Showing 1247 items matching "drinking"

-

Eltham District Historical Society Inc

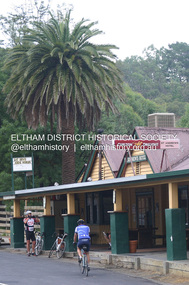

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, St Andrews Hotel, 2 February 2008

The c1860 St Andrews Hotel, with the c1930 additions, and the Canary Island Palm, and the surrounding site to the title boundaries are historically, socially and aesthetically significant to the Shire of Nillumbik. The St Andrews Hotel is historically significant because it may have given its name 'St Andrews' to the town (another suggestion is that the name came from St Andrews church) and for its connection to Ewen Hugh Cameron (1831-1915) the prosperous local farmer, member of the Eltham Roads Board/Shire Council and local MP. It is also significant as the oldest hotel building in the former Shire of Eltham, as one of the few surviving buildings connected with the Caledonian goldfields era and as one of a handful of early structures to have survived the 1960s bushfires; the additions and alterations to the hotel reflect its long life. The hotel is socially significant because it has served as an important meeting place for more than 160 years. The Canary Island Palm is historically significant as a rare example of exotic tree planting in this rural area. The tree is aesthetically and historically significant as a local landmark and for its contribution to the streetscape and landscape value. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p71 Built around 1860, St Andrews Hotel has changed little since it first welcomed thirsty gold diggers from the Caledonia Goldfields. The timber building, with gabled roof, beamed ceilings and a massive fireplace, is Nillumbik Shire’s oldest hotel and has always been an important community centre, particularly in its early days. Fortunately, the hotel and the near-by Canary Island Palm Tree, which is quite rare in this area, survived the 1960s bushfires, along with a few other early buildings. St Andrews (formerly Queenstown) was founded on gold, as were Panton Hill (formerly Kingstown), Research and Diamond Creek, from the mid-1850s to the 1860s. But by the early 20th century common use changed the name Queenstown to St Andrews, possibly after this hotel or after the church or the mining district.1 The Caledonia Diggings were probably named by Scottish settlers after the Roman name for Scotland, despite this land bearing little similarity to their homeland.2 Queenstown, which was proclaimed as a township in 1861, was the gold-mining centre on the Upper Diamond and in the 1850s had up to 600 European inhabitants and a small camp of Chinese on the flats along the creek. Queenstown was the administrative centre of the Upper Diamond with three hotels, a brewery and a slaughterhouse.3 It is unclear which hotel was the district’s first, as distinct from the earliest unlicensed grog shops, some of which operated in tents. John Corke Knell was one of eight unlicensed storekeepers supplying drink to miners at Caledonia in 1857, named by Sgt. McNamara of the Caledonia Police Station.4 In February 1859, Knell apparently bought most of the present hotel’s site at the first township land sales. As he was a local storekeeper, he might have first established a store there.5 Knell and his wife Eliza were early licensees of the St Andrews Hotel. The hotel had eight bedrooms – including three for public use – and the dining-room seated 30 people. It is thought they named the hotel St Andrews after Eliza’s hometown of St Andrews in Scotland. St Andrews Hotel was an important local centre in several ways. In the same building the Knells also operated a post office and general store. In 1867 Mrs Knell was appointed Deputy Registrar of Births and Deaths for Queenstown. The hotel was also used to hold inquests into people’s deaths when the police residence became too small.6 The hotel also became a fashionable destination at Christmas for parties from Melbourne. In 1868, possibly following her husband’s death, Mrs Knell applied for a temporary licence, which was then transferred to Robert Smith after their marriage in 1869. But then, possibly after Robert’s death, Mrs Smith operated the hotel until 1892. This contradicts a report in The Evelyn Observer 1882 that JC Knells of the St Andrews Hotel was granted a publican’s licence in the Queenstown Police Court. At that time he was supposed to have been dead for around 14 years! Although Mrs Smith was a respected citizen, known for her geniality and as an ideal hostess, she had a minor brush with the law when she was fined ten shillings for not lighting a lamp outside her licensed premises.7 From 1892 several publicans owned the hotel including W Atkins, from 1895. In 1909 the licensee was apparently Mrs Smith’s son, Walter Knell, who held the licence until at least the 1920s. Not surprisingly, this old hotel has attracted romantic stories. Mrs Smith is said to be seen roaming the pub in her nightdress – even though she was buried in the Queenstown Cemetery in 1911.8 A musical The Hero of Queenstown, set in the hotel, was written and produced by local actor Reg Evans in the 1970s.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, st andrews hotel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Cannon, Alexander Hall and Son, c. 1855

The Schomberg Cannon was recovered from the 1855 wreck of the SCHOMBERG in 1974 by Flagstaff Hill divers Peter Ronald, Colin Goodall and Gary Hayden. The wreck site was discovered in August 1973 by Stan McPhee and John Laidlaw. ABOUT THE SCHOMBERG When SCHOMBERG was launched in 1855, she was considered the “Noblest ship that ever floated on water.” SCHOMBERG’s owners, the Black Ball Line, commissioned the ship for their fleet of passenger liners. The ship was built by Alexander Hall of Aberdeen at a cost of £43,103. It was constructed with three skins: one planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Its first-class accommodation was simply luxurious; velvet pile carpets, large mirrors, rosewood, birds-eye maple, mahogany, soft furnishings of satin damask; an oak-lined library and a piano. Overall she had accommodation for 1000 passengers. At the launch, the SCHOMBERG’s 34-year-old master, Captain ‘Bully’ Forbes, had promised Melbourne in 60 days, "with or without the help of God." James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; MARCO POLO and LIGHTNING. In 1852 in the MARCO POLO he made the record passage from London to Melbourne in 68 days. There were 53 deaths on the voyage but the great news was of the record passage by the master. In 1954 Captain Forbes took the clipper LIGHTNING to Melbourne in 76 days and back in 63 days, this was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his own records. He cared little for the comfort of the passengers. On this, the SCHOMBERG’s maiden voyage, he was going to break records. SCHOMBERG departed Liverpool on her maiden voyage on 6 October 1855 flying the sign “Sixty Days to Melbourne”. The ship departed with 430 passengers and 3000 tons of cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, and 90,000 gallons of water for washing and drinking. It also carried 17,000 letters and 31,800 newspapers. The ship and the cargo was insured for $300,000, a fortune in those times. The winds were poor as she sailed across the equator, slowing SCHOMBERG’s journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, and Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the Third Mate Henry Keen, who reported land about 3 miles off, Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26 December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to SCHOMBERG and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS QUEEN at dawn and signalled the steamer. The master of the SS QUEEN approached the stranded vessel and all of SCHOMBERG’s passengers and crew were able to disembark safely. The SCHOMBERG was lost and with her, Forbes’ reputation. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the SCHOMBERG. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot! Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach SCHOMBERG, salvage efforts were abandoned. Parts of the SCHOMBERG were washed ashore on the south island of New Zealand in 1870, nearly 15 years after the wreck. The wreck now lies in almost 9 metres of water. Although the woodwork is mostly disintegrated the shape of the ship can still be seen due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. Flagstaff Hill holds many items salvaged from the SCHOMBERG including a ciborium (in which a diamond ring was concealed), communion set, ship fittings and equipment, personal effects, a lithograph, tickets and a photograph from the SCHOMBERG. One of the SCHOMBERG bells was in the old Warrnambool Library. The Schomberg cannon is currently on loan to the Port Campbell Visitor Information Centre.The SCHOMBERG collection is of historical and archaeological significance at a State level, listed on the Victorian Heritage Register VHR S612. Flagstaff Hill’s collection of artefacts from the SCHOMBERG is significant for its association with the Victorian Heritage Registered shipwreck. The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the SCHOMBERG. The SCHOMBERG collection is archaeologically significant as the remains of an international passenger ship. The shipwreck collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the shipwreck and the ship, which was designed to be the fastest and most luxurious of its day. The SCHOMBERG collection meets the following criteria for assessment: Criterion A: Importance to the course, or pattern, of Victoria’s cultural history. Criterion B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history. Criterion C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history.Cannon; 6-POUNDER (6pdr) smooth bore cannon, mounted on a wooden frame. The cannon has a metal lug on each side. It is commonly known as the Schomberg cannon. It was recovered from the wreck of the Schomberg in 1974.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, cannon, the schomberg cannon, schomberg cannon, peterborough, 1855, sailing ship -

