Showing 1243 items

matching collectors

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Balance Scale, Rebure Germany, 1930s

A mass produced utilitarian item made for domestic use, there is no history or manufacturing provenance currently available.The subject item at this time cannot be associated with an historical event or person It is believed the item was manufactured in Germany pre World War ll, in the 1930s, as other examples from the period are on a number of internet sale & auction sites. This item is regarded as a collectors piece however information and company history regards the manufacturer "Rebure" has not yet been established. Balance spring scale elongated brass graduation scale to 100 Lbs hook at one end and a ring the otherRebure Pocket Balance. Made in Germany measures from 0 to 100LBSflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spring balance scale, rebure scale company, rebure germany, domestic item, kitchen weighing scale -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Late 19th Century

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools. Archimedean drill with Rosewood hand, brass bearings, steel twist and wooden grip. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, archimedean drill with wooden hand, drilling tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Porcelain Insulators, Mid-twentieth century

White Porcelain “Made in Occupied Japan” electrical insulators. Insulators can be dated from September 1945 to April 1952 during the allied occupation of post WWII Japan. Pin insulators were manufactured specifically for Australian export. Pin insulators are made of non-conductive porcelain and were used to create a barrier between outer wrapped suspended wiring and threaded wood or metal dowel. Pin insulators such these have been found on utility poles around Australia.Porcelain insulators stamped with “Made in Occupied Japan” are often viewed with much interest by collectors given their connection to WWII and short seven year manufacturing time span. Pin insulators such as these are an example of Australia’s continued electronic development which began in the late 19th century. Collection of seven white porcelain insulators made in Occupied Japan. Insulators are cylindrical in shape, with indentation at top. The indentation creates a flat mushroom top head. Insulators display a manufacturer stamp at the bottom of the cylinder. Insulators are single walled and hollow inside with threading at the enclosed top end. flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, insulators, porcelain, electrical insulators, occupied japan -

Flagstaff Hill Maritime Museum and Village

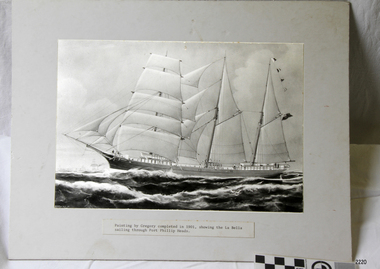

Flagstaff Hill Maritime Museum and VillagePrint - Vessel - Sailing Ship, A.V. Gregory, ca. 1899-1922

This photograph is a print from an original painting by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. The four-masted iron barque 'Rowena' was built in 1883 by Barclay, Curle & Co. of Glasgow as the 'Cluny Castle', and renamed about 1890 as 'Rowena' by owners Rowena Ship Co.. After consequent owners, the ship was converted to a hulk in 1922 at Port Adelaide. The detailed image of the vessel depicted in this print shows one of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors.Photograph of a print, black and white, mounted onto card. It depicts the four-masted iron barque ship 'Rowena', originally named 'Cluny Castle'. The original painting was by marine artist A V Gregory.Painted on bow "ROWENA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, photograph, photograph of rowena, gregory, cluny castle, a v gregory, rowena, iron baque, rowena ship co., barclay, curle & co, glasgow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel - Sailing Ship, A.V. Gregory, 1901

This photograph is a copy of an original painting by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. The barque "La Bella" was built in 1893 in Norway. On 31st October she commenced her maiden voyage. After six voyages, the vessel was offered for sale in Hamburg. After much negotiation, she was sold on December 1900 for £3,600 to Mr D C Turnbull and sailed back to New Zealand. The "La Bella" was primarily used on the Australian-New Zealand run, her cargo being timber, coal and produce. In October 1904, she ran aground at Owhira bay, New Zealand. The vessel was subsequently refloated. In November 1904, the "La Bella" attempted to enter Warrnambool Harbour without a pilot aboard. The vessel struck Annabella reef and many members of the crew perished. The "La Bella" captain was later charged and found guilty of negligence. In 1905 he was charged and tried for manslaughter. He died of a heart attack later that year and is buried in an unmarked grave at Melbourne General Cemetery.The detailed image of the vessel depicted in this photograph shows one of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors.Photograph of a painting of the three-masted sailing ship "La Bella" sailing through Port Phillip Heads. The original painting is by marine artist A V Gregory. A label is pasted below the photograph. The artist's signature is visible.Signed "GREGORY-01" Painted on the ship's bow "LA BELLA" Typed label "Painted by Gregory completed in 1901, showing the La Bella sailing through Port Phillip Heads'.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, la bella, d c turnbull, warrnambool harbour, lady bay -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessels - Sail and Steam, A.V. Gregory, Australian Rivals - Past and Present, 1899-1932

