepower to the real kind! In 1939 at the age of eighteen Len brought an old 1927 Chevy Truck. He was taught how to drive it and two weeks later got his driver’s Licence. The Chevy truck had an old wagon on the back with no doors, only hessian bags to keep the wind out! Len had paid 75 pounds for it, kept it for ten years and sold it for the same price! Len’s blue 1949 Bedford was brought new in 1950 for 900 pounds with only a tray back on it. Straight away Len had a wooden frame covered with canvas added, with a roll up front and back. In later years, more solid sides replaced the canvas. Benches were added to hold the boxes of fruit and vegetables, with room to move in the middle, a fruit shop on wheels. Len had large scales attached to a box for weighing the fruit and veggies and many a district baby was also weighed on them. Len would stop at customer’s homes, take their orders and with his big cane basket on his arm deliver their order to their door. On his rounds he always wore a big soft back leather apron and a black or navy beret. If it was cold, he wore a ‘bluey’ jacket on his tall slender frame. Len would go to the markets early Thursday morning, only buying what was not grown at home or brought from his brother in law’s orchard. On his way home Len would start his ‘rounds’ in Lower Plenty and then Montmorency and parts of Eltham. Friday’s regulars were in Research, Kangaroo Ground and Panton Hill. Saturdays were Panton Hill and Christmas Hills. When Len retired in 1978, due to changing social times, women were working more and supermarkets starting to take over; his ageing truck was retired too. In 1999 his son Jim had the Bedford restored, Len was very happy to see ‘Beddy’ all shiny and new once again with just a tray back, like when it was new. Jim still drives the ‘Beddy’ to Heritage Truck shows twenty years on. Len married, had five children and lived most of his life, (except during World War 2 when he served in New Guinea), at Watsons Creek, Christmas Hills dying there in 2006 and is buried at the Kangaroo Ground cemetery with his wife of 64 years, Stella nee Tosch 1917 - 2007. Grace de Visser, the author of this article, is the daughter of Len Parker and a descendant of the two former owners of the Eltham Hotel, both named Christopher Watson. bedford truck, len parker -

Melbourne Legacy

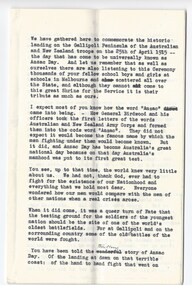

Melbourne LegacyDocument - Speech, ANZAC Commemoration Ceremony for Students

A copy of an Anzac Day Address at the Anzac Commemoration Ceremony for Students, the year is unknown but it is presumably the address given by the President of Legacy. It seems to be one of the earlier ceremonies. It was stored with documents about the building of the Shrine and another speech from the 1939 service. The presenter had probably served in World War 1 so was very close to the events he was talking about. The ceremony provides a valuable opportunity for students to gain an appreciation of the Anzac spirit, the significance of the Shrine and the meaning of Anzac Day. The ceremony is usually attended by representatives from schools throughout the state and the Governor of Victoria. The text says: 'We have gathered here too commemorate the historic landing on the Gallipoli Peninsula of the Australian and New Zealand troops on the 25th of April 1915 - the day that has come to be universally known as Anzac Day. . . I expect most of you know how the word 'Anzac' came into being. How General Birdwood and his officers took the first letters of the words Australian and New Zealand Army Corps and formed them into the code word "Anzac". They did not expect it would become the famous name by which the men fighting under them would become known. But it did, and Anzac Day has become Australia's greatest national day because on that day Australia's manhood was put to its first great test. You see up to that that time, the world knew very little about us. We had not, thank God, ever had to fight for the existence of our Nationhood and everything we hold most dear. Everyone wondered how our men would compare with the men of other nations when a real crises arose. . . . You have been told there thrilling story of Anzac Day. Of the landing at dawn on that terrible coast: the hand to hand fighting that went on continuously all that day and through the days and nights that followed. How the Anzacs - outnumbered, exhausted and tortured by thirst held on, and how during the terrible nine months that ensued all the efforts of a brave enemy to dislodge them failed. Such was their gallantry that a British Officer described the Australian soldier as "The bravest thing God ever made". What a wonderful tribute that was; and how proud we should be of the men who earned it. . . . These men carried on all the traditions of the Anzacs and made a wonderful name for Australia and New Zealand in France, in Belgium, in Egypt and Palestine and in all the theatres of war in which they served. And this great Shrine was build by the people of Victoria, not in any boastful sense of Victory, not in any attempt to glorify war - which is a horrible, dreadful thing, but in memory of those thousands of Victorian sailors and soldiers who so loved their country that they laid down their lives in her service. . . All of them were brave, but do not think that a soldier who is brave need alway be a great warrior. I hope when you have passed through the Shrine you will go and see a little bronze statue near the road yonder. A statue of a man leading a donkey which carries a wounded comrade. You will see the soldier leading the donkey carries no weapons. Yet he was a hero indeed, for he saved the lives of scores of his comrades at Anzac by carrying wounded from the battle to safety and the hospital. And in the end he too gave his life for his friends. . . Let us all try to help each other in peace as they did in war. Instead of divisions, let us have unity. If we think of no one but ourselves we shall not achieve anything nor shall we deserve to. Let those of you who are strong help those who are not so strong - all through life - like John Simpson, the man with the donkey did. Be proud of your country and do nothing to dishonour it. If you get an order from one in authority, obey it, even if you do not understand it.A good solider always obeys his orders. If he did not, he may bring disaster and cause harm to his fellow soldiers. Remember that those thousands of men died so that we could still live here in freedom. A country is judged by its citizens. Let us be worthy of those great citizens who have left us the legacy of their fame and devotion to duty. And when you file through the Shrine and look down on the Rock of Remembrance, read the inscription on it, "Greater Love Hath No Man", remember those wonderful words written in the greatest book in the world nearly two thousand years ago, "Greater love hath no man than this, that a man lay down his life for his friend."A record of a ceremony at the Shrine for school students. The text of the speech is significant in that it was written by a man who had served in World War 1 and knew first hand what it meant to be part of the first Anzacs. White quarto paper x 4 pages with black type of a speech at one of the Annual Anzac Commemoration Service for Students.Handwritten in blue pen 'Shrine, Children's Service'anzac commemoration for students, wreath laying ceremony, speech -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, c. 1885