Flagstaff Hill Maritime Museum and Village

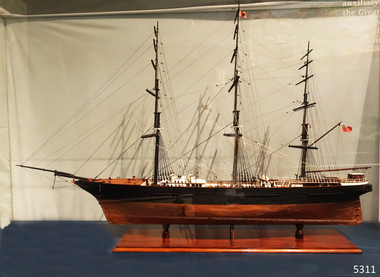

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, S.S. Schomberg, 1988

This model of the clipper ship SS Schomberg was researched and constructed to a scale of 1:64 by David Lumsden in 1988. When the Schomberg was launched in 1855, she was considered the "Noblest” ship that ever floated on the water. Schomberg's owners, the Black Ball Line had commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen for £43,103 and constructed with 3 skins. One planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Her First Class accommodation was simply luxurious with velvet pile carpets, large mirrors, rosewood, birds-eye maple and mahogany timbers throughout, soft furnishings of satin damask, and oak-lined library with a piano. Overall she had accommodation for 1000 passengers. At the launch, the Schomberg's 34-year-old master, Captain 'Bully' Forbes, had promised to reach Melbourne in sixty days stating, "with or without the help of God." Captain James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; Marco Polo and Lightning. In 1852 in the Marco Polo, he made the record passage from London to Melbourne in 68 days. Unfortunately, there were 53 deaths on the voyage, but the great news was off the record passage by Captain Forbes. In 1854 he took the clipper “Lighting” to Melbourne in 76 days and back in 63 days, this record was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his previous records. He cared little for the comfort of the passengers. On this, the Schomberg's maiden voyage, he was determined to break existing records. Schomberg departed Liverpool on her maiden voyage on 6th October 1855 flying a sign that read "Sixty Days to Melbourne". She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. The ship and cargo were insured for $300,000 a fortune for the time. The winds were poor as she sailed across the equator, slowing Schomberg's journey considerably. The land was first sighted on Christmas Day, at Cape Bridgewater near Portland, Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the third mate Henry Keen, who reported land about 3 miles off. Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26th December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes's map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the SS Queen at dawn and signaled the steamer. The master of the Queen approached the stranded vessel and all of Schomberg’s passengers and crew disembarked safely. The Black Ball Line's Melbourne agent sent a steamer to retrieve the passengers' baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1870, nearly 15 years after the wreck parts of the Schomberg had washed ashore on the south island of New Zealand. The wreck now lies in almost 9 metres of water and although the woodwork is mostly disintegrated the shape of the ship can still be determined due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. There have been many other artefacts salvaged from the wreck include ship fittings and equipment, personal effects, a lithograph, tickets and photographs from the Schomberg. This item was retrieved from the shipwreck site during early salvage efforts on the vessel. And was donated to the Flagstaff Hill collection of Schomberg shipwreck artefacts.This artifact is particularly significant in that along with other items salvaged from the wreck have helped in part to having legislation changed to protect shipwrecks, with far tighter controls being employed to oversee the salvaging of wreck sites. This item forms part of the Schomberg collection at Flagstaff Hill maritime museum. The collection as a whole is of historical and archaeological significance at a State level. Flagstaff Hill’s collection of artefacts from the Schomberg is also significant for its association with the Victorian Heritage Registered Schomberg shipwreck (VHR S 612). The collection is of additional significance because of the relationship between the objects salvaged, as together they help us to interpret the story of the Schomberg. The collection as a whole is historically significant for representing aspects of Victoria's maritime history and its potential to interpret social and historical themes from society at the time of the wreck.Wooden model of the clipper ship SS Schomberg. The three masts are rigged with lines but have no sails. The model is mounted on pedestals on a timber board, exhibited in a glass case. The scale of this model is 1:64.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ship model, schomberg ship model, 1855, david lumsden, ship model maker, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen -

Eltham District Historical Society Inc

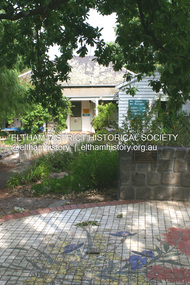

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Eltham Living and Learning Centre, 26 January 2008

In 1857, tanner John Pearson purchased three and a half acres of land in Little Eltham, at the western end of Pitt Street, with a 70-foot frontage to Maria Street (Main Road) and stretching down to the Diamond Creek for £100. He contracted Benjamin Oliver Wallis to build house for him. Wallis, a mason by trade who originated from the Cornish village of Newlyn, migrated to Melbourne in 1853 and was shortly engaged by Richard Warren to build the Eltham Hotel, which opened in 1854. When Warren fell into financial difficulty in 1858, Wallis purchased the hotel. That same year, Pearson constructed a tannery below the house with access to the water in the Diamond Creek. When Pearson became bankrupt in 1867, Wallis similarly acquired the house from Pearson’s creditors in 1868 and lived there until his death in 1896. For some of this time the house was in the name of Wallis’s son Richard but following his death in 1888, ownership reverted to his father. It was purchased by retired teacher Richard Gilsenen in 1899. Gilsenen was made acting head teacher at the Eltham State School in 1906 following the sudden death of head teacher John Brown. In the 1950s the house was bought by retired engineer Dr Alfred Fitzpatrick and his wife Claire who made various modifications to house goats and poultry as well as structural modifications to the house. In the early 1970s, Eltham Shire Councillors Frank Maas and Don Maling proposed an extended communities’ activities program be set up and the Commonwealth Grants Commission was approached for financial assistance. In 1974 a $50,000 Commonwealth Grant was received by the Shire Council to acquire the Fitzpatrick property as part of the planning to establish an extended communities’ activities program. The Fitzpatricks moved next door and Claire taught at the new Living and Learning Centre, which began in 1975, one of the first community education centres in Victoria. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p59 It’s a centre for sharing knowledge and friendship and it stands on the former hub of Eltham’s original township near Pitt Street. The Eltham Living and Learning Centre, with around 2000 participants a year, began in 1975 as one of the first Community Education Centres in Victoria. Classes ranging from macramé to wine making to environmental living have enriched the lives of thousands of people through the generosity of tutors sharing their skills free of charge. The centre’s heart is the brick cottage, built in 1858 by tanner John Pearson. He bought the three and a half acre (1.4ha) allotment fronting Maria Street (now Main Road) and stretching down to the Diamond Creek. The allotment formed part of a 316 acre (127.8ha) subdivision, owned by Josiah Holloway, called Little Eltham, north of the original Eltham Reserve.1 The allotment then passed through the hands of several speculators before it was sold to Pearson for £100 in 1857. Mr Pearson’s children attended the Eltham Primary School from 1864 to 1867. But creditors took possession of the property when his tannery folded in 1867. It was then sold to publican Benjamin Wallis, who owned the Eltham Hotel at the corner of Pitt Street and Main Road. In 1899 the property was bought by Richard Gilsenan, who became acting head teacher of the Eltham Primary State School in 1906. In the 1950s, retired engineer Dr Alfred Fitzpatrick and his wife Claire bought the property, and made structural changes. Claire, a journalist and community campaigner, modified and built pens for goats and poultry, a stable, a garage and planted fruit trees and a vegetable garden. In the early 1970s a young woman called Carina Hack approached Gwen Wesson at the Diamond Valley Learning Centre (Victoria’s first Community Education Centre) about starting a community centre. Following Wesson’s suggestion, Hack spoke to Shire President Alistair Knox ‘one bleak rainy afternoon, sipping hot drinks and discussing life’.2 Eltham Shire Councillors Frank Maas and Don Maling proposed a community activities program and the council received a $50,000 Commonwealth Government Grant for this venture.3 The Fitzpatricks sold their property to the council and moved next door and Claire taught at the new centre, which Hack named. Eltham obviously wanted such a centre as Hack recalls. ‘During the next two months we had about 50 volunteers working day, night and weekends, scrubbing down, plastering and painting walls, replacing floors, repairing fences, recycling furniture, sewing curtains and cushions, donating furniture, toys, equipment, clean-ing and gardening…’4 The first enrolment day saw a queue stretching up the driveway nearly to the gate and the first sessions attracted 270 people a week. Soon the outbuildings were converted into pottery studios and a large workshop. From 1979 the Eltham Art and Craft Market was held in the centre’s grounds and the Friends of the Centre ran it from 1980. A former program coordinator, Margaret Johnson, remembers enrolment day in the late 1970s and 1980s, when hundreds of people would queue – and some even camped overnight! Overnighters were greeted in the morning with fresh tea and toast. Another tradition was The Enrolment Day Cake with Recipe, given to volunteers. ‘One happy Enrolment Day fell on February 14 and let’s just say that St Valentine found some willing participants, paying $2 for a kiss.’5 Meanwhile the participants’ children could play at the Council Eltham Lower Park house in Hohnes Road, later in Susan Street. But the centre has had difficulties too. In 1990 a fire destroyed the stable and the police suspected arson. However the pavilion was built in its place.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, benjamin oliver wallis, claire fitzpatrick, don maling, dr alfred fitzpatrick, eltham living and learning centre, frank maas, john pearson, richard gilsenen, tannery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bell, Schomberg 1855, Before 1855