These photographs are copies of original paintings by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. These mounted photographs, by A.V. Gregory, show both steam and sailing ships sailing in the Tea Race from China to London in 1872. The information included with the photographs has the following text: “Tea Clippers “ Well done Cutty Sark, by Bobbie Burns The CUTTY SARK and THERMOPYLAE. The start of the 1872 Tea Race from China to London. The “Cutty Sark” first away, followed closely by the “Thermopylae”, finally parting after several days’ company. On this race the “Cutty Sark” lost her rudder in the Indian Ocean, putting her hopelessly out of the race, and enabling the “Thermopylae” to pass her and reach London on 11th October, 115 days out, the “Cutty Sark” limping home seven days later. The credit of the race was given to the “Cutty Sark” by the shipping world. Copies of the pictures may be had from A.V. Gregory, 326 Albert Road, South Melbourne."The detailed images of the vessels depicted in this photographs shows some of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors. The pictures and document are significant for their association with the Tea Clippers, famous for racing across the world to arrive in Australia with the fastest time.Photographs of paintings of sail and steamships, three photographs mounted together side by side, titled "Australian Rivals - Past and Present". The centre shows the sailing ships Thermopylae and Cutty Sark. It is flanked on each side by a photograph of a steamship. The document with the photographs gives the history of the famous Tea Race from China to London in 1872.Title: "Australian Rivals - Past and Present". Handwritten on Left photograph "A.V. GREGORY - SS KATOOMBA" Handwritten on Centre photograph; "THERMOPLAE - A.V. GREGORY - CUTTY SARK - FIRST AWAY" Handwritten on Right photograph; "CANBERRA - A/V/ GREGORY" Handwritten on accompanying card is the story of the Tea Clippers.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ss katoomba, thermopylae, cutty sark, tea race, tea race china to london 1872, canberra, tea clippers, a v gregory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hurricane Lantern, Nier Feuerhand, Between 1915-1920

The Feuerhand lantern works were established in Beierfeld in the Saxon Ore Mountains. Called Erzgebirge in German or Krušné hory in Czech, is a mountain range in the south of Saxony in Germany known for its craftwork. Lantern production began in the area by Hermann Nier who ran a plumber's workshop around the 1870s and made lanterns, amongst other things. In the town of Beierfeld, also well-known for its metalworking were the brothers Hermann and Ernst Nier who founded a modern production centre for hurricane lanterns manufacture in 1893. Five years after the foundation, the company Frankonia (Albert Frank metalware) bought up the production site and the brothers Nier became production managers. Owing to differences with Frankonia, Hermann Nier finally started its hurricane lantern factory "Hermann Nier Feuerhandwerk" in 1902. In the same year, he applied for a patent for the manufacturing of lanterns using the stamping and folding techniques with tinning by hot-dipping and without hand-soldering. In 1914 the trademark "Feuerhand" was registered for all products as a utility model of the German Reich in German: "Deutsches Reichs-Gebrauchsmuster" (DRGM) and in 1920 the round Feuerhand emblem was added to the brand. Finally, in 1926 the patents, as well as the trademark "Firehand", were also registered in the USA. The manufacture of the well-known small hurricane lanterns the “Baby Series” complete with fireproof borosilicate glass from the Firma Schott firm from Jena started in 1933. Between 1918 and 1938 Nier Feuerhand became the biggest producer of hurricane lanterns in the world. Production continued until 1990.A significant item that demonstrates from its fabrication a manufacturing process that was far in advance of its time and that influenced the production of lanterns from many other manufactures around the world. These types of lanterns made by Feuerhand around the early 20th century are now sought after by collectors.Monarch style Lantern painted black. Made in Germany has Freuerhand, manufactures logo on filler cap and top of lamp centre postflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hurricane lantern, kerosene lamp, feuerhand lantern works, albert frank metalware, hermann and ernst nier -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wash trough, Melvin Newton Lovell, Mangle was Patented June 10, 1898 by Lovell Trough is possibly of later manufacture by a local unknown cabinet maker between 1900-1920