150 years of experience and commitment. Norwegians have been producing and exporting cod liver oil for more than 1000 years. But it was not before 1645 it was reported that cod liver oil could be used to prevent and cure disease. At the end of the 18th century the first scientific article was published to support this. In the middle of the 19th century, the pharmacist Peter Möller observed that people along the west coast of Norway consuming cod liver oil regularly were rarely ill. He dedicated himself to finding out how this healthy liquid could be produced with better taste and pureness at a lower price. He developed a method of using steam to extract the oil from fresh cod livers. Based on this technological advance, the company Peter Möller was founded in 1854 in Lofoten on Norway’s arctic coast, where you find pure, cold, clean seas and high quality raw material. Peter Joachim Möller (1793-1869) At first Möller’s Cod Liver Oil was believed to be a good source of vitamin D and A, and the health benefits were associated with these vitamins. Peter Möller believed, however, that there were other significant benefits from fatty acids and other ingredients in the cod liver oil – both known and unknown. Peter Möller was dedicated to understanding more about these benefits. His dedication and commitment is clear in Möller's vision to improve people’s health by delivering the highest quality omega 3 products. Timeline 1793 Peter Möller is born in Røros, Norway 26 April. 1819 Peter Möller travels to Christiania (Oslo) and is employed by the pharmacist Frantz Peckel at the Svane chemist. He is employed on condition that he passes his pharmaceutical exam within one year. 1822 Graduated as a pharmacist with a unanimous first grade and with the award of the Professor's special satisfaction. 1842 Together with professors A. Holst and Chr. Boeck, Peter Möller participates in the commission which develops the first Norwegian Pharmacopoeia. 1853 Peter announces his method to cod liver oil works along the coast. He equips cod liver oil factories with new equipment in Lofoten, Ålesund and Kristiansund. The facility outside Ålesund is the most important for testing the method. 1854 The Peter Möller company is established as production has started at the three factories. Sales are lower than anticipated even though the quality is considerably better with the new method. The consumers of cod liver oil had been used to the fact that “good medicine must taste bad” and would not believe that the new and better quality was as healthy. Therefore, the following years are used to introduce consumers to the product, and also to convert more producers to the new method. 1869 Peter Möller dies. There are 70 cod liver oil steamers which use his steam rendering method, and 5000 barrels are produced every year. Möller’s company increases the quality by better routines for quality controls. 1870 Severin A Heyerdal, Möller’s son-in-law, assumes the leadership of the firm after Peter's death. He continues the work by improving the quality of the cod liver oil. The goal was to make it as pure and unaltered as in the liver. At this time, Möller had already started selling its product in the USA. In 1870, WH Schieffelin & Co. ("The oldest drughouse in America") was engaged by Peter Möller in the USA. 1881 Frantz Peckel Möller assumes the leadership of the Peter Möller company. He saw it as his duty to further the work on cod liver oil, and through a combination of solid scientific education and an eminent sense of the great mercantile possibilities, he made Möller’s cod liver oil the number one in the world market. 1914 The first world war leads to Möller’s bottled cod liver oil being shut out of the export market. However, domestic sales are good. 1924 The subsidiary Møystad Möller & Co. is established for bulk exports and the Association of Medicinal Cod liver oil Exporters is established in Bergen in 1925. 1925/26 The green bottles are introduced. Medicinal cod liver oil exports remain almost constant, while total Norwegian cod liver oil exports increase. 1938 The factory on the Løren grounds in Oslo, Norway is built. The factory is in the same place today. Peter Möller’s Pharmaceutical Laboratorium A/S is also established to separate out the scientific business. Investment is made in a new facility for refining and bottling veterinary cod liver oil, and increased production of industrial cod liver oil. 1940 The outbreak of the 2nd world war sees exports fall dramatically, while cod liver oil’s significance as a dietary supplement receives increased attention. Domestic sales increase strongly. 1945 After the war, medicinal cod liver oil retains its high status as an important dietary supplement in the “rebuilding" of the country. Cod liver oil becomes an ”emergency product in ravaged areas where the supply situation is difficult. Competition from other countries such as the USA, England and Iceland increases, and Norway no longer dominates the market. 1983 Möller’s cod liver oil in capsule form is launched and palatable cod liver oil is launched. 1990 Peter Möller A/S merges with Orkla Borregaard A/S (now ORKLA) 2005 Peter Möller merges with CollettPharma. The new company is called MöllerCollett. 2007 Merger between MöllerCollet and DanskDroge. The new company is called Axellus. Oval in section with a thin neck, mauve tinted clear glass bottle with text embossed on side.On side : 'P.MOLLER', 'OL JECOR', 'GADOR VER', 'CHRISTIANIA'.cod liver oil, norway, peter moller, christiana, oslo -