This bell was the smaller of the two bells rescued by the crew of the Schomberg when it was wrecked in 1855. All of the crew from the Schomberg wreck survived. They carried the two ship’s bells with them as they made their way along the coast, eventually arriving at the home of settler John Manning, who lived at Hopkins Point near Warrnambool. Manning acquired the Schomberg bells, presenting them to two Warrnambool churches: the smaller one to St Joseph’s Catholic Church and the larger bell to St John’s Presbyterian church. The small bell at St Joseph’s developed a crack after about a year and could no longer be used. Thomas Manifold imported a new bell for that church, and the cracked bell was stored at his farm. The property was sold years later to John Logan, who donated the discarded bell to the Warrnambool Museum when it first opened in 1886. The Curator, Joseph Archibald, displayed the bell in the entry. In 1975, the bell was transferred from the Warrnambool Art Gallery to Flagstaff Hill. THE SAILING SHIP, SCHOMBERG: - When the Schomberg was launched in 1855, she was considered the "Noblest” ship that ever floated on the water. Schomberg's owners, the Black Ball Line, had commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen for £43,103 and constructed with 3 skins. One planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Her First Class accommodation was simply luxurious with velvet pile carpets, large mirrors, rosewood, birds-eye maple and mahogany timbers throughout, soft furnishings of satin damask, and an oak-lined library with a piano. Overall, she had accommodation for 1000 passengers. At the launch, the Schomberg's 34-year-old master, Captain 'Bully' Forbes, had promised to reach Melbourne in sixty days, stating, "with or without the help of God." Captain James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships, Marco Polo and Lightning. In 1852, on the ship Marco Polo, he made the record passage from London to Melbourne in 68 days. Unfortunately, there were 53 deaths on the voyage, but the great news was of the record passage by Captain Forbes. In 1854, he took the clipper “Lightning” to Melbourne in 76 days and back in 63 days; this record was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his previous records. He cared little for the comfort of the passengers. On this, Schomberg's maiden voyage, he was determined to break existing records. Schomberg departed Liverpool on her maiden voyage on 6th October 1855, flying a sign that read "Sixty Days to Melbourne". She departed with 430 passengers and 3000 tons of cargo, including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, and 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. The ship and cargo were insured for $300,000, a fortune for the time. The winds were poor as she sailed across the equator, slowing Schomberg's journey considerably. The land was first sighted on Christmas Day, at Cape Bridgewater near Portland. Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the third mate, Henry Keen, who reported land about 3 miles off. Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26th December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes's map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the SS Queen at dawn and signalled the steamer. The master of the Queen approached the stranded vessel and all of Schomberg’s passengers and crew disembarked safely. The Black Ball Line's Melbourne agent sent a steamer to retrieve the passengers' baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later, one plunderer found a case of Wellington boots, but alas, all were for the left foot. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 186,4, after two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1870, nearly 15 years after the wreck, parts of the Schomberg had washed ashore on the south island of New Zealand. The wreck now lies in almost 9 meters of water, and although the woodwork is mostly disintegrated, the shape of the ship can still be determined due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby.The bell is particularly significant in that along with other items from the wreck helped in part to having the legislation changed to protect shipwrecks, with far tighter controls being employed to oversee the salvaging of wreck sites. This bell forms part of the Schomberg collection at Flagstaff Hill maritime museum. The collection as a whole is of historical and archaeological significance at a State level. Flagstaff Hill’s collection of artefacts from the Schomberg is also significant for its association with the Victorian Heritage Registered Schomberg shipwreck (VHR S 612). The collection is of additional significance because of the relationship between the objects salvaged, as together they help us to interpret the story of the Schomberg. The collection as a whole is historically significant for representing aspects of Victoria's maritime history and its potential to interpret social and historical themes from society at the time of the wreck. A small ship’s bell. The bell bears the ship’s name and year of construction on one side and the name and address of the ship’s builders on the other. These details are deeply engraved into the metal and formed in bold, upper-case lettering. The bell has two bell stands, a left and a right side. Both stands have an Iron pipe made into an inverted ‘Y’ shape with a hole made in the single length and feet attached to a rectangular metal plate at the other two ends. Feet are bolted into a timber base that has a hole drilled through the centre for mounting. Bell's front; “SCHOMBERG” with “1855” below. Bell's back “HALL & SONS (crack splits letter “N”) / BUILDERS (in italics) / ABERDEEN” (crack splits letter “B”).flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, schomberg, silver plated bell, mess bell, bell stands, captain ‘bully’ forbes, alexander hall and son, james baines and company, liverpool’s black ball line, bell, schomberg bell, ship's bell, small bell, st joseph's church, briggs marine, john manning, john logan, warrnambool museum -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Diamond ring, about 1855