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers). This item is now sought by collectors and is even rarer due to it's combination with a Lovell clothes wringer. Wooden wash trough with 2 troughs & attached a Lovell wringer (or mangle Anchor Brand) Hard to make out as worn off with useflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, wash trough, wringer, mangle, laundry, cleaning, washing, housework, domestic, melvin newton lovell, wooden was trough -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCalipers, Moore & Wright, 1925-1935

Established in 1906, Frank Moore soon became well known amongst discerning tradespeople for the quality & accuracy of his tools. The Company was acquired by John Shaw & Son in 1945 & James Neill & Co in 1970. Currently part of the Bower Meteorology UK Group, they still produce superb tools & measuring instruments in Sheffield. The subject item is made from high-grade carbon silver tool steel with the patented 'Firm Lock' joint, that identifies the maker as Moore & Wright.A tool used for external measurement of items made by a maker who patented the "firm lock" jointing system now used on many different types of tools in many different industries. These items are now collectible and quite rare as a result are sought by tool collectors in the USA and UK.‘Firm Joint’ external measuring calipers believed made by Moore & Wright. Impressed into the metal "L A J S" (Probably the owner and company that used the item nothing to do with manufacturing) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, calipers, callipers, external calipers, outer caliper, pottery tools, masonry tools, glass making tools, external measurement -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Letter Scale, Philip Jakob, Maul, 1930s

Jakob Maul (1866-1953) founded a metal works factory in 1912 at Zell in Odenwald not far from Frankfurt. He was born the son of a winegrower from the Rheinhessen region of Germany that lies on the left bank of the river Rhine. At the age of 45, he started a metal works factory to produce various types of scales but during the second world war the factory was bombed and production ended. Production for the manufacture of scales resumed in 1948. In 1953 at his death Jakobs son Fritz Scharmann an engineer who had been working with his father since 1923 took over the management of the Maul companies. In 1970 the production responsibilities for Philip J Maul was taken over by Porti Office Equipment who was based in Hamburg. The company has undergone several integrations with subsidiary companies. Today the company has diversified into different areas one of which is manufacturing solar scales. An original postal scale made in Germany before the Second World War and regarded today as a collector's item. It is significant as it is a snapshot into the past and how everyday vintage items were used and interacted within society in the 1930s.Antique German Jacob Maul "Concav" brass postal or letter scale, quadrant type, with pendulum, measuring up to 9ozs. The scale has a level-adjusting screw.The balance is marked "CONCAV" and graduated in imperial ounces to 9 ozflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scale, quadrant scale, postal weight, 9 oz, philip jakob, maul, scale manufacturer, german industry, weighing instrument, inclination scale -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1940's

Smiths began with a craftsman named Samuel Smith who in 1851 opened a shop in Newington Causeway, London, where he made and sold watches, clocks and precision instruments. Samuel had a son, Samuel Jnr who was apprenticed in his fathers business. Samuel Jnr eventually opened his own business at 85 Strand and later opened other premises at 9 Strand, Trafalgar Square and 68 Piccadilly. In 1899 he turned his business into a private limited company, S. Smith & Son Ltd. Samuel Jnr son, Sir Allan Gordon-Smith, joined him as Manager at 9 Strand in 1903 and laid the foundation of the vast Smiths organisation of the future, leading the company towards the supply of accessories for the then developing motor industry making car clocks and the first speedometers patented in 1904. In July 1914 a new company was formed under the name S. Smith & Sons (Motor Accessories) Ltd., to take over the motor accessory business of S. Smith and Son Ltd. and this became the main company of the group which eventually grew to become Smiths Industries Ltd. The original company S Smith and Sons Ltd., continued as jewelers and clock and watchmakers until 1930 when the company was taken over by Bravingtons retail jeweller chain. In 1931 Smiths decided to enter the domestic clock market and formed a new company, Smiths English Clocks Ltd., as the Clock and Watch division of S Smith & Sons (Motor Accessories) Ltd. This is the start of "Smiths Clocks" because this is when they began to manufacture domestic clocks in quantity. Moreover, they set out to produce these clocks at a price that the average householder could afford. S Smith & Sons (Motor Accessories) was at this time was the main company in the Smiths group of companies and their business developed both in the motor vehicle field and outside it. Smiths began to make automatic pilots for aircraft and, through the acquisition of a majority interest in Henry Hughes & Sons Ltd., entered the field of marine instruments. During the war from 1939 to 1945, Smiths' production expanded. There was a demand for motor, aircraft and marine instruments for the Services and the production of industrial instruments and it is at this time that our item was made. In 1944 many changes were made to the Smiths' organisation. The name of the principal company was changed from S Smith & Sons (Motor Accessories) to S. Smith & Sons (England) Ltd. and four new subsidiary selling companies were set up. These were Smiths Motor Accessories Ltd., Smiths Aircraft Instruments Ltd., Smiths Industrial Instruments Ltd., and Smiths English clocks Ltd. The manufacture of clocks and watches ceased in 1979 and 1983 saw Smiths withdraw from producing items for the motor industry.An item that is now regarded as a vintage, sought by horology collectors worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by the Smith company a well known British clock manufacture. Its provenance is well established and it was made during the world war II era specifically for merchant and naval vessels of the time. Naval brass ships bulkhead clock. The clock face is of white enamel with black Roman numerals, an outer minutes ring and black steel hands. There is a subsidiary seconds dial with sweeping hand just above the centre and a fast/slow adjustment lever above that. There is no manufactures name on the dial. There are a beveled glass and brass hinged lid to the front of the clock. The clock is housed in a heavy brass case with screw holes around the circumference for mounting. There are no markings on the clock or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s smith and sons, clock, maritime clocks, clock makers, bulkhead clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Anchor, Henry P Parkes & Co, 1885 - 1904