Kew Historical Society Inc

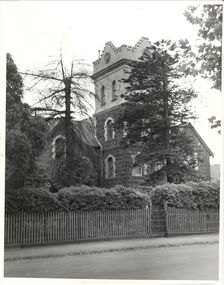

Kew Historical Society IncPhotograph, J E & B L Rogers, 'Ivy Grange', Malmsbury Street, c. 1965

Rate Book evidence records that by 1870 Charles Vickers, architect, was the occupier of this house, having an NA.V. at that date o f£1105, although it is apparent that the house was in fact built by 1864, from the dat; set in the brickwork above the main door. In 1873 the property was purchased by David Beath, a merchant, and it was in the following year that the house was first recorded as 'Ivy Grange'. Beath was a deeply religious man and was a foundation member of both the Congregational and the Presbyterian (the Church of Scotland) Churches of Kew . He added, probably the tower wing, to the house in 1877 when architects Crouch and Wilson called tenders in that year 'for the erection of bluestone additions to (a) villa at Kew, for Davis Beath Esq.' The house was again added to in 1885 by the leading firm Reed, Henderson and Smart. For a number of years in the 1920s 'Ivy Grange' was used as a private mental hospital and is currently a guest house. In 1921 a fete was held at Ivy Grange in aid of building a new church (Sacred Heart, Kew): "Garden Fete in Aid of New Church, Kew. A SUCCESSFUL FUNCTION. Beautiful weather favoured the opening of a garden fete at "Ivy Grange," the residence of Mr. and Mrs. J. Lawlor, Malmsbury and Princess streets, Kew, on last Saturday afternoon, in aid of the fine new Church of the Sacred Heart, Kew, which is now receiving its finishing touches. Not content to wait for the official opening, the lady stallholders did a good business on the previous evening. The ceremony was performed" by the Very Rev. Dean Hegarty, P.P., V.F. (Carlton), with whom were associated the Rev. J. Manly, P.P. (Kew), and the Rev. R. S. Benson, P.P. (South Yarra), Mr. and Mrs. J. Lawlor, and others. Fr. Manly, who was cordially received, said he desired to thank Mr. and Mrs. Lawlor for lending their charming grounds, and for the trouble, time and expense they had given to preparing for the fete. He wished to thank Dean Hegarty for coming to open the fete. The Dean had been a dear and lifelong friend of the late Fr. O'Donoghoe, the beloved pastor of the Kew parish. Next June the Dean would celebrate the golden jubilee of his priesthood, so they could see that he was not a young man. (Laughter.) He hoped that the fete would be a great success, and that when his Grace the Archbishop —: (applause) — should open the new church, he (the speaker) would be able to present a satisfactory financial statement. (Applause.) Dean Hegarty, who was very cordially received, said it was a source of great pleasure to him to come to Kew, of which he entertained many pleasant recollections. The new church would have delighted the heart of their late beloved pastor, but it had pleased God to take him to a holler temple. His mantle had fallen on worthy shoulders, in the person of Fr. Manly—(applause)—who was carrying on the work of the parish well and vigorously. (Applause.) Some wondered how these great works were successfully accomplished. The prime factor in the wonderful progress of the Church— the work of the people, priests and nuns—was their deep, abiding Catholic faith. (Applause.) Kew was not by any means a large parish, yet look at the magnificent church that Fr. Manly was building on the hill! He said to his people, "Come, follow me, and