In 1975, 120 years after the sailing ship Schomberg was wrecked, Flagstaff Hill divers (Peter Ronald, Colin Goodall and Gary Hayden) found an ornate communion set amongst the wreckage. The set comprised a jug, ciborium, lid, chalice and plate. The items, apart from the lid, were then displayed at Flagstaff Hill Maritime Village. The lid had etchings that did not match the chalice and sat in storage for several years. Then in 1978, while the marine concretion inside the lid was being examined, a surface layer came loose and revealed a glint of gold that was assumed to be a piece of brass. The layers of concretion were carefully removed and a ring-like band emerged. Further treatment exposed a 'large faceted stone in an intricate gold setting. Weeks later a detailed examination estimated the value of the ring, known as the Schomberg Diamond, to be $7000. When the Schomberg was launched in 1855, she was considered the "Noblest” ship that ever floated on the water. Schomberg's owners, the Black Ball Line had commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen at a cost of £43,103 and constructed with 3 skins. One planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Her First Class accommodation was simply luxurious with velvet pile carpets, large mirrors, rosewood, birds-eye maple and mahogany timbers throughout, soft furnishings of satin damask, an oak-lined library with a piano. Overall she had accommodation for 1000 passengers. At the launch, the Schomberg's 34-year-old master, Captain 'Bully' Forbes, had promised to reach Melbourne in sixty days stating, "with or without the help of God." Captain James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; Marco Polo and Lightning. In 1852 in the Marco Polo, he made the record passage from London to Melbourne in 68 days. Unfortunately there were 53 deaths on the voyage, but the great news was off the record passage by Captain Forbes. In 1854 he took the clipper “Lighting” to Melbourne in 76 days and back in 63 days, this record was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his previous records. He cared little for the comfort of the passengers. On this, the Schomberg's maiden voyage, he was determined to break existing records. Schomberg departed Liverpool on her maiden voyage on 6th October 1855 flying a sign that read "Sixty Days to Melbourne". She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. The ship and cargo were insured for $300,000 a fortune for the time. The winds were poor as she sailed across the equator, slowing Schomberg's journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the third mate Henry Keen, who reported land about 3 miles off. Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26th December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes's map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the SS Queen at dawn and signaled the steamer. The master of the Queen approached the stranded vessel and all of Schomberg’s passengers and crew disembarked safely. The Black Ball Line's Melbourne agent sent a steamer to retrieve the passengers' baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1870, nearly 15 years after the wreck parts of the Schomberg had washed ashore on the south island of New Zealand. The wreck now lies in almost 9 meters of water and although the woodwork is mostly disintegrated the shape of the ship can still be determined due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. The actual lid in which the ring was found has not yet been completely identified and could belong to a coffee pot, sugar bowl or maybe a jug or something similar. Although all survived the wreck no-one came forward to claim the valuable diamond. The Schomberg Diamond is currently on display in the Great Circle Gallery. Flagstaff Hill Maritime Village along with the rest of the communion set. Other artefacts salvaged from the wreck include ship fittings and equipment, personal effects, a lithograph, tickets and photographs from the Schomberg. One of the Schomberg bells is in the Warrnambool Library.The Schomberg Diamond is particularly significant in that it played a crucial part in having the legislation changed to protect shipwrecks, with far tighter control over the salvaging of items from wreck sites. This ring is registered as Artefact S/105 in the Schomberg collection, the Schomberg collection as a whole is of historical and archaeological significance at a State level. Flagstaff Hill’s collection of artefacts from the Schomberg is also significant for its association with the Victorian Heritage Registered shipwreck (VHR S 612). The collection is of prime significant because of the relationship between the objects salvaged, as together they help us to interpret the story of the Schomberg. The collection as a whole is historically significant for representing aspects of Victoria's maritime history and its potential to interpret social and historical themes. A mid-Victorian gentleman's solitaire diamond dress ring with a Brazilian cut diamond (cushion cut), one and one-third carat set within an 18 carat yellow gold ring consisting of four claws within an open scroll setting and a divided scroll shank. Colour is classified as 'J', clarity SII. The setting is handmade. warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, ciborium, ring, schomberg-diamond, schomberg-ring, gentleman's ring, dress ring -

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s - set of 32, Noel Simons, 25/02/1971 12:00:00 AM

Set of 31 transparencies taken on 25/2/1972 on Kodak mounts. 1201.1 - Bendigo No. 26 in Bond St. just after leaving Long Gully en route for Quarry Hill. Has Norris Supermarket in background. Has two SEC roof ads. 1201.2 - No. 26 climbing View St. from Charing Cross en route to Eaglehawk. Has ANZ bank and AMOCO service station in background. 1201.3 - as for 1201.3, but after tram has passed photographer. Has buildings west of Mackenzie St. in photograph. 1201.4 - Tram stop and centre of the road pole with two "CARS STOP BY REQUEST" signs mounted on pole at the corner of Mackenzie St. 1201.5 - same position as for 1201.3, but with No. 5 descending the street. 1201.6 - same position as for 1201.2, but with No. 5 descending the street. Photo taken after tram has passed photographer. 1201.7 - No. 7 in Nolan St. from across the park at Lake Weeroona. 1201.8 - No. 7 entering McCrae St from Nolan St. - distant view. Note "TRAM "sign on left hand side under tree and overhead in McCrae St. from former track that once was in this street. 1201.9 - No. 7 in High St. with Cathedral in background. Tram en route to North Bendigo. Note scaffolding around Cathedral main spire area. 1201.10 - No. 7 crossing Bendigo Creek bridge in High St. near Golden Square. Has a Caltex Service station in the background. 1201.11 - No. 7 at Golden Square terminus with Sunburst Fruit Juices and a Peters Ice cream delivery vans alongside. 1201.12 - as for 1201.11 but photo taken from behind tram, with the end of the rails in the photograph. 1201.13 - No. 7 and 21 in Pall Mall at Charing Cross with No. 5 in the background. Taken some distance away from the location. 1201.14 - No. 7 at Golden Square terminus, taken a short distance from the tram terminus. Shows Milk Bar on right hand side and the hotel on the left hand side. Taken from the south side of the roadway. 1201.15 - as from 1201.14 but taken from the north side of the roadway. 1201.16 - No 5 waiting at California Gully loop. Distant photo showing surrounds 1201.17 - No. 5 en route for Quarry Hill crossing No. 26 at California Gully. 1201.18 - No. 26 at Eaglehawk terminus with Eaglehawk Town Hall and Post Office in background. 1201.19 - No. 21 arriving at Charing Cross en route to North Bendigo. Has Alexandra Fountain in the background, ANZ bank RACV building, and other buildings on the north side of Pall Mall or Nolan St. 1201.20 - No. 26 en route for Quarry Hill at Charing Cross, with crew standing by front door. Has Colonial Mutual life building, Armstrong Tyre Service (Firestone) and a sign for Cohns Drinks in the background. 1201.21 - as for 1201.20 but with No. 5 en route to Eaglehawk now in photograph. 1201.22 - No. 26 at Quarry Hill terminus. 1201.23 - No. 26 at Quarry Hill terminus, view of front portion of tram only from a gate at the Bendigo cemetery. 1201.24 - Track at the end of the Quarry Hill line showing the point blades of the former "Y" terminus and the overhead for this. 1201.25 - No. 2 at the Quarry Hill terminus, looking along the former Trackwork. 1201.26 - as for 1201.25 1201.27 - number not used. 1201.28 - Golden Square terminus from some distance from the actual terminus, showing the Warning sign "TRAM" for motorists from the south. No. 7 at the terminus. 1201.29 - No. 7 passing through the Golden Square shopping centre. Numerous cars and pedestrians. Tram en route for North Bendigo. 1201.30 - No. 7 in High St. Golden Square, en route for North Bendigo. Photo taken after tram has passed photographer. 1201.31 - No. 7 in High St. just past Wattle St. with the Cathedral in the background. Tram has two SEC roof ads good side on photo, 'Everything's fine in my all electric kitchen' and 'Electrical cooking - clean, quick, economical'. 1201.32 - No. 7 in High St. nearing Wattle St. Has Cathedral in the background. Photo taken after tram has passed photographer.Information written on in black ink and date stamped on purple ink. 1201.1 - "No. 26 in Bond St just after leaving Long Gully" 1201.2 - "No. 26 climbing View St. from Charing Cross" 1201.3 - "No. 26 ascending View St. from Charing Cross (At Mackenzie St.)" 1201.4 - "View St. & Mackenzie St." 1201.5 - "No. 5 in View St. near Mackenzie St." 1201.6 - "No. 5 in View St. nearing Charing Cross." 1201.7 - "No. 7 in Nolan St. seen from Lake Weeroona Park." 1201.8 - "No. 7 entering McRae St. from Nolan St. Note "TRAM" warning sign on left. 1201.9 - "No. 7 in High St. passing Short St." 1201.10 - "No. 7 crossing Bendigo Creek bridge in High St. near Golden Square." 1201.11 - "No. 7 at Golden Square terminus" 1201.12 - "No. 7 at Golden Square terminus" 1201.13 - "No 7, 21 and 5 at Charing Cross" 1201.14 - "No. 7 at Golden Square terminus" 1201.15 - "No. 7 at Golden Square terminus" 1201.16 - "No 5 waiting at California Gully loop." 1201.17 - "Nos. 5 and 26 crossing at California Gully loop" 1201.18 - "No. 26 at Eaglehawk terminus" 1201.19 - "No. 21 arriving at Charing Cross from Golden Square" 1201.20 - "No. 26 at Charing Cross" 1201.21 - "Nos. 5 and 26 at Charing Cross." 1201.22 - "No. 26 at Quarry Hill terminus" 1201.23 - "No. 26 at Quarry Hill terminus seen through the gates of the Bendigo Cemetery." 1201.24 - "Quarry Hill terminus showing remains for former double track layout abandoned before 1964." 1201.25 - "No. 2 at Quarry Hill terminus" 1201.26 - "No. 2 at Quarry Hill terminus" 1201.28 - "The Southern approach to Golden Square with No. 7 standing at the terminus, "TRAM" warning sign on the left. 1201.29 - "No. 7 passing through Golden Square Shopping Centre" 1201.30 - "No. 7 in High St. Golden Square" 1201.31 - "No. 7 in High St. passing Wattle St." 1201.32 - "No. 7 in High St. nearing Wattle St."tramways, trams, bendigo, bond st., view st., nolan st., high st., eaglehawk, california gully, charing cross, quarry hill, trackwork, tram 2, tram 5, tram 7, tram 21, tram 26 -