In about 1820 Henry Pershouse Parkes, from Dudley, established the Tipton Green Chain and Anchor Works (Staffordshire). The firm’s products included cables, chains, anchors and all kinds of forgings. In 1851 some tests were carried out on the company’s chains to demonstrate the tensile strength and fibrous toughness of the iron used in their production. The iron used on this occasion was supplied by Summer Hill Iron Works. Some of the chains were exhibited at the Great Exhibition in 1851 and also at the 1855 French Exhibition in Paris, where they won a prize medal. Henry Pershouse Parkes died in 1867 and appears to have been succeeded by his son, who had the same name. In 1867 the firm produced the largest anchor in the world, at that time. It was built for Brunel’s S. S. Great Eastern to the patented design of Joseph Beterley, of Liverpool. The anchor, which weighed eight tons was twenty six and a half feet long and cast from iron supplied by Bloomfield Iron Works. It was tested at Tipton Proving House and found to be able to stand a strain of 100 tons. Henry Pershouse Parkes junior went into partnership with Alexander Stewart Ross to form Henry P. Parkes and Ross. The partnership came to an end in 1885 and the company became Henry P. Parkes & Company. In 1904 the business was sold and became H. P. Parkes and Company, under the control of N. Hingley & Sons Limited, of Netherton. In 1944 the company’s name was changed to Richard Sykes and Son Limited, then in 1947 it became H. P. Parkes & Company Limited. The business went into liquidation in 1966.The item is significant as an early example of a well known prize winning British anchor and chain maker from the mid 19th century. The company name on the anchor indicate the period of manufacture making it a significant item prized today by collectors.Anchor 5 pronged metal with loop at bottom to attach anti-snag rope. Long shank painted black. Label attached "Henry P Parker and Co"flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, five pronged anchor, henry p parkes & co, tipton green chain and anchor works -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Plane, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will named his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard's estate when he died in 1856. From John's will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool-making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield.A vintage tool made by a well-known company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items.Jack Plane metal body with rose wood filler.Mosley & Sons London No 2flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john moseley & son, jack plane, woodworking tool, carpenders tools, cabinet makers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Sides & Skinner, First half of the 20th century

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheelwrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. A now vintage tool made by an Australian manufacture in NSW who specialised in making pruning shears, hacksaw frames and heel shaves under the Erskin brand name. This tool is now sought after by collectors even though it was probably made in the first quarter of the 20th century. It gives a snapshot of how carpenters work with wood by hand showcasing their craftsmanship. Hollow face Spokeshave, metal body with black enamel finish. Erskin stamped on frontflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, cabinet makers tools, wood working, cutting tool, shaping tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Angular Bit Stock extension, 1897-1922