we shall win through." (Applause.) It gave him great pleasure to declare the fete open, and he wished it the highest measure of success. (Prolonged applause.) Mr. J. Lawlor, who was greeted with applause, in moving a hearty vote of thanks to Dean Hegarty for his presence and support, said he knew of the great work done by the Dean in Gippsland, where he (the speaker) lived when a young man. The Dean ministered to a parish at that time as large as was the diocese of Sale to-day. The Dean and Fr. Manly reflected credit on the pioneer priests, who had laid well and solidly the foundations, of religion in Victoria. (Applause.) He was glad that reference had been~made to the work of their late beloved pastor, Fr. O'Donoghoe. : Mr. Pierce Cody seconded the motion, which, was carried by acclamation. The Dean,* in acknowledging the compliment, paid a tribute to Mr. and Mrs. Lawlor for their great generosity in connection with the fete, and complimented them on their successful efforts. (Applause.). A cafe chantant, organised by Mr. John. Sullivan, was contributed to by Misses G. Hornal, M. O'Donnell, Ella Burke, Eileen Burke, Alice Marsh, and M. Carrucan, and Messrs. T. Hammond, J. Donovan, J. Sullivan, and Fr. Lanigan. Mrs. J. Donovan was at the piano. St. Vincent de Paul Boys' Orphanage Band (South Melbourne) rendered selections. The stalls ware as follow:—Cake and Sweets Stall: Mesdames Needham, Treacey, Lynch and Cody. Fancy Stall: Mesdames Lawlor, J. P. Martin, M. Treacey, Simpson, Giddons and A. Molton, and Miss, Shirley. Refrestiment Stall: Mesdames Shiels, Hunter, Kealy, Duane and the Misses Turner and Delahunty; Produce Stall: Mesdames O'Sullivan, Mareli, Carrucan, and Kennedy. Mr. P. J. Kennedy acted as hon. general secretary. The fete was continued in the evening, the grounds being brilliantly illuminated. (Advocate (Melbourne, Vic. : 1868 - 1954), Thursday 7 April 1921, page 13) In 1930 it was acquired by the Carmelite Fathers for use as a novitiate: "IVY GRANGE," KEW." Acquired for Carmelite Novitiate. The valuable property, "Ivy Grange," Kew. which" belonged to the McGuiness family has been acquired by the Carmelite Fathers for a novitiate." (Advocate (Melbourne, Vic. : 1868 - 1954), Thursday 18 September 1930, page 18This work forms part of the collection assembled by the historian Dorothy Rogers, that was donated to the Kew Historical Society by her son John Rogers in 2015. The manuscripts, photographs, maps, and documents were sourced by her from both family and local collections or produced as references for her print publications. Many were directly used by Rogers in writing ‘Lovely Old Homes of Kew’ (1961) and 'A History of Kew' (1973), or the numerous articles on local history that she produced for suburban newspapers. Most of the photographs in the collection include detailed annotations in her hand. The Rogers Collection provides a comprehensive insight into the working habits of a historian in the 1960s and 1970s. Together it forms the largest privately-donated collection within the archives of the Kew Historical Society.Ivy Grange, cnr Malmsbury and Princess Streets, Kew. Ivy Grange. Home of David Beath. Commenced 1864, Tower Wing added 1877. Chap 38.ivy grange, malmsbury street, dorothy rogers, david beath, charles vickers, crouch and wilson, kew houses -

Melbourne Legacy

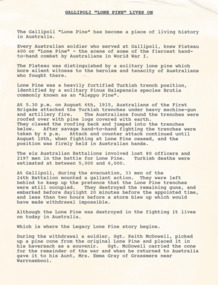

Melbourne LegacyDocument, Gallipoli's 'Lone Pine' Lives On