Eltham District Historical Society Inc

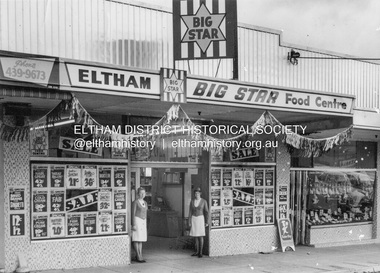

Eltham District Historical Society IncNewspaper clipping, Supermarket next on old site, Diamond Valley Mirror, Wed. Feb 17, 1965, p5, 1965

In February 1965, Staffs Railway Store, the oldest business premises in the Eltham shopping district was demolished. Formerly a self-service grocery, restaurant and electrical repair shop, the building for many years housed Eltham’s only ‘family’ grocer and feed store. Earlier it had appeared to have been the town’s bakery. The building had been purchased in late March 1939 by Mr Eric N. Staff. At the time of E.N. Staff’s purchase there were huge bakers’ ovens located at the rear and the building also had a well and four toilets for employees. When the ‘pictures’ came to Eltham with the opening of the Eltham Public Hall across the road in 1941, Mr E.N. Staff extended the business and opened a milk bar and sweet shop. Further extensions re-established the tea rooms of days gone by. Mr E.N. Staff conducted business for about 15 years before handing over the reins to his son, Ray Staff. When his son Ray took over, the milk bar and tea rooms were closed for several years but the milk bar and was later re-opened and subsequently became a greengrocers and later again, a restaurant. The tea rooms section was converted to an electrical repair shop about 1955. Electoral Roll records for 1967 record Raymond Charles Staff at 929 Main Road, Eltham, grocer, and in 1968 at Lot 4, Hillcrest Avenue, Eltham, taxi truck operator. So it would appear that Ray continued to run the business for approximately two years after the original store was demolished and a new supermarket was built. Today, 929 Main Road is the Nongkhai Thai Restaurant and is precisely where the original Staffs store stood. Even though the facade has been modified at eye level with new larger windows, the upper facade is identical to that of the new Eltham Big Star Food Centre of 1965/66. But how did the original building, the oldest premises in the 1965 era shopping centre come about? On August 12th, 1902 at the Eltham Courthouse, appearing before T. Smallman, Esq,. Police Magistrate, and Messrs. W. Duncan and W.J. Taylor, Justices of the Peace is Luther Haley, baker. Wilfred Henry Johnston, by his agent Stanley Ernest Elder had applied for a warrant of ejectment under the Landlord and Tenant Act 1890 against Luther Haley from the bakery premises at the corner of Main Road and York Street. From the evidence presented we learn that Mrs Burgoyne of Eltham had purchased the property some months earlier from Mr Johnston, which consisted of a store and bakery establishment at Eltham occupied by Mr. Luther Haley, and whose lease expired some little time back, and up to the present time, Mr. Haley was not prepared to leave. He informed the court that he is unable to secure at Eltham a suitable house in which to carry on his business, but was building a place near the railway station which he expected to be done in about three weeks time, and he is then prepared to give up possession of the premises he now occupies. Mr Smallman informed the defendant, Luther Haley, that he will have to quit the premises in three weeks from the present date, and that a warrant of ejectment would be issued. However he also informed Mr Haley that he would order the warrant to lie in the office for three weeks from that date. The premises under construction referred to by Luther Haley in court were situated on the western side of Main Road, near the railway station slightly opposite present-day Arthur Street. It was opened around September 1902 as a General Store, Bakery and Tea Rooms. This was the original building in the present-day shopping precinct. At the time the only thing nearby was the railway station. Luther Haley’s business appeared to prosper and he would have catered to not only the locals abut also day visitors by train on Sundays coming up from Melbourne, offering fresh baked produce, tea rooms and summer drinks. The fields across Main Road running between present day Arthur Street and Luck Street were known as Haley’s Paddock and at times were used for community festivities and picnics. A newspaper report on the annual State schools picnic held at Haley’s Paddock on March 11, 1904 described it as “quite close to the railway station, and is quite capable of holding comfortably 10,000 people. With its ample shade and hilly surroundings, it is an ideal place for any gathering.” Luther Haley successfully ran his general store, bakery and tea rooms until 1917 when he and his family departed the district and moved to Westgarth Street in Northcote where he changed careers and became a publisher. It was then taken over by Hannah Lloyd and became known as Lloyd’s Railway General Store from 1917 to 1920. From then it had a succession of owners, one as short as two months until March 31, 1939 when the Grocery Business formerly carried on by Mr. T.K. White of Eltham for the previous eight years was purchased by Mr Eric N. Staff of Research and became known as E.N. Staff’s Railway Store. The ownership timeline for the store is as follows: Luther Haley Sep 1902-1917 Hannah Lloyd 1917-c.Feb 1920 Messrs J.R. & N.E. Lee 1920-Sep 1922 A. & E. Copeland Sep 1922-Sep 1925 Mr Price Sep 1925-Nov 1925 Mr Warren Nov 1925?-Nov 1926 A.W.J. Edwards Nov 1926-1931 T.K. White 1931-Mar 1939 Eric Staff Apr 1939-c.1954 Ray Staff c.1954-Feb 1965 then demolished Ray Staff Eltham Big Star Food Centre c.1965-1967 Digital file only from scan of copy on loan to EDHSa. copeland, a.w.j. edwards, big star food centre, e. copeland, eltham, eric staff, general store, hannah lloyd, j.r. lee, lloyd's general store, luther haley, main road, n.e. lee, price, ray staff, staffs general store, supermarket, t.k. white -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Eltham Big Star Food Centre, Main Road, Eltham, c.1966