Millers Falls Co. is a tool manufacturing company originally based in Millers Falls, Massachusetts. It was established in Greenfield, Massachusetts in 1868 as Gunn & Amidon by Levi J. Gunn and Charles H. Amidon. Gunn and Amidon, along with a third partner, Henry L. Pratt built a factory in the north of Greenfield. After the Greenfield factory burned down, the company was reorganized as the Millers Falls Manufacturing Co. It merged with Backus Vise Co. in 1872 to form the Millers Falls Co. In 1931 Millers Falls tools purchased the majority of the shares of Goodell-Pratt tools and merged with that manufacturer in 1932.In 1962 the company was acquired by Ingersoll Rand. In 1982, Ingersoll Rand sold the Millers Falls business to the newly created Millers Falls Tool Co. The company was head quartered in Alpha, New Jersey. Since 2002 the company trademark has belonged to Hangzhou Great Star Industrial Co., Ltd, of Hangzhou, China.An interesting an unusual tool made by the Millers Falls Tool company that continued to be featured in it’s catalogue up and till 1922. The tool was manufactured from 1897 until this date and is sought out by collectors of vintage tools.Universal Angular hand operated bit stock with spring type alligator jaws, main casting is Japanned bright parts are nickel plated item used with a bit & brace as an extension or angular borer. Millers Falls Co. USA Model 109flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tools, screw driver, angular hand operated driver, tool accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Mid to late 1800s

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools.Archimedean drill with wooden grip and butterfly nut on chuck.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, fretwork tools, wood working tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Ships Lamp, Telford, Grier and Mackay, 1914-1915

The subject item was produced in 1914/15 by the Telford Grier and Mackay Company in Glasgow, Scotland, this lantern was not used to provide visibility for Sailors on a ship, rather, it is meant to help other vessels identify the ship’s presence and heading in low visibility conditions hence it is marked Port and has a red filter. The lantern would have been placed along the port side of larger vessels to provided an unbroken light and would be visible in an arc from as well as at an angle from the port side of the vessel. The company was established in 1904 at 11 Fairley Street Glasgow and in 1922 moved to 10 Carrick Street. The company manufactured patented lamps for marine use, later moving into the manufacture of electrical and mechanical items. A significant marine kerosene lantern made by a company that patented this type of lantern for use by the British Navy and for merchant ships the world over. This item today is rare and sought by collectors.Ship's port side sidelight lamp with clear glass frenal lens with red filter behind, burner missing, replacement with modern electric fittingTwo makers lozenges one marked PORT the other has the maker Telford, Grier and Mackay, Glasgow, 1915 marked on main body chimney has 1914 marked . Also serial No C976 stamped on backplate.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp ship's sidelight, ship's sidelight lamp, port lamp, marine light, navigation light, kerosene ship lamp -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Ogee Complex Moulding Plane Alex Mathieson & Son. Stamped W Worrel, (owner) & No 2.flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alexander mathieson & sons, complex moulding plane, carpenders tools, cabinet makers tools, wood working tools, wood planes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Joiner, Jack or Smoothing Plane, Akin & Son, 1900 to 1966

The subject item is a smoothing plane traditionally wood planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade use for achieving a flat and smooth finish to timber. The blade, or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and flat bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. The maker Atkin and Sons were a prolific Birmingham plane maker, active from 1863 to 1900 when they became Atkin and Sons Ltd and traded until 1966. Their trademark was actually "BENEFACTUM" which is Latin for "well made."A well-made tool from the early 20th century from a well-known company that ceased trading in Birmingham in 1966, today this tool from this company is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes as well as smoothing timber projects were created by the use of hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to finish timber.Jointer or Jack Plane with fishtail handle, Size of iron 2 1/2 inches wide, Stamped GN inside W made by Akins and Sons Birmingham UKflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jointer plane, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Ships Navigation Lamp, William Harvie & Co, First half of the 20th century

William Harvie was granted a patent in 1868 for improvements in the manufacture of lamps, lanterns and lenses for ships navigation and signal lamps 1868. Production began at 222 Broomielaw street Glasgow Scotland. Another patent was issued in 1873 for additional improvements to the companies lamps. Records show that in1873 William Harvie was in partnership with Malcolm Graham & Co, grease manufacturers and rosin distillers at 50 Anderson Street Gallowgate Glasgow. It appears around this time the business was transferred to George Moffat of 128 Garthland Drive Dennistoun Glasgow to continue under the same name (William Harvie & Co at premises situated at 100 East John St Gallowgate Glasgow. It is unclear but at some point W T George & Co were one in the same with William Harvie & Co. W T George made lamps with the trade name “Meteorite” and after gaining a patent for improvements to his lamps in 1941 the patent numbers were affixed to his lamps. In the Scottish Post Office annual Glasgow Directory 1900-1902 William Haveie & Co. Ltd is listed with two addresses; 222 Broomielaw and 24 McAlpine Streets, Glasgow. In the early 20th century the business moved to Birmingham until 1983 when the company went into voluntary liquidation after a meeting was held at Newhall Street Birmingham on the 10th January 1983 for WT George and William Harvie. This meeting was for the purposes regarding the insolvency of a company as set out in Sec 294 & 295 of the companies Act 1948 as a result Harvie & Co cease production of their products.An item made by a company that was an innovator of significant improvements in the manufacture of marine signal and navigation lamps during the late 19th and 20th centuries. Lamps made by this manufacturer are now sought after collector's items that are of significant value. Navigation lamp, round ship's lamp with clear glass and a red filter, handle at top, fitted with hinged and catch section at top to service lamp. Bracket at back for hanging lamp item painted red with black handles.Black nameplate is unreadable. Front reference plate reads " Meteorite" then "Meteorite No. 92276" warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, meteorite, william harvie, navigation lamp, kerosene lamp, signal lamp, marine equipment, marine navigation, w t george & co, george bocock & co, william harvie & co. ltd. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Marine Kerosene Lamp, W T George & Co, 1941 +

WT George & Co of Sherlock Street Birmingham were makers of ships lanterns under the trade name “Meteorite”. In 1941 Thomas George writer assumes a relative of WT George was granted a patent number GB546575 relating to improvements to his lamps. After this date a plate was affixed with this number. What's confusing with the companies records is that they show that in Birmingham three companies are listed making lamps together and the writer is assuming under a partnership agreement. First in 1983 W T George & Co with William Harvie & Co went into liquidation with G Bocock & Co, together, then in 1992 George Bocock and Harvie Ltd were in liquidation. Although these companies seem to have different addresses in Birmingham they were linked together given they were all liquidated at the same time for two of them. They all appear to have been partners in some way making marine lamps under the William Harvie banner. William Harvie & Co. Ltd advertised as being electric light and power engineers, and patent ship lamp manufacturers, as early as 1901-1902, as listed in the Post Office annual Glasgow Directory 1901-1902.An item made by a company that was an innovator of significant improvements in the manufacture of marine signal and navigation lamps during the late 19th and 20th centuries. Lamps made by this manufacturer are now sought after collector's items that are of significant value. Lamp, round ship's copper lamp with clear glass, handle at top, fitted with hinged and catch section at top to service lamp. Bracket at back for hanging lamp. Stamped "Meteorite 110560" Bottom stamped "Patent no GB546575 and others pending".warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, round ship's lamp, kerosene marine lamp, w t george & co, william harvie & co, george bocock & co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chisel, 1911 - 1970

Ward & Payne was founded in Sheffield by David Ward, an edge-tool manufacturer in 1803. The company had the name, David Ward. David Ward's son Edward joined the company around 1837 and the company name was changed to David Ward & Sons or David Ward & Co. Perhaps both names were used in succession it is unclear. Henry Payne appears as an edge tool maker in 1837 and joins the company before 1845. Perhaps he joined in 1837, as a result, this caused the name change to David Ward & Co. In 1843 Henry Payne registered the trademark name of Ward & Payne consisting of the crossed hammers above an anvil with W to the left and P to the right. Henry Payne became the junior partner in 1845 and died in 1850 and ownership of the company then reverted to the Ward family. After 1845 the firm built a large business in edge tools concentrating on carving tools, chisels, and gouges. Another David Ward (1835 - 1889), possibly the son of Edward Ward, took over the company in 1855 and was an aggressive young executive with the company before that. He grew the company's fortunes in both the sheep shearing scissor and carving tool businesses. The company grew and expanded its factory to a full city block and published a 501-page catalog in 1911. The company was still in business up to around 1970.A tool made by a well-known company and regarded today as a collector's item for those enthusiasts that collect vintage woodworking tools. However for further details regards provenance see the note in the provenance section this document.Socket chisel cast steel "Ward Cast steel" inscribed on blade flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hand tool, ward chisel, woodwork chisel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chisel, Ward, 1855 - 1911