In February 1965, Staffs Railway Store, the oldest business premises in the Eltham shopping district was demolished. Formerly a self-service grocery, restaurant and electrical repair shop, the building for many years housed Eltham’s only ‘family’ grocer and feed store. Earlier it had appeared to have been the town’s bakery. The building had been purchased in late March 1939 by Mr Eric N. Staff. At the time of E.N. Staff’s purchase there were huge bakers’ ovens located at the rear and the building also had a well and four toilets for employees. When the ‘pictures’ came to Eltham with the opening of the Eltham Public Hall across the road in 1941, Mr E.N. Staff extended the business and opened a milk bar and sweet shop. Further extensions re-established the tea rooms of days gone by. Mr E.N. Staff conducted business for about 15 years before handing over the reins to his son, Ray Staff. When his son Ray took over, the milk bar and tea rooms were closed for several years but the milk bar and was later re-opened and subsequently became a greengrocers and later again, a restaurant. The tea rooms section was converted to an electrical repair shop about 1955. Electoral Roll records for 1967 record Raymond Charles Staff at 929 Main Road, Eltham, grocer, and in 1968 at Lot 4, Hillcrest Avenue, Eltham, taxi truck operator. So it would appear that Ray continued to run the business for approximately two years after the original store was demolished and a new supermarket was built. Today, 929 Main Road is the Nongkhai Thai Restaurant and is precisely where the original Staffs store stood. Even though the facade has been modified at eye level with new larger windows, the upper facade is identical to that of the new Eltham Big Star Food Centre of 1965/66. But how did the original building, the oldest premises in the 1965 era shopping centre come about? On August 12th, 1902 at the Eltham Courthouse, appearing before T. Smallman, Esq,. Police Magistrate, and Messrs. W. Duncan and W.J. Taylor, Justices of the Peace is Luther Haley, baker. Wilfred Henry Johnston, by his agent Stanley Ernest Elder had applied for a warrant of ejectment under the Landlord and Tenant Act 1890 against Luther Haley from the bakery premises at the corner of Main Road and York Street. From the evidence presented we learn that Mrs Burgoyne of Eltham had purchased the property some months earlier from Mr Johnston, which consisted of a store and bakery establishment at Eltham occupied by Mr. Luther Haley, and whose lease expired some little time back, and up to the present time, Mr. Haley was not prepared to leave. He informed the court that he is unable to secure at Eltham a suitable house in which to carry on his business, but was building a place near the railway station which he expected to be done in about three weeks time, and he is then prepared to give up possession of the premises he now occupies. Mr Smallman informed the defendant, Luther Haley, that he will have to quit the premises in three weeks from the present date, and that a warrant of ejectment would be issued. However he also informed Mr Haley that he would order the warrant to lie in the office for three weeks from that date. The premises under construction referred to by Luther Haley in court were situated on the western side of Main Road, near the railway station slightly opposite present-day Arthur Street. It was opened around September 1902 as a General Store, Bakery and Tea Rooms. This was the original building in the present-day shopping precinct. At the time the only thing nearby was the railway station. Luther Haley’s business appeared to prosper and he would have catered to not only the locals abut also day visitors by train on Sundays coming up from Melbourne, offering fresh baked produce, tea rooms and summer drinks. The fields across Main Road running between present day Arthur Street and Luck Street were known as Haley’s Paddock and at times were used for community festivities and picnics. A newspaper report on the annual State schools picnic held at Haley’s Paddock on March 11, 1904 described it as “quite close to the railway station, and is quite capable of holding comfortably 10,000 people. With its ample shade and hilly surroundings, it is an ideal place for any gathering.” Luther Haley successfully ran his general store, bakery and tea rooms until 1917 when he and his family departed the district and moved to Westgarth Street in Northcote where he changed careers and became a publisher. It was then taken over by Hannah Lloyd and became known as Lloyd’s Railway General Store from 1917 to 1920. From then it had a succession of owners, one as short as two months until March 31, 1939 when the Grocery Business formerly carried on by Mr. T.K. White of Eltham for the previous eight years was purchased by Mr Eric N. Staff of Research and became known as E.N. Staff’s Railway Store. The ownership timeline for the store is as follows: Luther Haley Sep 1902-1917 Hannah Lloyd 1917-c.Feb 1920 Messrs J.R. & N.E. Lee 1920-Sep 1922 A. & E. Copeland Sep 1922-Sep 1925 Mr Price Sep 1925-Nov 1925 Mr Warren Nov 1925?-Nov 1926 A.W.J. Edwards Nov 1926-1931 T.K. White 1931-Mar 1939 Eric Staff Apr 1939-c.1954 Ray Staff c.1954-Feb 1965 then demolished Ray Staff Eltham Big Star Food Centre c.1965-1967 Research and copy: Peter Pidgeon (EDHS) Digital file only from scan of copy on loan to EDHSa. copeland, a.w.j. edwards, big star food centre, e. copeland, eltham, eric staff, general store, hannah lloyd, j.r. lee, lloyd's general store, luther haley, main road, n.e. lee, price, ray staff, staffs general store, supermarket, t.k. white -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWood sample, 1855