Ward & Payne was founded in Sheffield by David Ward, an edge-tool manufacturer in 1803. The company had the name, David Ward. David Ward's son Edward joined the company around 1837 and the company name was changed to David Ward & Sons or David Ward & Co. Perhaps both names were used in succession it is unclear. Henry Payne appears as an edge tool maker in 1837 and joins the company before 1845. Perhaps he joined in 1837, as a result, this caused the name change to David Ward & Co. In 1843 Henry Payne registered the trademark name of Ward & Payne consisting of the crossed hammers above an anvil with W to the left and P to the right. Henry Payne became the junior partner in 1845 and died in 1850 and ownership of the company then reverted to the Ward family. After 1845 the firm built a large business in edge tools concentrating on carving tools, chisels, and gouges. Another David Ward (1835 - 1889), possibly the son of Edward Ward, took over the company in 1855 and was an aggressive young executive with the company before that. He grew the company's fortunes in both the sheep shearing scissor and carving tool businesses. The company grew and expanded its factory to a full city block and published a 501-page catalog in 1911. The company was still in business up to around 1970. A tool made by a well-known company and regarded today as a collector's item for those enthusiasts that collect vintage woodworking tools. However for further details regards provenance see the note in the provenance section this document.Socket chisel with 1 inch blade end of handle has been sawn off.Has "E" stamped on bladeflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hand tool, ward chisel, woodwork chisel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Brace & Bit, John S Fray, 1883 - 1906

Context: A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. The pressure is applied to the top and the tool is rotated with a U-shaped grip. Bits used to come in a variety of types but today the more commonly used Ridgeway and Irwin pattern bits also rely on a snail point (called the snail), which is a tapered screw point shaped the same as a wood screw thread, which helps to pull the bit into the wood as the user turns the brace handle and applies pressure. The designs used today come from an original idea and pattern invented by John S Fray. Company History: John S. Fray (1833 ) immigrated to Bridgeport Connecticut USA from England in the 1850s and established a working relationship with Nelson Spofford, who held an 1858 patent for a bit brace (the tool could be augured in a continuous circular motion by hand). He established the John S. Fray Co. around the same time and immediately began producing the Spofford bit brace. Fray himself held at least two patents: one awarded in 1869 for a boring brace attachment, and another awarded in 1883 for a tool handle. By 1889, the firm was located at the industrial complex that sits between the former International Silver Company and the former Bridgeport Chain Company on Crescent Avenue and is identified on the Sanborn Insurance Atlas as a manufacturer of Spofford bit braces, hollow handle awl, and toolsets. The company was in competition with Peck Stow and Wilcox Co. of Southington, and in 1898 was enjoined from making a ratchet bit brace for which the latter company held a patent. By the 1920s, the factory had been purchased by the Stanley Company of New Britain and leased to the American Tube and Stamping Company, a manufacturer of brass, copper, seamless, and bicycle tubing, which also ran a rolling mill to the south on Stafford Avenue (now demolished). The Stanley Company bought both mills in 1926, perhaps as a strategic move to be located along the Bridgeport Harbour, through which much of the raw material used in its operations throughout the state came. By the 1950s, the Crescent Avenue operations had been moved to other sites in Connecticut, and Stanley again leased the building to a company called Cornwall and Patterson, a manufacturer of piano hardware. Today the building appears to be vacant. An early carpenters tool made by a well known early manufacturer from America who instigated many innovations to the making of tools. His early pattern for the improvement of a tool that could be used for the boring of holes in wood was a significant step forward. His design for a boring brace attachment and later a specific handle is still in use today and his original brace and bit is now sought after by collectors of antique tools. Spofford Carpenter's Bit Brace metal has bit attached. Wing nut holds bit in place but nut missing. holds bit in place. 285mm long x 160mm Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Mid to late 19th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc. or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tongue and groove match plane with metal strip affixed with 5 screws Mc Vicar stamped on end and No 2. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, John Wilson Dryburgh, Early to late 19th century

John Wilson Dryburgh Snr started plane making in Dundee in 1837 at 42 Murraygate until 1854 when he and his family moved to Toronto Canada. He continued plane making in Canada as did his sons, notably was his son John Dryburgh Jnr who began making planes at an early age and by sixteen years of age around the 1880s was a skilled maker, having been trained by his father, most likely by the time the family came to Canada. Three years later, the entire family had moved to a farm in Northeast Hope, near Stratford, Ontario. John Jnr. would continue in Northeast Hope until 1887, has become the firm's principal plane maker from 1876 onwards when John Jnr had moved to a farm property near Bright, Ontario. He was regarded as a very skilled toolmaker and had made high-quality tools in his youth. J Dryburgh Jnr's plane-making career would likely have spanned more than 55 years.A tool made by a significant and early maker of moulding planes, his moulding planes and that of his father are highly sought after by collectors today and the efforts of John Wilson Dryburgh and his son John Jnr give us a snapshot into times past.Box type moulding planeJ Dryburgh maker also stamped P Steven (owner) size 3/8''flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