The artefact is a piece of ship’s timber from the wreck-site of the SCHOMBERG, a vessel which collided with the Peterborough reef on her maiden voyage in December 1855. This small wooden remnant of the disaster has been concreted on one side by the accrual of marine sediment while submerged. The build-up of sediment over the remains of the vessel is typical of the site as a whole. This artefact illustrates the reclaiming power of the ocean and the gradual disappearance of timber constructed vessels that have come to grief along this coastline (for example, the THISTLE in 1837, and the CHILDREN in 1838). The SCHOMBERG was a 2,000 ton clipper ship, specifically designed for the Australian immigration trade (back-loading wool for Britain’s mills), and constructed in Hall’s shipyard in Aberdeen, Scotland. She was owned by the Black Ball Line and launched in 1855. Alexander Hall & Son were renowned builders of sleek and fast 1,000 ton clippers for the China trade (opium in, tea out) and were keen to show they could also outclass the big North American ships built by Donald Mackay. Consequently the SCHOMBERG was ‘overbuilt’. Her hull featured five ‘skins’ of Scotch Larch and Pitch Pine overlaying each other in a diagonal pattern against a stout frame of British Oak. Oak has been favoured by builders of wooden ships for centuries. Its close, dense grain made it harder to work, but also gave it great strength and durability. In addition, the lateral spread of its branches supplied a natural curvature for the ribs of a vessel’s hull, as well as providing the small corner or curved pieces (‘knees’ and ‘elbows’) that fit them together. The shape and texture of this wood sample suggests a dense hardwood like Oak. The timber has been cut off at one end since its recovery from the sea, exposing a smooth and almost shiny surface. Seasoned English Oak has a similar light brown colour and tight grained finish. At the launch the SCHOMBERG’s 34 year old master, Captain ‘Bully’ Forbes, had promised Melbourne in 60 days, "with or without the help of God." James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; MARCO POLO and LIGHTNING. In 1852 in the MARCO POLO he made the record passage from London to Melbourne in 68 days. There were 53 deaths on the voyage but the great news was of the record passage by the master. In 1954 Captain Forbes took the clipper LIGHTNING to Melbourne in 76 days and back in 63 days, this was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his own records. He cared little for the comfort of the passengers. On this, the SCHOMBERG’s maiden voyage, he was going to break records. SCHOMBERG departed Liverpool on her maiden voyage on 6 October 1855 flying the sign “Sixty Days to Melbourne”. She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, 90,000 gallons of water for washing and drinking. It also carried 17,000 letters and 31,800 newspapers. The ship and cargo was insured for $300,000, a fortune for the time. The winds were poor as she sailed across the equator, slowing SCHOMBERG’s journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, and Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the Third Mate Henry Keen, who reported land about 3 miles off, Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26 December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to SCHOMBERG and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS QUEEN at dawn and signalled the steamer. The master of the SS QUEEN approached the stranded vessel and all of SCHOMBERG’s passengers and crew were able to disembark safely. The SCHOMBERG was lost and with her, Forbes’ reputation. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the SCHOMBERG. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot! Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach SCHOMBERG, salvage efforts were abandoned. Parts of the SCHOMBERG were washed ashore on the south island of New Zealand in 1870, nearly 15 years after the wreck. The wreck now lies in almost 9 metres of water. Although the woodwork is mostly disintegrated the shape of the ship can still be seen due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. Flagstaff Hill holds many items salvaged from the SCHOMBERG including a ciborium (in which a diamond ring was concealed), communion set, ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the SCHOMBERG. One of the SCHOMBERG bells is in the Warrnambool Library. The SCHOMBERG collection as a whole is of historical and archaeological significance at a State level, listed on the Victorian Heritage Register VHR S612. Flagstaff Hill’s collection of artefacts from the SCHOMBERG is significant for its association with the Victorian Heritage Registered shipwreck. The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the SCHOMBERG. The SCHOMBERG collection is archaeologically significant as the remains of an international passenger ship. The shipwreck collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day. The SCHOMBERG collection meets the following criteria for assessment: Criterion A: Importance to the course, or pattern, of Victoria’s cultural history. Criterion B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history. Criterion C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history. A piece of wood, concreted in sediment, from the wreck of the SCHOMBERG (1855). The limestone accretion includes sand, shell grit and marine worm casings. The exposed surface of the wood is broken and worn smooth along the grain. One end of the timber has been cut or sawn off across the grain, presenting a smooth and shiny surface.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood segment, schomberg, shipwreck timber, alexander hall and son, limestone concretion, oak-framed hull -

Melton City Libraries

Melton City LibrariesPhotograph, Martha (Watson) Myers, 1907, c.1930 and 1953

Martha Watson was born on 17 October 1888 in Ballarat, Victoria, Australia as the first child of Robina (Ruby) WATSON. She died on 23 March 1976 in Geelong, Victoria, Australia. Memories of Martha by Valcia nee Twigg Lowrie, granddaughter of Arthur Watson. My memories and recollections as told to me my Grandmother ‘Mum’ Myers. As a child she had scarlet fever and did not attend school during the illness and missed a lot of school (Macarthur Street State School). When she was meant to return to school having fallen behind her classmates, confused and behind with the school work, she instead spent her time wandering around Lake Wendouree feeling too ashamed to attend school. Her uncle Arthur, born in 1874, whom she idealized, was a type of father/mentor figure who played and important part in her early life. He moved to Queensland in the early 1900’s and they did not meet again until he visited Melton in 1949, he died in 1954. He was a champion rower in Victoria and Queensland and a noted cyclist who rode in three Warrnambool to Melbourne races, and footballer. Her mother’s death certificate reveals her place of death as the Ballarat Hospital on 8th September 1903 aged 36. Martha was not told of the death of her mother, it was some time later when she found out her mother had died. She was greatly distressed when she eventually found out. The grief and the circumstance of her mothers death and her unfortunate life had a permanent effect on Martha’s life. Robina was buried in Open Ground at the New Cemetery Ballarat. Marjorie likened to this to the death of Mozart at the age of 35 who was also buried in a common grave. Martha also told me the stories about how as a child she played at the cemetery, taking the oranges placed as offerings on the Chinese graves and being chased away in fright when caught by a Chinese man. Her description left a vivid impression on my mind. The Burnbank street house was just across the road from the cemetery. The pieces of this story I had heard made sense when I visited the location in recent years. Martha’s described how Nanna would sing on the front verandah, and send her off to t get drink for her. This situation might help explain the reason for Martha’s strong aversion to alcohol. As a young girl it had been distressing to her. Nanna was a colourful and theatrical personality and danced with the Duke when he visited Ballarat. She was also known to have stated that she would marry a man who could give her a bucket of gold, possibly around the time after her first husband, Charles death, she had her young boy Edward to bring up. Martha was about 13 years old when Nanna Watson left Ballarat going to Queensland to visit her son Arthur. Martha slept that night afraid and alone in the empty house. The person who was meant to collect her did not come until the next day. She went to work for a family, a woman with children, they took most of the money that Nanna had left with Martha. There was a new baby in the house and the Scottish man in the house behaved suspiciously towards Martha. She was afraid of him and would hide from him under the bed. At this young age she managed to survive on her wits and sense of self preservation. It is not known how long she worked with this family. The place was from my impression, away from the town of Ballarat. Her very difficult formative years are testament to her strength of character and determination to succeed in life and ambition to provide the best opportunities for her own children. In 1905 Martha received a post card from Uncle Arthur in Brisbane addressed – c/o Mrs Styles 14 High Street Ballarat. Dolly Styles was a Ballarat friend and she kept in contact with her for many years. A letter reveals her living in Minyip in her older years. Martha is thought to have spent a few years working before she arrived in Melton. Miss Shebler hired Martha to help her in the care of her father and to assist with work in the Golden Fleece Hotel. Mr Shebler was a nice old man and mostly confined to his room and somewhat childlike as described by Martha. [The elderly Mr August Shebler died in February 1908]. Martha’s exact arrival in Melton is not known, but could be estimated as late 1906 to early 1907. In her room at the hotel she could hear the spring cart of Mr Minns going on the milk delivery rounds in the very early hours of the morning after coming across the creek from his house When she was 19, she married Frederick Thomas MYERS, son of Henri MIERS and Ann DOWLING, on 30 April 1908 ( Fitzroy, Victoria, Australia). Frederick Thomas MYERS and Martha Mary WATSON had the following children: 1. Frederick John Watson MYERS was born on 01 October 1908 in Melton, Victoria, Australia.He died on 07 February 2001.He married Mary June BATTYE on 18 September 1948 in Victoria, Australia. 2. Marjorie Gretchen MYERS was born on 21 February 1912 in Melton, Victoria, Australia.She died on 10 September 2004 in Frankston, Victoria, Australia.She married Herbert Vivian BUTLER on 07 January 1939 in Victoria, Australia. 3. Eva Edna MYERS was born on 15 October 1918 in Melton, Victoria, Australia.She died on 31 January 2008 in Bacchus Marsh, Victoria, Australia.She married Ernest Wesley BARRIE on 25 October 1941 in Melton, Victoria, Australia. 4. Arthur Bruce MYERS was born on 29 April 1925 in Melton, Victoria, Australia.He died on 26 March 2015 in Melbourne, Victoria, Australia.He married Olive Irene NORTON in April 1953 in Balliang, Victoria, Australia (or Church of Christ Footscray? (WB)). 5. Maxwell Douglas MYERS was born on 10 August 1927 in Melton, Victoria, Australia.He died on 03 May 2005 in Geelong, Victoria, Australia.He married Rosemary Rebecca BARRIE on 31 August 1951 in Melton, Victoria, Australia. Valcia nee Twigg Lowrie granddaughter of Arthur Watson, daughter of Mercia and Val Twigg did extensive research on the Marshall family of Lerwick Shetland Isle obtaining birth information of the Scottish forebears. She also got the birth/marriage and death certificates of the Ballarat connection of Robina’s husbands and children. Copies were sent to Edna and Wendy during the early 1990’s. Bruce and Irene also obtained certificates and Myers family information. Wendy applied for certificates at this time.Photographs of Martha (Watson) Myers taken at different times of her life -