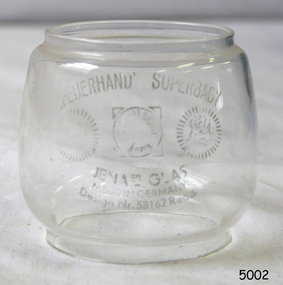

Flagstaff Hill Maritime Museum and VillageFunctional object - Lantern Glass, Nier Feuerhand, 1933

The Feuerhand lantern works were established in Beierfeld in the Saxon Ore Mountains. Called Erzgebirge in German or Krušné hory in Czech, is a mountain range in the south of Saxony in Germany known for its craftwork. Lantern production began in the area by Hermann Nier who ran a plumber's workshop around the 1870s and made lanterns, amongst other things. In the town of Beierfeld, also well-known for its metalworking were the brothers Hermann and Ernst Nier who founded a modern production centre for hurricane lanterns manufacture in 1893. Five years after the foundation, the company Frankonia (Albert Frank metalware) bought up the production site and the brothers Nier became production managers. Owing to differences with Frankonia, Hermann Nier finally started its hurricane lantern factory "Hermann Nier Feuerhandwerk" in 1902. In the same year, he applied for a patent for the manufacturing of lanterns using the stamping and folding techniques with tinning by hot-dipping and without hand-soldering. In 1914 the trademark "Feuerhand" was registered for all products as a utility model of the German Reich in German: "Deutsches Reichs-Gebrauchsmuster" (DRGM) and in 1920 the round Feuerhand emblem was added to the brand. Finally, in 1926 the patents, as well as the trademark "Firehand", were also registered in the USA. The manufacture of the well-known small hurricane lanterns the “Baby Series” complete with fireproof borosilicate glass from the Firma Schott firm from Jena started in 1933. Between 1918 and 1938 Nier Feuerhand became the biggest producer of hurricane lanterns in the world. Production continued until 1990.A significant item that demonstrates from its fabrication a manufacturing process that was far in advance of its time and that influenced the production of lanterns from many other manufactures around the world. These types of lanterns made by Feuerhand around the early 20th century are now sought after by collectors.Small round lantern replacement glass called "Feuerhand" Superbaby Model. Design No 58162.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hurricane lamp glass replacement, glass, hurricane lamp, feuerhand lantern, jena glass works -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlane Compass, 1941-1943

This compass is the type used by an artillery unit of the Australian Military Forces during World War 2 and made by J W Handley. Although having owned the factory site since 1935 at 657 Victoria St J W Handley began to produce various items for the Australian Military forces after purchasing and expanding the factory to 655 Victoria St. It appears that he, or some one else may already have been occupying the site for industrial purposes, such as (Manufacturing, Foundry and Electroplating) since at least 1929. J W Handley Pty Ltd was actively producing items for the Military during the war years, a newspaper article from 1939 shows the factory in production and employing 420 people during 1939. J W Handley after the war moved into producing other non military items including a range of fishing reels. The company ceased trading in 1987 and was deregistered as J W Handley Pty Ltd in 1990.The item demonstrates the industrial capability of Australia at the start of World War 2, this item is actively sort by collectors of Australian Military memorabilia and represents a time in Australian history when the country was at war and the general population was concerned about an invasion from Japanese forces. It also therefor is of social significance as many Australians served in the Military forces at that time and the item is complete and in very good condition.A plane table compass, sometimes referred to as a trough compass, used by surveyors and artillery crew to accurately establish magnetic north. The compass is precision machined of brass material with a long needle to ensure accuracy. The compass scale is marked with a centre zero (for magnetic north) and graduations indicating plus and minus five degrees. The compass is housed in a protective wooden case with a sliding lid. The lid has a brass slide which locks the compass needle during periods when the compass is not in use.J.W.H./V Mark 11 D�D. Made by J W Handley Richmond Melbourne, Victoria. Serial number 1333 on boxflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, trough compass, navigation instrument, surveyor's instrument, j w handley, artillery, australian army, trough, plane compass, world war 2