Melton City Libraries

Melton City LibrariesPhotograph, Mrs Knox and Beryl Gillespie at the First Hundred Years Celebration of Melton State School 430, 1970

Beryl Knox speaking about early life in Melton. Page 1 1949 – 64 years ago. We began our married life at Melton Sth. The house on the corner of the Exford Rd and Staughton St-- dusty gravel roads, box thorns and noxious weeds everywhere and a sprinkling of houses and vacant land. It was a friendly community consisting of old family names. McDonalds, Blacks, Dodemaide, Cahill, Coopers, Minns, Tinklers, Nesbitts, Cochranes, Wickhams, Exells. Mavis Butler. The home owned by Mr. Robinson and Miss Robinson had been shifted in two parts transported from Diggers Rest and it is still standing 2013. Bruce’s father purchased the house and two adjoining blocks, the Conways built on one and the Rawlinson family on the other block. Eileen still resides there, she was only a baby in a pram and the family had not long arrived from England. The railway line was close to the house and the contents would rattle when heavy steams trains went through, and on a clear frosty night the 1am paper train would echo roar through very loudly when labouring towards the Exford Bridge. Then the two carriage motor train was introduced, this was great for the workers and schoolies who travelled to Melbourne. The train pulled up at the crossing or riding to pick up or drop off. Melva Gillespie (nee Hirt) Bill Cahill delivered the milk by the billy and then in bottles. Len Kennedy (Paul Kennedy’s father, Norma Murrays son) delivered Jongebloeds bread, he always had a sweep going for the Melbourne Cup and raffles for the footy club. Mr. Woodgate owned an old bus and pick up point was the Post Office when there was a Saturday film on a Melton. There were no doctors or dentists in the district. If we need a Doctor we had to travel to Bacchus Marsh or discuss problems over the phone. In later years a Bacchus Marsh Doctor rented the Bluestone building in McKenzie St a couple of days a week. If we needed the Dentist we had to travel to West Footscray or Footscray. We did our banking at “State Savings” then the Miss Minns had the agency and then Bardsleys Store. We travelled to Bacchus Marsh to the National and Commercial banks. Station Rd to Western Highway, now (High Street) was a narrow stretch of bitumen and gravel farmland either side and a couple of farm houses and large gum trees on the properties. Page 2 North of the Railway line Mrs Bessie Jones, mother of Chas and Betty Jones managed the Post Office, next door to her Chas and Betty had the Shell Centre, and later moved the business to Melton. Hughie Nesbitt and mother owned the grocery and hardware store, and I bought my first set of saucepans there. On the opposite side of Station road Mr Coombe owned the fruit shop, and also provided soft drinks and lollies for children. The Chaff Mill was on the corner of Station Rd and Brooklyn Rd. Mr Lumsden was manager and later years Bernie Trethowan and Jack Butler were partners. It finally burnt down and is a Service Station now. Along Brooklyn Rd there were a few houses and Victoria Hall, not a very big hall, but catered for lots of functions, Balls, Fancy Dress, Bazaars, Square Dancing and meetings. The Bacchus Marsh Baptists held Sunday School in the hall. A group of shops were built south of the railway line Molly and Len Skinner managed the Post Office and handled a few essential groceries. Tom McDonald and Ron Lunsberg were the butchers. Mary and Syd Cooper lived next door to us and often in turn would run out of something when we had a baking spree we would borrow or exchange, sugar flour etc over the fence. Mavis and Jack Butler lived there before the Coopers. Bernie and Iris Trethowan lived two doors up. Neighbours were invited into their home to view the first black and white television in Melton Sth. Bill Exell was one of the first Melton Sth farmers to sell his land to developers, the land was idle for years before housing developed. I joined the Melton Valley Golf Club in 1960. The Gun Club as our Club House, an old tin shed consisting a water tank, trestle table and forms and dirt floor. It was a 9 hole course with sand scraps and landscape putting before greens. The Common or parkland was part of the Golf Course. It was open for every ones recreation. Roy Norton an old identity trained his trotters on the Common and wouldn’t clear the track for the golfers. The golfers had to avoid him to continue to play. We had to keep clear when the young youths came in their paddock cars and motorbikes. Over the years the Toolern Creek flooded its banks, water and debri covered the course on one year our first Club house was flooded out. It took several working bees to clean it up. We lived at Melton Sth for 15 years and moved to Melton on the farm “Croxton Park.” The Nixon family farm “Mowbray” adjoined the farm. Bruce worked the land cropping the farm when Mrs Nixon died. Page 3 (page 4 on the handwritten script) Bruce had the first offer to buy, in those days it wasn’t easy to get good bank loans. Part of the land is the Golf Course now and Mr O’Shea purchased the bulk. Moving to Melton was totally different – I became involved with Committees, Scouts, Guides, Mothers Clubs, CWA, Church Op shop (8 years). Melton Amateurs players produced and tutored by Mabel Rogers exerts from Pyjama Game, South Pacific, Carousel - later years a group of ladies did gentle water exercise at Essendon and Station Road swimming pool. I was 20 or so years in Probus. The local followed the football, there was always a Gymkhana on the long weekend in June. The tennis always created a lot of interest during the finals. It didn’t matter which team played the supporters were treated to a cup of tea and leftovers from their afternoon tea. In 1978 were the first residents to move into the Jennings Estate Kurunjang and lived there 31 years and retired 4 years ago into Unit. The amazing changes I have experienced. Merrimu supplied our water, after depending on tanks. The landscape changed completely when developers came in, no more dusty plains \ typed web Sept 2013 McFarlane, Mrs Knox and Beryl Gillespie at the First Hundred Years Celebration of Melton State School 430. The event was held at Mechanics Hall, Melton.local identities, local significant events, education -

Flagstaff Hill Maritime Museum and Village

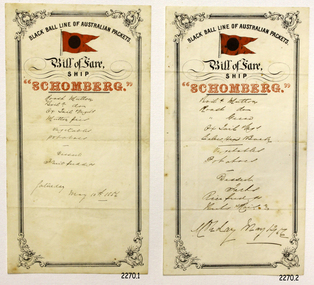

Flagstaff Hill Maritime Museum and VillageDocument - Menu, Bill of Fare ship Schomberg, circa 1855 - May 12 1856